Struggling with poor cuts? You might think a thinner blade1 is the sharpest solution. But this common belief can actually ruin your production and increase your operating costs.

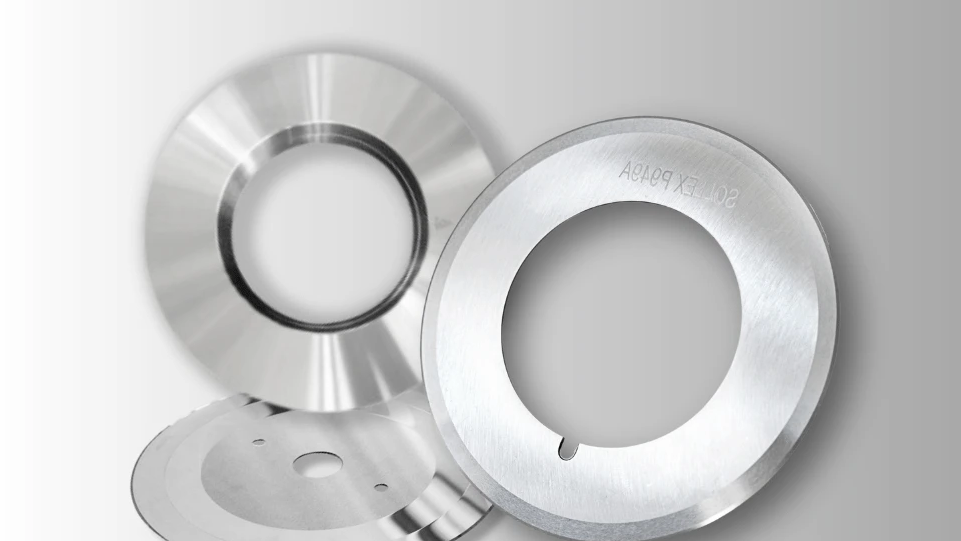

While a thinner edge is technically sharper from a physics standpoint, this is a common misconception in industrial applications. Optimal sharpness balances edge thickness2 with blade strength3, grinding angle, and material. An overly thin blade will chip or break, reducing its lifespan and cutting quality.

You might be surprised to hear this. After all, it seems logical that a thinner edge would slice better. But the reality is much more complex. The "thinnest is best" approach is one of the most common and costly mistakes I see customers make before we start working together. Let's break down why this simple idea can be so misleading in the real world of industrial cutting. We need to look beyond the initial sharpness and consider how a blade performs over thousands or even millions of cuts.

Why Does A Thinner Blade Edge Not Guarantee Better Performance?

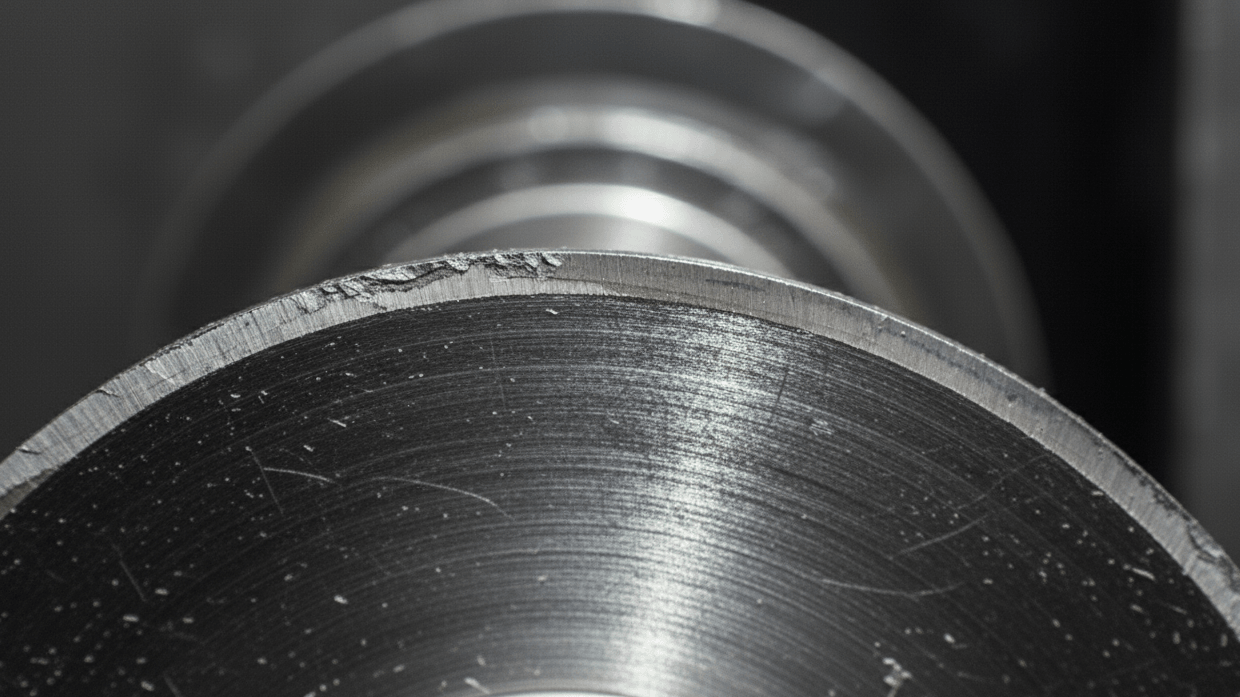

Are your blades chipping or wearing out too fast? You might blame blade quality, but the real issue could be that your cutting edge is simply too thin for the job.

A thinner edge lacks the structural strength to handle industrial cutting forces. It is prone to chipping, rolling, or breaking when cutting tough or abrasive materials4. This instability leads to poor cut quality, frequent blade changes, and decreased production efficiency. Strength is just as crucial as sharpness.

I often explain this using a simple comparison. Think of a razor blade used for shaving versus an axe used for chopping wood. The razor is incredibly thin and sharp, perfect for cutting soft hairs on a smooth surface. But if you tried to chop a log with that same razor, the edge would instantly chip and break. It lacks the strength and mass to handle the impact. Industrial cutting is much closer to chopping wood than shaving. Even when cutting materials that seem delicate, like plastic film or paper, the speeds and forces involved are immense.

The Trade-Off: Sharpness Vs. Durability

An overly thin blade creates a weak point. The concentrated force of cutting can easily exceed the material's structural limit, causing the edge to fracture. This is especially true when cutting materials that are not perfectly uniform, contain hard impurities, or are fibrous in nature. A slightly thicker, well-supported edge can withstand these forces much better, leading to a longer, more predictable lifespan.

| Edge Profile | Pros | Cons | Best For |

|---|---|---|---|

| Very Thin | Extremely sharp initially, low cutting resistance | Fragile, prone to chipping, short lifespan | Very soft, clean, uniform materials |

| Optimized Thickness | Good balance of sharpness and strength, long life | Slightly higher initial cutting resistance | Most industrial applications |

Ultimately, a blade that stays serviceably sharp for a longer period is far more valuable than one that is exceptionally sharp for only a few minutes.

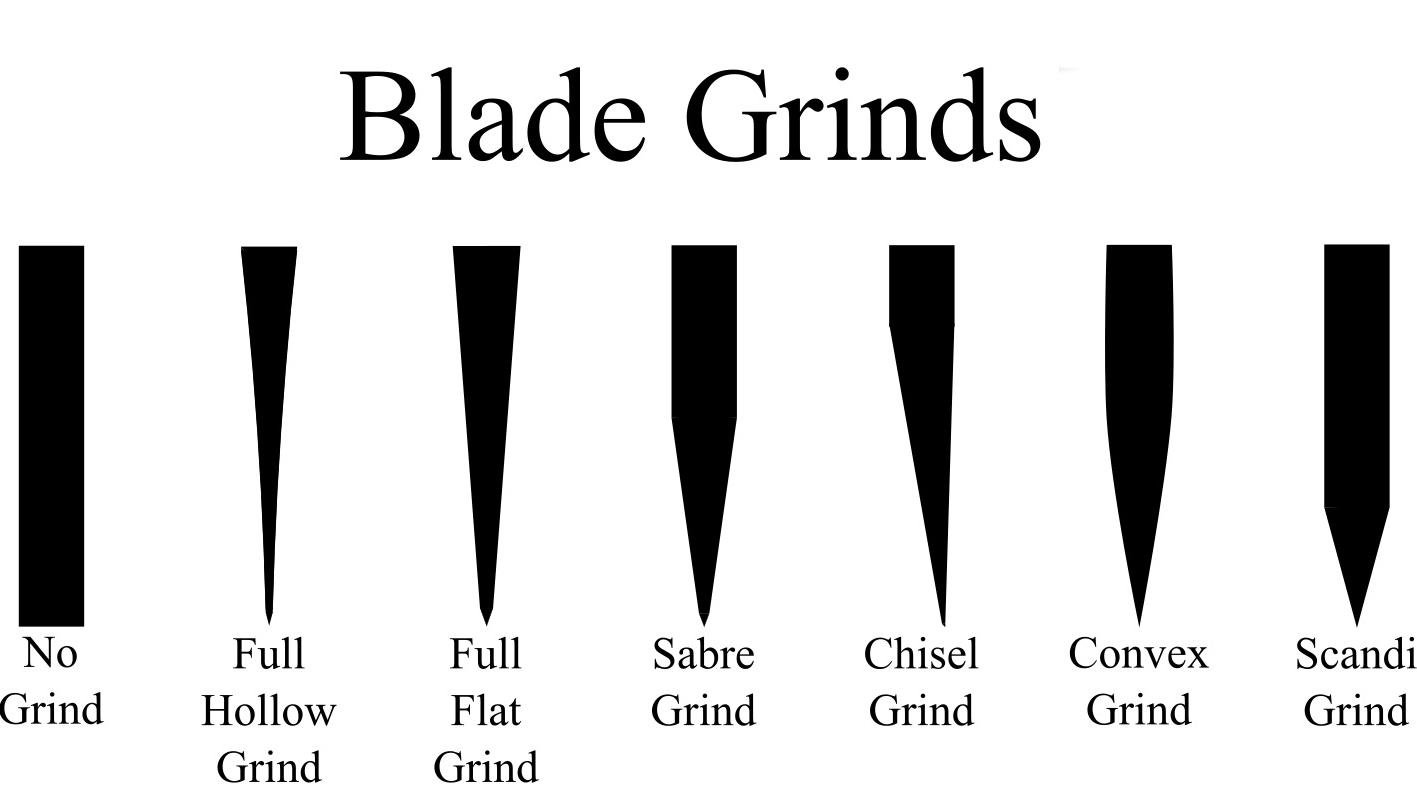

How Does The Blade Angle Affect Cutting Sharpness And Durability?

Do your cuts start sharp but quickly degrade? The grinding angle of your blade, not just its thickness, could be the hidden reason for this rapid performance drop.

The blade angle5 is a critical trade-off. A smaller angle (like 20°) creates a very sharp edge ideal for clean cuts on delicate materials. However, a larger angle (around 30°-45°) provides more support behind the edge, making it durable enough for tough materials like metal or thick plastics.

When I consult with clients, the blade's grinding angle is one of the first technical details we discuss. It's just as important as the blade's overall thickness. Imagine the cutting edge in cross-section. A small, acute angle creates a very fine point, which slices with minimal force. This is perfect for applications where a flawless edge finish is needed, like slitting thin packaging films. However, that fine point is also mechanically weak. A larger, more obtuse angle forms a sturdier wedge. It requires more force to cut but can withstand much higher impact and stress without failing.

Balancing Sharpness And Strength

Finding the right balance is key to optimizing performance. The goal is to use the smallest angle possible that still provides enough durability for the specific application. This minimizes cutting resistance while maximizing the blade's working life. Furthermore, the surface finish of this ground edge matters. A highly polished or mirror-finished bevel reduces friction, which in turn reduces heat buildup and allows for a smoother cut.

| Material to Cut | Recommended Angle | Reason |

|---|---|---|

| Thin Plastic Film | 20° - 25° | Requires extreme sharpness for a clean cut. |

| Paper & Cardboard | 25° - 30° | Balances sharpness with durability for fibrous material. |

| Sheet Metal | 30° - 45° | Needs maximum strength to withstand high shear stress. |

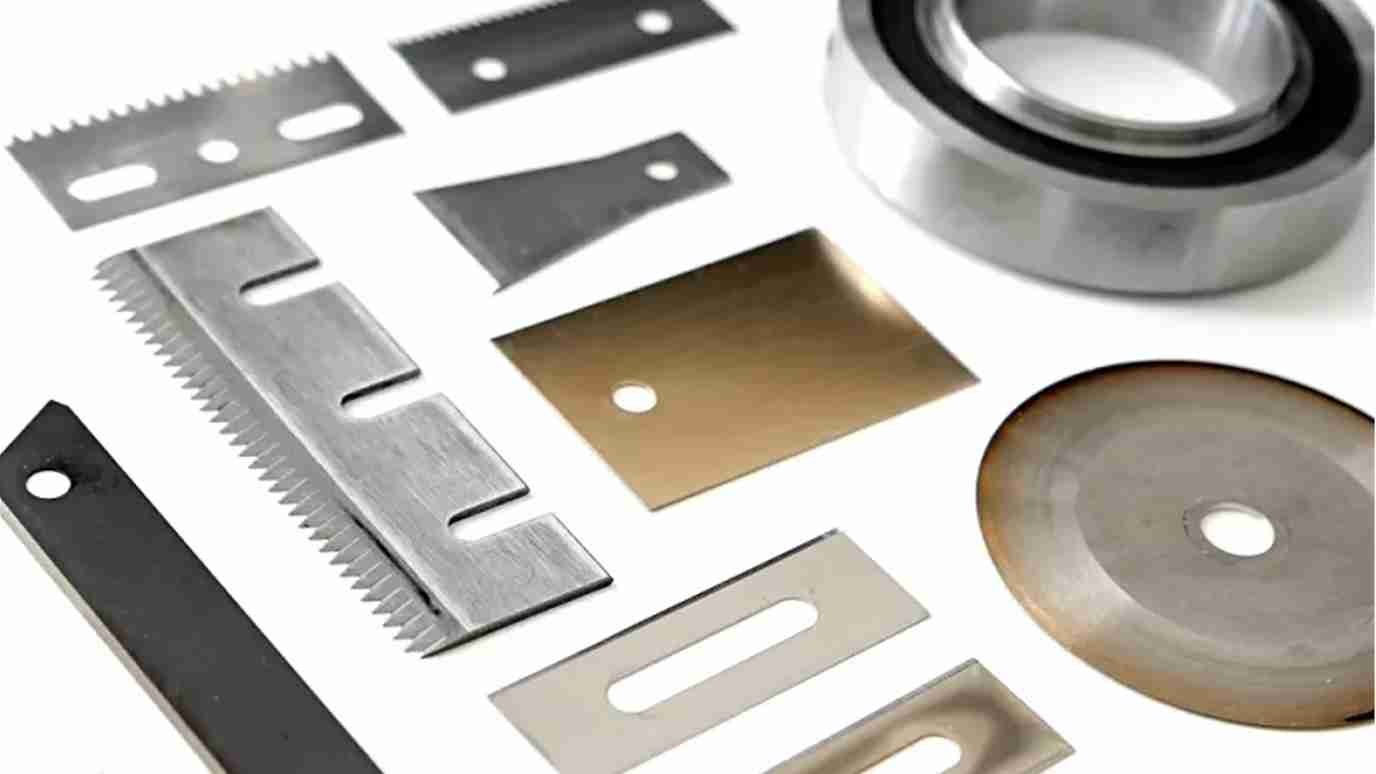

What Is The Role Of Blade Material In Achieving Optimal Sharpness?

Ever wonder why some blades hold an edge for a long time while others dull almost instantly? The secret is not just the design; it's the material the blade is made from.

Blade material determines how sharp an edge can be made and how long it will last. Hard materials like Tungsten Carbide or ceramics can be ground to a very fine, sharp angle and will resist wear. Softer steels are tougher but cannot hold as sharp of an edge without deforming.

Even the perfect blade angle will fail if the material itself isn't up to the task. The material's properties directly influence our design choices. A harder material has better wear resistance, meaning it can hold that sharp edge for a much longer time, especially when cutting abrasive materials. However, extreme hardness often comes with a trade-off: brittleness. A tougher material might be less likely to chip from an accidental impact, but it will lose its sharp edge more quickly.

Matching Material To The Task

This is why we have a range of materials available. For cutting highly abrasive materials like fiberglass or loaded plastics, a very hard material is necessary. For high-impact applications like chopping or rough shearing, a tougher steel that can absorb energy without fracturing is a better choice. The "best" material is always relative to the application.

| Material | Key Property | Common Use Case |

|---|---|---|

| Tungsten Carbide (WC) | Extremely hard, high wear resistance | Film slitting, cutting abrasive materials |

| High-Speed Steel (HSS) | Good balance of hardness and toughness | General purpose cutting, paper, wood |

| Ceramic | Exceptional hardness, heat resistant | Cutting synthetic fibers, magnetic tape |

| Tool Steel (D2, SKD-11) | High toughness, good wear resistance | Metal shearing, heavy-duty cutting |

How Do You Choose The Right Blade For Your Specific Application?

Choosing the wrong blade costs time and money. Are you tired of the guesswork in finding a cutting solution that actually works for your specific manufacturing line?

To choose the right blade, you must analyze four key factors: the material being cut, the cutting machine's speed and force, the required edge quality, and the desired blade lifespan. A holistic approach that considers all these elements is essential for optimal performance and cost-effectiveness.

Let me share a quick story that illustrates this perfectly. I recently worked with a client, Sam, who is the production manager for a large packaging company in Germany. His team was struggling with cutting a specific type of plastic film. They believed a "sharper"—meaning thinner—blade was the answer. They kept trying thinner and thinner blades, but their problem got worse. The blades were dulling in just a couple of hours, causing ragged edges on the film and forcing them to stop the production line constantly for blade changes.

When he contacted me at PASSION, my first step wasn't to send him an even thinner blade. Instead, I asked him about his entire process: the exact type of film, the line speed, and the specifications of his current blades. It turned out the film had an abrasive coating, and his standard steel blades, despite being very thin, were simply not hard enough to withstand it. The thin edge was wearing away almost immediately.

The Solution We Provided

Based on our analysis, we recommended a completely different approach. We manufactured a blade for him made from micro-grain Tungsten Carbide, which is extremely hard and wear-resistant. We also designed it with a slightly larger, dual-bevel angle. This provided more material to support the cutting edge against the abrasive film. The blade was still incredibly sharp, but it was also durable. The result? Alex reported that his blade life increased by over 300%. Cut quality remained perfect for the entire run, and his downtime for blade changes was drastically reduced. The right solution wasn't the thinnest blade, but the smartest one.

Conclusion

In summary, blade sharpness is not just about a thin edge. It is a careful balance between edge geometry, material science, and your specific application for true cutting excellence.

Understanding the pros and cons of thinner blades can help you make informed decisions for your cutting needs. ↩

Find out how edge thickness impacts cutting quality and blade lifespan. ↩

Explore how blade strength affects durability and efficiency in industrial cutting. ↩

Discover the best blade options for handling tough, abrasive materials effectively. ↩

Understanding blade angle can help you optimize cutting performance for different materials. ↩