Struggling to choose between powdered steel and stainless steel blades? Making the wrong choice can lead to lost time and money. Let's clear up the confusion for good.

No, powdered steel is not a type of stainless steel. Powdered steel is a high-speed tool steel made through powder metallurgy. This gives it extreme hardness1 and wear resistance2, while stainless steel's main feature is its ability to resist rust and corrosion.

This distinction isn't just a technical detail. It has a massive impact on a blade's performance, lifespan, and price. Understanding the core differences is the first step toward optimizing your cutting operations. Let's dive deeper to see why these two materials are in completely different leagues and how to choose the right one for your business.

What Exactly Is The Difference Between Powdered Steel Blades And Stainless Steel Blades? Why Is There Such a Significant Price Difference?

Are you paying a premium for powdered steel without fully understanding its benefits? This uncertainty can lead to overspending or using a blade that isn't right for the job.

The main difference lies in their microscopic structure and manufacturing process3. Powdered steel has tiny, uniformly distributed carbides, providing unmatched hardness and wear resistance. This advanced production method is why it costs significantly more than conventional stainless steel, which is made through a simpler melting process.

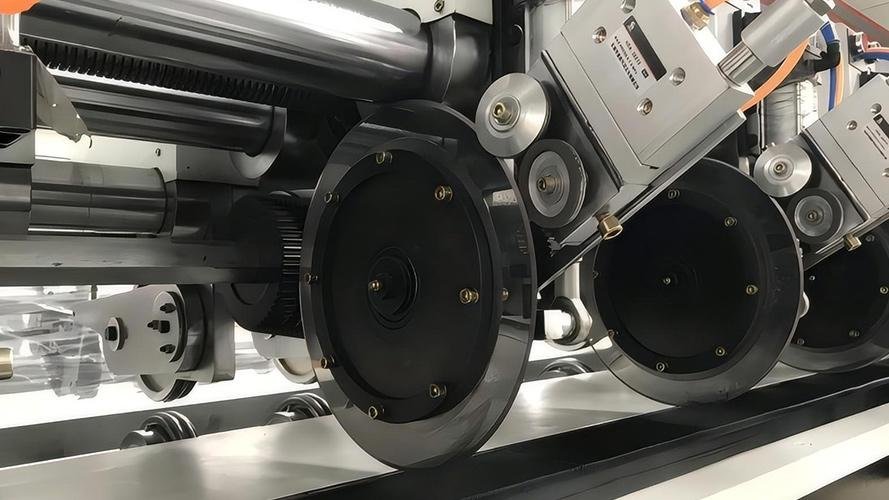

To really understand the gap, we need to look at how they are made. Powdered steel begins as a fine alloy powder. This powder is fused together under immense pressure and heat in a process called sintering. This method creates a steel structure with extremely fine and evenly spread carbides, which are the hard particles that do the cutting. Think of it like a cake with finely milled sugar mixed perfectly throughout. Stainless steel, on the other hand, is made by melting alloys in a furnace. This can result in larger, less evenly distributed carbides, like a cake with clumps of sugar. This micro-structural difference is what gives powdered steel its edge. The complex, energy-intensive process of powder metallurgy directly contributes to its higher price, but the performance boost justifies the investment for demanding jobs.

Key Property Comparison

| Feature | Powdered High-Speed Steel | Stainless Steel |

|---|---|---|

| Hardness (HRC) | Very High (63–70) | Moderate to High (55-60) |

| Wear Resistance | Exceptional | Good |

| Corrosion Resistance | Low to Moderate | Excellent |

| Manufacturing | Powder Metallurgy (Complex) | Traditional Melting (Simpler) |

| Cost | High | Moderate |

Why Is It Said That Stainless Steel Blades, No Matter How Hard, Cannot Replace Powdered Steel Blades?

Are you trying to save costs by using hardened stainless steel for high-demand jobs? This common mistake often backfires, leading to frequent downtime and blade changes, costing you more in the long run.

The critical factor is "red hardness," or the ability to stay hard at high temperatures. High-speed cutting generates intense heat. Stainless steel softens quickly under this heat, losing its sharp edge. Powdered steel maintains its hardness, ensuring consistent performance and a much longer lifespan.

"Red hardness" is just a term for a blade's ability to resist heat. When a blade cuts through material at high speeds, like in the corrugated paper or textile industries, friction creates a huge amount of heat. A blade without good red hardness will become dull almost instantly. Martensitic stainless steels, such as 440C, can be hardened to a respectable level, but they simply can’t handle the heat. Their performance drops off a cliff as soon as the temperature rises. Powdered steel, however, is designed for this exact environment. Its alloy composition allows it to remain extremely hard even when glowing red-hot.

I remember a client in Germany who runs a large packaging facility. They were using top-of-the-line 440C stainless steel blades for their slitting machines but were replacing them every two shifts. The downtime was hurting their production targets. We sent them a set of our powdered steel blades to trial. The result was immediate. The new blades lasted over ten shifts before needing a resharpening, reducing their downtime by 80% and dramatically improving their output. This case perfectly shows that for high-intensity work, there is simply no substitute for the red hardness of powdered steel.

How Do I Choose The Right Blade Material For My Application?

Are you worried about which blade material is correct for your specific cutting machine? Choosing incorrectly leads to poor quality cuts, wasted material, and frustrating production delays. Let’s make the decision simple.

Choose powdered steel for high-speed, high-load applications that demand extreme wear resistance, like cutting paper, textiles, or lithium battery components. Choose stainless steel when hygiene and corrosion resistance4 are the top priorities, such as in food processing5 or medical industries.

The right choice always comes down to the job at hand. You wouldn't use a racecar to haul groceries, and you wouldn't use a delivery truck to win a race. The same logic applies to blades. If your operation involves high speeds, continuous friction, and tough materials, you need the durability and heat resistance of powdered steel. This is common in industries like chemical fiber production6, corrugated paper slitting, and slitting lithium battery foils, where blade stability is essential for product quality. If you cut material where cleanliness is paramount and cutting intensity is lower, stainless steel is the perfect fit.

I worked with a food processing company in Brazil that was slicing frozen vegetables. Their main concerns were preventing rust and meeting strict food safety standards. The cutting was demanding, but it wasn't a high-heat, high-friction process. We supplied them with our food-grade martensitic stainless steel blades. They have been a perfect solution, offering good sharpness and durability while being easy to clean and completely corrosion-resistant. They didn't need the extreme performance—or the cost—of powdered steel. By matching the material to the application, they got the exact performance they needed efficiently and affordably.

Application Guide

| Industry | Primary Need | Recommended Material |

|---|---|---|

| Corrugated Paper, Textiles | Wear & Heat Resistance | Powdered High-Speed Steel |

| Lithium Battery, Chemical Fiber | Extreme Hardness & Stability | Powdered High-Speed Steel |

| Food Processing, Medical | Corrosion Resistance & Hygiene | Stainless Steel |

| Film & Foil (Low Speed) | Cleanliness & Sharpness | Stainless Steel |

Conclusion

Ultimately, choosing the right material is simple. Powdered steel delivers unmatched performance for tough, high-speed jobs, while stainless steel is the ideal choice for applications demanding cleanliness and rust prevention.

Understand how blade hardness impacts cutting efficiency and longevity. ↩

Discover the importance of wear resistance in selecting cutting tools for various applications. ↩

Learn about the complex manufacturing process that gives powdered steel its superior properties. ↩

Find out why corrosion resistance is crucial for blades used in food processing and medical industries. ↩

Find out which blades are best suited for food processing to ensure safety and efficiency. ↩

Learn about the specific cutting tool requirements for the chemical fiber industry. ↩