You invested in coated industrial blades for longer life, but now you worry about them peeling. This would waste money and stop production. Understanding why it happens is key to prevention.

Yes, coated blades1 can peel off. This happens when the blade surface is not prepared well, the coating process is flawed, or the blade is used under extreme stress or heat. Proper selection and use are crucial to prevent the coating from failing under pressure.

This is a common concern I hear from many customers. They want the performance benefits of a coated blade without the risk of it failing and causing problems. The good news is that peeling is almost always preventable. It all comes down to understanding the critical factors that create a strong, lasting bond between the coating and the blade steel. Let's look at what can go wrong and, more importantly, how you and your blade supplier2 can get it right from the start.

Is A Clean Blade Surface The Most Critical Factor For Coating Adhesion?

You might assume a new blade is ready for coating right away. But invisible oil or dust can ruin the bond, leading to early failure and expensive downtime. Meticulous cleaning is the foundation.

Absolutely. A perfectly clean and properly prepared substrate surface is essential for strong coating adhesion. Any contaminants, even microscopic ones, create weak spots. This can cause the coating to blister or peel off once the blade is put into use in your facility.

Think of it like painting a wall in your house. If the wall is dusty or has a greasy spot, you know the paint will eventually bubble and peel off. It’s the same exact principle for industrial blades, but the contaminants we worry about are on a microscopic level. I remember working with a client in Germany, who runs a large paper converting facility. He was frustrated because the TiN-coated slitter knives he bought from another company were failing way too fast. The coating was flaking off, contaminating his paper rolls, and causing costly rejects. We suspected the problem was poor surface preparation3 before the coating was applied.

Pre-Coating Process

| Step | Description | Purpose |

|---|---|---|

| 1. Degreasing | Removes machine oils and grease from manufacturing. | Creates a clean base for the next steps. |

| 2. Ultrasonic Cleaning | Uses high-frequency sound waves in a solution to dislodge tiny particles. | Ensures the surface is microscopically clean. |

| 3. Surface Roughening | Micro-blasting creates a more textured surface. | Increases the surface area for the coating to grip onto. |

| 4. Final Plasma Clean | An in-chamber cleaning right before deposition starts. | Removes any last-minute atmospheric contaminants. |

By providing him with blades that went through this strict preparation, his peeling issues completely disappeared. His blades lasted three times longer, and he no longer had to worry about product contamination. This is a perfect example of how the work done before the coating goes on is just as important as the coating itself.

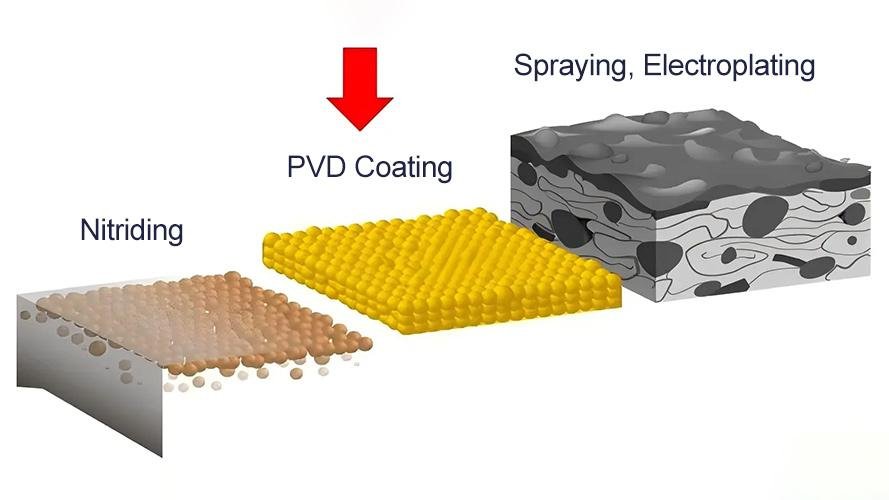

Does The Coating Technology Itself Affect Peeling?

You hear technical terms like PVD4 and CVD5, and they can sound complicated. But choosing a supplier with the wrong process means your coating could fail. Understanding the basics helps you make a better choice.

Yes, the technology and the control over the coating process are crucial. Both PVD and CVD are great methods, but inconsistent process control can create a weak coating. Bad control over temperature or pressure will lead to a coating that is prone to flaking off.

Let me break this down simply. PVD4 (Physical Vapor Deposition) and CVD5 (Chemical Vapor Deposition) are the two main ways we apply these hard, thin coatings. The best method depends on the blade's steel and its final use. But more important than the specific method is the control over the process. A great recipe for a cake can be completely ruined by a bad baker who doesn't control the oven temperature. It's the same with coatings. A supplier must have tight control over every parameter.

PVD Vs. CVD Process Control

| Parameter | Importance in Preventing Peeling |

|---|---|

| Temperature | Must be perfectly stable and uniform to prevent internal stresses from building up in the coating. |

| Chamber Pressure | Controls the energy of the particles hitting the blade; this affects the coating's density and strength. |

| Gas Composition | The precise mix of reactive gases is what determines the coating's final properties and structure. |

| Deposition Rate | A slow, controlled deposition rate often creates a denser, more adherent coating that resists peeling. |

I worked with a customer in Mexico, Maria, who was cutting tough plastic films. Her new blades, coated with DLC (Diamond-Like Carbon), were showing small chips on the cutting edge. We analyzed the failed blades and found the coating thickness was uneven. This was a clear sign of poor process control from her previous supplier. We supplied her with our DLC-coated blades1, made using an advanced PVD4 process with real-time monitoring. This ensures every part of the blade gets a uniform, dense coating. Maria's production runs became smoother, and her blade life6 doubled.

Can The Wrong Application Cause A Perfect Coating To Fail?

You bought a top-of-the-line coated blade, so you expect it to handle anything. But using it on the wrong material can cause extreme heat or impact. This can make even the best coating peel off.

Definitely. A coating is not a one-size-fits-all solution. High temperatures from friction or heavy impacts from cutting hard materials create immense stress between the coating and the blade. If the coating was not designed for those specific stresses, it will fail.

My job is to find the perfect blade and coating for the material they need to cut. The forces involved in industrial cutting are huge, and they change with every material. For example, the stress of cutting soft tissue paper is completely different from the stress of slicing through half-inch thick aluminum plate. The coating must be chosen specifically to handle the challenge.

Matching Coating To Application

| Material to Cut | Common Challenge | Recommended Coating | Why it Works |

|---|---|---|---|

| Plastic Film | Frictional heat, sticky material buildup | DLC (Diamond-Like Carbon) | Very low friction, acts like a non-stick surface. |

| High-Tensile Metal | Extreme temperature and abrasive wear | TiAlN (Titanium Aluminum Nitride) | Forms a protective oxide layer at high heat. |

| Corrugated Board | Abrasive wear from paper dust and fibers | CrN (Chromium Nitride) | Very hard and resistant to corrosion and abrasion. |

I recently helped a client in India, Rajesh, who manages a textile factory. He was cutting synthetic fabrics with standard TiN-coated blades1. The blades were dulling fast and the coating was peeling. This was caused by the high friction and heat generated by the synthetic fibers. We switched him to a blade with a specialized, low-friction DLC coating7. This not only stopped the peeling but also prevented the melted fibers from sticking to the blade edge. His cut quality improved, and he cut his blade changeover time in half.

How Do My Machine Settings And Maintenance Affect Coating Life?

You have the right blade with the right coating. The job is done, right? But running your machine too fast, or without proper cooling, can destroy the coating and undo all your careful preparation.

Your machine settings have a massive impact on coating life. Pushing a blade too hard with high speeds or aggressive feed rate8s generates excessive heat. This heat is a primary cause of coating delamination. Regular maintenance and proper cooling are not optional for coated blades1.

It is a common mistake to think the blade is the only important part of the cutting process. The machine and the operator are just as critical. A blade is part of a larger system. If one part is out of sync, the whole system suffers. For example, if your cutting speed9 is too high, you generate a lot of heat. This heat can cause the blade's steel to expand at a different rate than the hard ceramic coating. This mismatch creates huge stress right where the coating meets the steel, and the coating can literally pop off. This is called thermal shock10.

Key Operational Parameters

| Parameter | Effect on Coating | Best Practice |

|---|---|---|

| Cutting Speed | Running too fast creates excessive heat and stress. | Stay within the recommended speed range for the material. |

| Feed Rate | Being too aggressive causes high impact stress on the edge. | Balance your cutting speed with a smooth, steady feed rate. |

| Cooling/Lubrication | Lack of it leads to thermal shock and high friction. | Use proper coolant whenever possible, especially on hard materials. |

I had a case with a food processing company in the United States. They were using our CrN11-coated blades to cut large frozen blocks of product. They called me because the coating was peeling too soon. We went through my checklist: the blade material was right, the surface prep was perfect, and the coating type was correct. So what was the problem? I discovered that the machine operators had turned off the cooling lubricant spray to keep the area around the machine cleaner. Without that coolant, the blade tip temperature was soaring, causing thermal shock10 and stress. Once his team turned the cooling system back on, the peeling problem stopped.

Conclusion

Preventing coated blades1 from peeling requires a partnership. It starts with a quality supplier, includes choosing the right coating, and ends with proper machine operation. Control these factors for reliable performance.

Explore the advantages of coated blades to enhance your production efficiency and reduce costs. ↩

Find tips on selecting a reliable blade supplier to ensure quality and performance. ↩

Learn why meticulous surface preparation is crucial for ensuring strong coating adhesion and blade performance. ↩

Gain insights into PVD technology and its benefits for enhancing blade performance. ↩

Explore CVD technology to understand its role in improving the durability of industrial blades. ↩

Learn effective strategies to maximize the lifespan of your coated blades and reduce costs. ↩

Explore the advantages of DLC coating for improved cutting performance and reduced wear. ↩

Find out how to balance feed rate for optimal cutting efficiency and blade life. ↩

Discover the relationship between cutting speed and blade longevity to optimize your operations. ↩

Understand thermal shock to prevent coating failure and extend blade life. ↩

Discover how CrN coating can improve resistance to wear and corrosion in cutting applications. ↩