Struggling to find high-quality industrial blades without the premium price tag? You worry that choosing Chinese suppliers means sacrificing quality, a common but outdated fear. Discover how modern Chinese manufacturing has closed the gap.

The perception of Chinese industrial blades remains outdated because of slow-to-change brand bias and a lack of awareness about the rapid advancements in China. Top manufacturers now use high-grade imported materials, advanced CNC processes, and strict international quality controls, delivering performance that rivals Western brands.

The story of Chinese industrial blades is one of rapid transformation. For years, I’ve spoken with customers who carry an image of Chinese manufacturing from 20 years ago. But the reality on the ground today is completely different. The advancements are not just small improvements; they are fundamental shifts in technology, materials, and philosophy. To really understand this change, you need to look closer at the details. Let's break down the key areas where this evolution is most evident and how it impacts your business.

Raw Materials: The Gap Between China And Foreign Suppliers Is Narrowing?

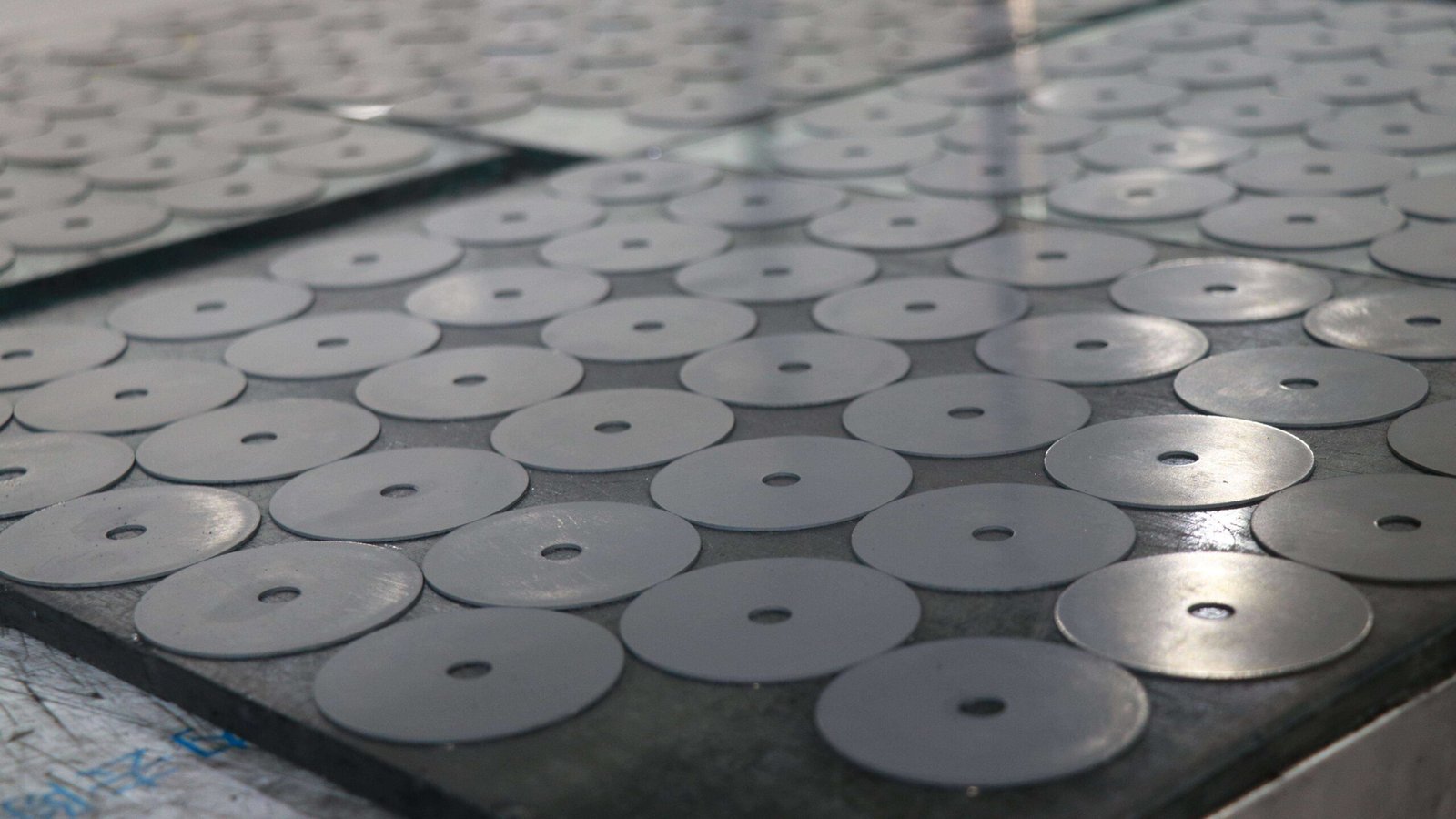

Doubting the quality of steel used in Chinese blades? This uncertainty makes you hesitate, fearing premature wear and costly downtime for your production line. The reality is, top makers use imported, high-grade materials.

Chinese manufacturers increasingly use high-performance materials like imported cemented carbide and powder metallurgy steel1, significantly narrowing the quality gap. The key factor is now the manufacturer's selection and processing capabilities, not the material's origin, ensuring top-tier wear resistance and performance for every blade.

A common question I hear is, "Where does your steel come from?" It's a valid concern because the foundation of any great blade is the material itself. In the past, this was a clear advantage for European manufacturers. Today, that is no longer the case. The difference is not in the material, but in a manufacturer's expertise in selecting the right material for a specific application and processing it correctly. A client in Brazil's flexible packaging industry was skeptical. They used German slitter blades and worried our materials would wear out quickly. I sent them our sample blades. After a three-month trial, they found our blades performed identically but cost 30% less. They're now a long-term partner.

Material Sourcing And Selection

We understand that different cutting tasks require different material properties.

- Tungsten Carbide: For high-wear applications like paper converting or corrugated cutting.

- High-Speed Steel: For high-impact jobs like metal shearing.

- Powder Metallurgy Steel: For superior toughness and edge retention in plastic granulation.

By working closely with our clients, we ensure the material perfectly matches the need.

Manufacturing Processes: Generational Technology Gaps And Cost-Driven Approaches?

Worried that Chinese factories still use outdated manufacturing methods? This suggests inconsistent quality and a lack of precision, risking your final product's integrity. Modern Chinese facilities now use automated CNC grinding and advanced heat treatment.

The old idea of cost-cutting at the expense of technology is gone. Leading Chinese companies invest heavily in automated production lines, precision CNC grinding, and advanced coating technologies2. This commitment ensures blade consistency, precision, and durability, directly challenging older generational technology gaps.

The image of crowded, manual assembly lines is decades out of date. When you walk into our facility, the first thing you notice is the technology. We operate advanced 5-axis CNC grinding centers and precision heat treatment furnaces. This investment in automation is not just for show; it's essential for quality. Machines provide a level of consistency that is impossible to achieve manually. This means every blade we produce has the exact same angle, the same surface finish, and the same hardness. I remember working with a paper converting company in Poland. They were having issues with their guillotine blades, which were causing uneven cuts. The problem was a lack of straightness in the blades from their previous supplier. I explained our multi-step grinding and digital measurement process. We sent them a trial set, and the feedback was immediate. Their cuts were perfectly clean, and the blade life was longer because the cutting edge was manufactured with much higher precision.

Key Technological Upgrades

- CNC Grinding: Ensures consistent edge geometry and surface finish, critical for clean cuts.

- Vacuum Heat Treatment: Provides uniform hardness across the entire blade, preventing soft spots and premature failure.

- Advanced Coatings (e.g., TiN, TiCN): Applied to reduce friction and increase wear resistance, extending blade life3 significantly.

Quality Control: Implementation Of Standards Is Key?

Afraid that "Made in China" means no real quality control? This fear can stop you from exploring cost-effective options, keeping your operational costs high. Reputable manufacturers adhere to strict international standards like ISO 90014.

Absolutely. Strict quality control is no longer an exception but a rule for leading Chinese blade manufacturers. By implementing international standards like ISO 9001 and using advanced inspection equipment, these companies ensure every blade meets precise specifications before it ships.

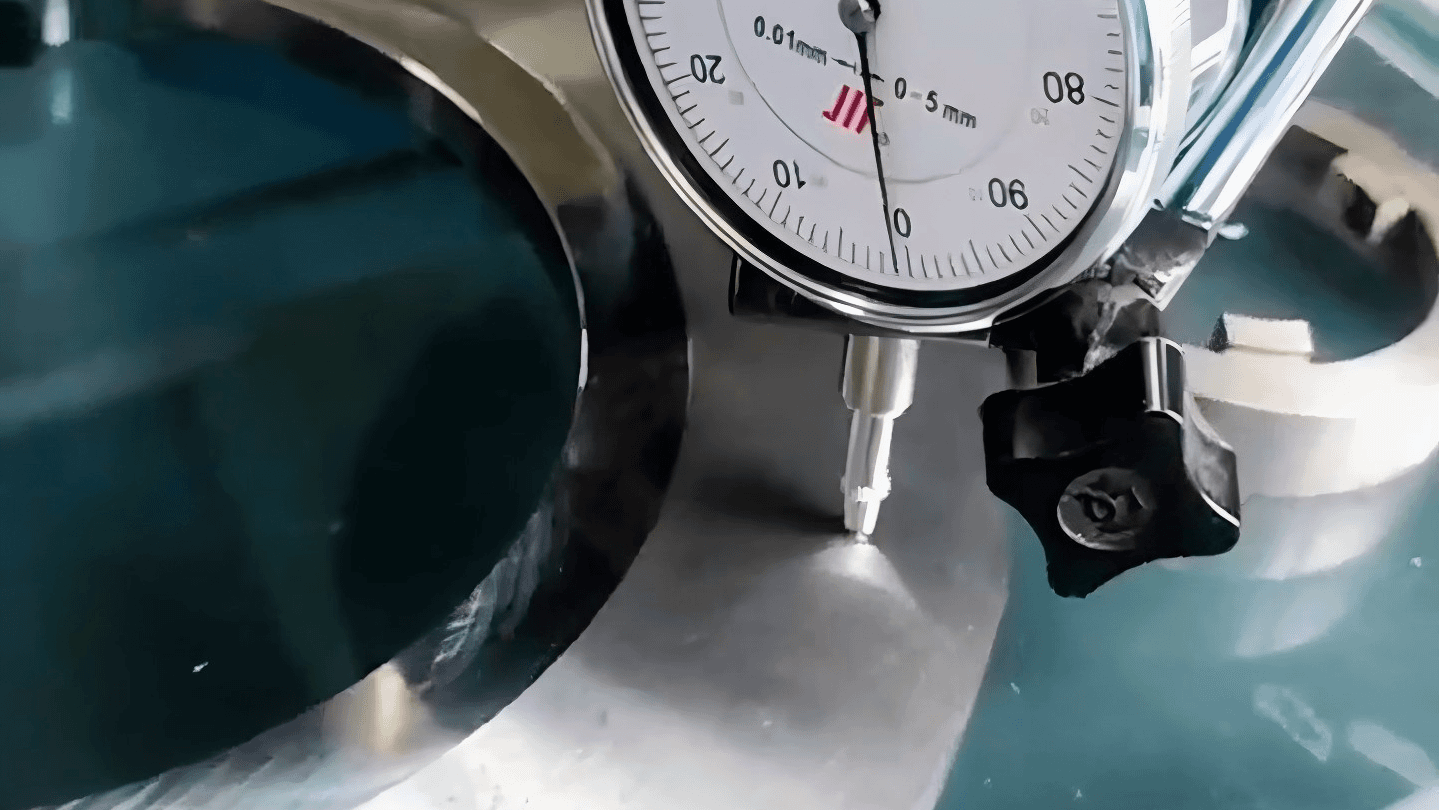

A great blade is not just made; it's verified. Quality control is arguably the most critical step in our entire process. It's not enough to have good machines and good materials. You must have a robust system to check the quality at every stage. We are an ISO 9001 certified company, which means our processes are documented and audited. We inspect raw materials when they arrive, we conduct in-process checks during manufacturing, and we perform a 100% final inspection on every blade before it is packaged. I worked with a textile manufacturer in Turkey who was frustrated with inconsistent hardness from their supplier. Some blades would last for weeks, others for days. I explained our QC process: after heat treatment, we test the Rockwell hardness of every single blade. We provided them a trial batch where each blade was laser-marked with a serial number and accompanied by its own quality report. They saw a 50% increase in average blade life and a huge reduction in unplanned downtime.

Our QC Checklist

| Inspection Point | Technology Used | Purpose |

|---|---|---|

| Material | Spectrometer | Verify correct alloy composition |

| Hardness | Rockwell Hardness Tester | Ensure proper heat treatment |

| Dimensions | Laser Micrometer / CMM | Check for precise tolerance |

| Sharpness | Digital Microscope | Inspect edge for micro-defects |

Technological Innovation And Customization Capabilities?

Need a custom blade for a unique application? You might think Chinese factories only handle mass production, leaving you stuck with standard solutions. In fact, many Chinese manufacturers excel at creating custom blades5.

Chinese manufacturers are no longer just followers; they are innovators. With strong in-house engineering teams, they offer incredible customization. They work with clients to design, prototype, and produce non-standard blades, often with faster turnaround times than their Western counterparts.

One of the biggest advantages of working with a modern Chinese manufacturer is our flexibility. While huge European brands can be slow to respond to custom requests, we have built our business on being agile. Our in-house engineering team loves a challenge. We can work from a technical drawing, a sample part, or even just a conversation about the problem you're trying to solve. A food processing plant in Mexico needed a special serrated blade to cut frozen food. The blade from their machine's OEM was very expensive and had a 12-week lead time. This was causing serious production delays. They sent us a used blade, and our engineers analyzed the material, tooth profile, and hardness. Within 48 hours, we provided a detailed technical drawing for their approval. After they confirmed it, we produced and shipped the custom blades in just four weeks. They received an identical-performing blade at a significantly lower cost and in one-third of the time.

From Concept To Reality

- Consultation: We discuss your cutting application and challenges.

- Design & Drawing: Our engineers create a technical design for your approval.

- Prototyping: We can produce a small batch for testing and validation.

- Full Production: Once approved, we scale up production to meet your needs.

Customer Perception: Brand Influence Versus Reality Discrepancies?

Do you automatically trust a European brand over a Chinese one? This brand bias, shaped by old perceptions, could be costing you money and efficiency without any real-world justification. It's time to look past the label.

There is a significant gap between the perception and reality of Chinese blades. While established Western brands benefit from decades of trust, the actual quality of top Chinese manufacturers often meets or exceeds expectations. The discrepancy is more about brand influence than product reality.

Brand perception is powerful. For decades, German, Swedish, and American brands built a reputation for untouchable quality, and they deserved it. During that time, "Made in China" was associated with low-cost, mass-produced goods. But the industrial landscape has changed dramatically. The reality is that the best Chinese manufacturers have caught up. The challenge is that perception changes much more slowly than reality.

How To Judge For Yourself

- Ask for specifications: Request detailed material composition and hardness data.

- Request a trial: The best way to test a blade is in your own machine.

- Check certifications: Look for ISO 9001 or other international quality standards.

Comparing Chinese Blades To European And North American Blades?

Trying to decide between a Chinese blade and a Western one? The choice seems complicated, a trade-off between perceived quality, cost, and delivery. Let's break it down into a simple, clear comparison.

When comparing directly, top-tier Chinese blades offer similar performance in sharpness and durability to their Western counterparts. The main advantages of Chinese blades are significant cost-effectiveness, faster delivery times, and greater flexibility in producing custom or small-batch orders.

So, how do Chinese blades truly stack up? For the vast majority of industrial applications, the performance is comparable. We use the same materials and often more modern machinery. Where some specialized European brands might have an edge is in very niche, ultra-high-end applications, like cutting advanced composites under extreme heat. But for 99% of tasks in paper, plastics, metal, and food processing, the performance gap has closed. The real difference is in the value proposition. A printing company in the United Kingdom used to buy all their three holes blades from Switzerland. The quality was excellent, but the cost was a major expense. I provided them with a comparison sheet showing our equivalent tungsten carbide grade, identical hardness specs, and tighter grinding tolerances. They started with a small order to verify our claims. Today, they source 80% of their blades from us, providing the best overall value for their operation.

Head-to-Head Comparison

| Feature | Top-Tier Chinese Blade | European/North American Blade |

|---|---|---|

| Material Quality | Comparable (Often sourced globally) | High |

| Performance | Comparable for most applications | High (May excel in niche areas) |

| Cost | Significantly Lower | High |

| Lead Time | Shorter (Often 3-5 weeks) | Longer (Often 8-12+ weeks) |

| Customization | High Flexibility, Fast Turnaround | Less Flexible, Slower |

Conclusion

The "Made in China" label for industrial blades has been redefined. Today's reality is one of high quality, innovation, and value. It's time to judge the blade, not its background.

Explore the benefits of powder metallurgy steel in enhancing blade performance. ↩

Learn how advanced coatings can significantly extend the life of industrial blades. ↩

Find tips and techniques to enhance the longevity of your industrial blades. ↩

Discover why ISO 9001 certification is crucial for ensuring quality in manufacturing. ↩

Explore resources on designing custom blades tailored to unique industrial needs. ↩