Your tungsten carbide blades are producing rough edges and slowing down work. You thought they lasted forever. This common myth can cost you time and money, but there's a simple solution.

No. While incredibly hard (HRA92) and long-lasting, tungsten carbide blades still get dull with use. They need professional resharpening1 to maintain cut quality. This is a normal part of their lifecycle, not a sign of a bad blade.

I remember a conversation with Daniel, a factory manager from the UK. He called me, frustrated. "Lyn," he said, "I thought these blades never needed sharpening, but my cuts have burrs and burn marks2." He was facing the exact issue this myth creates. The truth about blade wear isn't complicated. Understanding it is the key to unlocking the full potential of your tools. Let's break it down together.

What Really Causes Tungsten Carbide Blades To Wear Down?

Frustrated that your 'invincible' blades are losing their edge? The invisible wear is real and it affects every cut. I'll show you exactly what's happening at a microscopic level.

Even super-hard tungsten carbide wears down from three main causes. These are normal abrasive wear3 from friction, micro-chipping4 from impacts, and plastic deformation5 under extreme heat. Each type of wear slowly dulls the cutting edge.

Even the toughest materials have their limits, and tungsten carbide is no exception. It's important to understand that "wear" isn't a single event. Instead, it's a gradual process caused by several factors working against the blade's edge. Here at PASSION, we help customers like Daniel understand these forces to better manage their tools.

Normal Abrasive Wear

Think of this as the blade being slowly sanded down on a microscopic level. Every time the blade cuts through material, there is friction. This high-speed friction slowly rubs away tiny particles from the blade's edge. This creates what we call a "wear land6" or a "wear band." As this band gets wider, the blade becomes duller. It requires more force to cut, which can lead to lower-quality cuts and more pronounced burrs. This is the most common and unavoidable type of wear.

Micro-Chipping

Tungsten carbide is extremely hard, but that also means it has limited toughness. It's brittle, like glass. When the blade hits a hard impurity in the material it's cutting—like a small piece of metal or a knot in wood—the edge can suffer tiny fractures or chips. Even vibrations in the machine can cause this micro-chipping4. These tiny nicks on the cutting edge will tear the material instead of slicing it cleanly, leading to rough finishes.

Plastic Deformation

This is less common and usually happens under extreme conditions. While tungsten carbide itself has a very high melting point, the cobalt binder that holds the carbide particles together can soften at high temperatures. If the cutting process generates extreme heat, this cobalt binder can start to flow. This causes the cutting edge to change shape or "deform," which ruins its cutting geometry and makes it ineffective.

How Do You Know When It's The Right Time To Sharpen Your Blades?

Are you waiting until your cuts are terrible before you sharpen? This reactive approach costs you money and wastes material. There is a much smarter, proactive way to manage blade maintenance.

Don't wait for serious cut quality issues. You should sharpen your blades based on a preventive schedule. The best indicators are checking the width of the wear land under a microscope or monitoring for a sudden increase in cutting power consumption7.

Waiting until a blade is completely dull or chipped is a costly mistake. It puts more strain on your machinery, produces scrap material, and can even damage the blade beyond repair. The goal should be preventive maintenance8, not reactive repair. By setting up a system to monitor blade wear9, you can schedule resharpening at the perfect time to maximize both blade life and cut quality. This is exactly what I advised Daniel to do, and it transformed his production efficiency.

Establishing A Preventive Maintenance System

A good system doesn't rely on guesswork. It uses clear, measurable indicators to tell you when it's time for maintenance. You should track these signs regularly to catch wear before it becomes a major problem.

Here's a simple table to guide your monitoring process:

| Indicator | How to Check | Action Threshold |

|---|---|---|

| Wear Land Width | Use a microscope to regularly inspect the flank face of the blade's edge. | Sharpen when the wear land reaches a pre-determined width (e.g., 0.2mm). |

| Cut Quality | Visually inspect the finished product for burrs, burn marks, or rough edges. | Schedule sharpening as soon as quality begins to decline consistently. |

| Power Consumption | Monitor the electrical power draw of the cutting machine's motor. | A sudden or steady rise in power indicates the blade is dull and requires more force. |

By using these metrics, you create a data-driven approach. You're no longer guessing. You're making informed decisions that extend the life of your expensive tooling, reduce waste, and keep your production running smoothly.

What Is The Professional Way To Resharpen Tungsten Carbide?

You know your blade needs sharpening, but a bad sharpening job can ruin it completely. Using the wrong equipment or technique will cost you more than the sharpening service itself.

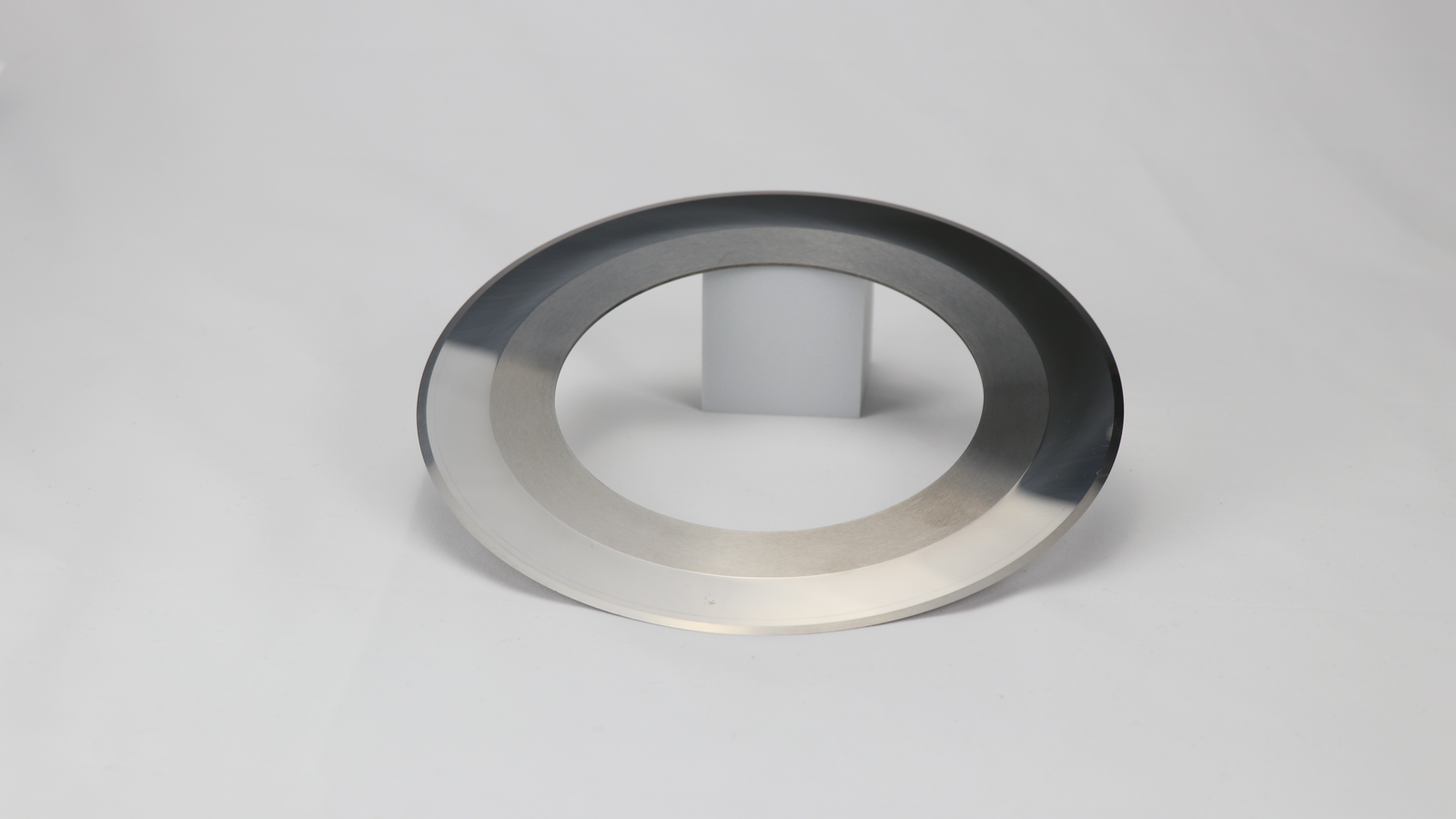

Professional resharpening is non-negotiable. It must be done with a specialized diamond grinding wheel. The process must also perfectly restore the blade's original geometry, including its precise cutting angles10. Anything less will permanently damage the blade.

When a blade is sharpened incorrectly, it can lose its temper, its hardness, and its all-important geometric shape. I’ve seen blades returned to customers after a cheap sharpening job that were actually worse than when they were sent out. The money saved was lost ten times over in poor performance and a ruined tool. This is why we always emphasize that resharpening is a science, not a simple grinding job.

The Right Tool: Diamond Grinding Wheels

Tungsten carbide has a hardness of around 92 on the HRA scale. It's one of the hardest materials made by man. To grind or sharpen something that hard, you need something even harder. That's where diamond comes in. Diamond grinding wheels are the only tools suitable for resharpening tungsten carbide effectively without generating excessive heat that could damage the blade. Using a standard abrasive wheel will either fail to sharpen the blade or create so much heat that it ruins the blade's structure.

The Right Method: Restoring Original Geometry

A blade's performance is defined by its angles—the rake angle, the clearance angle, etc. These are engineered with extreme precision. A professional sharpening service uses advanced CNC machines11 to ensure these original angles are restored perfectly.

Here is a comparison of what to expect:

| Factor | Professional Sharpening | Improper Sharpening |

|---|---|---|

| Grinding Wheel | Diamond Wheel | Standard Abrasive Wheel |

| Cutting Angles | Restored to original factory specs | Altered, inconsistent angles |

| Edge Finish | Smooth, uniform, often with proper edge prep (honing) | Rough, may have micro-fractures |

| Outcome | Blade performs like new, long service life | Poor performance, short life, often scrapped |

Investing in professional resharpening isn't a cost; it's an investment in maintaining the performance you paid for when you first bought a high-quality PASSION blade.

Conclusion

Tungsten carbide blades are not eternal. But with professional, proactive maintenance, they offer unmatched durability and precision. Proper care is the key to maximizing their long and productive service life.

Learn how professional resharpening can restore your blades to optimal performance and extend their lifespan. ↩

Discover the causes of burrs and burn marks and how to prevent them for cleaner cuts. ↩

Learn about abrasive wear and how it affects the lifespan and efficiency of cutting tools. ↩

Find out the causes of micro-chipping and how to prevent it for better cutting efficiency. ↩

Explore the phenomenon of plastic deformation and its impact on cutting tool performance. ↩

Understand the concept of wear land and its significance in tool maintenance and performance. ↩

Learn how monitoring power consumption can help you identify when your blades need sharpening. ↩

Learn about preventive maintenance strategies to enhance the longevity and performance of your tools. ↩

Learn to identify the signs of blade wear to maintain cutting efficiency and quality. ↩

Understand the significance of cutting angles in tool design and their effect on cutting performance. ↩

Explore how CNC machines enhance the precision and quality of tool sharpening. ↩