Are you frustrated with frequently replacing blades? This downtime costs you money and slows production. Finding the right cutting speed1 is the solution to extending blade life and boosting efficiency.

Yes, both excessively fast and slow cutting speeds directly and significantly impact the lifespan of industrial blades. Unsuitable speeds lead to premature wear, such as chipping or heat damage, ultimately reducing a blade's service life and overall performance. Finding the optimal speed is essential for durability.

This seems like a contradiction, doesn't it? You might think faster is always better for productivity, or that slower is always safer for the blade. The truth is more complex. The key isn't just about going fast or slow; it's about finding the perfect balance for your specific material and blade type. Let's explore why both extremes can be damaging and how you can find that sweet spot to maximize your investment and keep your production line running smoothly.

Why Does High-Speed Cutting Wear Down Your Blades So Quickly?

Are your blades overheating and failing too soon? The intense friction from high-speed cutting generates extreme heat. This heat can ruin blade integrity and lead to costly, frequent replacements.

High-speed cutting dramatically increases friction between the blade and the workpiece. This generates excessive heat, which softens the blade's edge, causes thermal cracks, and accelerates wear through oxidation. The blade loses its hardness and sharpness, leading to rapid failure and poor cut quality.

When I work with clients, one of the first things we analyze is their operational speed. Pushing for maximum output by simply cranking up the speed is a common mistake. The science is straightforward: more speed means more contact per second, which means more friction. This friction creates a pocket of intense heat right at the cutting edge. This isn't just about the blade getting warm; it can reach temperatures that fundamentally change the steel's properties.

The Destructive Power Of Heat

Heat is the primary enemy when cutting too fast. It triggers several types of wear that can destroy a blade prematurely.

- Thermal Wear: The blade material softens, losing the hardness needed to maintain a sharp edge.

- Oxidation: At high temperatures, the blade's surface reacts with oxygen, forming a brittle oxide layer that flakes off, taking sharp material with it.

- Micro-Cracks: Rapid heating and cooling cycles create stress in the metal, leading to tiny cracks that can grow and cause the blade to chip or fracture completely.

For example, a blade made from high-speed steel (HSS) will lose its temper and hardness far sooner than a tungsten carbide blade, which is designed to withstand higher temperatures. But even carbide has its limits. Without proper cooling, high speed is a recipe for disaster.

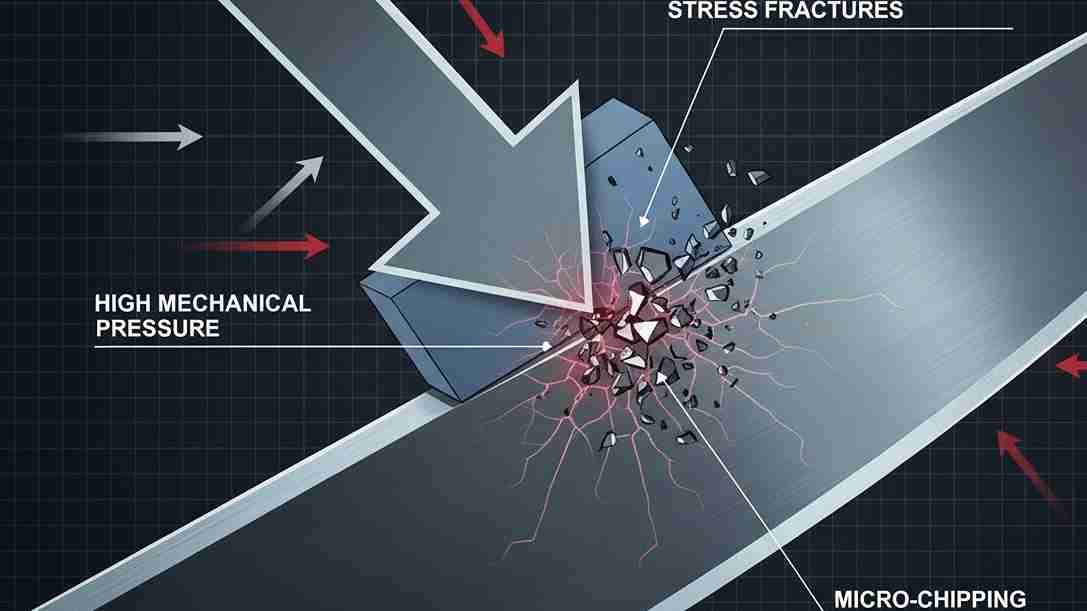

Can Cutting Too Slowly Actually Damage Your Industrial Blades?

Do you run your machines slowly hoping to protect your blades? This common strategy can backfire. The increased pressure and stress can cause the blade edge to chip or deform.

Yes, cutting too slowly can damage blades. It increases the cutting force and mechanical stress2 on the blade's edge. This can lead to chipping, edge rolling, or plastic deformation, especially when cutting tough or high-tensile materials. The blade is under immense pressure for longer periods.

It feels counterintuitive, but I've seen it happen. A client in the textile industry from Vietnam, was cutting thick synthetic fabrics. He slowed his machines way down, thinking he was extending the life of his circular blades. Instead, he was calling us for replacements more often! The problem was that the slow speed wasn't allowing the blade to slice cleanly. Instead, it was "plowing" through the material. This massively increased the force exerted on the cutting edge.

Understanding Mechanical Stress Vs. Thermal Stress

While high speed creates thermal problems, low speed creates mechanical ones. Here’s a breakdown of what happens when the cutting speed is too low:

| Problem Type | Description | Resulting Damage |

|---|---|---|

| Increased Cutting Force | The blade pushes material instead of shearing it cleanly. This puts immense direct pressure on the cutting edge. | Chipping, fracturing |

| Built-Up Edge (BUE) | Material can weld itself to the blade tip due to prolonged pressure and friction, altering the cutting geometry. | Poor surface finish, eventual breakage |

| Work Hardening | Some materials, like stainless steel, harden when worked slowly, making them even harder to cut on the next pass. | Accelerated blade wear |

Think of it like trying to chop a carrot. A quick, decisive chop splits it cleanly. A slow, forceful push is more likely to crack the carrot and might even chip your knife if you hit the cutting board too hard. For industrial blades, especially those cutting tough or gummy materials, a certain amount of speed is necessary to achieve a clean, efficient shearing action. For client, increasing the speed (along with using a blade coated for lubricity) solved his chipping problem and significantly extended his blade's service life.

How Can You Find The Perfect Cutting Speed For Maximum Blade Life?

Are you tired of guessing the right speed for your cutting operations? This guesswork leads to inconsistent results and worn-out blades. A systematic approach is needed for optimal performance and longevity.

To find the perfect cutting speed, start with the blade manufacturer's recommendations for your specific material. Then, conduct controlled tests, adjusting the speed in small increments. Monitor cut quality, chip formation, and blade temperature to find the sweet spot that maximizes efficiency without causing premature wear.

Finding the "perfect" speed is more of a process than a single number. It's a balance of multiple factors, and it's one of the most valuable adjustments you can make in your facility. The ideal speed is a balance between productivity and durability. Go too fast, you get thermal wear3. Go too slow, you get mechanical wear. The goal is to operate in that productive middle ground.

A Practical Guide To Optimizing Speed

Here’s a step-by-step approach I recommend to my clients:

- Start with the Baseline: Always begin with the cutting parameters recommended by both the machine manufacturer and the blade supplier. These are your safest starting points.

- Consider the Variables: The ideal speed changes based on several key factors.

- Blade Material: Tungsten carbide can handle much higher speeds than high-speed steel (HSS).

- Workpiece Material: A soft plastic requires a different speed than hardened steel or thick paperboard.

- Machine Rigidity: An older, less stable machine may vibrate at high speeds, damaging the blade.

- Coolant/Lubrication: A good cooling system4 can enable you to run at higher speeds by managing heat effectively.

- Test and Observe: Make small, incremental changes to the speed. After each adjustment, carefully inspect both the workpiece for cut quality and the blade for any signs of early wear. Listen to the machine. An unusual sound is often the first sign that something is wrong.

Ultimately, optimization is about paying attention. By methodically testing and documenting your results, you move from guessing to making data-driven decisions that save you money in the long run.

Conclusion

Both excessively fast and slow cutting speeds ruin blades. Finding the optimal speed is a critical balance between managing heat and mechanical stress to maximize blade life and efficiency.

Understanding the right cutting speed can significantly enhance blade life and production efficiency. ↩

Explore the concept of mechanical stress and its implications for blade durability. ↩

Discover how thermal wear affects cutting tools and ways to mitigate its impact. ↩

Explore the role of cooling systems in maintaining blade performance at higher speeds. ↩