Are you tired of blades that dull quickly? This costs you time and money. Understanding how tungsten carbide blades are made shows why they are the powerfully durable solution you need.

Tungsten carbide blades are created through a meticulous process. It involves mixing tungsten carbide and cobalt powders, pressing them into shape, and then sintering1 at high temperatures. The blades are then precisely ground, sharpened, and sometimes coated to achieve their final, superior performance.

This process seems complex, and honestly, it is. Each step is absolutely essential for creating a blade that meets standards. I often walk my clients through this journey, as it builds a deep appreciation for the quality and reliability packed into every tool. It’s not just a piece of metal; it’s a product of advanced engineering. Let's dive into the details.

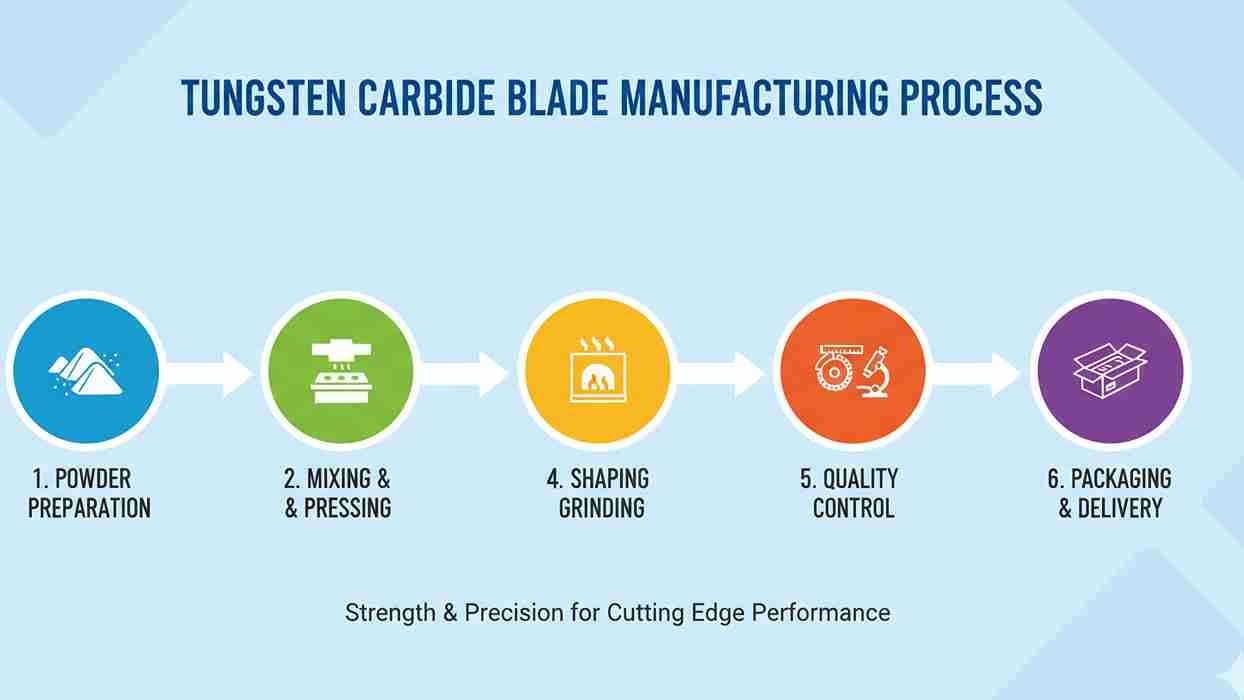

What Are The Steps In Making A Tungsten Carbide Blade?

The manufacturing process can feel like a secret. This makes it hard to judge a blade's true quality. I'll walk you through the essential stages from start to finish.

The steps include preparing raw powders, pressing them into a blank, sintering to harden and densify the material, and then precisely shaping the blade through cutting and grinding. Each stage builds upon the last to create a high-performance, ultra-durable cutting blade.

At PASSION, we control every single step to guarantee the final product is perfect. I know that firsthand how a small change in one stage can affect the final blade. It’s a bit like baking a perfect cake; you have to get every ingredient and every step just right. The whole process can be broken down into a few main stages.

Stage 1: Foundation And Forming

This is where it all begins. We start with the basic ingredients and give the blade its initial shape.

- Raw Material Preparation: We use high-purity tungsten carbide powder for hardness and cobalt powder as a binder for toughness. The quality of these raw materials is the foundation for a great blade.

- Mixing and Pressing: The powders are mixed perfectly to ensure consistency. Then, we press this mixture into a "blank," which is the rough shape of the final blade.

Stage 2: Hardening And Refining

This stage transforms the fragile blank into a cutting powerhouse.

- Sintering: This is the most critical part. We heat the blank to around 1500°C for about 15 hours. The heat melts the cobalt, which permanently bonds the tungsten carbide particles together.

- Precision Shaping: The sintered blade is extremely hard. We use a process called Wire EDM to cut the precise shape, which can achieve an accuracy of ±0.004mm.

Stage 3: Finishing And Sharpening

Here, we create the perfect cutting edge and add final touches.

- Grinding: After sintering, the blades undergo multiple grinding processes, including: Rough Grinding2: Removes excess material and corrects the overall shape; Surface Grinding3: Forms the reference surface and controls thickness; Finish Grinding4: Ensures geometric accuracy and surface finish (surface roughness can reach Ra ≤ 0.2 μm).

- Polishing5: For higher-end blades, drill paste polishing or ultra-fine grinding is also required to achieve a smoother surface (Ra up to 0.05 μm). Polishing not only improves the quality of the cutting surface, it also reduces friction and minimizes chip and heat buildup.

- Edge Sharpening: This is where the blade gets its function. We use diamond wheels to create a sharp, strong, and stable cutting edge.

- Coating: For some applications, we add a final coating like TiN or DLC. This makes the blade even more resistant to wear and corrosion.

Why Is Sintering The Most Critical Step?

Many steps seem important, so what's the big deal with sintering? If this one step goes wrong, the blade will fail. Let me explain why this is the true heart of the process.

Sintering is critical because it transforms the fragile powder blank into a dense, incredibly hard solid. At around 1500°C, the cobalt binder melts and fuses the tungsten carbide particles together. This step determines the blade's final hardness, strength, and durability.

I think the transformation during sintering is amazing. I once handled a pre-sintered blank, and it was so fragile it felt like a piece of chalk. It’s hard to believe that this brittle form becomes one of the hardest materials used in industry.

Before And After

Before sintering, the blade blank is just compressed powder. It has a shape, but it has no real strength. After a 15-hour cycle in our controlled-atmosphere furnace, everything changes. The blade shrinks slightly as the internal pores are eliminated, resulting in a fully dense and unified structure. This is what gives tungsten carbide its famous hard-wearing properties.

I remember working with a client from Germany, who runs a large packaging facility. His machines were running 24/7, and his old blades were chipping constantly, causing expensive downtime. After he switched to our PASSION blades, the chipping problem disappeared. I explained that our rigorous sintering process ensures there are no internal weaknesses, which is why his blades now last so much longer. The quality is literally baked in.

Conclusion

Manufacturing tungsten carbide blades is a precise science. From powder to polished edge, each step ensures the strength and precision you rely on for every single cut.

Learn how sintering transforms materials and why it's crucial for blade strength and durability. ↩

Explore this link to understand how Rough Grinding enhances blade quality and performance, ensuring durability and precision. ↩

Explore this link to understand surface grinding's role in achieving precision and quality in tungsten carbide blade manufacturing. ↩

Explore this link to understand how finish grinding enhances blade precision and performance, ensuring superior cutting quality. ↩

Explore this resource to understand how polishing enhances blade performance and durability, ensuring superior cutting quality. ↩