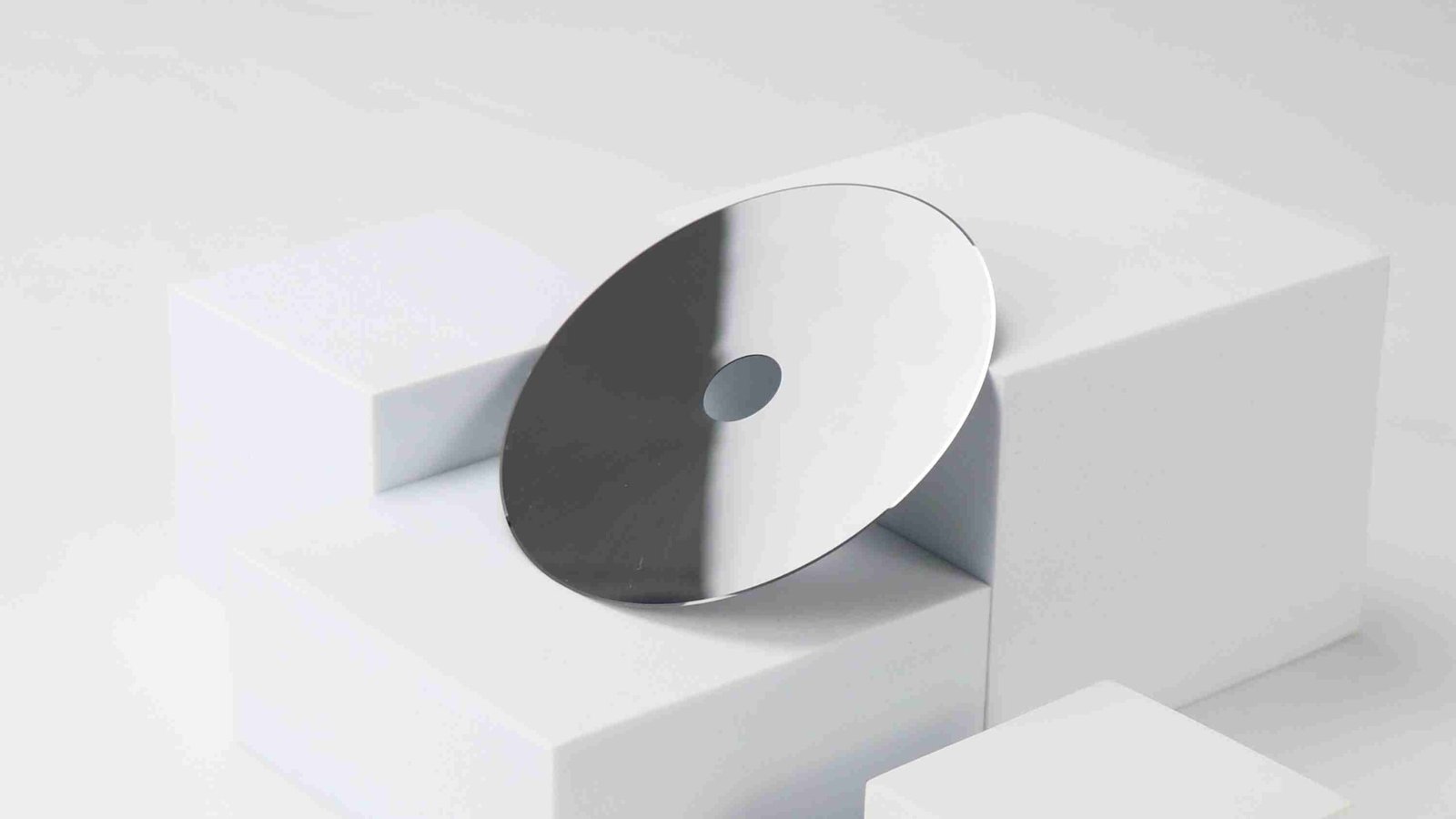

Dull blades and flawed cuts slowing you down? This costs money and creates waste. A mirror finish1 is a powerful solution that boosts performance and longevity.

Mirror finishing greatly improves industrial blade performance by creating an ultra-smooth surface. This reduces friction and heat, enhances corrosion resistance2, eliminates microscopic defects, and prevents material adhesion, leading to cleaner cuts and a significantly longer service life for the blade.

The production line's efficiency was limited not by the machine, but by the blade itself. Even the best steel can underperform if its surface isn't right. A mirror finish isn't just about making a blade look good; it's a high-precision process that changes how the blade interacts with the material it cuts. This is where we unlock a blade's true potential and turn a good cutting process into a great one. Let's dive deeper into how this works and what it can mean for your operations.

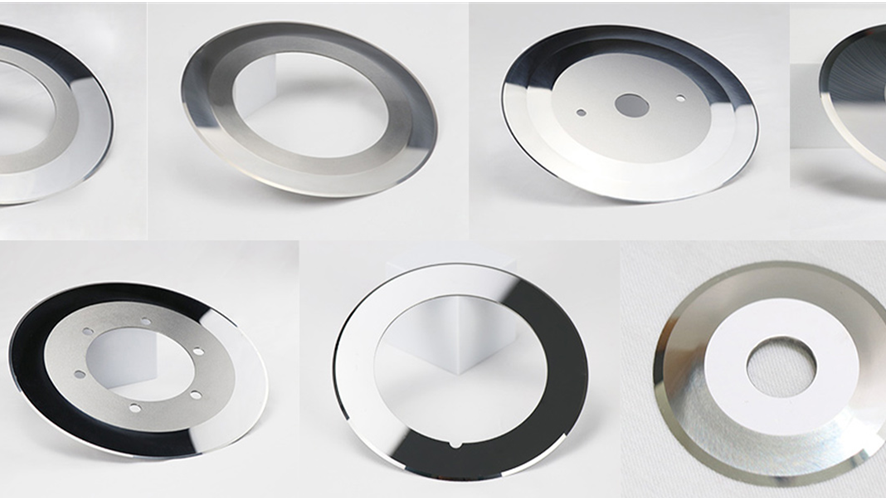

What Are The Different Methods Of Mirror Finishing For Blades?

Think all polishing is the same? Using the wrong method can damage your blades or fail to deliver results. Let's explore the right techniques for your specific needs.

The main methods include mechanical polishing3 for smooth surfaces, electrolytic polishing4 for corrosion-resistant metals, ultrasonic for hard materials, and magnetic polishing5 for complex shapes. Each technique is chosen based on the blade material, its shape, and its final application.

The choice of mirror finishing method is critical and depends entirely on the blade's material and what it will be used for. I always tell my clients that the process is just as important as the blade steel itself. We need to match the technique to the job to get the best results. For example, a blade for cutting delicate plastic film requires a different finish than one used in a corrosive food processing environment. Understanding these differences is key to maximizing performance.

Precision Mechanical Polishing

This is the most traditional method. It involves a multi-step process using progressively finer abrasive materials and polishing compounds. We start with a coarse grit to remove the initial machine marks and then move through several stages, ending with a very fine paste. This physically smooths the surface, removing peaks and valleys to create a brilliant, flat finish. It's excellent for a wide range of metal blades, especially in industries like paper, film, and foil converting, where an ultra-smooth edge is needed to prevent tearing.

Electrolytic Polishing

This is a more advanced, non-contact method. The blade is submerged in an electrolyte bath and an electric current is applied. This process removes metal ions from the surface, starting with the microscopic high points. The result is an incredibly smooth, stress-free, and often more corrosion-resistant surface. I often recommend this for our clients in the medical and food industries. The process not only creates a mirror finish but also passivates the surface of stainless steel, making it highly resistant to rust and very easy to clean.

Ultrasonic Polishing

For extremely hard materials like tungsten carbide or ceramic, mechanical polishing can be difficult. This is where ultrasonic polishing6 shines. A tool vibrating at high frequency—over 20,000 times per second—drives a slurry of fine abrasive particles against the blade's surface. This action performs micro-chipping and grinding on a microscopic level, achieving a fine polish without creating too much heat. We use this for specialized blades in the electronics or fiber optics industries.

Magnetic Polishing

When we're dealing with blades that have complex shapes or internal cutouts, traditional methods can't reach every surface evenly. Magnetic polishing uses a magnetic field to move fine, magnetic abrasive particles across the blade's surface. This "magnetic brush" is flexible and can conform to any shape, ensuring a uniform and high-quality finish everywhere. It’s a very specialized technique for high-performance, intricate cutting tools.

| Finishing Method | Best For | Key Advantage | Common Industry |

|---|---|---|---|

| Mechanical Polishing | Most metals (steel, aluminum) | High brightness, cost-effective | Paper, Plastic Film, Foil |

| Electrolytic Polishing | Stainless steel, alloys | Superior corrosion resistance, stress-free | Medical, Food Processing |

| Ultrasonic Polishing | Hard materials (carbide, ceramic) | Precision on hard-to-grind materials | Electronics, Fiber Optics |

| Magnetic Polishing | Complex shapes, intricate parts | Uniform finish on all surfaces | Aerospace, Custom Tooling |

What Specific Performance Benefits Does Mirror Finishing Bring To Industrial Blades?

Is the extra cost of mirror finishing really worth it? Many people I talk to wonder if the benefits justify the investment. I'm here to show you the clear, measurable returns.

The benefits are significant. Mirror finishing can cut friction by 50%, boost corrosion resistance by up to 50%, and improve product yield rates from 95% to over 99%. It also increases fatigue strength7, which means fewer blade fractures and a longer operational life.

When a customer is on the fence, I don't just talk about a "better" blade. I talk about what it means for their bottom line: less downtime, fewer rejected products, and longer intervals between blade changes. These aren't small improvements; they are major operational gains. The initial investment in a superior finish pays for itself many times over through enhanced efficiency and reliability. Let's break down exactly where these gains come from.

Reduced Friction And Heat

A standard ground blade might look smooth, but under a microscope, its surface is a series of peaks and valleys. As the blade cuts, these microscopic imperfections create friction, which generates heat. This heat can cause the material being cut—especially plastics—to melt and stick to the blade. It also accelerates blade wear. A mirror-finished surface is incredibly flat, reducing the surface contact area and thus lowering the coefficient of friction by as much as 50%. Less friction means less heat, smoother cutting, and less material adhesion. This translates to cleaner cuts and less frequent cleaning stops.

Enhanced Corrosion Resistance

The rough surface of a standard blade provides countless tiny sites where moisture and contaminants can collect, leading to rust and corrosion. This is a major concern in food processing and medical applications. The electrolytic polishing process, in particular, removes the outer layer of iron molecules from stainless steel, leaving a chromium-rich surface. This passive layer is extremely resistant to corrosion. In salt spray tests, a mirror-finished blade can last 30-50% longer before showing signs of rust compared to a standard blade.

Improved Fatigue Strength

Every microscopic scratch or grinding mark on a blade's surface is a potential stress riser. It's a weak point where a crack can begin to form under the repeated stress of cutting. Over millions of cycles, these tiny cracks can grow, leading to premature blade failure or chipping. Mirror finishing removes these surface defects. By creating a flawless, uniform surface, we eliminate these stress concentration points. This significantly increases the blade's resistance to fatigue, reducing the risk of unexpected fractures and extending its reliable service life.

Better Cutting Quality And Yield

For industries working with delicate materials like thin films or nonwovens, cut quality is everything. The rough edge of a standard blade can snag or tear the material, leading to defects. A mirror-finished blade glides through the material with minimal resistance. I worked with a client in flexible packaging whose yield rate was stuck at 95% due to tiny tears caused by their slitting blades. After switching to our mirror-finished blades, their yield rate jumped to over 99%. This reduction in waste had a direct, positive impact on their profitability.

What Are The Key Factors Affecting The Quality Of Mirror Finishing?

Ever received a "mirror-finished" blade that still underperformed? Not all finishes are created equal. The final quality depends on several critical, often-overlooked factors.

The quality of a mirror finish depends on four key factors: the base material and its heat treatment, the precision of the polishing process parameters, the technician's skill and experience, and the stringency of the final quality control inspections.

I often explain to customers that a great mirror finish starts long before the polishing stage. It's a result of a holistic approach to manufacturing. You can't take a poorly made blade and expect to achieve a world-class finish. It requires excellence at every step, from selecting the raw steel to the final inspection. If any one of these factors is weak, the final performance of the blade will be compromised, no matter how shiny it looks.

The Blade's Base Material

The foundation of a good mirror finish is the steel itself. The quality of the finish is directly limited by the quality of the material. High-quality steel with a fine, uniform grain structure and minimal impurities will polish to a much higher standard. If the steel has inclusions, voids, or a coarse grain, no amount of polishing can completely hide these underlying defects. Furthermore, the heat treatment process is crucial. A properly hardened and tempered blade provides a stable and consistent surface to work with. An improper heat treatment can lead to soft spots or internal stresses that will affect the final finish.

The Polishing Process And Parameters

This is where the science comes in. Each polishing method has a set of critical parameters that must be tightly controlled. For mechanical polishing, this includes the type of abrasive, the grit sequence, the pressure applied, and the speed of the polishing wheel. Using the wrong pressure can create too much heat, altering the temper of the blade edge. For electrolytic polishing, the chemical composition of the electrolyte, the temperature, the current density, and the processing time must be exact. Even small deviations can result in an uneven finish, pitting, or a failure to achieve the desired level of corrosion resistance.

The Skill Of The Technician

While the process is scientific, achieving a perfect mirror finish, especially with manual or semi-automated methods, is an art. An experienced technician develops a "feel" for the process. They know how to handle the blade, how to interpret the sounds and feedback from the machine, and when to move from one stage to the next. They can identify and correct for subtle variations in the material that an automated system might miss. This human element is often the difference between an acceptable finish and a truly exceptional one. It takes years of training to develop this expertise.

Quality Control And Measurement

You can't control what you can't measure. A visual inspection isn't enough to guarantee a high-quality mirror finish. Using advanced measurement tools to quantify the quality of our surfaces. A key metric is Surface Roughness (Ra), which we measure with a profilometer. For a true mirror finish, we aim for an Ra value of 0.02 micrometers or less. We also use high-power microscopy to inspect the surface for any residual scratches, pitting, or other defects. This rigorous QC ensures that every blade we ship meets our highest standards and will deliver the performance our customers expect.

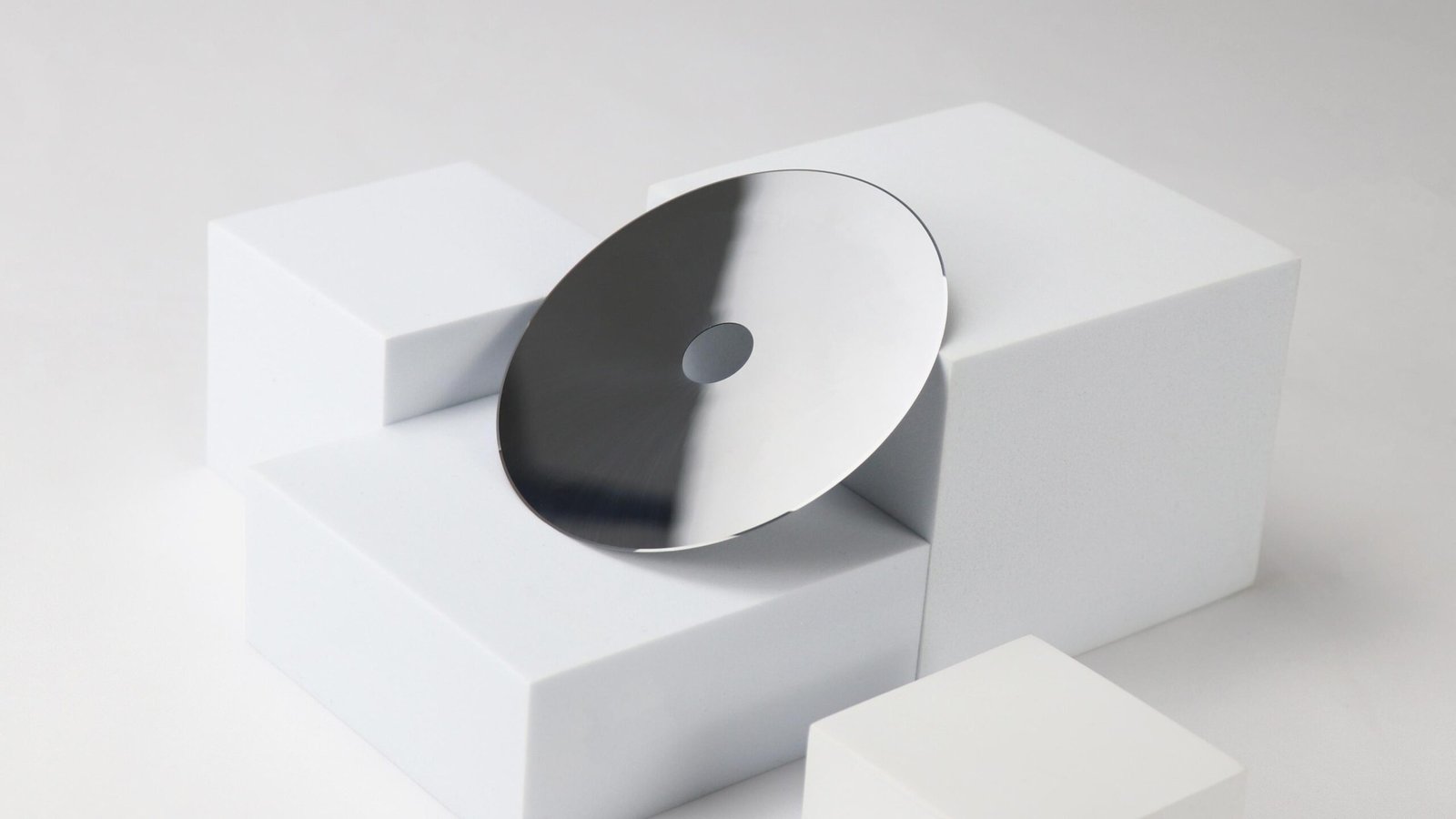

How Did Mirror Finishing Solve A Real-World Cutting Problem For Our Client?

Theory is helpful, but real-world results are what matter. A client faced significant losses from poor cutting quality. Let me share how a specific change in their blade finish solved this expensive problem.

A German client in the packaging film industry was struggling with material sticking and high defect rates. By switching to our mirror-finished blades, they eliminated adhesion8, doubled their blade's service life, and improved their product yield to over 99%.

I remember my first call with Mr. Kevin, the production manager at a high-end food packaging company in Germany. He was frustrated. His production line, which slits thin, sticky plastic films, was a constant headache. "Lyn," he said, "we have to stop the line three or four times a shift just to clean the blades. The plastic builds up, the cuts get ragged, and our scrap rate is killing our margins." They were using standard ground blades from a local supplier and thought this was just a normal part of the process. I knew we could do better.

The Problem: Adhesion, Downtime, and Waste

Mr. Kevin's problem was a classic case of what happens with the wrong surface finish. The standard blades had a microscopic roughness that was creating just enough friction to heat the plastic film. This slight temperature increase, combined with the sticky nature of the film's coating, caused material to transfer and build up on the blade edge. This buildup, in turn, led to several issues:

- Poor Cut Quality: The buildup made the edge dull and uneven, causing it to tear instead of cleanly shear the film. This resulted in a defect rate of around 5%.

- Frequent Downtime: To maintain quality, operators had to stop the slitting machine every two hours to meticulously clean the blades with solvents, a time-consuming and inefficient process.

- Short Blade Life: The constant need for aggressive cleaning, combined with the friction and heat, meant the blades wore out quickly. They were changing blades every week.

My Solution: The PASSION Mirror Finish

After listening to his challenges, I explained the concept of mirror finishing. I told him how an ultra-smooth surface would drastically reduce friction. With less friction, there would be less heat generated at the cutting point. With less heat, the sticky coating on his film would be far less likely to activate and adhere to the blade. I proposed sending him a trial set of our slitter blades with a high-grade mirror finish, specifically produced using our electrolytic polishing process to ensure maximum smoothness and integrity.

The Results: A Transformation in Production

Mr. Kevin was skeptical but willing to try. The results were immediate and dramatic. He called me a week later, and his tone was completely different.

- No More Adhesion: The plastic film no longer stuck to the blades. The mirror-smooth surface provided nothing for the material to grip onto.

- Downtime Eliminated: They went from cleaning the blades four times a shift to just a quick wipe-down once a day as a preventative measure.

- Product Yield Soared: With clean, consistent cuts, their scrap rate plummeted from 5% to less than 1%. The value of the saved material alone paid for the cost of the new blades in the first month.

- Blade Life Doubled: Because the blades ran cooler and required less aggressive cleaning, their operational life more than doubled. They went from changing blades weekly to changing them every two to three weeks.

This case is a perfect example of what I always tell my clients: the right blade is more than a part; it's a productivity tool. Investing in an advanced feature like a mirror finish delivers a tangible return by solving real-world production problems.

Conclusion

Mirror finishing is not a cosmetic choice; it's a strategic investment in blade performance, longevity, and overall production quality. It truly delivers precision in every cut.

Explore how a mirror finish can enhance blade performance and longevity, reducing costs and waste. ↩

Discover techniques to enhance corrosion resistance, crucial for longevity in various industries. ↩

Understand the mechanical polishing process and how it contributes to achieving a high-quality blade finish. ↩

Find out how electrolytic polishing can improve blade performance and corrosion resistance. ↩

Learn how magnetic polishing can achieve uniform finishes on intricate blade designs. ↩

Explore the advantages of ultrasonic polishing for hard materials and its applications in various industries. ↩

Discover the relationship between mirror finishing and increased fatigue strength, leading to longer blade life. ↩

Find out how to prevent material adhesion on blades, improving cutting quality and reducing downtime. ↩