Are production stoppages hurting your output? Frequent downtime for blade changes costs valuable time and money. These interruptions make it hard to hit your targets and disrupt your workflow.

The design of a slotter blade directly impacts your output. A poor design causes rough cuts and edge tearing, forcing frequent blade changes and downtime. A well-designed blade ensures clean cuts, longer life, and fewer stoppages, which maximizes your production efficiency.

It’s easy to think a blade is just a blade. But in my years of experience, I’ve seen how the small details in blade design1 make a huge difference. They can be the key to unlocking better performance. Let's look at exactly how specific design features can make or break your production line.

How Can The Wrong Blade Teeth And Structure Cripple Your Production Speed?

Do your finished boards have messy edges or burrs? These quality issues often point to a bigger problem. They are signs that your slotter blades are slowing down the entire operation.

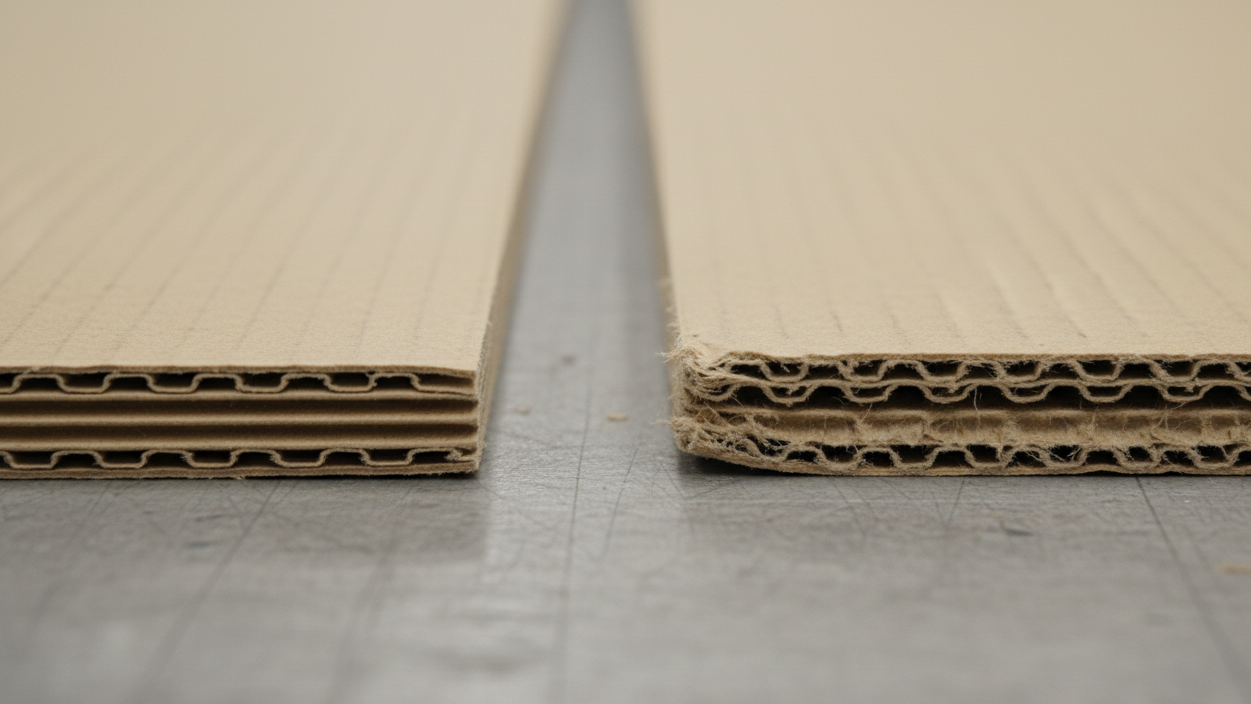

The wrong blade teeth create burrs and edge collapse2, forcing you to stop production to change blades. A weak blade structure3 leads to poor cutting precision and a shorter blade life. Both problems cause constant downtime, directly reducing your production speed.

I once cooperated with a corrugated cardboard factory manager, Clay, who was frustrated with his output numbers. He was changing slotter blades multiple times a shift. He thought it was an issue with the cardboard material, but we soon discovered the real problem was the blade design itself. The issues he faced fell into two main categories: the tooth design4 and the overall blade structure.

The Problem With Poor Tooth Design

If the teeth on your slotter blade are not designed correctly, you will see a lot of problems. You will get burrs, which are those fuzzy, uneven fibers along the cut line. You might also see the edges of the cardboard collapse or tear instead of being cut cleanly. When this happens, you can't just keep running the machine. You have to stop production, get a new blade, and replace the old one. This downtime is a direct hit to your efficiency. For every minute the machine is off, you are losing potential output.

The Impact Of Unstable Blade Structure

The body of the slotter blade is just as important as the teeth. An unstable or poorly designed structure can cause major issues. The slotter blade might loosen during operation due to vibrations. Or, the upper and lower blades might not align perfectly, leading to inaccurate cuts. This not only produces bad-quality cardboard but also causes the blades to wear out much faster. An unstable blade has a very short life, meaning you have to stop and adjust or replace it far more often. More changes mean more downtime and lower production.

Here is a simple table to show the difference:

| Feature | Good Blade Design | Bad Blade Design |

|---|---|---|

| Tooth Edge | Sharp, precise angle for clean shearing. | Dull or improper angle causing tearing. |

| Blade Body | Solid, balanced, and stable during operation. | Prone to vibration and loosening. |

| Blade Fit | Secure mounting, perfect alignment. | Poor fit, leading to misalignment. |

| Production Impact | Long runs, consistent quality, high output. | Frequent stops, poor quality, low output. |

Why Does Difficult Blade Installation Cost You More Than Just Time?

Are your maintenance teams spending too long changing blades? That extended downtime isn't just a minor delay. It's a hidden cost that eats away at your overall productivity and profits.

Difficult blade installation and replacement directly increase machine downtime. A blade that is hard to mount or align extends the stoppage period for every change, significantly lowering your total production output over time and increasing labor costs.

During a visit to a customer in the UK, I saw this problem firsthand. Their team was skilled, but they were taking nearly 30 minutes to swap out a single set of slotter blades. The design of the blades they were using made them incredibly difficult to handle and align properly. The mounting holes were slightly off, and the blades were awkward to secure. This company was losing hours of production time each week just to basic maintenance. This is a perfect example of how the design of a blade is also critical.

The Cost Of Complex Installation

When a blade is designed without thinking about the person who will install it, the process becomes slow and complicated. It might require special tools or very precise, difficult adjustments. Each minute your machine is stopped for a blade change is a minute it's not making you money. If a well-designed blade takes 10 minutes to change but a poorly designed one takes 30, you've lost 20 minutes of production. Over a year, this adds up to days of lost output.

The Risk Of Incorrect Installation

A blade that is hard to install is also easy to install incorrectly. If a blade is not perfectly seated or aligned, it will not cut properly. This leads to wasted material and a lower-quality product. Even worse, an incorrectly installed blade can be a safety risk. It might come loose during operation, potentially damaging the machine or harming an operator. A good blade design is simple and intuitive, which helps prevent these installation errors. At PASSION, we focus on creating blades that are not only high-performance but also easy and safe for teams to handle.

How Does Choosing The Right Blade Tooth Profile Boost Your Efficiency?

Are you using one type of blade for all your cardboard? This "one-size-fits-all" approach may seem simple. But it could be the reason your production line is not as efficient as it could be.

Different blade tooth profiles are designed for specific cutting purposes. Using a profile matched to your material, like a serrated blade for thick recycled board, makes cutting easier, protects the blade from wear, and reduces the cutting force needed, boosting overall efficiency.

I always advise clients like Clay that the material they are cutting is just as important as the machine they are using. For example, recycled cardboard is very different from virgin corrugated cardboard. Recycled materials are often thicker, more abrasive, and contain more impurities. Using a standard blade on this material is a recipe for quick wear and poor performance. Choosing the right tooth profile is a strategic decision that directly impacts your efficiency.

Matching The Blade Tooth To The Task

Think of it like using the right tool for the job. You wouldn't use a small screwdriver for a large screw. The same logic applies to slotter blades.

- Serrated Slotter Blades: These are excellent for cutting through thick cardboard. The teeth act like a saw, easily gripping and cutting the tough fibers. This reduces the cutting force required, which puts less strain on the machine and the blade itself.

- Specialized Teeth Slotter Blades: Some designs have unique tooth shapes that help push dust and debris away from the cut. This keeps the cut clean and protects the blade edge from abrasive paper dust, helping it stay sharp for much longer.

- Smooth Edge Slotter Blades: For thin, high-quality linerboard, a very fine, smooth edge might be better to avoid any tearing and produce a perfect finish.

The Direct Impact On Efficiency

When you use the right tooth profile, everything works better. The cut is easier, which means the machine can often run at a higher speed. The blade lasts longer because it's designed for the stress of that specific material. A longer blade life means fewer stops for changes.

Conclusion

In short, your slotter blade's design is key to production output. Choosing the right blade improves cut quality, extends blade life, and minimizes downtime, directly boosting your factory's efficiency.

Discover how the right blade design can enhance cutting performance and reduce downtime. ↩

Understanding the causes of burrs and edge collapse can help you choose better blades, enhancing production efficiency. ↩

Understanding blade structure can help you select better tools for your production line. ↩

Explore the relationship between tooth design and cut quality for better production outcomes. ↩