Struggling with high blade costs or frequent replacements? This constant trade-off between performance and budget hurts your efficiency. Inlay welding1 provides a powerful solution, giving you the best of both.

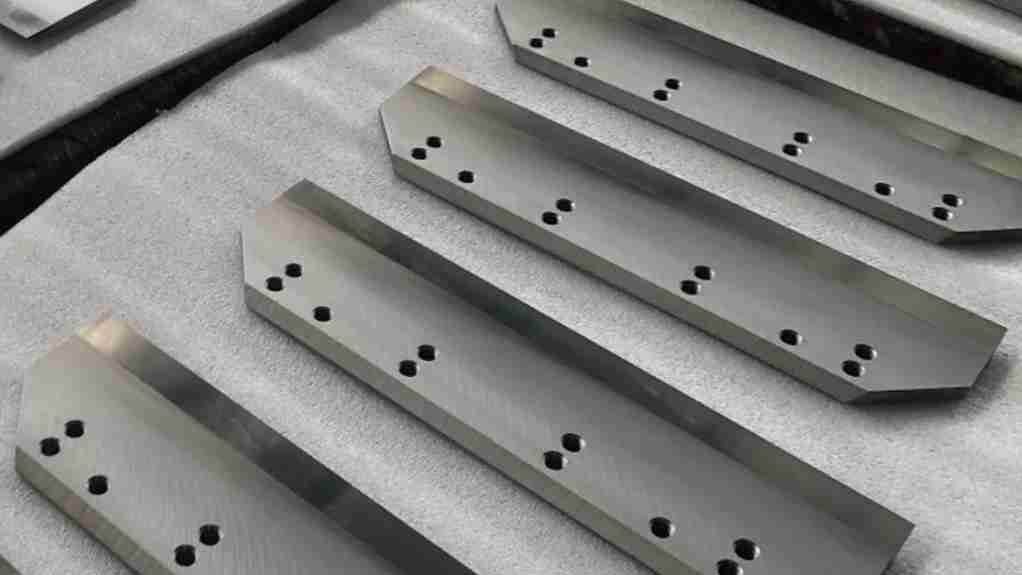

Inlay welding bonds a durable, hard-material cutting edge to a tough, cost-effective blade body. This composite structure provides elite cutting performance and longevity where it matters most—at the edge—while significantly reducing the overall material cost compared to solid high-performance alloy blades.

This sounds simple, but the technology behind it is quite advanced. I often get asked how this "best of both worlds" approach truly works. Let's break down the core principles, the economic benefits, and the real-world applications I've seen firsthand. Understanding this will change how you look at your cutting tools forever.

What Is The "Best Of Both Worlds" Principle Behind Inlay Welding?

Have you ever noticed how blades can be either extremely hard but brittle, or tough but quick to dull? This dilemma forces a compromise. Inlay welding eliminates this compromise entirely.

The principle is simple yet effective: use materials for their best properties. A tough, flexible steel body2 absorbs shock and stress, while a strip of ultra-hard material like tungsten carbide is welded onto the cutting edge for superior sharpness, wear resistance3, and a longer life.

The genius of inlay welding lies in creating a composite blade that outperforms a blade made from a single material. It's about putting the right material in the right place. To really understand this, we need to look at the two key components separately.

The Foundation: A Tough And Resilient Body

The main body of an inlay welded blade is typically made from a high-quality, resilient steel. The primary job of the body is not to cut, but to provide structural integrity and absorb the immense physical stress of industrial cutting operations. Think of it as the backbone of the blade. This toughness prevents the blade from shattering or cracking under high impact or vibration, which is a common failure point for fully hardened, brittle materials. We carefully select the steel for the body to ensure it has the perfect balance of toughness and machinability, providing a stable foundation for the cutting edge.

The Cutting Edge: A Hard And Wear-Resistant Tip

This is where the cutting action happens. For the edge, we use a small, inlaid strip of a much harder and more expensive material, like tungsten carbide or a specialized high-speed steel. These materials are chosen for their exceptional hardness and ability to hold a razor-sharp edge for an incredibly long time, even when cutting abrasive or tough materials. By concentrating this premium material only on the working edge, we get all the benefits of its superior wear resistance without the extreme cost and brittleness of a solid carbide blade. The welding process itself is critical, as it creates a permanent, metallurgical bond that ensures the tip will not break away from the body.

| Blade Feature | Solid Steel Blade | Solid Carbide Blade | Inlay Welded Blade |

|---|---|---|---|

| Hardness | Low | Very High | Very High (at edge) |

| Toughness | High | Low | High (in body) |

| Cost | Low | Very High | Medium |

| Wear Resistance | Low | Very High | Very High |

| Best For | Low-intensity cutting | High-precision, stable jobs | High-impact, high-wear cutting |

How Does Inlay Welding Drastically Reduce Blade Costs Without Sacrificing Performance?

Does the price of solid tungsten carbide blades make you hesitate? The high investment can be a barrier, forcing tough budget decisions. Inlay welding provides a smart financial alternative.

The cost reduction comes from intelligent material usage. Instead of making the entire blade from expensive carbide, we only use it for the cutting edge. The blade's body is made from more affordable, high-toughness steel, cutting material costs by up to 50% or more.

When I talk to clients about blade costs, I always encourage them to look beyond the initial purchase price. The most significant savings from inlay welded blades are realized over the entire life of the tool. Let’s break down the economics.

Targeted Material Application

The primary reason inlay welding is so cost-effective is simple: you only pay for high-performance material where you need it. Tungsten carbide can be many times more expensive than steel. A solid carbide blade is 100% expensive material. An inlay welded blade might be 95% affordable steel and only 5% carbide. Our data shows that this can reduce the upfront cost by 30% to 50% compared to a solid carbide equivalent, while delivering over 80% of its cutting life and performance. This makes high-performance cutting accessible for businesses where a full carbide solution would be financially impractical.

The True Cost: Total Cost Of Ownership (TCO)

The real financial benefit comes from a lower Total Cost of Ownership. A blade’s true cost includes its purchase price plus the costs associated with its use, such as downtime for changes, resharpening services4, and scrapped products from dull cuts.

I often use this simplified comparison with my customers:

| Cost Factor | Low-Cost Steel Blade | Solid Carbide Blade | PASSION Inlay Welded Blade |

|---|---|---|---|

| Initial Cost | $20 | $250 | $100 |

| Lifespan (Units) | 100,000 | 2,000,000 | 1,600,000 |

| Changes per 2M Units | 20 | 1 | 1-2 (resharpening) |

| Downtime Cost | High | Very Low | Low |

| Total Cost | High (due to frequent changes) | High (due to initial price) | Optimized |

An inlay welded blade lasts significantly longer than a steel blade, which drastically cuts down on machine downtime and labor for blade changes. While it may not last quite as long as a solid carbide blade, its much lower initial cost and the ability to be resharpened multiple times often make it the most economical choice over a full production cycle. You get premium performance without the premium price tag.

Why Are Inlay Welded Blades The Go-To Choice For Demanding Industries?

Running your machines at high speeds or for long hours? Standard blades often overheat, dull quickly, or even chip under such intense pressure. This leads to unplanned downtime and wasted material.

They are the go-to choice because their composite structure offers a unique combination of heat dissipation and durability. The steel body pulls heat away from the cutting edge, while the hard inlay resists wear, ensuring consistent, reliable performance in high-stress industrial applications.

In industries where machines run 24/7, blade failure isn't just an inconvenience; it's a major disruption that costs money every minute. This is where inlay welded blades truly shine. Their unique properties make them exceptionally reliable under pressure.

Superior Thermal Management

One of the biggest enemies of a sharp blade is heat. Friction from high-speed cutting generates intense temperatures right at the blade's tip. A solid carbide blade, despite its hardness, is a poor conductor of heat. This means the heat gets trapped at the cutting edge, which can lead to thermal shock, micro-cracking, and premature failure. In contrast, the steel body of an inlay welded blade acts like a massive heat sink. It actively pulls heat away from the delicate carbide tip and dissipates it across the larger blade body. This keeps the edge cooler, more stable, and less prone to heat-related damage. The result is a blade that maintains its sharpness and structural integrity far longer during continuous, high-temperature operations.

Versatility Across Applications

This combination of toughness, wear resistance, and thermal stability makes inlay welded blades incredibly versatile. I've worked with clients across a wide range of sectors who rely on this technology. It’s a proven solution in:

- Packaging: For slitting plastic films and laminates.

- Paper Converting: For cutting paper tubes and cores.

- Rubber & Tire: For trimming and cutting tough rubber compounds.

- Metal Processing: For shearing thin aluminum foil and other non-ferrous metals.

- Textiles: For cutting dense fibers and non-wovens.

I remember working with a client, Oliver, who manages a large packaging film facility in Mexico. They were using solid steel blades for their slitting machines and had to change them every single shift because they would dull so quickly. Their downtime was enormous. We introduced them to inlay welded blades. The upfront cost was higher, but the results were immediate. They went from changing blades every 8 hours to simply resharpening them once every two weeks. Their machine uptime soared, and the quality of their cuts became far more consistent. David told me the investment paid for itself in less than three months, purely from the reduction in downtime and wasted product.

Conclusion

Inlay welding is not a compromise; it's a smart strategy. It delivers the strength, durability, and cost-efficiency modern industries demand, making it an essential technology for any cutting operation.

Explore how inlay welding enhances blade performance and reduces costs in various industries. ↩

Discover why a resilient steel body is crucial for blade durability and performance. ↩

Find out how wear resistance contributes to the longevity of blades in demanding applications. ↩

Learn how resharpening can extend the life of cutting tools and reduce costs. ↩