Struggling with poor cuts on different fabrics? This leads to frayed edges1 and wasted material. Adjusting your blade parameters2 is the key to achieving perfect, clean cuts every time.

For different fabric densities, adjust blade angle3, speed, and material. Use sharper, smaller-angle blades at high speeds for low-density fabrics4. For high-density materials, use stronger, larger-angle blades with wear-resistant coatings5 and moderate speeds to prevent chipping and ensure clean cuts.

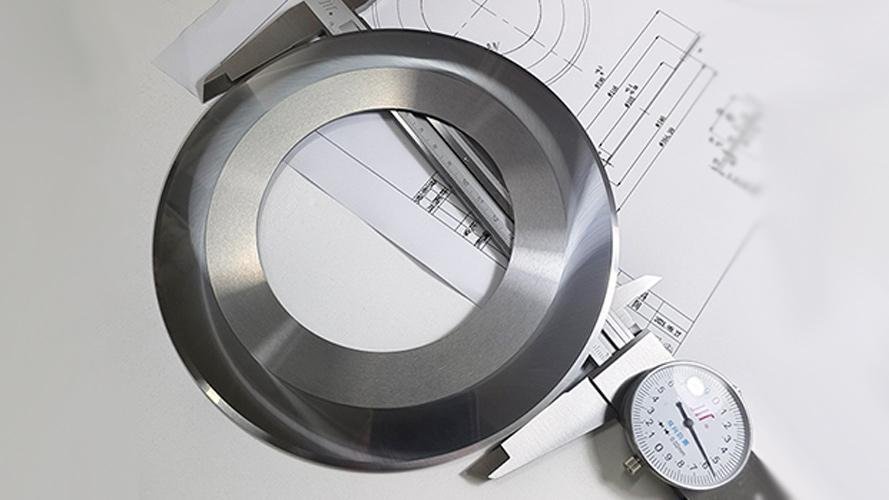

Getting the right cut is about more than just having a sharp blade. It’s about matching the tool to the material precisely. I've learned that small adjustments to your blade setup can make a huge difference in your production quality and efficiency. Let’s explore how we fine-tune the cutting process for different materials. This is how you can achieve precision in every cut.

How Should You Cut Low-Density Fabrics Like Cotton And Non-Wovens?

Are your soft fabrics snagging or tearing during cutting? This leads to frayed edges and wasted material, slowing down your entire production line. A sharp, fast-moving blade with the right angle can solve this.

For low-density fabrics, use a very sharp blade with a small rake angle (15°–20°) and a high cutting speed6. Polished stainless steel or ceramic blades work best to prevent fibers from sticking and ensure a clean, smooth cut without pulling or deforming the material.

When cutting soft or low-density materials, the goal is to slice through the fibers cleanly without pulling or bunching them up. This requires a blade that acts more like a scalpel than an axe. A sharp cutting edge combined with a small rake angle (around 15° to 20°) creates this precise slicing action. High cutting speeds work well here because they don't give the material time to deform. For materials like non-wovens that can get sticky, using polished stainless steel or even ceramic blades helps. The smooth surface reduces friction and prevents fibers from adhering to the blade, which means less downtime for cleaning.

Real-World Example: Medical Non-Wovens

A client in Vietnam was manufacturing non-woven fabrics for medical gowns. They faced constant issues with fibers melting and sticking to their standard steel blades, causing rough, inconsistent edges. Their machines needed frequent stops for blade cleaning, which was hurting their output. I suggested they switch to one of our polished ceramic blades with a sharper 18° angle. The result was immediate. The cuts became perfectly clean, and the non-stick surface of the ceramic blade eliminated the adhesion problem. They were able to increase their machine speed by 20% and significantly reduce waste.

| Parameter | Low-Density Fabric (e.g., Cotton) | Recommended Setting |

|---|---|---|

| Blade Angle | Rake Angle | 15° – 20° |

| Blade Material | Standard | Polished Stainless Steel, Ceramic |

| Cutting Speed | Relative | High |

| Edge Finish | Sharpness | Highly Polished, Sharp Edge |

What Is The Best Blade Setup For High-Density Fabrics Like Kevlar Or Carbon Fiber?

Are your blades chipping or wearing out quickly when cutting tough materials? This means frequent blade changes and inconsistent cut quality on expensive fabrics. A stronger blade with a wider angle and a special coating is the answer.

For high-density fabrics7, use a blade with a larger wedge angle (25°–35°) for added strength. Apply a wear-resistant coating like TiN or AlCrN to protect the edge. A slower, more controlled cutting speed prevents overheating and blade chipping, ensuring durability.

High-density fabrics like nylon, Kevlar, and carbon fiber are tough and abrasive. They will destroy a standard blade in no time. For these materials, you need to prioritize blade strength and durability over sharpness alone. A larger wedge angle, typically between 25° and 35°, provides more support behind the cutting edge, making it much more resistant to chipping. However, this reinforcement alone isn't enough. The extreme abrasiveness of these fibers requires a wear-resistant coating. Coatings like Titanium Nitride (TiN) or Aluminum Chromium Nitride (AlCrN) create a super-hard barrier that protects the blade, reduces friction, and dissipates heat. This combination allows the blade to power through dense material without failing prematurely.

Real-World Example: Carbon Fiber Composites

I remember working with an automotive parts manufacturer in Germany. They were cutting carbon fiber composites, and their uncoated steel blades were dulling and chipping after just a few hundred cuts. The constant downtime for blade replacement was a major bottleneck. We supplied them with tungsten carbide blades that had a 30° wedge angle and an AlCrN coating8. It was a game-changer for them. Blade lifespan increased by over ten times, cut quality remained consistent, and their production line ran much more smoothly.

| Parameter | High-Density Fabric (e.g., Carbon Fiber) | Recommended Setting |

|---|---|---|

| Blade Angle | Wedge Angle | 25° – 35° |

| Blade Material | Standard | Tungsten Carbide, HSS |

| Coating | Recommended | TiN, AlCrN, or Diamond-Like Carbon (DLC) |

| Edge Finish | Durability | Micro-ground for strength |

How Does Blade Thickness Impact Cutting Performance Across Different Densities?

Are you seeing blade vibration or wavy cuts on wider materials? Your blade might be too thin for the job, causing instability and poor results. Choosing the right blade thickness is crucial for stability.

Blade thickness ensures stability, especially for wide cuts or dense fabrics. A good rule of thumb is to use a blade with a thickness of at least 1/100th to 1/150th of the slitting width9. Thicker blades prevent vibration and ensure a straight, clean cut.

Blade thickness is all about stability. When a blade is too thin for the task, it can flex or vibrate during the cut, especially at high speeds or with wide material. This vibration leads to a wavy or uneven cut edge, poor quality, and can even cause the blade to wear out unevenly or fail. A simple and effective guideline we use at PASSION is that the blade's thickness should be no less than 1/100 to 1/150 of the planned slitting width. For example, if you are slitting a 300mm wide roll, you'd want a blade that is at least 2mm to 3mm thick. When cutting very high-density fabrics, I often recommend going even thicker to guarantee the blade stays rigid under the increased cutting forces.

Real-World Example: Wide Textile Slitting

A textile client in Turkey was slitting wide rolls of heavy-duty woven polypropylene. They were using thin, budget blades, and were complaining about "blade flutter" that resulted in wavy edges and inconsistent roll widths. We analyzed their process and recommended a thicker, more rigid high-speed steel (HSS) blade. It was 4mm thick to match their 450mm slitting width. The extra rigidity completely eliminated the vibration. Their cut quality became perfect, and the blade's stability also meant it stayed sharp for much longer, reducing their overall operating costs.

| Slitting Width | Minimum Blade Thickness (1/150) | Recommended Blade Thickness (1/100) |

|---|---|---|

| 150 mm | 1.0 mm | 1.5 mm |

| 300 mm | 2.0 mm | 3.0 mm |

| 450 mm | 3.0 mm | 4.5 mm |

| 600 mm | 4.0 mm | 6.0 mm |

Conclusion

By adjusting blade angle, material, thickness, and speed for different fabric densities, you can achieve perfect cuts, reduce waste, and extend the life of your blades.

Find effective methods to avoid frayed edges and ensure clean cuts on various fabrics. ↩

Understanding blade parameters is crucial for achieving clean cuts and reducing material waste. ↩

Explore how adjusting blade angles can significantly improve cutting precision and material handling. ↩

Learn the best techniques for cutting low-density fabrics to avoid frayed edges and improve production efficiency. ↩

Learn how wear-resistant coatings can extend blade life and improve cutting performance. ↩

Find out the ideal cutting speeds for various fabrics to ensure clean and efficient cuts. ↩

Discover the optimal blade setups for high-density fabrics to enhance durability and cut quality. ↩

Find out how AlCrN coating can protect blades and improve their cutting performance. ↩

Understand the relationship between slitting width and blade selection for optimal cutting. ↩