Frustrated by production halts because your industrial blades keep clogging? These jams reduce efficiency, waste materials, and cost you time and money, but simple optimizations can prevent them entirely.

To prevent blade clogging, use blades with low-friction coatings like DLC1 or TiN2, optimize cutting speeds to reduce heat buildup, and maintain a strict cleaning and sharpening schedule3. These actions minimize material adhesion and ensure the blade cuts cleanly, preventing jams and improving overall production efficiency.

Production grinds to a halt, not because of a major machine failure, but because of sticky residue on a small blade. It often comes down to a few key areas that are easily overlooked. By understanding these details, you can keep your production line moving smoothly. Let's break down the solutions one by one, starting with the very design of your blade. Are you paying enough attention to this critical first step?

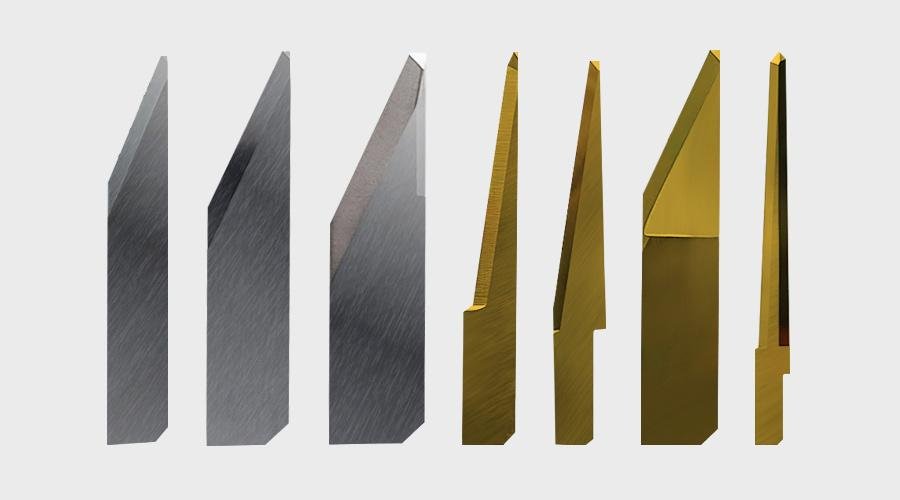

Why Is The Right Blade Material And Coating The First Line Of Defense?

Choosing a blade seems simple, but are you using one that actively fights clogging? The wrong choice can cause sticky residue to build up, stopping your line cold.

Blade materials with low friction, like tungsten carbide4, combined with surface coatings like DLC or TiN, create a non-stick surface. This actively prevents sticky materials like plastics or adhesives from adhering to the blade, which is the primary cause of clogging and jamming during high-speed cutting operations.

Dive Deeper

The foundation of a clog-free operation starts with the blade itself. The material your blade is made from and the coating applied to its surface are your most powerful tools against material buildup. Materials with a naturally low friction coefficient, such as cemented carbide or certain powder metallurgy steels, are a great starting point. They are harder and slicker than standard tool steels, meaning material is less likely to stick.

Then we have coatings, which take this to the next level. Think of it like a non-stick pan in your kitchen. A good coating creates a micro-barrier5 that prevents adhesion. I once cooperated with a packaging company in the USA who was struggling with this. His team was cutting adhesive-backed plastic film, and their standard steel blades were gumming up every hour. Production was a nightmare. I recommended he switch to a tungsten carbide blade with a DLC (Diamond-Like Carbon) coating. The change was immediate. Clogging was virtually eliminated, and his team could run a full shift without stopping to clean blades. This simple switch boosted their productivity by over 20%.

Here’s a quick guide to common coatings:

| Coating Type | Best For | Key Benefit |

|---|---|---|

| DLC | Adhesives, Plastics, Rubber | Extremely low friction, non-stick |

| TiN | General Purpose, Metals | High hardness, good wear resistance |

| CrN | Plastics, Copper | Excellent anti-adhesion properties |

| TiAlN | High-Speed Cutting, Dry Machining | Maintains hardness at high temps |

How Can Adjusting Cutting Speed And Temperature Stop Material Buildup?

Do you just set your machine to the fastest speed and hope for the best? Pushing too hard generates excess heat, which can melt materials onto your blade, causing gummy buildup.

Lowering cutting speeds reduces frictional heat, which stops polymers or adhesives from melting and sticking to the blade. Additionally, using cooling methods6 like air jets or lubricants actively removes heat. This controlled thermal environment ensures the material is cut cleanly instead of melting onto the tool.

Dive Deeper

Speed and heat are partners in crime when it comes to blade clogging. Every cut generates friction, and friction generates heat. When you run a machine too fast, especially with materials that have a low melting point, you are essentially welding tiny bits of that material onto your blade. Polymers, plastics, and adhesives are especially sensitive to this. The fix isn't always about going slower, but about finding the right balance—what we call the "sweet spot" for your specific application. This involves optimizing both the spindle speed and the feed rate.

Simple thermal management can make a huge difference. You don’t always need a complex liquid cooling system. I remember a client, who runs a textile factory in Mexico. They were cutting synthetic fabrics that contained polymers. At the high speeds they were running, the fibers would melt and fuse to the blade, causing jams and ragged cuts. I suggested they reduce the cutting speed by 15% and install a simple compressed air line aimed directly at the cutting edge. This small, inexpensive adjustment was enough to keep the blade cool. The melting stopped, production became consistent, and fabric waste dropped significantly.

Here is how speed can affect different materials:

| Material | High Speed Effect | Recommended Action |

|---|---|---|

| Soft Plastics (LDPE) | Melts easily, creates severe buildup | Reduce speed significantly, use cooling air |

| Adhesive Tapes | Softens adhesive, causes instant clogging | Use very slow speeds and a coated blade |

| Synthetic Fabrics | Fuses fibers to the blade edge | Moderate speed, ensure sharp blade, use cooling |

Could A Simple Maintenance Routine Be The Key To Uninterrupted Operation?

Is blade maintenance something you only do when there's a problem? A dull or dirty blade forces the machine to work harder, increasing friction, heat, and the chances of a jam.

Yes, a simple routine is fundamental. Regularly cleaning blades removes the initial residue that attracts more buildup. Periodically sharpening or regrinding the edge keeps it sharp, which lowers cutting force and heat generation. This ensures the material is sliced cleanly rather than being crushed or melted.

Dive Deeper

Even the most advanced, perfectly coated blade will eventually clog if it isn't cared for. Maintenance is not what you do when something goes wrong; it's what you do to prevent something from going wrong. A dull blade is a major cause of jamming. Instead of slicing, it starts to push and tear the material. This requires more force, which generates more friction and heat, and the cycle of clogging begins all over again. You can often tell a blade is getting dull before it fails completely. Listen for increased cutting noise, look for rougher edges on your finished product, or notice if the machine motor sounds like it's straining.

Here’s a basic checklist to get started:

Daily Check

- Visually inspect the blade for any visible residue.

- Clean the blade surface with an appropriate solvent for the material being cut.

Weekly Check

- Inspect the cutting edge for micro-chips or dullness, perhaps with a small magnifier.

- Ensure mounting bolts are tight and the blade is properly aligned.

Scheduled Regrinding

- Don't wait for failure. Set a regrinding schedule based on operating hours and the material you are cutting.

Conclusion

Preventing blade clogging is simple. Focus on the right blade coating, control your speed and temperature, and stick to a regular maintenance schedule for smooth, continuous production.

Explore this link to understand how DLC coatings enhance blade performance, reduce friction, and prevent clogging, boosting production efficiency. ↩

Explore this link to understand how TiN coating enhances blade performance, durability, and efficiency in cutting operations. ↩

Discover best practices for maintaining blades to ensure optimal performance. ↩

Find out why tungsten carbide is a preferred material for cutting blades. ↩

Explore the concept of micro-barriers in coatings and their role in preventing adhesion. ↩

Explore various cooling methods to enhance blade performance and reduce heat. ↩