Dull blades slowing you down? Wasting money on frequent replacements? The problem might not be the blade itself, but the grinding wheel you're using to sharpen it.

To scientifically select a grinding wheel, you must match its material, grit, and shape to your blade's properties and the specific grinding task.

I've seen countless companies struggle with inefficient grinding. It’s a common bottleneck that directly impacts production quality and cost. But the good news is that with a bit of knowledge, you can solve this problem for good. Let’s walk through the process together, starting with the fundamentals. Understanding your tools is the first step toward mastering your process.

How Do You Choose The Right Grinding Wheel Material And Shape For Your Blade?

Choosing between a diamond and an aluminum oxide wheel can feel overwhelming. Using the wrong type can cause blade damage and waste time. Are you sure you're using the right tool for the job?

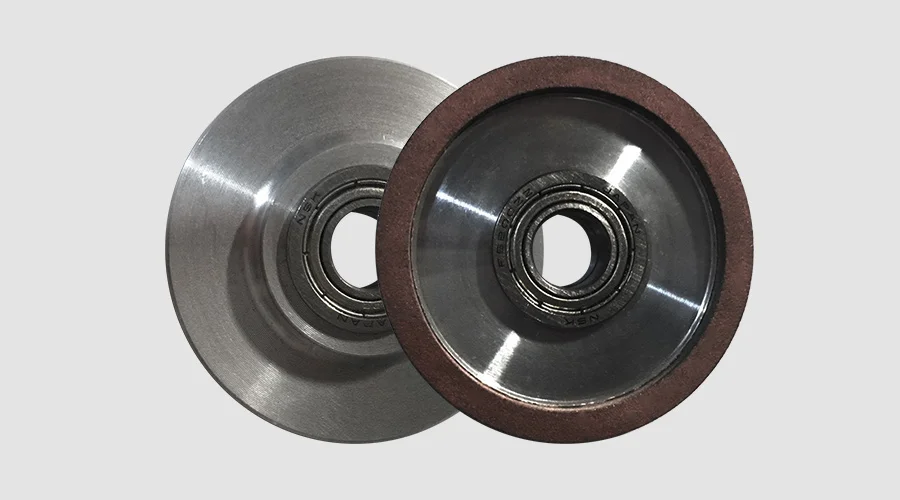

Match the wheel’s abrasive material to the blade’s material. Use diamond wheels1 for tungsten carbide, CBN for HSS, and aluminum oxide for softer steels. The correct shape—flat, cup, or dish—depends on the surface you are grinding.

When you select a grinding wheel, you are essentially choosing a cutting tool to sharpen another cutting tool. It sounds simple, but the interaction between the wheel and the blade is a complex science. The wrong choice leads to problems like heat damage, micro-cracks, and a dull edge, no matter how skilled the operator is. I always tell my clients that about 80% of grinding problems2 can be traced back to a mismatch in the wheel selection. Let's make sure you're in the other 20%.

Abrasive Materials Explained

The abrasive material is the heart of the grinding wheel. Each type has a specific job.

- Diamond Wheels: Diamond is the hardest material known. It is the best choice for grinding extremely hard materials like tungsten carbide, ceramics, and composites. However, it’s not ideal for ferrous metals like steel because the high heat of grinding can cause a chemical reaction that degrades the diamond.

- Cubic Boron Nitride (CBN) Wheels3: CBN is the second hardest material. It is the perfect choice for grinding hardened ferrous materials like high-speed steel (HSS) and tool steels. It doesn't react with iron and has excellent thermal stability4, which means it cuts cooler and faster on steel.

- Silicon Carbide (SiC) Wheels: These are great for grinding hard but brittle materials. Think cast iron, non-ferrous metals like aluminum or brass, and some ceramics.

- Aluminum Oxide (or Corundum) Wheels: This is the most common and versatile abrasive. It's best for grinding materials with high tensile strength, like carbon steels and alloy steels. It’s a cost-effective workhorse for general-purpose grinding on less-hardened blades.

Common Grinding Wheel Shapes

The shape of the wheel determines how it makes contact with your blade.

| Wheel Shape | Primary Use |

|---|---|

| Flat Wheel | Most common shape, used for grinding flat surfaces and external diameters. |

| Cup/Bowl Wheel | Used for sharpening cutting tool edges and grinding flat surfaces with the wheel face. |

| Dish Wheel | Ideal for grinding complex tool profiles and tight slots, like in form tools. |

What Factors Determine The Correct Grinding Wheel Specification For Your Application?

You have the right type of wheel, but your blades are still burning or chipping. Sound familiar? The secret to perfect grinding is hidden in the wheel's detailed specifications.

Key factors are blade material hardness, the grinding stage (rough vs. fine), machine speed, and cooling. A common rule is "hard material, soft wheel." You must also match the grit size5 to the required surface finish.

I once worked with a customer who was convinced their new batch of blades was defective. The edges were chipping almost immediately after sharpening. After a quick call, I discovered they were using a very hard, fine-grit wheel for a rough grinding6 pass. The wheel wasn't breaking down to expose new abrasive; it was just rubbing and creating immense pressure and heat, which made the blade edge brittle. We switched the wheel, and the problem vanished. Details like grit size and wheel hardness aren't minor—they are everything.

Blade Material Hardness

A fundamental principle in grinding is: use a soft-grade wheel for hard materials and a hard-grade wheel for soft materials. This sounds backward, but it makes sense. When grinding a hard material, you want the wheel's bond to break down at a controlled rate. This releases dull abrasive grains and exposes fresh, sharp ones. A soft wheel does this effectively. If you use a hard wheel on hard material, the grains will dull but won't be shed, causing rubbing, heat, and damage.

Grinding Stage And Grit Size

The "grit" is the abrasive particle size. This directly controls the material removal rate and the surface finish.

- Rough Grinding: The goal is to remove a lot of material quickly. Use a coarse grit, typically 46# or lower. The finish will be rough, but the process is fast.

- Fine/Finish Grinding: The goal is a smooth, sharp edge. Use a medium to fine grit, usually from 60# to 100#. This removes less material but provides a much better finish.

- Polishing/Lapping: For a mirror-like, razor-sharp edge, you need an ultra-fine grit of 120# or higher. This is for applications requiring extreme precision.

Operating Parameters (Speed & Feed)

Every wheel is designed for an optimal speed range. Running it too slow is inefficient, and running it too fast is extremely dangerous.

- General Rule of Thumb:

- Conventional Wheels (Al_2O_3, SiC): 20–30 m/s is a safe and effective range.

- Diamond Wheels: 25–35 m/s often gives the best balance of removal rate and wheel life.

- CBN Wheels: These can be run at very high speeds, often above 40 m/s, which is a key part of their high efficiency. The feed rate (how fast you move the blade into the wheel) must be balanced with the wheel speed and grit to avoid excessive heat or pressure.

Equipment And Cooling

Your machine's rigidity and power matter. A high-speed, high-performance wheel like a metal bond CBN wheel requires a very rigid and powerful machine to perform correctly. Using it on a flimsy machine will cause vibration and poor results. Lastly, coolant is not optional. It must be applied generously and aimed directly at the point of contact to prevent thermal damage to the blade edge.

Why Are Grinding Wheel Dressing And Cooling Critical For Blade Quality?

Your brand-new grinding wheel is already performing poorly. It seems clogged and is burning the blades. This common issue can ruin your grinding quality and is often completely avoidable.

Regularly "dress" your wheel to restore its sharp cutting surface and correct its shape. Use ample coolant to prevent the blade from overheating, which causes burn marks and micro-cracks. These two steps are non-negotiable for quality.

Think of your grinding wheel like a kitchen knife. Even the best knife gets dull with use and needs to be sharpened. A grinding wheel is no different. Its tiny abrasive grains get dull, or the spaces between them get clogged with metal particles (a problem we call "loading"). If you don't maintain the wheel's surface, you're not grinding anymore; you're just rubbing and generating friction. This is where wheel dressing7 and proper cooling come in—they are the maintenance that keeps your grinding process sharp and efficient.

The Importance Of Wheel Dressing

Dressing is the process of conditioning the cutting surface of the wheel. It achieves two goals:

- Truing: This ensures the wheel is perfectly round and runs true with the machine's spindle. An out-of-true wheel will cause vibration and an inconsistent finish.

- Sharpening: Dressing breaks away the dull abrasive grains and the "loaded" material that has become clogged in the wheel's pores. This exposes fresh, sharp cutting points, restoring the wheel's grinding ability.

Without regular dressing, a wheel will start to "glaze over." The surface becomes smooth and slick. At this point, it generates far more heat than it removes material, which is the primary cause of grinder burn and thermal damage to the blade edge. You must dress the wheel periodically to keep it in optimal cutting condition.

Coolant Management: More Than Just Cooling

Coolant, or grinding fluid, does three critical jobs:

- It Cools: Grinding generates intense, localized heat. Without coolant, this heat can easily "anneal" or soften the blade's hardened edge, making it lose its ability to stay sharp. It can even cause burn marks or micro-cracks.

- It Lubricates: Coolant reduces friction between the wheel and the workpiece. This lowers the energy needed to grind and helps produce a better surface finish.

- It Cleans: The flow of coolant flushes away the tiny metal chips and abrasive particles produced during grinding. This helps prevent the wheel from loading and keeps the grinding zone clear.

For consistent, high-quality results, the coolant supply must be abundant and precisely aimed at the grinding interface. Starving the process of coolant is a recipe for disaster.

How Did A Real-World Client Boost Efficiency By Optimizing Their Grinding Process?

Theory is great, but does this actually work in the real world? Let me share a story about a client in Germany who faced this exact challenge and how we solved it.

A metal fabricator in Germany, struggled with burnt HSS blades and slow output. By switching from a standard abrasive to a specific CBN wheel and adjusting his cooling, he doubled his grinding efficiency.

I remember getting a call from the client, the production manager at a large metal converting plant in Germany. He was frustrated. His team was responsible for sharpening the high-speed steel (HSS) slitter knives used in their production lines, but something was wrong. "Lyn," he told me, "we're burning through blades. We sharpen them, and within a few hours, they're dull or showing heat marks. Our downtime is killing us." This is a story I've heard before, and I knew we could help.

The Problem and My Analysis

His's team was using a standard aluminum oxide wheel for the job. While these wheels are good for general-purpose work, HSS is a different beast. It's a very hard and heat-sensitive tool steel. When I listened to he describe the bluish burn marks on the blade edges, I knew what was happening. The aluminum oxide wheel was generating too much heat. It was loading up quickly, and instead of cutting the steel, it was rubbing against it. This friction was overheating the blade edge, softening the steel, and making it unable to hold a sharp edge. It was a classic case of a tool mismatch.

The PASSION Solution

I explained to him that for HSS, a CBN (Cubic Boron Nitride) wheel is a far superior choice. CBN's high thermal conductivity and extreme hardness make it perfect for grinding hardened steels without generating excessive heat. I recommended a specific vitrified bond CBN wheel from our portfolio, which is designed for high-efficiency, cool grinding. But the tool was only half the solution. We also reviewed his process. I had him check his coolant nozzles to ensure a heavy, consistent flow of fluid was aimed directly at the point where the wheel met the blade.

The Outstanding Result

A few weeks later, he called me back, and he was thrilled. "It's a night and day difference," he said. He reported that the grinding time for each blade was cut by nearly 50% because the CBN wheel could remove material more aggressively without any risk of burning. More importantly, the quality of the edge was visibly better—sharper and burr-free. The blades sharpened with the new process were lasting over 30% longer in their slitting machines, which significantly reduced their production downtime. By making a scientific choice on the grinding wheel and process, he didn't just solve a sharpening problem; he improved his entire plant's efficiency.

Conclusion

Choosing the right grinding wheel isn't a minor detail. It is a critical step that directly boosts efficiency, improves blade quality, and lowers your overall production costs.

Learn about the benefits of diamond wheels, especially for hard materials, and how they can enhance your grinding process. ↩

Explore common grinding issues and effective solutions to enhance your grinding operations. ↩

Discover why CBN wheels are ideal for high-speed steel and how they improve grinding efficiency. ↩

Learn about thermal stability and its significance in preventing overheating during grinding. ↩

Understand the importance of grit size in achieving the desired surface finish and material removal rate. ↩

Understand the distinctions between rough and fine grinding to choose the right approach for your tasks. ↩

Learn about wheel dressing techniques to maintain optimal grinding performance and prolong wheel life. ↩