Is your industrial blade wearing out much faster than you expect? This downtime costs money and can ruin your products. The solution is to match the blade material to your workpiece chemistry.

Selecting the right industrial cutting blade involves matching its chemical properties1 to the workpiece. The goal is to find a chemically stable pairing that avoids reactions at high temperatures. This prevents adhesion, diffusion wear2, and corrosion, ensuring longer blade life and better performance.

Many customers found that a blade that worked perfectly on one material failed completely on another. It's not just about hardness; it's about chemistry. We need to look at specific material pairings to understand why this happens. Let's break down some common scenarios I’ve seen in my work to make this clearer.

Why Is Pcd A Poor Choice For Cutting Steel?

Have you ever used a PCD blade3 on steel and watched it fail almost instantly? It’s a frustrating and costly mistake. This happens because of a powerful chemical reaction.

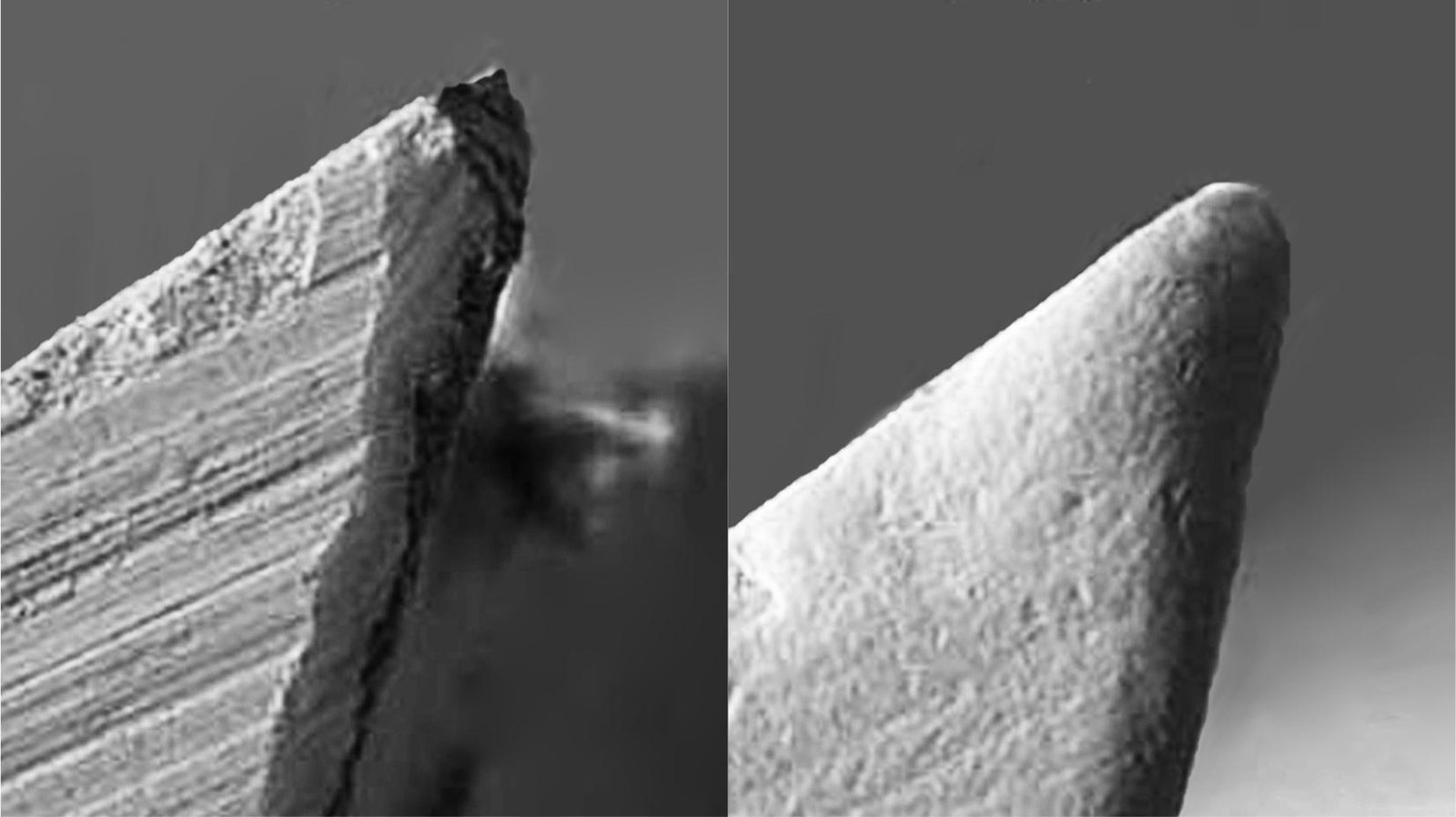

PCD, or Polycrystalline Diamond, should not be used for cutting steel or other iron-based materials. The high heat from cutting causes the carbon in the diamond to react with the iron. This chemical reaction breaks down the blade's cutting edge, causing it to wear out very quickly.

I remember a client in Brazil who runs a metal packaging company. They were trying to increase their cutting speeds on thin steel sheets. They bought some PCD blades, thinking that "diamond" meant it could cut anything. The blades failed in minutes. When they called me, I explained what was happening at a chemical level.

At high temperatures, carbon has a very high affinity for iron. The PCD blade is essentially pure carbon. When it gets hot while cutting steel, the carbon atoms from the blade want to diffuse into the iron workpiece. This process is called diffusion wear. It also causes the diamond's strong crystal structure to break down into graphite, a much softer form of carbon. This is called graphitization4. The blade edge literally dissolves and becomes weak, leading to catastrophic failure. We switched them to a coated carbide blade, which solved the problem immediately.

Here is a simple breakdown:

PCD Blade Compatibility

| Workpiece Material | Chemical Compatibility | Result |

|---|---|---|

| Steel (Ferrous) | Very Poor | High diffusion, graphitization, rapid blade failure. |

| Cast Iron (Ferrous) | Very Poor | High chemical reactivity, quick edge wear. |

| Aluminum (Non-Ferrous) | Excellent | Chemically stable, long blade life, great finish. |

| Copper (Non-Ferrous) | Excellent | Chemically stable, long blade life, good finish. |

| Composites | Excellent | Chemically inert, ideal for abrasive materials. |

This shows why knowing the chemistry is so important. For non-ferrous metals like aluminum or copper, PCD is one of the best choices available. But for any material with iron, you must avoid it.

When Should You Choose Pcbn Blades For Your Application?

Are you struggling to get a clean cut on hardened steel or cast iron? Slow speeds and poor finishes can stop your production line. A chemically stable material is what you need.

You should choose Polycrystalline Cubic Boron Nitride (PCBN) blades for cutting hard ferrous materials5. PCBN is chemically inert with iron, even at very high temperatures. This prevents chemical reactions, reduces wear, and allows for much faster and cleaner cutting.

PCBN is the second hardest material after diamond, but its biggest advantage is its chemical stability when cutting iron-based materials. A few years ago, I worked with a customer in Germany who manufactured high-precision molds for the plastics industry. They needed to machine hardened steel components, and their traditional ceramic blades6 were chipping and wearing out too fast. This caused imperfections in their expensive molds.

I recommended they try our PCBN blades7. The cubic boron nitride in the blade does not react with iron. This means there is no diffusion wear and no chemical breakdown of the cutting edge. They can run their machines at higher speeds and temperatures without worrying about the blade sticking to the steel. The result for the German client was a game-changer. Their blade life increased by over five times, and the surface finish on the molds was perfect. This saved them a lot of money in both tool costs and production time.

Blade Material Selection For Ferrous Metals

| Workpiece | Carbide | Ceramic | PCBN |

|---|---|---|---|

| Hardened Steel (>45 HRC) | Poor | Good | Excellent |

| Cast Iron | Fair | Good | Excellent |

| High-Temp Alloys | Fair | Excellent | Good |

| Soft Steel (<45 HRC) | Excellent | Fair | Not Cost-Effective |

PCBN is a premium material, so it's best used where its chemical stability provides a clear advantage. For cutting extremely hard or tough ferrous materials, it is often the best possible choice.

How Do Coatings Improve The Performance Of Carbide Blades?

Do you need one type of blade that can handle many different materials? Buying specialized blades for every job is expensive and complex. Coated carbide blades can give you that versatility.

Coatings on carbide blades act as a protective shield. This thin, hard layer serves as a chemical and thermal barrier. It prevents the carbide from reacting with the workpiece, reduces friction, and resists heat, which makes the blade last much longer and cut more materials.

The substrate of a cemented carbide blade is very tough, but it has a high chemical affinity for steel. This means it wants to react and bond with steel at high temperatures, causing wear. A coating solves this problem. I recently helped a client in Turkey who works in the textile industry. They were cutting a new type of synthetic fabric that was reinforced with fine steel wires. Their uncoated carbide blades8 were becoming dull in just a few hours. The combination of abrasive fabric and chemically reactive steel was too much.

I suggested a blade with a Titanium Aluminum Nitride9 (TiAlN) coating. This ceramic coating is extremely hard and, more importantly, chemically stable. It created a barrier between the carbide blade and the steel wires. The coating also has a lower friction coefficient, which means less heat is generated during the cut. This simple change had a huge impact. The new coated blades lasted for several days instead of a few hours, drastically reducing their downtime and costs. Coatings turn a good blade into a great, versatile blade.

Common Blade Coatings And Their Benefits

| Coating | Key Benefit | Ideal For |

|---|---|---|

| TiN (Titanium Nitride) | General purpose, reduces friction. | Softer steels, non-ferrous materials. |

| TiCN (Titanium Carbonitride) | Increased hardness and wear resistance. | Abrasive materials, cast iron. |

| TiAlN (Titanium Aluminum Nitride) | Excellent heat resistance. | High-speed cutting, hardened steels. |

| AlCrN (Aluminum Chromium Nitride) | Superior oxidation resistance, low friction. | Dry machining, cutting tough alloys. |

By choosing the right coating, you can fine-tune a carbide blade to perform well in many different situations, making it a very cost-effective solution.

Conclusion

Choosing a blade is about more than just hardness. Chemical compatibility is key. Matching the blade material to your workpiece ensures longer life, better cuts, and more efficient production.

Learn about the importance of chemical properties in selecting the right cutting blade for your needs. ↩

Understand diffusion wear and its impact on cutting tool performance to make informed choices. ↩

Discover the reasons behind PCD blade failures when cutting steel and how to avoid costly mistakes. ↩

Explore graphitization and its effects on blade durability and performance. ↩

Find out which cutting tools work best for various ferrous materials. ↩

Learn about the applications and benefits of ceramic blades in cutting operations. ↩

Find out when PCBN blades are the best choice for cutting hard ferrous materials. ↩

Learn how coatings enhance the versatility and lifespan of carbide blades. ↩

Discover the advantages of TiAlN coatings for cutting tools and their applications. ↩