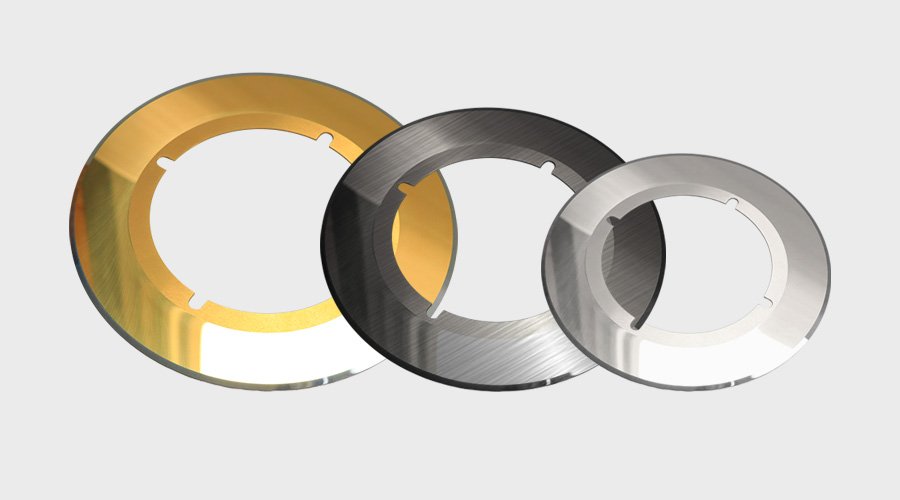

Choosing the wrong blade causes poor cuts and rapid wear. This costs you time and money. Matching the blade material to the workpiece is the simple solution.

Select industrial blades by matching its physical properties to the workpiece. Use high-heat-resistant blades for hard materials that create a lot of heat. Use high-toughness blades for softer materials that can bend or deform. This simple rule improves cut quality and blade life.

Choosing the right material seems complex, but it's straightforward when you see it in action. Let me share a few stories from my experience to show you what I mean and help you make a better choice.

What Blade Material Works Best For Low-Hardness, Flexible Materials?

Flexible films snag and tear with the wrong blade. This ruins your product and stops production. A tougher blade material gives you a clean, consistent cut every time.

High-speed steel (HSS)1 is the best choice for low-hardness, flexible materials. Its superior toughness prevents the blade edge from chipping or breaking under impact. This makes it ideal for cutting materials like packaging films, textiles, and thin plastics without causing damage.

I'll tell you about a client in Brazil who works in the flexible packaging industry. They were using cemented carbide blades to cut thin polymer films. The problem was that the rigid carbide blades were too brittle for their application. Any small vibration or misalignment caused the cutting edge to develop micro-chips. These tiny chips would then snag and tear the delicate film. This led to a lot of wasted material. They were constantly replacing blades, which was expensive and slowed down production. I suggested they switch to blades made from high-speed steel (HSS). HSS has lower hardness than carbide, but its main advantage is much higher toughness. This means it can absorb shocks and vibrations without fracturing. For them, toughness was more important than wear resistance because the film itself was not very abrasive. The switch to HSS blades solved their problem immediately. The cuts were clean, waste was reduced, and the blades lasted much longer because they weren't chipping.

Key Property Comparison: HSS Vs. Carbide

| Property | High-Speed Steel (HSS) | Cemented Carbide (WC-Co) |

|---|---|---|

| Main Feature | High Toughness | High Hardness |

| Hardness (HRA) | 65–70 | 89–94 |

| Best For | Flexible materials, high-impact cutting | Hard and abrasive materials |

How Do You Choose A Blade For High-Speed Cutting Of Abrasive Materials?

Abrasive materials2 like corrugated paper dull blades quickly. This leads to frequent downtime and poor cut quality. You need a blade that stays sharp even at high speeds.

For high-speed cutting of abrasive materials, cemented carbide is the ideal choice. It offers an excellent balance of high hardness and wear resistance. Its superior thermal conductivity also helps to dissipate heat quickly, which protects the cutting edge from breaking down at high speeds.

I worked with a paper mill in Poland that was slitting large rolls of corrugated paper. They were running their machines very fast to meet demanding production targets. They were using HSS blades, but the abrasive nature of the paper, which contains recycled content and glues, was wearing the blades down in just a few hours. This meant stopping their production line frequently for blade changes, which was killing their efficiency. We analyzed their process and the material. The key challenges were abrasion and the heat generated from the high cutting speed. I recommended they test our WC-Co (Tungsten Carbide-Cobalt) based cemented carbide blades. Carbide is much harder than HSS, so it can resist abrasive wear for a much longer time. It also has great thermal conductivity. This means it pulls heat away from the cutting edge very effectively. This property is critical in high-speed applications. The results were amazing. The carbide blades lasted for an entire shift, sometimes even longer. The cut quality was consistently high, and they drastically reduced their downtime.

Key Property Comparison: Carbide Vs. HSS

| Property | Cemented Carbide (WC-Co) | High-Speed Steel (HSS) |

|---|---|---|

| Hardness (HRA) | 89–94 | 65–70 |

| Thermal Conductivity | High (70-110 W/m·K) | Low (25-30 W/m·K) |

| Best For | High-speed, abrasive | Low-speed, high-impact |

When Should You Use Ultra-Hard Materials Like PCBN?

Machining hardened steel feels impossible. Standard blades wear out instantly or break. This stops your finishing process. You need a material that is even harder than your workpiece.

Use ultra-hard materials like PCBN (Polycrystalline Cubic Boron Nitride)3 when cutting extremely hard ferrous materials, such as hardened steel or cast iron. PCBN maintains its extreme hardness at very high temperatures, allowing it to cut these materials cleanly where other blades would fail.

A client in Vietnam manufactured high-precision components from hardened steel with a hardness above HRC 55. Their final machining step was a finishing cut to achieve a perfectly smooth surface. They tried using cemented carbide blades, but the steel was so hard that the carbide edges would deform from the intense heat and pressure. The blades had a very short life, and the surface finish was inconsistent. Their production was slow and very expensive. This is a classic case where the workpiece is simply too hard for conventional materials. I explained that we needed a blade material harder than the hardened steel itself. The solution was PCBN. PCBN is one of the hardest materials available, second only to diamond. More importantly, it has excellent thermal stability. It stays hard even at temperatures up to 1500°C. This allows it to slice through hardened steel without losing its edge. We supplied them with PCBN-tipped blades. The change was like night and day. They could run their machines at higher speeds, the blades lasted for hundreds of parts, and the surface finish was perfect every time.

Key Property Comparison: PCBN Vs. Carbide

| Property | PCBN (Cubic Boron Nitride) | Cemented Carbide (WC-Co) |

|---|---|---|

| Hardness (HV) | 3000–5000 | 1400–1800 |

| Thermal Stability Temp (°C) | 1400–1500 | 900–1100 |

| Best For | Hardened steel, cast iron | General steel, non-ferrous |

Why Is PCD The Top Choice For Cutting Abrasive Non-Ferrous Materials?

Cutting composite materials like fiberglass is very tough. The abrasive fibers destroy blade edges quickly. This results in costly blade replacements and poor-quality, frayed cuts.

PCD (Polycrystalline Diamond)4 is the top choice for abrasive non-ferrous materials and composites. Its extreme hardness provides unmatched wear resistance against abrasive fillers like glass or carbon fiber. Its high thermal conductivity also prevents heat buildup, ensuring a clean cut and very long blade life.

I remember a case with a plastics fabricator in Mexico. They were cutting sheets of glass-fiber-reinforced plastic (GFRP). This material is notoriously difficult because the glass fibers are extremely abrasive. They were using special wear-resistant grade carbide blades, but even those were only lasting for half a day. The edge would become dull, and the cut would start to look frayed and burned. The problem here is pure abrasion. PCD is the hardest of all cutting materials. It is perfect for handling highly abrasive materials, as long as they are not iron-based, because high heat can cause a chemical reaction with iron. Since GFRP is a plastic composite, PCD was the ideal candidate. It also has the highest thermal conductivity of any blade material, which is a huge benefit. It pulls heat away from the cut zone so fast that the plastic matrix does not melt or burn. We provided them with PCD-tipped slitting blades. Their blade life went from hours to months. The cut edge was clean and smooth, and they could increase their cutting speeds significantly.

Key Property Comparison: PCD Vs. Carbide

| Property | PCD (Polycrystalline Diamond) | Cemented Carbide (WC-Co) |

|---|---|---|

| Hardness (HV) | 6000–8000 (Extremely High) | 1400–1800 (Very High) |

| Thermal Conductivity | Extremely High (300-700 W/m·K) | High (70-110 W/m·K) |

| Best For | Abrasive non-ferrous, composites | General purpose, ferrous metals |

Conclusion

Matching blade properties like hardness, toughness, and heat resistance to your workpiece is key. This simple step improves quality, reduces downtime, and saves you money.

Explore the benefits of HSS in cutting flexible materials, ensuring clean cuts and longer blade life. ↩

Understand the specific challenges abrasive materials present and how to overcome them. ↩

Discover how PCBN outperforms other materials in cutting hardened steel, ensuring precision and efficiency. ↩

Find out how PCD enhances cutting performance for composites, providing unmatched wear resistance. ↩