Are you struggling with poor cut quality or rapid blade wear? The hidden cause is often cutting temperature1. Ignoring this critical factor leads to wasted material, damaged blades, and production delays.

To select the right blade, you must match its material to the workpiece's ideal cutting temperature. For plastics (40-100°C), use carbide. For steel (400-700°C), use coated carbide. This simple step prevents melting, wear, and ensures a clean, efficient cut.

You might think a faster cut is always better, but that speed generates heat. This heat can be your biggest enemy or your best friend, depending on how you manage it. Let’s break down how to control this for different material groups.

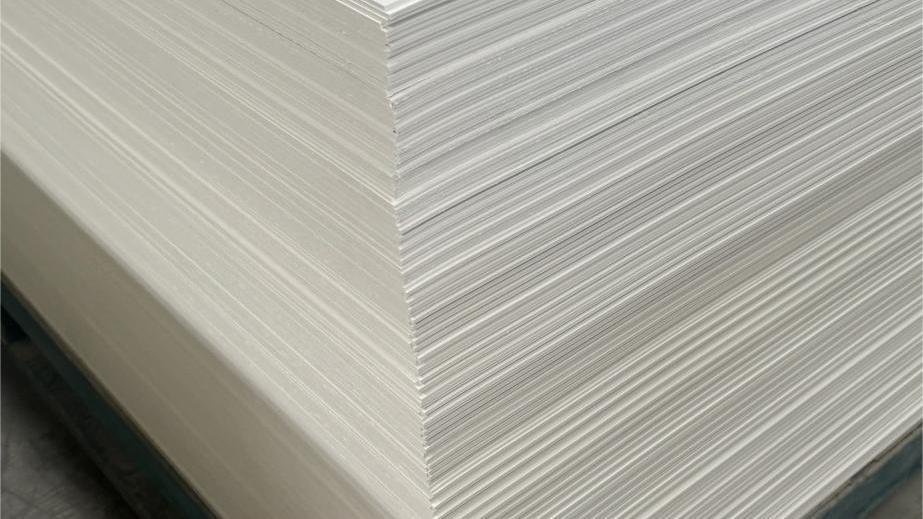

How Do You Cut Soft Materials Without Melting Or Tearing Them?

Cutting plastics, paper, or composites often results in melted edges, burrs, or delamination. These issues ruin your product's finish, leading to high rejection rates and wasted resources. The key is managing low cutting temperatures with ultra-sharp blades and proper cooling.

For soft and brittle materials, keep cutting temperatures low, typically below 300°C. Use sharp carbide2, PCD3, or diamond-coated blades4. Low speeds and cooling are essential to prevent melting, resin decomposition5, or tearing, ensuring a clean and precise finish on every part.

When I speak with clients in the packaging, electronics, or textile industries, their biggest challenge is often heat sensitivity. These materials don't have the structure to withstand high temperatures. Excessive heat causes them to melt, deform, or simply fall apart at the cut line. The goal here is a "cold cut" that cleanly slices through the material without altering its properties.

Low-Temperature Plastics And Rubbers

For soft materials like PVC, ABS, or rubber, you need to keep things cool. If the temperature gets above 100°C, the material can start to get sticky. This leads to it melting onto the blade, a problem we call tool adhesion. The result is a messy cut and a contaminated blade edge. The solution is to use extremely sharp, polished blades and maintain low cutting speeds. Sometimes, a simple stream of cool air is all you need to keep the temperature in the sweet spot.

Fibers, Composites, And Brittle Materials

Materials like paper, carbon fiber (CFRP), or glass present a different challenge. For paper, too much heat can char the edges. For composites, heat can break down the resin that holds the fibers together, causing delamination. For brittle materials like ceramics, sudden temperature changes can cause thermal shock, leading to cracks. Here, PCD or diamond blades are best because they are extremely hard and conduct heat away from the cutting zone effectively.

Here is a simple guide for these delicate materials:

| Material Group | Ideal Temp. (℃) | Recommended Tools | Key Challenge |

|---|---|---|---|

| Soft Plastics & Rubber | 40 – 100°C | Carbide, Polished SS | Melting, Adhesion |

| Paper & Fibers | 60 – 150°C | HSS, SKD11 | Tearing, Charring |

| Composites (CFRP) | 100 – 300°C | PCD, Diamond-Coated | Resin Decomposition |

| Brittle (Ceramics, Glass) | 30 – 150°C | Diamond (PCD) | Thermal Shock, Cracking |

What's The Secret To Cutting Metals And Woods Without Scorching Or Adhesion?

Are you dealing with built-up edges on your blades when cutting aluminum? Or scorch marks on wood? This adhesion ruins your cut quality and quickly dulls expensive blades. You end up with rework and high blade replacement costs. The solution lies in controlling temperature with the right blade coating and cutting parameters6.

For soft metals7 (200-400°C) and woods (150-350°C), temperature control is key. Use coated carbide or Polycrystalline Diamond (PCD) blades. These prevent material adhesion and scorching. Proper coolant for metals and correct feed rates for wood ensure a clean cut and extend blade life.

Just last month, a client cutting aluminum alloy parts came to me with a serious problem. After a few hundred cuts, aluminum would start sticking to the blade edge. This "built-up edge" caused rough surfaces and made their parts go out of spec. I called he took a look at their process. Their spindle speed was too high and the coolant wasn't reaching the cut zone effectively. The temperature was spiking over 420°C, basically welding tiny bits of aluminum to the blade.

Soft Metals: The Adhesion Problem

Aluminum, copper, and brass are great at conducting heat. This is good because the heat doesn't stay in one spot, but it also makes them prone to adhesion when temperatures rise. The built-up edge my client saw is a classic sign of this. It tears the material instead of shearing it, leading to a poor finish. We switched them to our PCD blades, which have an ultra-sharp edge and a surface that aluminum doesn't stick to easily. We also lowered the cutting speed and used cold air cooling. The temperature stabilized around 250°C. Their edge quality improved by over 30%, and the adhesion problem disappeared completely.

Wood And Engineered Wood: Avoiding Scorch Marks

Wood has the opposite problem. It's a poor heat conductor, so heat builds up right at the cutting edge. This can scorch the wood, leaving black marks. It can also melt the resins in materials like MDF or plywood, causing them to stick to the blade. The solution is to use blades that can handle heat, like carbide, and to control the feed rate. A faster feed rate means the blade spends less time in one spot, reducing heat build-up.

| Material Group | Ideal Temp. (℃) | Recommended Tools | Key Challenge |

|---|---|---|---|

| Soft Metals (Al, Cu) | 200 – 400°C | Coated Carbide, PCD | Built-Up Edge (Adhesion) |

| Wood & Engineered Wood | 150 – 350°C | Carbide (WC-Co), PCD | Scorching, Resin Adhesion |

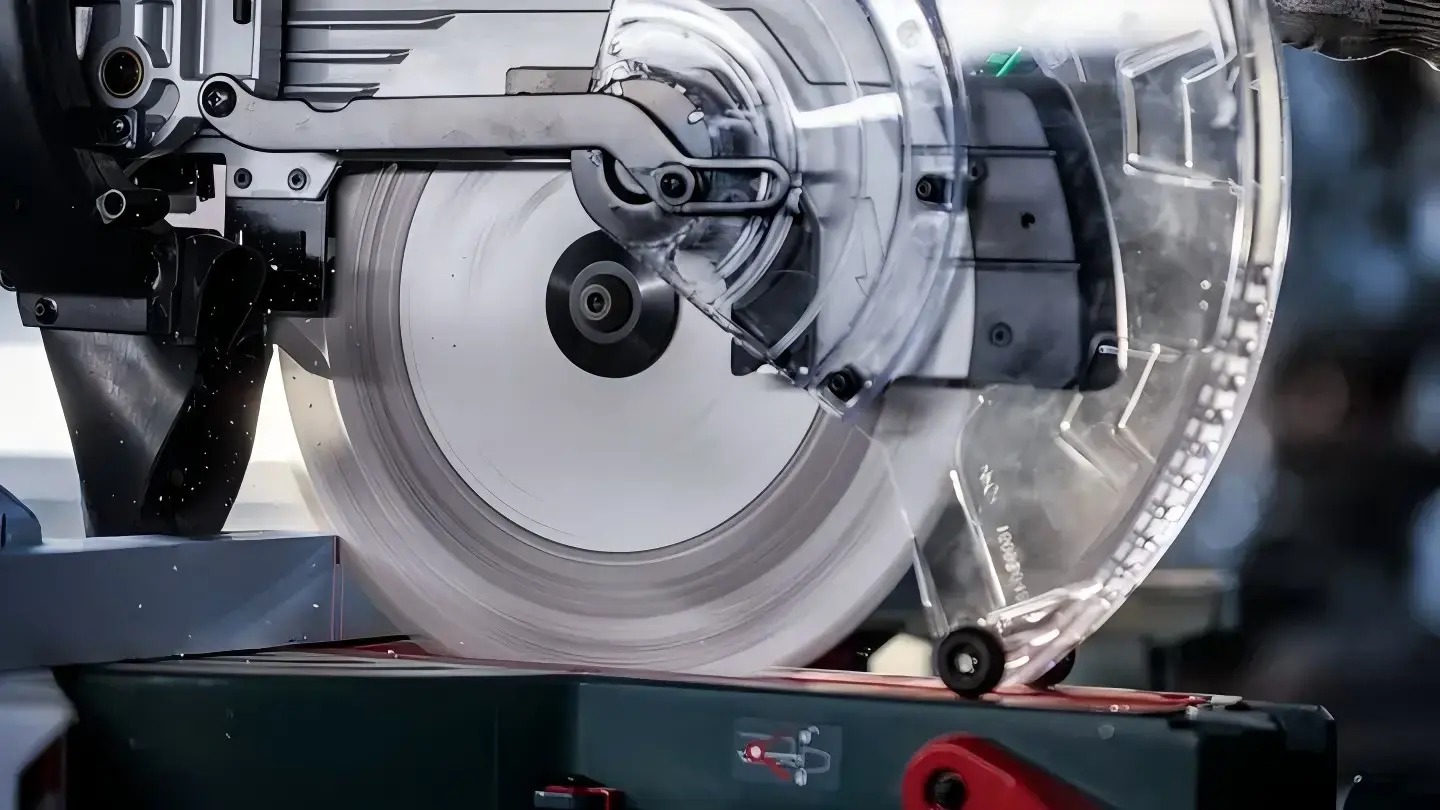

How Can You Machine Hard Steels Efficiently Without Burning Up Your Blades?

Cutting through tough materials like stainless steel or tool steel feels like a battle. Your blades wear out fast, and performance drops. This rapid wear means constant blade changes, production downtime, and inconsistent quality. The secret is to embrace the heat, using blades designed to perform at very high temperatures.

For hard steels and cast iron, ideal cutting temperatures range from 400°C to 900°C. Use blades made of coated carbide, Cubic Boron Nitride (CBN), or ceramic. These materials maintain their hardness at extreme heat, preventing rapid wear and ensuring consistent, efficient machining.

It sounds strange, but for hard metals, heat can actually be beneficial. A moderately high temperature can soften the workpiece material right in front of the cutting edge. This reduces the cutting forces needed and can make the process more efficient. The trick is that the cutting blade must be able to withstand this heat without softening, oxidizing, or breaking down itself. This is where advanced blade materials become so important. You are creating a tiny, localized heat zone where the material is easy to cut, while the tool remains hard and stable.

Carbon, Alloy, And Stainless Steels

These materials require significant energy to cut, which generates a lot of heat. Stainless steel is particularly tricky because it's a poor thermal conductor. This means heat gets trapped at the cutting edge instead of flowing into the workpiece. If the temperature gets too high, it can cause the blade to fail quickly. Using blades with coatings like TiAlN is critical. This coating acts as a thermal barrier, protecting the carbide blade underneath while staying slick at high temperatures.

High-Hardness Tool Steels And Cast Iron

When you get into very hard materials like tool steel or the abrasive nature of cast iron, you need the toughest blades available. CBN and ceramic blades are perfect here. They barely lose any hardness even when glowing red-hot. For these applications, we often recommend high-speed cutting. This helps by ejecting the heat away with the chip, rather than letting it soak into the blade or the part. A stable setup and adequate cooling are non-negotiable to prevent blade failure.

| Material Group | Ideal Temp. (℃) | Recommended Tools | Key Challenge |

|---|---|---|---|

| Carbon & Alloy Steels | 400 – 700°C | Coated Carbide, HSS-Co | Tool Softening, Oxidation |

| Stainless Steel | 500 – 800°C | Coated Carbide, Ceramic, CBN | Heat Buildup, Adhesion |

| High-Hardness Steel | 700 – 900°C | Coated Carbide, CBN, Ceramic | Extreme Heat, Micro-chipping |

| Cast Iron | 500 – 900°C | Coated Carbide, Ceramic | Brittleness, Abrasive Wear |

Conclusion

Matching your blade to the material's ideal cutting temperature is not a small detail. It is the foundation for efficient production, high-quality results, and much longer blade life.

Understanding cutting temperature is crucial for optimizing blade performance and preventing wear. ↩

Carbide blades offer durability and precision, making them ideal for various materials. ↩

PCD blades provide exceptional hardness and wear resistance, perfect for tough materials. ↩

Diamond-coated blades offer superior cutting performance and longevity for challenging materials. ↩

Preventing resin decomposition is vital for maintaining the integrity of composite materials. ↩

Understanding cutting parameters is essential for optimizing machining processes. ↩

Learning to cut soft metals properly can improve efficiency and reduce blade wear. ↩