Choosing the wrong industrial blade finish can ruin your cuts and halt production. This leads to material waste, equipment damage, and costly downtime. Let me show you how to fix it.

To select the appropriate surface roughness1, you must match it to your material and application. For high-precision, thin, or sticky materials, a smoother, mirror-like finish2 (low Ra value3) is best. For general or rough cutting, a standard, coarser finish is more cost-effective.

This small detail, the surface roughness of a blade, has a massive impact on your final product quality, tool life, and overall operational efficiency. It's a topic my clients ask about all the time. Many people think a sharper blade is always better, but the smoothness of the blade's surface is often just as critical. Let’s break down exactly what this means and how you can make the right choice for your specific needs, ensuring every cut is a perfect one. I'll walk you through the technical details in simple terms and give you a clear framework to follow.

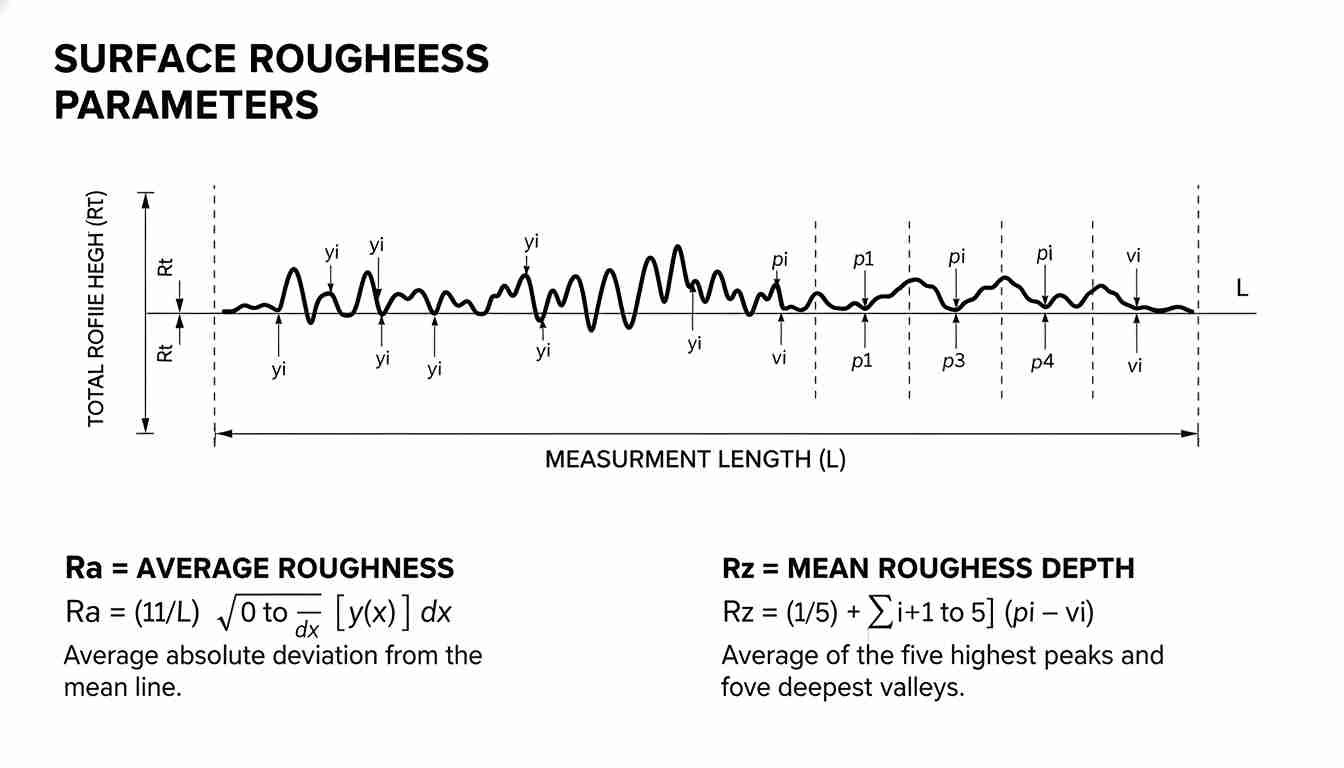

What Do Surface Roughness Numbers Like Ra And Rz Actually Mean?

Technical terms on a spec sheet can be confusing. If you ignore them, you can't properly communicate your needs and might get a blade that fails. I'll explain them simply.

Ra is the arithmetic average of the microscopic peaks and valleys on a blade's surface, giving a general measure of its smoothness. Rz4 measures the average maximum height, showing the extremes between the highest peak and lowest valley.

When we talk about surface roughness, we are describing the tiny, microscopic imperfections left on the blade after the manufacturing process. You can't see them with your naked eye, but they determine how the blade interacts with the material it cuts. The most common parameter I discuss with my clients is Ra, or Arithmetic Average Roughness. Think of it as the overall "smoothness score." A lower Ra value means a smoother, more polished surface. Rz gives us a bit more detail by focusing on the most extreme high and low points. This is useful for understanding the potential for scratches or snags in very delicate materials.

From Grinding To Polishing

The final roughness is a direct result of how the blade is finished. Here is a simple breakdown:

| Manufacturing Process | Typical Ra Value (µm) | Surface Appearance |

|---|---|---|

| Standard Grinding | > 0.8 | Matte, visibly rough |

| Fine Grinding | 0.2 - 0.8 | Satin, smooth |

| Polishing | 0.1 - 0.2 | Reflective |

| Mirror Polishing | ≤ 0.1 | Mirror-like |

Understanding these numbers helps you specify exactly what you need for optimal performance.

How Does Surface Finish Affect Different Cutting Applications?

Using a one-size-fits-all blade often leads to problems. You might see sticky buildup when cutting plastic film or frayed edges when slicing textiles. Matching the blade finish to the job is crucial.

Ultra-fine, mirror-like surfaces (Ra ≤ 0.1µm) prevent sticking with adhesive or soft materials. A medium finish (Ra 0.2–0.8µm) offers a balance of performance and cost for general use. Coarse finishes (Ra > 0.8µm) are for rough cutting where edge quality is not critical.

The right surface finish directly translates to better performance. A smooth finish reduces friction, which means less heat buildup and a cleaner cut. A rougher finish might be cheaper, but it can cause material to drag, tear, or stick to the blade. Let me share how this applies to different scenarios.

Ultra-Fine Surface (Mirror Finish)

For high-tech industries like medical device manufacturing, lithium battery production, or cutting optical films, a mirror finish is non-negotiable. With an Ra of 0.1µm or less, the blade surface is incredibly smooth. This dramatically lowers the coefficient of friction. Materials, especially sticky ones, slide right off without adhering to the blade. This prevents gummy buildup, ensures the cleanest possible cut, and extends the time between blade cleanings, boosting productivity.

Medium Surface (Standard Finish)

This is the workhorse for a huge range of industries. With an Ra between 0.2µm and 0.8µm, these blades provide an excellent balance between performance and cost. They are perfect for cutting materials like corrugated cardboard, paper tubes, textiles, leather, and non-adhesive plastics. I remember a client, Marco from a large packaging company in Italy, who was struggling with excessive dust and a ragged cut on his cardboard. His blades were too rough. We supplied him with our fine-ground blades at an Ra of 0.4µm. The problem disappeared, and his line efficiency improved by 15%. This is the most common range we sell because it’s so versatile.

Coarse Surface (Grinding Finish)

When cost is the single most important factor and cut quality is secondary, a coarse finish (Ra > 0.8µm) is the way to go. These blades typically undergo only the initial grinding stages, making them the most economical option. They are common in applications like wood processing and recycling, where the goal is simply to break down material. The cut edge will be rough, but the blade gets the job done at the lowest possible price point.

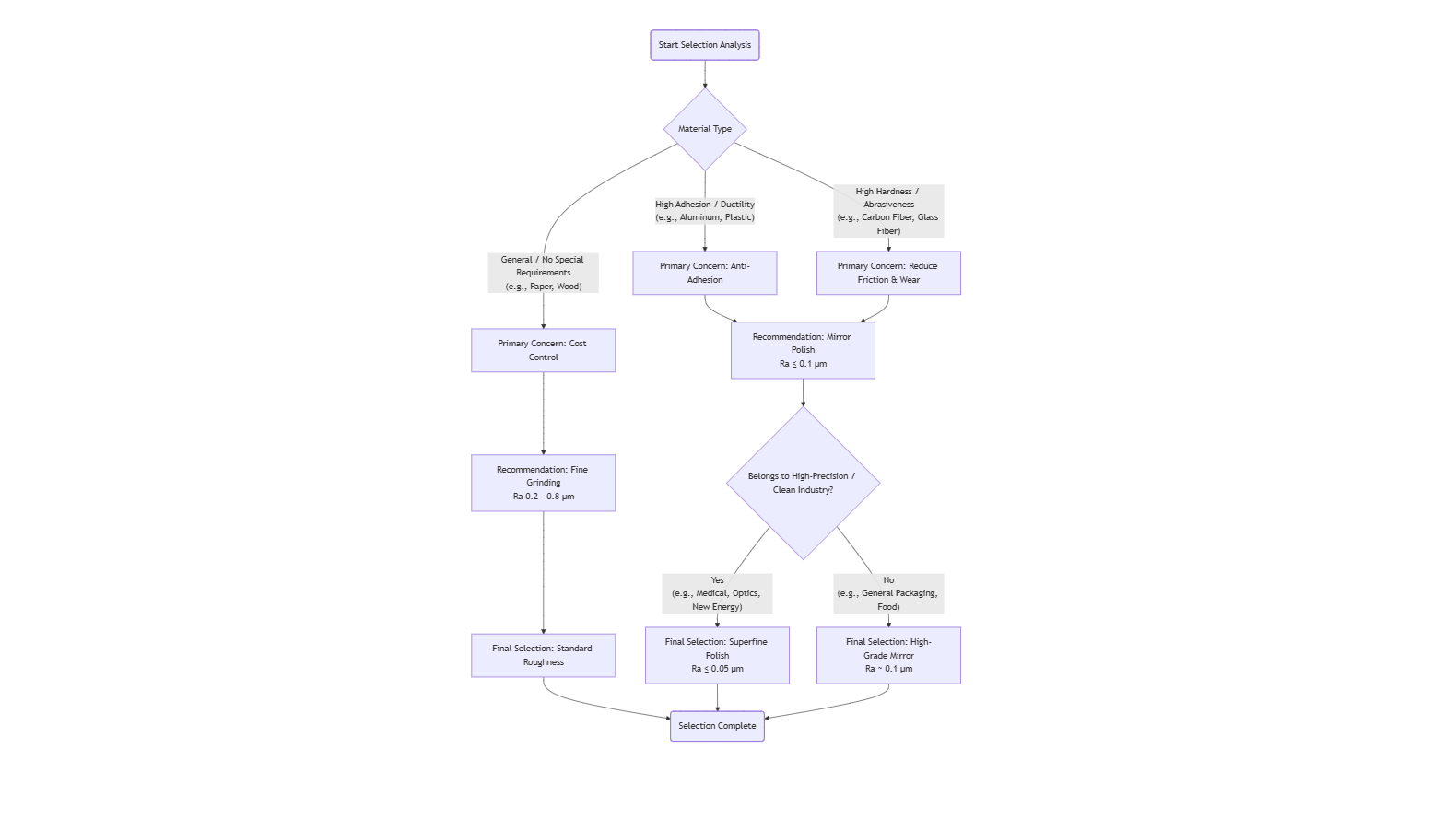

What Is The Best Way To Choose The Right Roughness For My Material?

Choosing the right blade finish can feel like a guessing game. Guessing wrong leads to wasted time, materials, and money. I can provide you with a simple decision-making framework to get it right.

Start by analyzing your material. For sticky, hard, or abrasive materials5, choose a mirror polish (Ra ≤ 0.1µm) to minimize friction and wear. For general-purpose materials where cost is a factor, a standard fine-grind finish (Ra 0.2-0.8µm) is the most practical choice.

To get the best results, your choice should follow a logical process, not guesswork. It all begins with the material you are cutting. After that, you can refine your choice based on your industry's specific demands and other technical factors.

Step 1: Analyze Your Material's Challenges

The physical properties of your material are the most important factor. Is it sticky? Is it hard and abrasive? Or is it a standard material? Answering this will point you to the right solution.

| Material Challenge | Recommended Process | Target Ra (µm) | Primary Goal |

|---|---|---|---|

| General Use (e.g., Paper, Wood) | Fine Grinding | 0.2 - 0.8 | Balance of Cost & Performance |

| Sticky/Ductile (e.g., Plastic Film, Tape) | Mirror Polishing | ≤ 0.1 | Prevent Material Adhesion |

| Hard/Abrasive (e.g., Fiberglass) | Mirror Polishing | ≤ 0.1 | Reduce Friction & Wear |

| High Precision (e.g., Medical Tubing) | Ultra-Fine Polishing | ≤ 0.05 | Maximum Purity & Precision |

Step 2: Consider Coatings And Standards

Finally, two more points. First, if you plan to add a coating like TiN or DLC for extra wear resistance, talk to your supplier. An extremely smooth surface (like Ra < 0.05µm) can sometimes be too smooth for the coating to adhere properly. A finish around Ra 0.2-0.4µm often provides the best foundation for a coating to bond to. Second, always use international standards like ISO 42876 to define and verify roughness.

Conclusion

Choosing the right surface roughness is not a minor detail; it’s essential for performance. Use these insights to improve your efficiency, reduce waste, and achieve the perfect cut every time.

Understanding surface roughness is crucial for selecting the right tools and achieving optimal cutting performance. ↩

Discover how a mirror-like finish can enhance cutting efficiency and reduce material adhesion. ↩

Learn about Ra value to ensure you choose the right blade finish for your specific cutting needs. ↩

Understanding Rz is crucial for selecting the right blade finish, ensuring optimal cutting performance and material quality. ↩

Learn how to select the right blade finish for abrasive materials to reduce wear and tear. ↩

Understanding ISO 4287 ensures consistency and quality in your blade specifications. ↩