Choosing the wrong industrial blade wastes time and ruins materials. This halts production and costs you money. Following a clear selection process ensures you choose the perfect blade every time.

To select the right indexable industrial cutting blade, you must match three key things to your specific job. These are the blade's material and coating1, its geometry and chipbreaker design, and the clamping system2 used. This ensures optimal performance, longer blade life, and lower costs.

Making the right choice seems complicated, but it is simpler than you think when you break it down. It is not just about buying a blade; it is about investing in efficiency and quality for your production line. Let's look at the key factors you need to consider.

How Do You Match The Blade Material To Your Workpiece?

Your blades wear out too quickly. This stops your machines and costs a lot of money in replacements. The right material and coating can make your blades last much longer.

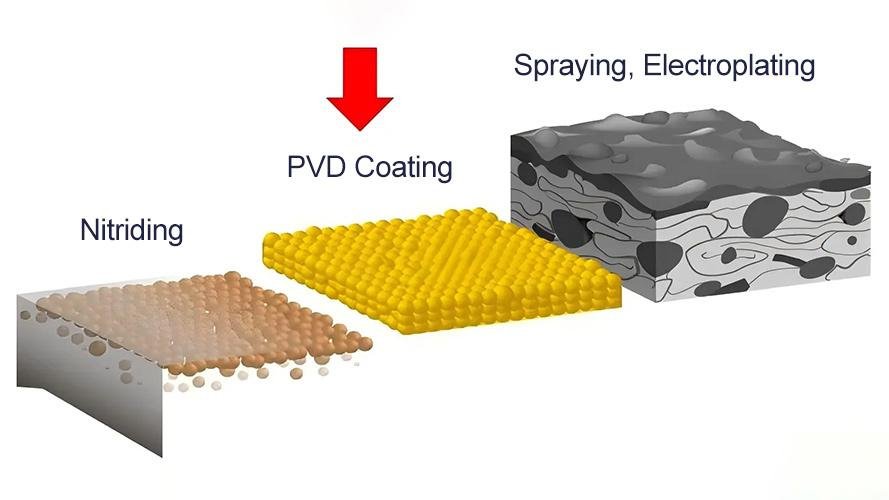

First, look at what you are cutting. Cemented carbide is the best choice for over 75% of jobs. For tougher materials or very high-speed cutting, you should use advanced ceramics3 or PCBN4. A PVD coating5 adds extra life and heat resistance.

The foundation of any great blade is its substrate material. For most applications, cemented carbide6 is the go-to choice because it offers a great balance of hardness and toughness. However, for specialized jobs, we have to look at other options. High-performance materials like alumina ceramic or polycrystalline cubic boron nitride (PCBN) can handle cutting speeds two or three times faster than carbide. This is a huge advantage in high-volume production. Then we add a surface treatment. A Physical Vapor Deposition (PVD) coating, like titanium carbide, creates a super-hard layer on the blade's surface. This coating protects the cutting edge from heat and wear, which makes the blade last much longer.

I remember a client in Germany who runs a metal fabrication plant. They were cutting stainless steel parts and their blades were wearing out in just a few hours. This caused constant downtime. After we talked, I suggested they switch from their standard uncoated carbide blades to our cemented carbide blades with a PVD coating. The new blades lasted for days, not hours. They were able to run their machines longer, which increased their output and significantly cut their costs for new tools.

Matching Blade Material To Workpiece

| Workpiece Material | Recommended Blade Material | Key Properties |

|---|---|---|

| Steel (General) | PVD-Coated Cemented Carbide | Good balance of hardness and toughness. |

| Cast Iron | Uncoated Cemented Carbide | High wear resistance for abrasive materials. |

| Stainless Steel | PVD-Coated PCBN | Excellent heat resistance and chemical stability. |

| Non-Ferrous Metals | Polycrystalline Diamond (PCD) | Very high hardness, prevents material buildup. |

Why Does Understanding ISO Codes For Blade Geometry Matter?

You are getting inconsistent cuts or a poor surface finish. The shape of your blade is probably the problem. Using the wrong geometry leads to wasted material and extra work.

ISO codes7 are a simple language for blade specifications. They tell you the blade's shape, clearance angle, and size tolerance. Matching this code to your job ensures you get the right geometry for a perfect finish and consistent quality every time.

The shape, or geometry, of a blade is just as important as its material. The ISO coding system makes it easy to understand and choose the right one. This code has at least seven digits, and sometimes up to twelve. Each digit tells you something important. For example, the first letter tells you the shape, like 'T' for triangular. Other digits define the clearance angle and the tolerance grade, which tells you how precise the blade is made. A key specification is the inner circle diameter, and its tolerance can be as tight as ±0.025mm for precision-grade blades. Another critical feature is the cutting edge radius8, which ranges from 0.2mm to 2.4mm. A smaller radius is better for fine finishing, while a larger one is stronger for rough cutting. The chipbreaker groove design also plays a big role. It helps control the metal chips produced during cutting. A three-level closed groove structure is very versatile and works well for over 80% of cutting jobs.

I worked with a company in Brazil that recycles plastic. They were cutting large plastic sheets, but the edges were rough and uneven. They thought it was their machine. I looked at the blade they were using. By checking the ISO code, I saw that the cutting edge radius was too large for their material. We switched them to a blade with a sharper edge and a concave chipbreaker designed for soft materials. The change was immediate. They started getting clean, smooth cuts, which improved their product quality and reduced waste.

Which Clamping System Is Best For Your Machining Operation?

Are machine vibrations ruining your precise work? This can lead to inaccurate parts and even damage your equipment. A secure clamping system gives you the stability you need for perfect results.

The right clamping system holds the blade tightly for high repeatability and stability. Wedge clamps and lever clamps are very common. For tasks with a lot of vibration, like deep hole boring, a dual-clamp structure is better because it prevents blade movement.

An indexable blade is only as good as the system holding it in place. The clamping mechanism must position the blade with very high accuracy every time it is indexed or replaced. A wedge clamp, for example, uses a wedge and screw to press the blade down and sideways at the same time. This creates strong axial and radial forces that lock it in place. Another common type is the lever clamp, which uses a lever arm to push down on the blade. These systems are a huge improvement over old brazed blades. They remove over 95% of the risk of cracks caused by welding stress. In action, these systems provide amazing stability. For face milling cutters, a three-point positioning principle can control axial runout to within 0.02mm. For boring deep holes, a dual-clamp system provides excellent vibration resistance9, which is much better than what welded blades can offer.

I had a customer at a paper mill in Canada who faced a serious challenge. They were cutting massive paper rolls, but machine vibration was causing chatter marks and inconsistent cuts. Production was slow, and a lot of paper was wasted. Their single-screw clamping system was not strong enough. We recommended they upgrade to a boring bar system that uses a dual-clamp structure. This system provides much more support and rigidity. After they made the change, the vibration was almost completely gone. Their cuts became clean and consistent, their machine speed increased, and they saved a lot of money by reducing waste.

Conclusion

Choosing the correct indexable blade is easy. Just match the material, geometry, and clamping system to your specific job. This simple process will improve your efficiency and lower your costs.

Learn how different materials and coatings can enhance blade performance and longevity. ↩

Find out which clamping systems provide the best stability and precision for your machining operations. ↩

Explore this resource to understand how advanced ceramics enhance cutting performance and durability, crucial for high-speed applications. ↩

Learn about PCBN's unique properties and its suitability for high-speed cutting of tough materials. ↩

Understand how PVD coating can extend the life of your blades and improve cutting performance. ↩

Explore the advantages of cemented carbide in cutting applications and its performance characteristics. ↩

Discover how ISO codes simplify the selection process and ensure you choose the right blade geometry. ↩

Understand how cutting edge radius affects the quality of cuts and the type of materials you can work with. ↩

Explore the relationship between vibration resistance and cutting accuracy for improved production quality. ↩