Choosing the wrong blade for your cutting process leads to rapid wear and poor results. This downtime costs you money and materials. Understanding your method is key to picking the right tool.

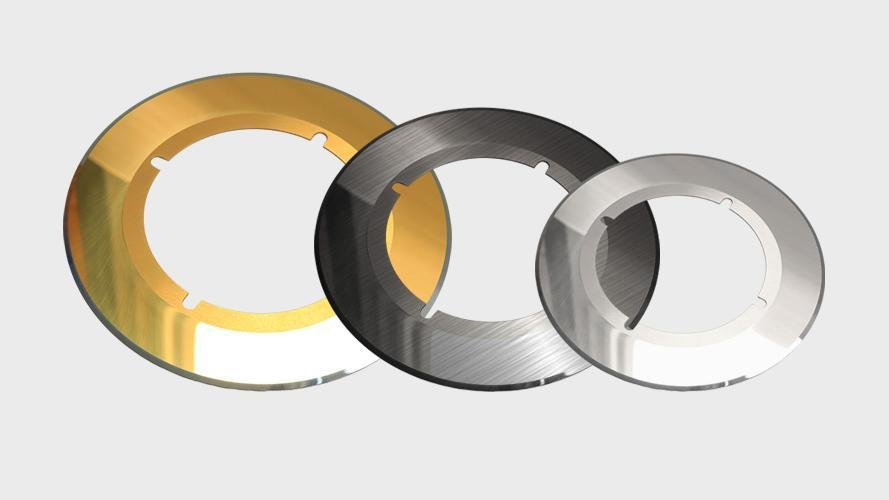

The main difference is coolant1. For wet cutting, use blades that resist corrosion from fluids. For dry cutting, where heat is high, you need blades with excellent heat resistance, such as those with TiAlN2 or AlCrN3 coatings, to prevent wear and failure.

Choosing between wet and dry cutting is a major decision that impacts your entire operation. It affects everything from the machine you use to the final quality of your product. I've seen many companies struggle with this choice, but it doesn't have to be complicated. Once you understand the core principles behind each method, selecting the right blade becomes much clearer. Let's break down the details to help you find the perfect blade for your specific needs and improve your production efficiency.

What Blade Materials And Coatings Work Best For Wet Cutting?

Your coolant is causing your blades to rust and fail too soon. This means you are constantly buying replacements and getting inconsistent cuts. The solution is using a blade with the right corrosion-resistant material.

For wet cutting, you need blades made from materials like tungsten carbide4 or certain ceramics5. Adding a coating like Titanium Aluminum Nitride (TiAlN) is even better. These materials resist damage from cutting fluids, hold a sharp edge longer, and give you a superior surface finish.

In my experience, wet cutting is the best choice for heavy-duty or high-precision jobs. This is because the cutting fluid, or coolant, does several important things. It cools the blade and the material, it lubricates the cut to reduce friction, and it washes away small chips that could ruin the surface. But this fluid can also be harsh on the blade itself. That is why material selection is so important. You need a blade that can stand up to the constant exposure to liquid without corroding or losing its edge.

I remember working with a metal fabrication company in Germany. They were cutting thick stainless steel plates and their blades were wearing out in just a few days. The coolant they used was causing microscopic corrosion on the cutting edge, which quickly led to chipping and failure. After analyzing their process, we recommended a custom tungsten carbide blade with a multi-layer TiAlN coating. This combination was perfect. The carbide provided the toughness for the heavy cuts, and the coating acted as a shield against the chemical wear from the coolant. They saw their blade life increase by over 300%, which saved them a lot of money and reduced their machine downtime significantly.

Key Blade Properties For Wet Cutting

The coolant environment demands specific features from a blade.

- Corrosion Resistance: The blade must not rust or chemically break down when exposed to water, oils, or synthetic coolants.

- Chemical Stability: The coating should not react with the additives in the cutting fluid, which could reduce its effectiveness.

- Toughness: The blade material needs to be strong enough to handle heavy cutting forces without fracturing.

Here is a simple table to compare common materials for wet cutting:

| Blade Material | Pros | Cons | Best For |

|---|---|---|---|

| Coated Carbide | Excellent toughness, good wear resistance, versatile | Can be less corrosion resistant without a good coating | General metal cutting, heavy loads |

| Ceramics | High chemical stability, good in high temperatures | Can be brittle, may chip under high impact | Cutting hard metals, ceramics |

| Stainless Steel | Very high corrosion resistance | Softer, loses edge faster than carbide | Food processing, textile cutting |

Why Is Heat Resistance So Vital For Dry Cutting Blades?

Your blades get extremely hot during dry cutting and wear out almost instantly. This stops your production line and can damage your materials beyond repair. The answer is to use blades made from materials designed for high heat.

Dry cutting blades must survive intense heat without a coolant. Materials like PCBN, silicon nitride ceramics, or carbide blades with advanced high-temperature coatings like Aluminum Chromium Nitride (AlCrN) are necessary. These coatings create a thermal barrier to prevent the blade from softening and failing.

Dry cutting is becoming more popular because it's cleaner, better for the environment, and can be cheaper since you don't buy coolant. However, it puts all the stress on the blade. Without fluid to carry away heat, the temperature at the cutting edge can get incredibly high. All that heat gets transferred directly into the blade, the workpiece, and the chips. The goal is to force most of that heat to leave with the chip. To do this, the blade must be able to stay hard and sharp even when it gets very hot.

A few years ago, I helped a client in Mexico who manufactures plastic components. They were using dry cutting for its speed and cleanliness, but their standard blades were failing constantly due to overheating. The plastic would melt onto the blade, ruining the cut and causing long delays for cleaning and blade changes. We switched them to a solid carbide blade with a specialized AlCrN coating. This coating is exceptional at resisting oxidation at high temperatures and has a very low friction coefficient. The heat no longer softened the blade's edge, and the slick surface of the coating prevented the melted plastic from sticking. Their production speed increased, and their surface finish quality became much more consistent.

Managing Heat In Dry Cutting

Success in dry cutting depends on controlling the heat.

- Thermal Stability: The blade material cannot soften or deform when its temperature rises.

- Oxidation Resistance: The blade, especially its coating, must resist reacting with air at high temperatures, which would cause it to degrade.

- Chip Evacuation: The blade's geometry should help clear chips away quickly, as they carry a lot of the heat away from the cutting zone.

Here is a look at different coatings and their role in managing heat:

| Coating Type | Key Feature | Primary Function | Ideal Application |

|---|---|---|---|

| TiAlN | Forms a hard aluminum oxide layer at high temps | Acts as a thermal barrier, increases hardness | High-speed cutting of steels |

| AlCrN | Excellent high-temperature oxidation resistance | Protects blade from heat-related wear and softening | Dry cutting tough materials, plastics |

| TiN | General purpose, low friction | Reduces friction and adhesive wear | Light-load cutting, non-ferrous metals |

Is Near-Dry Machining (MQL) A Good Middle Ground?

You want the clean, low-cost benefits of dry cutting but require better lubrication for a good finish. Finding this balance seems complex, and you are unsure which blade to use. Near-Dry Machining could be the perfect answer.

Near-Dry Machining, or Minimum Quantity Lubrication (MQL)6, uses a tiny amount of oil mixed with air. For MQL, a versatile blade like a coated carbide tool works well. It offers good heat resistance while benefiting from the slight lubrication for an improved surface finish.

Sometimes, neither pure wet nor pure dry cutting is the perfect fit. That is where a third option comes in: Near-Dry Machining, also known as MQL. As noted in authoritative guides like the ASM Handbook, MQL is its own distinct process. It isn't just "less wet" cutting. Instead, it uses a high-pressure jet of air mixed with a very small amount of oil—just a mist. This provides just enough lubrication to improve the surface finish and reduce friction, but without the mess and cost of a full flood coolant system. It is a fantastic compromise that gives you many of the benefits of both worlds.

I worked with a paper converting facility in Brazil that was struggling with this exact problem. They used circular blades to slit large paper rolls. Dry cutting created too much dust and the friction caused premature blade wear. Full wet cutting was not an option because it would have damaged the paper product. We helped them implement an MQL system. We paired it with our PVD-coated carbide blades. The fine oil mist drastically reduced friction, which extended the life of the blades and resulted in a much cleaner cut with less dust. The client was happy because they achieved higher quality and longer blade life without the expense or product damage associated with flood coolant.

Comparing The Three Methods

Understanding the trade-offs is key to making the right choice.

- Wet Cutting: Best for cooling and lubrication in heavy-duty applications. Requires coolant management and blades that resist corrosion.

- Dry Cutting: Cleanest and often lowest cost. Demands highly heat-resistant blades and coatings.

- MQL: A balanced approach. Offers improved lubrication over dry cutting without the mess of wet cutting.

Here is a table comparing the key aspects of each method:

| Feature | Wet Cutting (Flood) | Dry Cutting | Near-Dry Machining (MQL) |

|---|---|---|---|

| Lubrication | Excellent | None | Good |

| Cooling | Excellent | Poor (relies on air) | Moderate |

| Cost | High (coolant, disposal) | Low (no fluids) | Low-to-Moderate |

| Cleanliness | Messy | Excellent | Very Good |

| Blade Needs | Corrosion Resistance | Heat Resistance | Versatility, good coating |

Conclusion

Choosing the right blade is simple when you match it to your cutting method. Use corrosion-resistant blades for wet cutting and heat-resistant blades for dry cutting to get the best performance.

Understanding coolant's role can enhance your cutting efficiency and blade longevity. ↩

Learn how TiAlN coating enhances heat resistance and blade durability. ↩

Discover how AlCrN coatings can extend blade life in high-temperature applications. ↩

Find out why tungsten carbide is a top choice for durability in wet cutting. ↩

Explore the benefits of ceramic blades for high-precision cutting tasks. ↩

Learn how MQL can optimize your cutting process while reducing costs. ↩