Poor cuts and frequent stops hurt your production line. Using the wrong blade leads to waste and downtime. Let me show you how to choose the perfect blade every time.

To select the right blade, match its dimensions to your machine. Then, choose a blade type (straight, serrated) for your material. Finally, pick a blade material and coating (like stainless steel with DLC) for durability and performance, especially with sticky foods.

It seems simple, but getting these details right is crucial for your machine's health and your product's quality. A single wrong choice can lead to a domino effect of problems on the production floor. Let's start with the most fundamental step: ensuring the blade fits your equipment perfectly.

Does Your New Machine Blade Actually Fit Your Machine?

You have a new blade, but it doesn't fit, halting production. A simple mismatch can cause major delays. Let’s cover the essential checks to guarantee a perfect fit every time.

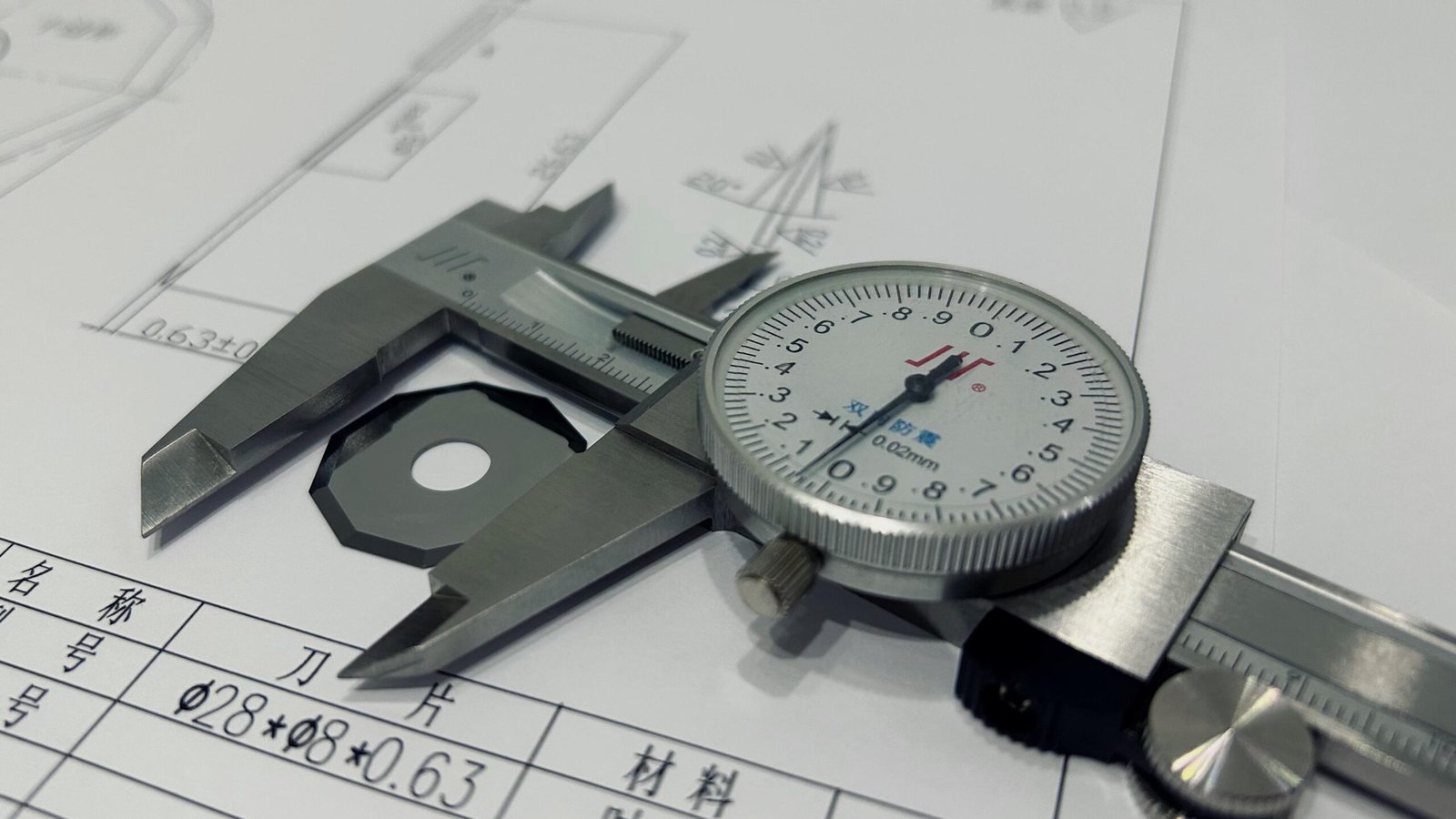

A perfect fit means the blade's dimensions, shape, and mounting holes1 match your equipment exactly. This ensures stable operation, high-quality cuts, and prevents damage to your machine. Always check these three elements against your machine's specifications before ordering a new blade.

Before we even think about cutting performance, we have to talk about compatibility. A blade that doesn't fit is useless, or even dangerous. The fit must be exact because even a tiny deviation can cause big problems like machine vibration2, uneven wear, or poor cut quality. I remember a client who had constant issues with tearing film. It turned out the blade they were using was just a millimeter too short, causing instability during high-speed cuts. Precision is a requirement for smooth operation.

Key Fitment Checks

To avoid this, you need to confirm three things:

- Overall Dimensions: This includes the length, width, and thickness of the blade. It must sit securely in its holder without any wobble.

- Shape: The overall geometry of the blade has to match the machine's design.

- Mounting Holes: The position, size, and shape of the mounting holes are critical. If they don't align perfectly with the machine's bolts or clamps, you simply can't install the blade correctly.

When you work with us at PASSION, we always ask for a technical drawing or a sample of your current blade to ensure we produce a perfect match.

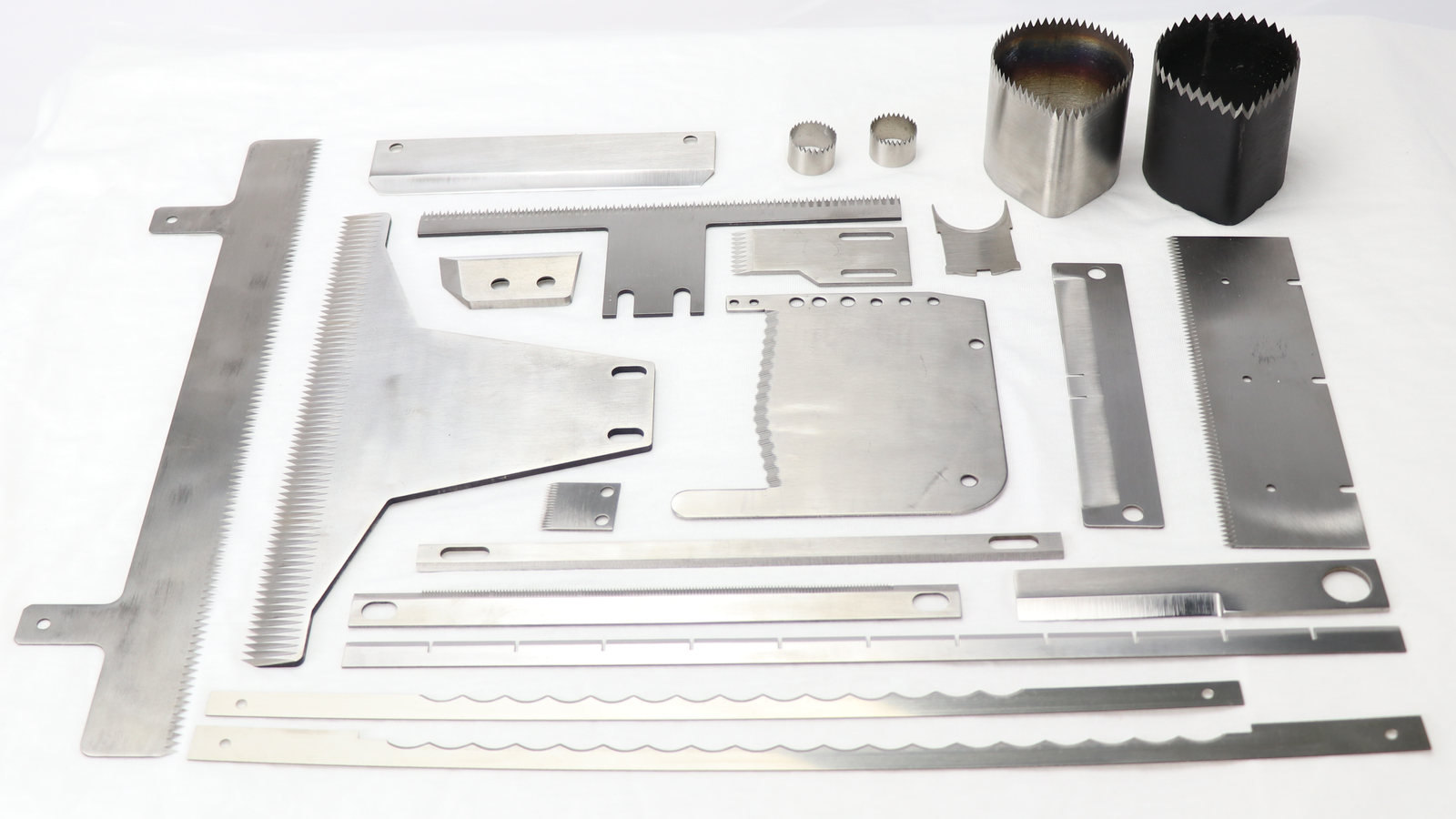

Which Blade Shape Is Right For Your Packaging Material?

Are your cuts ragged and messy? This not only looks bad but can also weaken your package seals. The solution is simple: match the blade shape to the material you’re cutting.

Use a straight blade for thin, soft films. A serrated blade is better for thicker or tougher materials. For dense products like cheese or dried fruit, a circular blade provides a clean, non-stick cut. The right shape prevents tearing and ensures a perfect finish.

Once you know the blade will fit, the next step is choosing the right tool for the job. Different packaging materials behave differently when cut. A blade that slices cleanly through a thin plastic film might just tear a thicker, multi-layered bag. The shape of the blade's edge is what determines the cutting action. For example, a straight edge relies on pure slicing pressure, while a serrated edge uses a sawing motion. Beyond the basic shape, we also need to consider the edge itself. Is it sharp enough? Does it need mirror polishing3 to reduce friction? At PASSION, we often fine-tune the edge geometry and finish for specific applications to get that perfect cut.

Common Blade Types And Their Uses

| Blade Type | Best For | Why It Works |

|---|---|---|

| Straight Blade | Thin, flexible films (e.g., plastic wrap, BOPP) | Provides a clean, swift slice with minimal force. |

| Serrated Blade | Thicker or tougher materials (e.g., laminated bags) | The teeth grip and saw through the material, reducing tearing. |

| Circular Blade | Dense products (e.g., cheese, dried fruit, dough) | The rolling motion gives a clean cut without dragging or sticking. |

| Perforating Blade | Creating easy-to-open tear lines | Creates a line of small cuts, not a full separation. |

How Do Blade Materials And Coatings Impact Performance?

Are your blades dulling too fast or getting gummed up with product? This forces frequent stops for cleaning and replacement. The right material and coating can dramatically boost blade life and performance.

The blade material determines its hardness and corrosion resistance. Martensitic stainless steel is a great all-rounder. For high-speed lines, consider carbide or ceramic. Coatings like DLC4 reduce friction and prevent sticking, perfect for sugary products, extending blade life significantly.

Finally, we need to talk about what the blade is made of. The material and any surface treatments directly affect sharpness, durability, and corrosion resistance. The goal is to choose a blade that stays sharp for as long as possible and resists wear and tear from both the material being cut and the operating environment. A harder material typically holds an edge longer but might be more brittle. That's why the specific grade of steel and its heat treatment are so important. But the material is only half the story. Coatings are often a game-changer. I saw this firsthand with a client, Alessandro, an Engineering Supervisor at a UK food packaging plant. He was having trouble with sticky blades and poor seals when cutting film. We recommended a food-grade stainless steel5 blade but added a mirror polish and a DLC (Diamond-Like Carbon) coating. The change was immediate. The super-smooth, low-friction surface stopped the material from sticking, the cuts were clean, and his production efficiency improved.

Materials And Coatings Breakdown

| Category | Option | Key Feature | Ideal Use Case |

|---|---|---|---|

| Material | Martensitic Stainless Steel | Good balance of hardness and corrosion resistance. | General-purpose food packaging. |

| Powder Metallurgy Steel | Extremely high wear resistance. | High-speed, high-volume production lines. | |

| Ceramic | Excellent heat and wear resistance; non-metallic. | Cutting highly abrasive materials. | |

| Coating | Chromium Nitride (CrN) | Reduces friction and material adhesion. | Cutting sticky or gummy products. |

| Diamond-Like Carbon (DLC) | Very low friction and high hardness. | Demanding applications with sticky foods. |

Alessandro's case was a perfect reminder that the best solution is often a combination of the right material and a smart surface treatment.

Conclusion

To select the perfect blade, ensure it fits your machine, match the shape to your material, and choose the right material and coating. This guarantees performance and durability.

Proper alignment of mounting holes is critical for safe and effective blade operation. ↩

Understanding the causes of machine vibration can help prevent production issues and improve efficiency. ↩

Mirror polishing can reduce friction and improve cutting efficiency, especially for sticky materials. ↩

Explore this resource to understand how DLC coatings enhance blade durability and cutting efficiency, crucial for production lines. ↩

Food-grade stainless steel is essential for safety and durability in food packaging applications. ↩