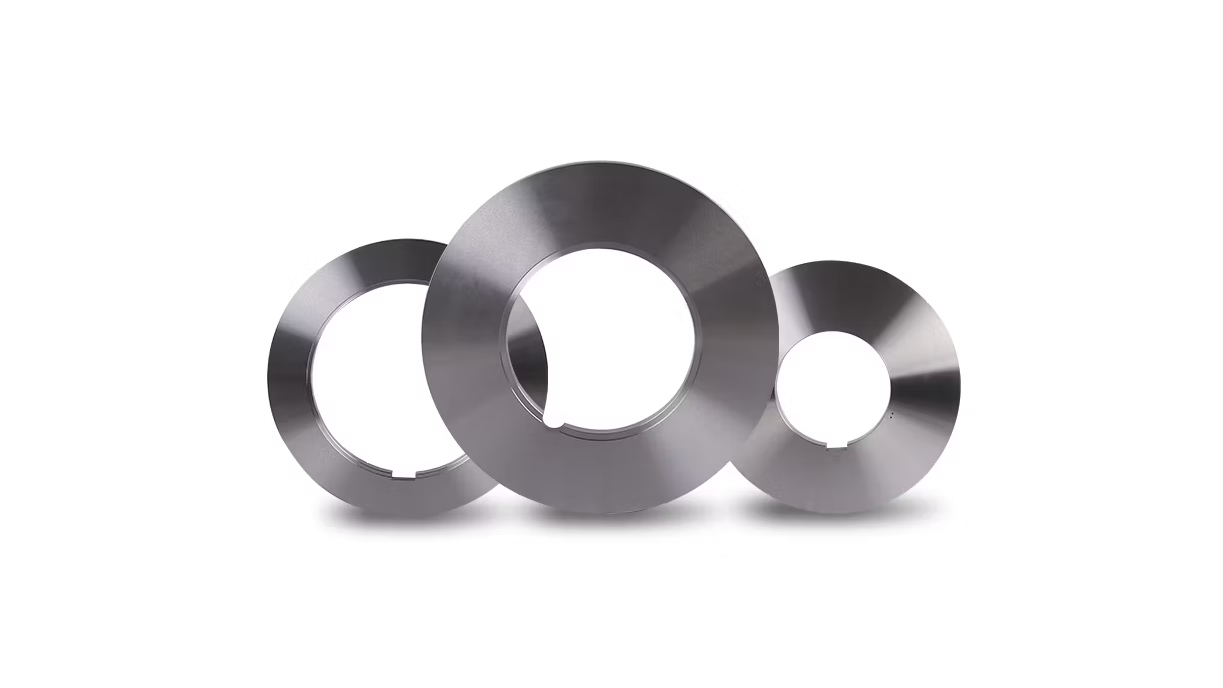

Are you tired of dealing with poor slit quality? Burrs and wrinkles on your material are a constant problem. The wrong spacer might be the secret villain, damaging your tools and profits.

Selecting the right metal slitting spacer1 is simple when you focus on three things. Match the spacer's material to your work environment. Match its hardness to the material you are slitting. And match its precision (tolerance and parallelism) to your quality standards. This ensures perfect cuts every time.

A common issue I see is companies investing in high-quality slitting knives but overlooking the spacers. They think a spacer is just a simple piece of metal. But this small component plays a huge role in the entire slitting process. Choosing the right one can make the difference between a profitable run and a pile of scrap. Let's walk through how you can make the best choice for your operation.

How Does Tolerance Stack-Up Affect Multi-Knife Setups?

Are your slitting widths2 inconsistent across the coil? You measure one strip, and it's perfect, but the next is out of spec. This issue, known as tolerance stack-up3, is probably costing you a lot in scrap material.

Tolerance stack-up is the total of all the small errors from each spacer and knife. To manage it, you must use spacers with a very tight thickness tolerance, like ±0.001mm. This keeps the total accumulated error small, ensuring every slit is accurate and consistent.

When you set up a slitter with many knives, you are creating a long assembly on the arbor. Every single component, both the blade and the spacer, has a small manufacturing tolerance. For example, a single spacer might be just +0.002mm thicker than its stated size. By itself, this is a tiny error that you can't even see. But what happens when you have 20, 30, or even more spacers in a single setup?

The Accumulation Effect

These tiny, individual errors add up. This is the "stack-up" effect. If you have 20 spacers that are each +0.002mm off, the total error at the end of the arbor can be a significant +0.04mm. This directly impacts the width of your final slit strip, pushing it out of the acceptable range for your customers. I’ve seen this happen firsthand with clients who were baffled by their inconsistent quality.

Why High-Precision Spacers Are The Solution

This is why we always stress the importance of precision. You need to look for spacers with the tightest possible tolerances.

| Precision Level | Thickness Tolerance | Best For |

|---|---|---|

| Standard | ±0.005mm | General purpose, wide-tolerance slitting |

| High-Precision | ±0.002mm | Slitting standard metals, paper, film |

| Ultra-Precision | ±0.001mm or less | Narrow slitting, foils, high-strength steel |

In addition to thickness tolerance, parallelism is also critical. Parallelism means the two faces of the spacer are perfectly flat and parallel to each other. If they are not, the spacer will tilt slightly when clamped on the arbor. This tilt also stacks up, causing uneven pressure on the knives. The result is premature blade wear and poor cut quality. At PASSION, our ultra-precision spacers are ground to ensure the highest level of parallelism, which solves this problem.

What Spacer Material Is Best For Your Slitting Job?

Are your spacers rusting or wearing out much faster than you expect? You find yourself stopping production for frequent replacements. This unplanned downtime hurts your bottom line and can make you late on important customer orders.

The solution is to match the spacer material to your specific job. For humid or corrosive areas, choose stainless steel. For high-speed or heavy-duty slitting, use a hardened tool steel like SKD11. For very soft materials like aluminum foil, the surface finish is most important.

A spacer isn't a one-size-fits-all product. The right material choice depends entirely on what you are doing. I always ask my clients three questions to determine the best fit for their needs. Let's break them down.

1. What Is Your Working Environment?

The conditions in your facility have a big impact on a spacer's life.

- High Humidity or Corrosive Chemicals: If your plant is humid, or if you use water-based coolants, standard steel spacers will rust. Rust changes the spacer's thickness and surface, ruining your precision. In these cases, 420 or 440B stainless steel is an excellent choice. A chrome-plated spacer also provides a great barrier against rust.

- High Temperatures: In some processes, the slitting area can get very hot. The material must be stable and not expand or lose its hardness at high temperatures. High-alloy tool steels perform very well here.

2. What Is The Material You Are Slitting?

The material you cut determines the force and wear on your tooling.

- Soft Materials (Aluminum Foil, Copper Foil, Film): For these materials, the biggest risk is scratching or marking the product. The spacer's surface finish is more important than its hardness. You need a spacer with a mirror polish to prevent defects.

- Hard Materials (Steel, Stainless Steel): Here, you need spacers that can withstand the high clamping forces and abrasion. A high-hardness tool steel like Cr12MoV or SKD11 is necessary. A standard, softer spacer will get crushed or deform over time, leading to inconsistent gaps between your knives.

3. What Is Your Production Demand?

How hard are you running your machines?

- High-Speed or High-Load Lines: If you are running double or triple shifts at high speeds, you need maximum durability. This is where high-strength alloy tool steels4 are the only option. They resist wear from friction and impact, giving you a longer service life and more stable performance.

Here is a simple guide I share with my clients:

| Your Need | Recommended Spacer Material/Feature | Why It Works |

|---|---|---|

| Wet/Humid Environment | Stainless Steel, Chrome-Plated | Resists rust and corrosion, maintains accuracy. |

| Slitting High-Strength Steel | Hardened Tool Steel (SKD11) | Withstands high pressure without deforming. |

| Slitting Thin Foil | Mirror-Polished Surface | Prevents scratches and damage to the material. |

| High-Speed, 24/7 Operation | High-Alloy Tool Steel (Cr12MoV) | Offers superior wear resistance for longer life. |

Why Does Surface Treatment On Spacers Matter?

Your spacers look fine, but your expensive slitting knives are wearing out too quickly. You are dealing with friction and wear, the silent killers of slitting efficiency. This means you are spending more money on replacement tools than you should.

Surface treatments, like chrome plating5 or nitriding, make a spacer's surface harder and smoother. This simple step reduces friction against the blades. It also prevents corrosion and greatly extends the life of both your spacers and your valuable knives.

Many people see surface treatment6 as an extra cost, but I see it as an investment that pays for itself. When a spacer and a slitting knife are pressed together on an arbor, there is constant micro-friction between them as the machine runs. Over millions of rotations, this friction causes wear. A worn spacer face is no longer perfectly flat, which affects the knife alignment. A good surface treatment creates a protective shield that fights this wear.

Common Surface Treatments And Their Benefits

We offer several types of treatments depending on the customer's application. Each one solves a different problem.

| Surface Treatment | Key Benefit(s) | Best For... |

|---|---|---|

| Precision Polishing | Creates an ultra-smooth, mirror-like surface. | Slitting soft, sensitive materials like foils and films to prevent scratching. |

| Chrome Plating | Adds high surface hardness and corrosion resistance. | General-purpose use, especially in humid environments, to increase tool life. |

| Nickel Plating | Provides excellent corrosion and chemical resistance. | Environments with aggressive coolants or chemicals. |

| Nitriding Treatment | Infuses nitrogen into the steel for extreme surface hardness. | Heavy-duty applications, slitting abrasive or high-strength metals. |

How Surface Treatment Leads To A Lower Cost Per Ton

Let's think about the total cost. You might save a small amount by buying untreated spacers. However, the increased friction will wear out your slitting knives faster. Knives are often the most expensive part of your tooling setup.

I once worked with a client who was slitting abrasive materials. They were changing their knives every week. We switched them to spacers with a nitriding treatment. The new spacers were much harder and slicker. The friction was so low that their knife life doubled. They now change their knives every two weeks. The initial investment in the treated spacers saved them thousands of dollars in replacement blades over the year. It's a clear example of how a small upgrade can have a big impact on your overall operational costs.

What Is The Standard Operating Procedure For Installing Slitting Spacers?

Do you notice that slit quality changes depending on which operator set up the machine? One shift produces perfect coils, while the next has issues. This inconsistency comes from a lack of a standard procedure for tooling setup.

A Standard Operating Procedure (SOP) ensures every setup is the same. It starts with cleaning the arbor and all tools. Then, you carefully load the knives and spacers in order. Finally, you tighten the lock nut to the correct torque. This creates a repeatable and precise setup.

A good setup is the foundation of a good cut. Even the best blades and spacers in the world will perform poorly if they are not installed correctly. An SOP removes guesswork and ensures that every operator, whether they are a new trainee or a 20-year veteran, performs the setup the same way. This consistency is key to quality control.

Here is a basic SOP that I recommend to all my clients.

Step 1: Preparation And Cleaning

- Goal: Remove all dirt and debris that could interfere with alignment.

- Action:

- Wipe down the entire surface of the slitter arbor with a clean, lint-free cloth and a solvent.

- Individually clean each spacer and slitting knife. Pay close attention to the faces and the bore.

- Lay out all tools on a clean workbench in the correct order for assembly.

Step 2: Inspection

- Goal: Identify any damaged tooling before it causes problems.

- Action:

- Visually inspect each spacer for nicks, scratches, or burrs. A damaged spacer should never be used.

- Check the slitting knives for chips on the cutting edge or signs of wear.

- Make sure the keyways on the arbor and tooling are clean and free of damage.

Step 3: Assembly

- Goal: Load the tooling onto the arbor correctly and safely.

- Action:

- Carefully slide the first spacer and knife onto the arbor. Make sure the key is aligned. Never force a component onto the arbor.

- Continue loading the spacers and knives according to your setup sheet. A common mistake I see is operators mixing up similar-sized spacers. Double-check each one.

- Ensure that the faces of each component are perfectly flush against each other with no gaps.

Step 4: Final Tightening And Checks

- Goal: Secure the entire tool pack with the correct and even pressure.

- Action:

- Install the lock nut and hand-tighten it.

- Use a calibrated torque wrench to tighten the nut to the manufacturer's specified torque. Overtightening can distort the spacers, while under-tightening can allow the tools to move during operation.

- Gently run your hand over the side of the assembled tool pack. You should not be able to feel any high or low spots between the knives and spacers.

By following a simple SOP like this, you create a baseline for quality and make troubleshooting much easier.

Conclusion

Selecting the right spacer requires matching its material, precision, and surface treatment to your specific job. Proper handling and installation are just as important for achieving perfect, consistent slitting results every time.

Understanding metal slitting spacers can enhance your cutting efficiency and quality. ↩

Identifying causes of inconsistent slitting widths can help improve your quality control. ↩

Learn about tolerance stack-up to minimize scrap and improve your production quality. ↩

Understand the advantages of using high-strength alloy tool steels in demanding applications. ↩

Learn how chrome plating can enhance durability and performance in slitting applications. ↩

Explore how surface treatments can extend the life of your spacers and knives. ↩