A bent HSS blade stops production and ruins expensive materials. Trying a quick fix can cause cracks and make it worse. But with the right method, you can save the blade.

Straightening a bent High-Speed Steel (HSS) blade1 requires careful steps. First, assess the bend's severity. Use segmented cold pressing for minor bends. For moderate bends, apply low-temperature heat2 (150–250°C) to assist correction. If you see any cracks, replace the blade immediately.

That is the basic process. However, every step has details that matter. Getting it wrong can permanently damage the blade or even your machine. A bent blade is a common issue, but the solution requires precision. Let’s walk through the exact steps to do this safely and effectively, and more importantly, when you should not even try.

How Do You Accurately Assess The HSS Blade Bend Before Straightening?

Guessing the severity of a bend is a big risk. You might apply pressure in the wrong spot, adding more stress. Precise measurement is the essential first step to a good repair.

To properly assess the blade bend, you must use precision tools like a flatness tester, a dial indicator on a granite surface plate, or optical measuring equipment. These tools map the exact location and curve of the bend, which tells you exactly where and how to apply pressure.

This first step is the most critical. Without an accurate map of the bend, any attempt to straighten the blade is just guesswork. I remember a client, John from a packaging company in the United States, who faced this exact issue. His team tried to straighten a blade by eye on a workbench. They ended up creating a second, smaller bend in the opposite direction, making the blade useless. When I spoke with them, I emphasized that you must measure first. We sent them a guide on setting up a simple testing station with a dial indicator. This allows you to find the highest point of the bend. You mark this point, as it is where you will apply corrective pressure. This accuracy prevents over-correction and ensures you are working on the right area, not creating new stress points elsewhere in the blade.

Key Assessment Tools

| Tool | How It Works | Best For |

|---|---|---|

| Flatness Tester | Provides a highly accurate surface for measurement with feeler gauges. | High-precision workshop environments. |

| Dial Indicator | Measures small deviations as the blade is moved under it. | Very practical for most machine shops. |

| Optical Equipment | Uses light and sensors to create a digital map of the surface. | Complex bends or quality control labs. |

Is Heat-Assisted Straightening A Safe Method For HSS Blades?

Cold pressing is not working on a more stubborn bend. Applying more force might snap the blade. You feel stuck. A little bit of controlled heat can make the metal more cooperative.

Yes, heat-assisted straightening is safe, but only when done correctly. The method uses very low temperatures, typically between 150–250°C (300–480°F), to slightly increase the metal's plasticity. This helps release internal stress, allowing the blade to be straightened with less force and reducing the risk of fracture.

The key is "low temperature." You are not trying to re-temper the steel. Exceeding this temperature range can soften the HSS and ruin its hardness and edge retention, which defeats the purpose of the repair. After John’s team learned how to assess bends, they found a moderately bent blade that wouldn’t respond to cold pressing. They were worried about using heat. I explained that it is not about making it red-hot; it is a gentle warming process. I advised them to use a calibrated industrial oven to bring the entire blade to a uniform 200°C. Once heated, they placed it on the straightening bench and applied gradual pressure. The bend came out much more easily than before. This gentle heat makes the steel less brittle, so it can be corrected without the high risk of micro-cracks forming under pressure. It's a technique for moderate bends, not severe ones.

Simple Heat-Assisted Steps

| Step | Action | Purpose |

|---|---|---|

| 1. Assess | Measure and mark the bend's high point. | Know where to apply pressure. |

| 2. Heat | Warm the blade uniformly to 150–250°C. | Increase plasticity, release stress. |

| 3. Press | Apply gradual pressure on the high point. | Slowly correct the bend. |

| 4. Cool | Allow the blade to cool down slowly to room temperature. | Prevent new internal stresses. |

| 5. Re-Inspect | Check the straightness again. | Confirm the repair and avoid over-correction. |

When Should You Replace A Blade Instead Of Trying To Fix It?

You want to save money by repairing every bent blade. But using a compromised blade can lead to catastrophic failure, damaging your machine. Knowing when to stop is the most important skill.

You must replace a blade immediately if you see any cracks, no matter how small. Also, discard it if you notice signs of surface decarburization3 or if testing shows its hardness has dropped. Repairing a structurally compromised blade is a major safety and performance risk.

This is a rule I always stress with my clients. A machine blade operates under extreme force. A tiny crack you can barely see will grow under operational stress, a process called crack propagation4. Eventually, the blade can shatter during use. This can injure an operator, damage expensive machine parts, and cause major downtime. The integrity of the steel is everything. A blade that has lost its hardness or has surface issues will not hold an edge or cut cleanly, even if it is perfectly straight.

Checklist: Signs It's Time For A New Blade

| Check For | Description | Why It's a Problem |

|---|---|---|

| Visible Cracks | Any hairline fracture, especially near the bend or edge. | Will grow under stress and lead to blade failure. |

| Reduced Hardness | The blade feels softer or fails a Rockwell hardness test. | The blade has lost its temper and won't hold an edge. |

| Surface Pitting | Small pits or decarburization on the surface. | Indicates the steel's structure is compromised. |

| Severe Bend | A sharp kink or extreme curve in the blade. | The internal stress is too great to be safely removed. |

How Can You Prevent HSS Blades From Bending In The First Place?

You are tired of constantly dealing with bent blades. It causes frustrating downtime and adds repair costs to your budget. Proper machine setup and operation is the best way to stop it.

You can prevent most bends by ensuring proper blade clamping, using uniform feed rates, and controlling cutting loads. Also, maintaining optimal cooling is essential to manage heat. Good operational habits are far more effective and less costly than any repair. This is the foundation of long blade life.

Proper Clamping And Support

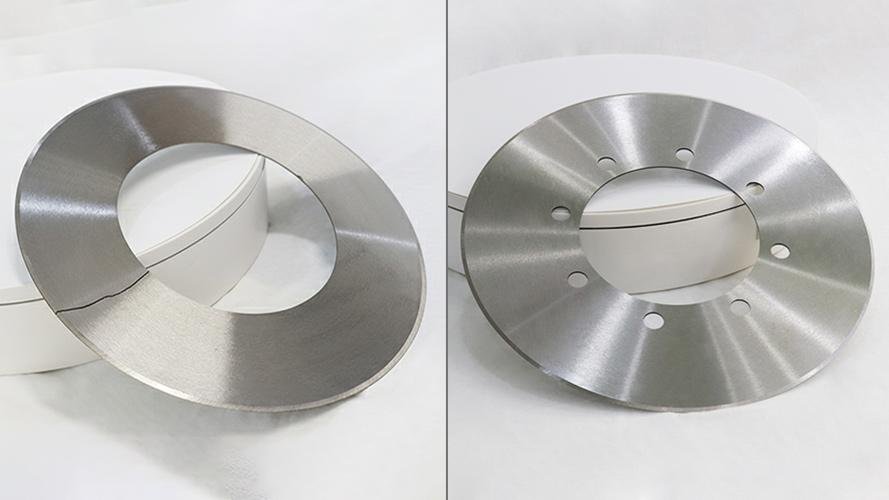

Uneven clamping pressure is a primary cause of blade bending. If one side of the blade holder is tighter than the other, it creates a fulcrum point, and the cutting forces will bend the blade. We recommended you use a torque wrench to ensure even pressure on all clamping bolts.

Controlled Machine Parameters

Pushing a blade too fast or trying to cut too much material at once puts an enormous load on the blade, causing it to deflect and bend.

Conclusion

Straightening an HSS blade is possible with care, but knowing when to replace it and preventing bends in the first place are the true secrets to production efficiency and workplace safety.

Explore expert tips on maintaining HSS blades to enhance their longevity and performance. ↩

Discover the science behind low-temperature heat treatment and its benefits for metalworking. ↩

Explore the causes of surface decarburization and its impact on steel performance. ↩

Learn about crack propagation and its implications for the safety of metal blades. ↩