Experiencing unpredictable blade failures? This inconsistency costs you time and money. The hidden cause is often uneven heat treatment1, a problem you can identify and solve.

To test if a blade's heat treatment is even, use methods like hardness testing2 across the blade, microscopic analysis3 of the grain structure4, and stress tests5. These checks confirm consistent hardness, toughness, and durability, preventing premature wear and breakage in your industrial applications.

Ensuring uniform heat treatment is one of the most critical steps in blade manufacturing. It is the foundation of a blade's strength, durability, and overall performance. A blade that isn't treated evenly will fail, it is just a matter of when. So, how can you be sure the blades you rely on are made to last? Let's dive into the essential methods to guarantee quality in every single blade.

Why Is Hardness Testing The First Step To Check Uniformity?

Do you worry about the quality of a new blade shipment? A single faulty blade can damage your machine and materials. Hardness testing provides a quick, reliable first look at its integrity.

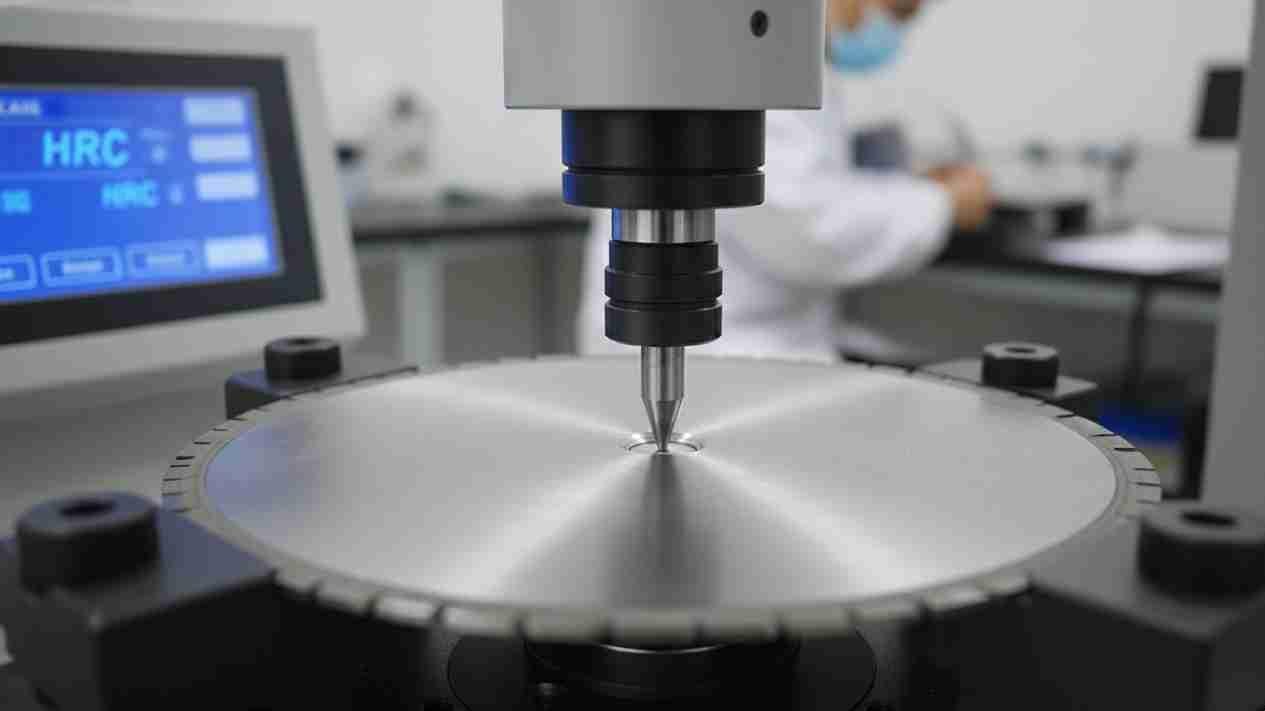

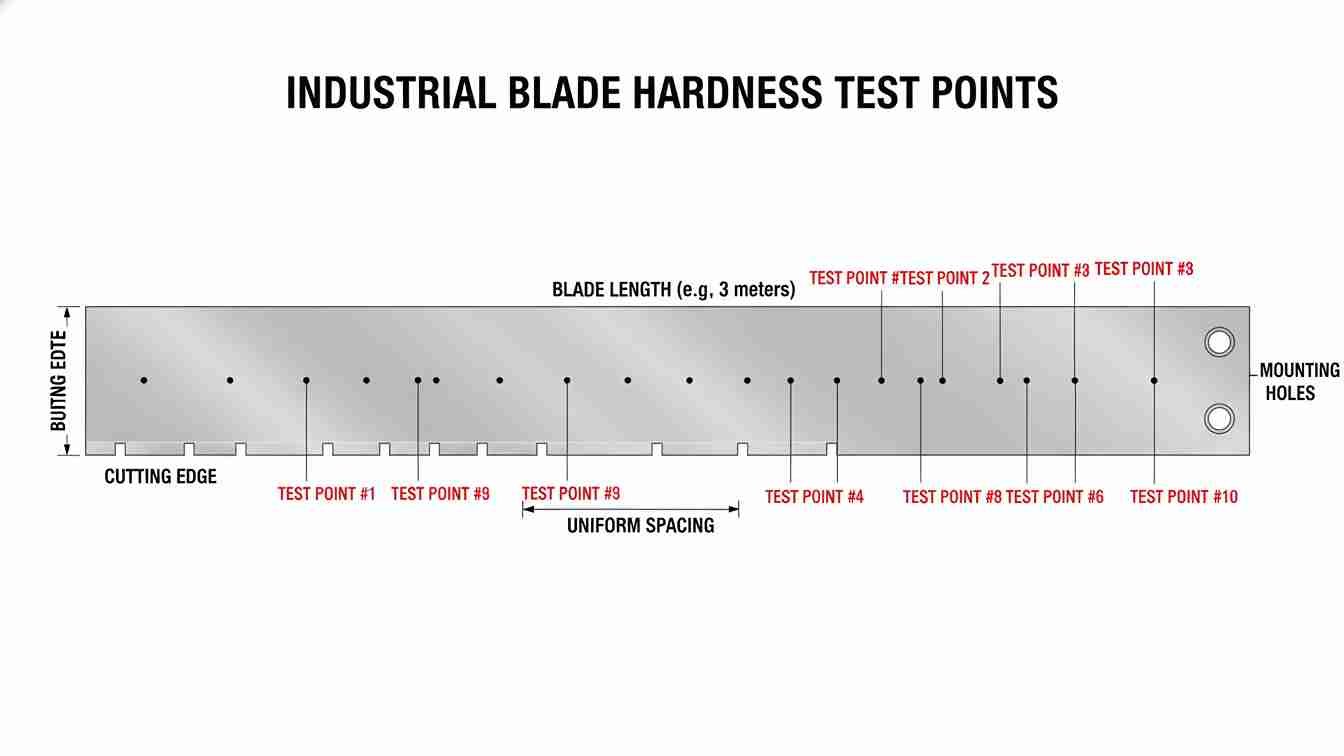

Hardness testing is the first step because it's fast, direct, and doesn't damage the blade. By measuring hardness at different points—like the edge, middle, and back—you can quickly spot inconsistencies. A uniform reading indicates good heat treatment and reliable blade performance.

When we receive an inquiry about blade performance, the first thing I often ask about is consistency. I remember a case with Mr. Sanchez, a manager at a large packaging facility in Mexico. He told me, "Lyn, some of our blades last for weeks, but others from the same box fail in days. We can't plan our production." This is a classic sign of uneven heat treatment. The simplest way to check this is with a hardness test, typically using a Rockwell6 or Vickers hardness tester7. We take readings from multiple locations on the same blade. For high-quality blades, the variation should be no more than ±1 HRC (Rockwell Hardness). When we tested his old supplier's blades, we found variations of 3-4 HRC. That's a huge red flag. It means some parts of the blade are too soft and will wear quickly, while others might be too hard and brittle, leading to chipping.

Reading The Results: What The Numbers Mean

A simple hardness test gives us a clear picture. The data doesn't lie, and it provides a solid foundation for evaluating blade quality before it ever reaches your machines.

| Test Location | Good Blade (PASSION) | Flawed Blade (Old Supplier) | Implication of Flaw |

|---|---|---|---|

| Blade Edge | 58 HRC | 61 HRC | Too brittle, prone to chipping |

| Blade Middle | 58.5 HRC | 59 HRC | Inconsistent core strength |

| Blade Back | 58 HRC | 57 HRC | Too soft, will deform under pressure |

What Can Microscopic Analysis Tell You About Blade Quality?

Your blade seems hard enough but still chips under pressure. This can be confusing and very costly. Microscopic analysis goes beyond surface hardness to reveal the blade's true internal strength.

Microscopic analysis reveals the blade's internal grain structure4. A uniform, fine-grained structure ensures both hardness and toughness. This helps us spot defects like large carbides or weak spots that hardness tests can miss, predicting how a blade will perform under stress.

A hardness test tells us what the hardness is, but a metallographic or microscopic analysis tells us why. After the initial hardness tests for Mr. Sanchez showed problems, we took the next step. We cut a small sample from one of the failed blades, polished it to a mirror finish, and examined it under a high-powered microscope. The images were revealing. His old blades had a coarse, uneven grain structure. We saw large clusters of carbides8, which are very hard but create weak points, making the blade brittle. A properly heat-treated blade should have a fine, uniform martensitic structure. This structure gives the blade the perfect balance of being hard enough to hold an edge and tough enough to resist shock and impact without chipping.

From The Lab To The Factory Floor

Seeing the difference is everything. When I showed Mr. Sanchez the microscopic photos comparing his old blade to a PASSION blade, he immediately understood the problem. It wasn't just about numbers on a report; he could physically see the quality difference in the blade's DNA.

| Microstructure Feature | Ideal Structure (PASSION) | Flawed Structure | Consequence of Flaw |

|---|---|---|---|

| Grain Size | Fine and uniform | Coarse and irregular | Prone to fracture and chipping |

| Carbide Distribution | Small and evenly distributed | Large clusters or clumps | Creates brittle weak spots |

| Phase Composition | Tempered Martensite | Untempered Martensite/Bainite | Inconsistent wear and toughness |

How Do Stress And Fracture Tests Uncover Hidden Flaws?

Have you ever had a blade warp or crack for no reason? This is often a sign of hidden internal stress from poor heat treatment. Specific tests can find these invisible flaws before they cause failure.

Uneven heating and cooling create internal stress, causing blades to warp or even crack. Stress tests measure flatness to detect deformation. Fracture analysis, a destructive test, examines the break's surface. A clean, fine-grained break signals quality; a coarse one indicates problems.

Not all defects are visible, even under a microscope. Sometimes, the problem is trapped inside the steel as residual stress. If a blade is not cooled uniformly during the quenching process, some parts shrink faster than others. This creates internal tension, like a tightly wound spring. A blade with high residual stress may look perfect, but it's a ticking time bomb. It can warp during storage, or worse, crack spontaneously when put under load. We check for this by measuring the blade's flatness and straightness with precision tools. For our most demanding customers, we also perform destructive tests. We intentionally break a blade from a batch and study the fracture surface. A good blade will have a smooth, velvety, fine-grained break. A poorly treated blade often shows a coarse, crystalline, "sugary" break, which is a clear sign of overheating during heat treatment.

Destructive But Decisive: Why We Break Blades

While nobody likes to destroy a perfectly good product, this test gives us the ultimate confidence in our heat treatment process. It proves the blade is as strong on the inside as it looks on the outside.

| Test Type | What It Measures | Signs of Good Quality | Signs of a Problem |

|---|---|---|---|

| Stress Test | Blade flatness, straightness | Within tight geometric tolerances | Warping, bowing, or twisting |

| Fracture Test | Internal grain structure at break | Fine, gray, velvety surface | Coarse, shiny, crystalline surface |

Are Performance And Non-Destructive Tests Worth The Investment?

For critical operations, you cannot afford a single failure. Standard spot-checking still leaves room for error. Advanced tests like performance trials and Non-Destructive Testing (NDT) offer complete assurance.

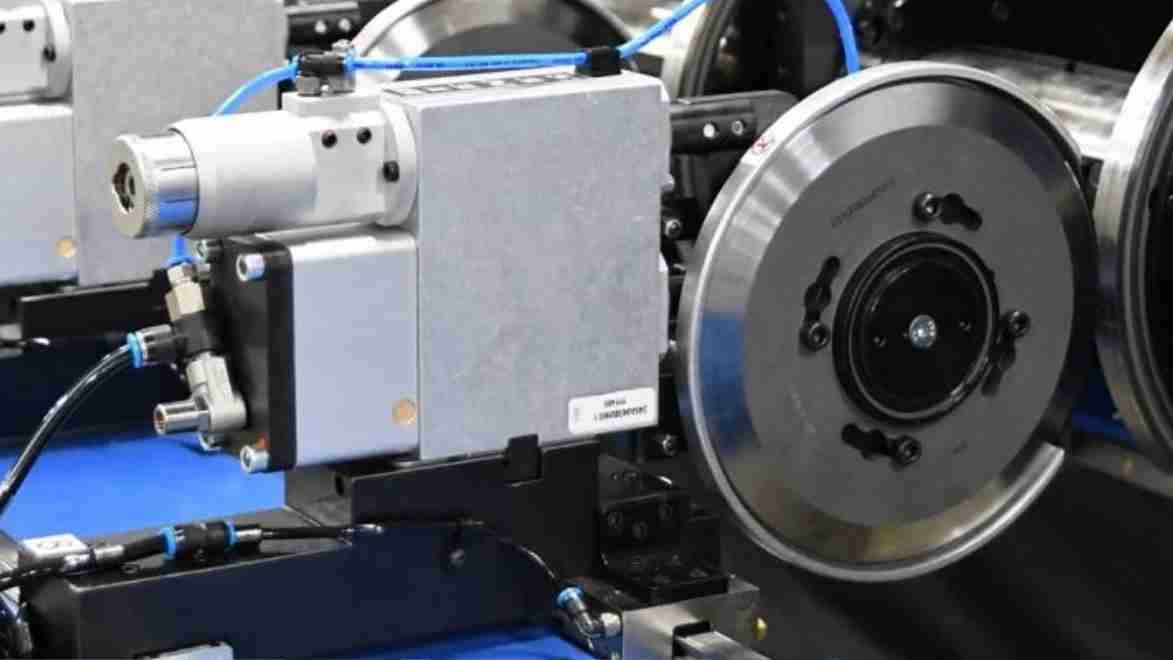

Yes, for high-value applications, they are essential. Performance tests simulate real-world use to confirm lifespan. Non-Destructive Testing (NDT) like eddy current checks every blade quickly, screening for defects without damaging it, ensuring 100% quality control.

For the most critical applications, we move beyond standard lab tests. The ultimate proof is how the blade performs in the real world. We conduct cutting trials where we install our blades on machines and run them under controlled conditions, measuring edge wear and cut quality over time. This gives us, and our customers, hard data on blade lifespan. For customers who need 100% inspection on every single blade, we use Non-Destructive Testing (NDT) methods like Eddy Current Testing. This high-tech method passes an electric current through the blade. Any variation in hardness, microstructure, or internal cracking changes the current's flow. The machine compares this "electronic signature9" to a perfect reference blade and can instantly flag any part that deviates. After seeing the proof from our other tests, Mr. Sanchez's company now relies on our blades, and his production line has never been more stable.

The Ultimate Proof: Real-World And High-Tech Testing

These final tests close the loop on quality control. They ensure that the blade's excellent lab results translate directly into superior performance and reliability on your factory floor.

| Test Method | Purpose | How It Works | Best For |

|---|---|---|---|

| Performance Test | Verify real-world lifespan & wear | Running blades on actual machines | Validating a new design or material |

| Eddy Current (NDT) | 100% inspection of a batch | Measuring changes in electrical current | High-volume, high-precision applications |

Conclusion

Testing blade heat treatment is key to performance. From hardness checks to advanced analysis, these methods ensure every PASSION blade delivers the reliability and precision your operation needs.

Delve into the heat treatment process and its critical role in blade performance and longevity. ↩

Explore this resource to understand the importance of hardness testing in ensuring blade quality and performance. ↩

Learn how microscopic analysis reveals internal flaws that affect blade performance, ensuring you choose the best products. ↩

Understand the impact of grain structure on blade strength and durability, essential for making informed choices. ↩

Discover the significance of stress tests in identifying hidden flaws that could lead to blade failure. ↩

Explore this link to understand the Rockwell hardness test's significance in ensuring blade quality and performance. ↩

Learn about the Vickers hardness tester and its application in ensuring blade durability. ↩

Understanding clusters of carbides is crucial for ensuring blade durability and preventing failures in industrial applications. ↩

Learn how electronic signatures are used in non-destructive testing to ensure blade quality. ↩