Are you struggling with blade selection? The wrong blade causes production delays and waste. This guide will help you choose the right cutting solution for your specific industry.

Industrial blades are crucial across many sectors. From corrugated packaging using carbide slitting blades to new energy employing ceramic film-cutters, each industry requires specific materials and designs for optimal performance, precision, and blade life. Proper selection is key to efficiency and quality.

It's important that helping clients find the perfect cutting solutions1. Choosing the right blade is more than just a technical decision; it impacts your bottom line. Let’s explore the specific needs of ten major industries. This deeper look will give you the knowledge to make better choices for your own operations.

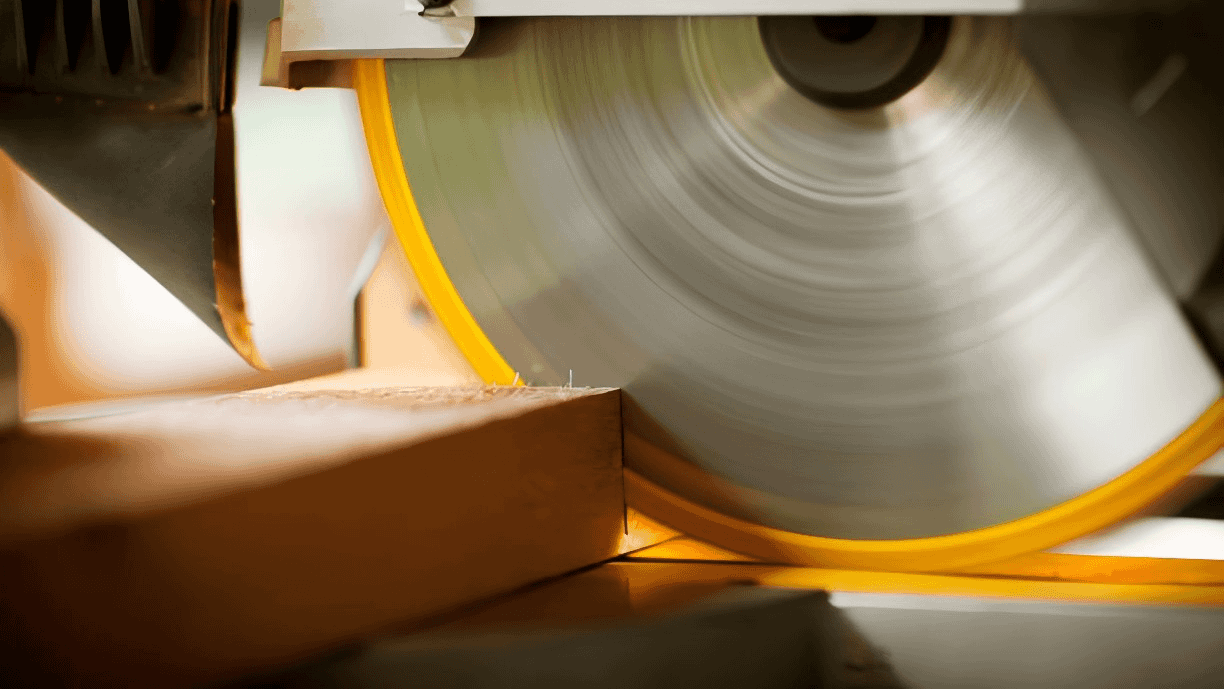

How Do You Choose The Right Blade For The Corrugated Packaging Industry?

Are your corrugated lines running slow? Dusty cuts and frequent blade changes are costing you money. The right tungsten carbide blade2 can solve these problems and boost your output.

For corrugated packaging, choose slitting blades and cutters made from high-toughness steel3 or cemented carbide. These materials ensure excellent wear resistance and flatness. This is critical for producing clean, long cuts on abrasive cardboard materials without crushing the flutes.

A few years ago, I worked with a packaging manufacturer in Brazil. They were having a terrible time with their slitting process. Their steel blades wore out quickly on long runs of double-walled cardboard. This caused excessive dust and crushed edges, leading to a high rejection rate. Their production line was stopping every few hours for blade changes. We looked at their process and recommended a switch to our tungsten carbide slitting blades. The result was immediate. Their blade life4 increased by over five times. The cuts were clean, the dust was gone, and their production efficiency went way up.

Key Blade Considerations

The main challenge in cutting corrugated board is its abrasive nature. The material is designed to be tough, so the blade needs to be tougher. You need a blade that holds its edge for a long time.

Material And Design Comparison

| Material | Key Advantage | Best For |

|---|---|---|

| High-Toughness Steel | Good balance of toughness and cost | Lighter-duty, single-wall cardboard |

| Cemented Carbide | Superior wear resistance and hardness | High-volume, multi-wall cardboard |

By matching the blade material to the specific cardboard type, you can get much better results.

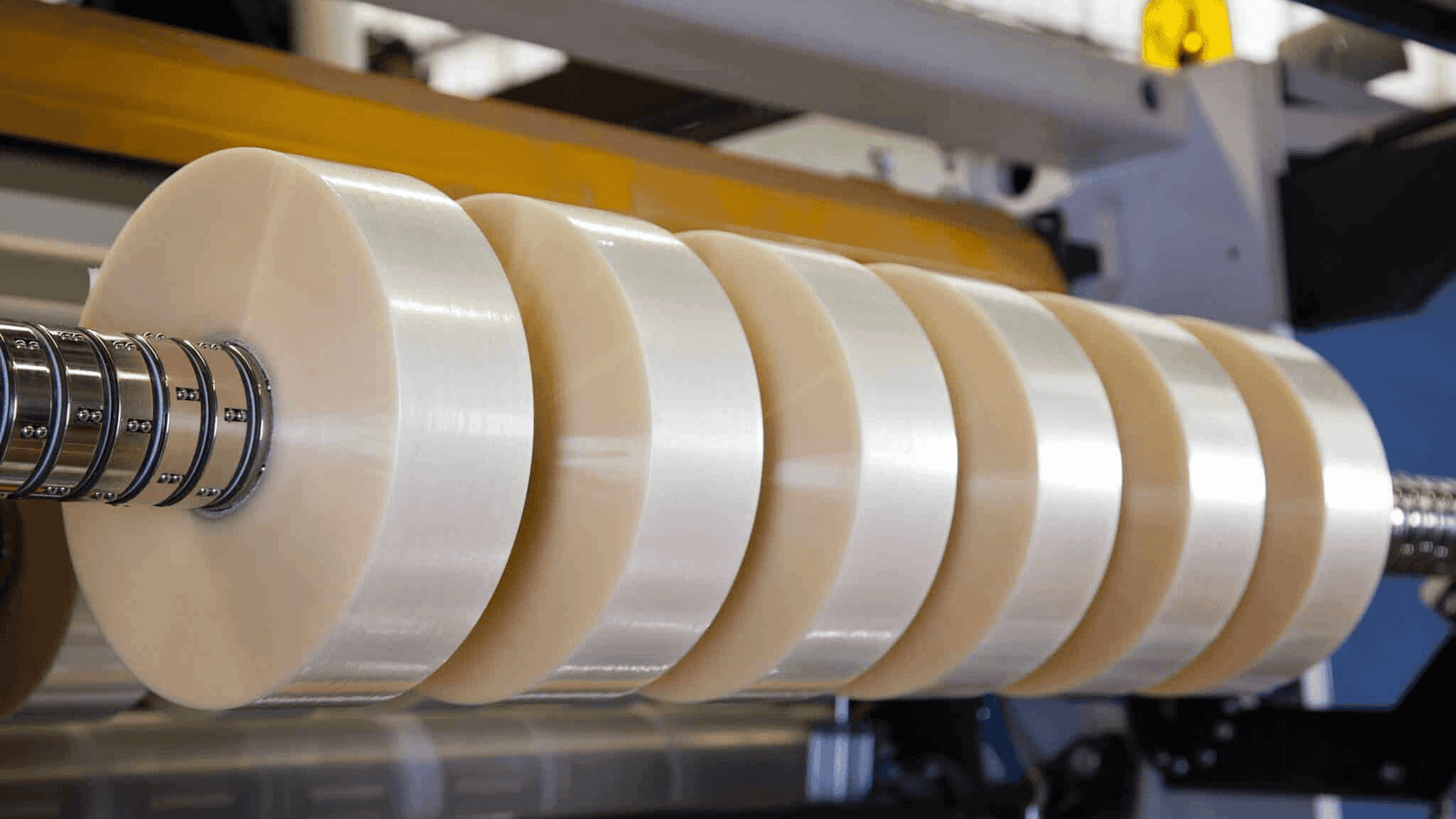

What Blades Are Best For The Paper Products Processing Industry?

Are you getting inconsistent paper cuts? Poor blade choice leads to waste and customer complaints. High-speed steel blades provide the sharpness needed for perfect stacks every time.

The paper processing industry relies on extremely sharp shearing, slitting, and trimming blades5. Materials like high-speed steel (HSS) or tungsten carbide are preferred. They maintain a stable cutting edge during high-frequency operations, minimizing fraying and ensuring clean, precise cuts.

I remember a case with a large commercial printing company in Germany. They specialize in high-quality art books with heavily coated paper. Their standard HSS guillotine blades were chipping frequently. This left slight imperfections on the paper edge, which was unacceptable for their customers. They needed a blade that was both sharp and incredibly durable. We supplied them with a micro-grain tungsten carbide blade. The much harder material resisted chipping completely. It also stayed sharp much longer, reducing their downtime and ensuring every cut was flawless. This small change helped them maintain their reputation for premium quality.

Common Blade Designs

In paper processing, you often find three main types of blades working together to turn large paper rolls into finished products. Each one has a specific job.

Sharpness And Durability

| Blade Type | Function | Material Focus |

|---|---|---|

| Shearing Blades | Cutting large stacks of paper | Extreme sharpness and stability |

| Slitting Blades | Cutting paper rolls into narrower widths | High wear resistance for long runs |

| Trimming Blades | Final cuts for books and magazines | Perfect edge quality |

The right material ensures these blades perform their function without fail.

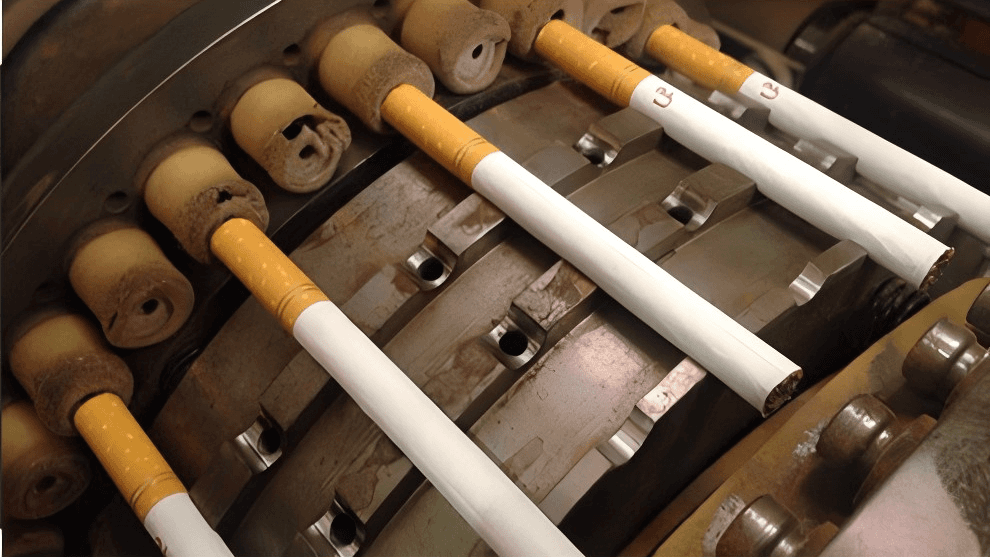

Which Blades Excel In The Tobacco Industry?

Are your tobacco slitting operations producing inconsistent cuts? This damages delicate materials and hurts quality. Precision blades made from chrome steel6 ensure a perfect slit every time.

The tobacco industry demands ultra-precise narrow-band slitting blades, stripping blades, and rotary blades. Chrome steel or cemented carbide are the go-to materials. They provide exceptional wear resistance and cut quality for delicate tobacco paper and filter materials.

I once assisted a filter rod manufacturer in Vietnam. Their biggest problem was production uptime. They were cutting very thin, specialized paper to wrap filters, and their blades dulled quickly. This meant they had to stop their machines frequently for replacements, which slowed down their entire operation. We analyzed their process and recommended our specialized HSS blades. These blades have a unique metallurgy that provides excellent wear resistance against the abrasive additives in the paper. After they made the switch, their blade lifespan nearly tripled. This greatly reduced their downtime and improved their overall output.

Specialized Blades For Tobacco

The tobacco industry is all about precision. The materials are thin and sensitive, so the blades must be perfect. Even a small defect in the cut can ruin the final product.

Material Selection For Precision

| Material | Key Property | Common Use |

|---|---|---|

| Chrome Steel | High wear resistance and cost-effective | Slitting tobacco paper and filter wrap |

| Cemented Carbide | Ultimate hardness and longest life | High-speed rotary cutting of tobacco strips |

Choosing between these comes down to the specific application and production volume.

What Cutting Solutions Dominate The Printing Industry?

Are frequent blade changes disrupting your printing workflow? Downtime costs more than just the blade. Coated carbide blades extend life and keep your presses running.

In printing, shearing blades, folding knives, and slitting knives are essential. Coated carbide materials are dominant because they handle rapid, repetitive cutting of paper and films. This focus on durability reduces replacement frequency and ensures consistent cut quality over long runs.

We worked with a large printing house in Italy that produces glossy fashion magazines. They were using uncoated carbide blades7 for trimming the final product. The heavy ink coverage and clay coatings on the paper were extremely abrasive. Their blades would only last for a few shifts before the cut quality started to decline. This was causing bottlenecks in their finishing department. I suggested they try blades with a Titanium Nitride (TiN) coating. The coating creates a super-hard, low-friction surface. This simple change made a huge difference. Their blade life doubled, the cuts stayed clean, and their production workflow became much smoother.

Blades For Finishing

After the ink is on the paper, the final cutting and folding stages determine the quality of the finished product. Blades here need to be reliable and long-lasting.

Why Coatings Matter

| Coating Type | Main Benefit | Ideal For |

|---|---|---|

| TiN (Titanium Nitride) | General purpose, reduces friction | Standard paper and cardstock |

| TiCN (Titanium Carbonitride) | Higher hardness and wear resistance | Abrasive coated papers and films |

Coatings are a small investment that delivers a big return in blade life and performance.

How Can You Master Cutting In The Chemical Fiber Film Industry?

Are your film slitting lines creating burrs? Poor cuts on plastic films lead to material waste. Ceramic blades offer the precision needed for a flawless finish.

The chemical fiber film industry relies on rotary cutters, circular blades, and slitting knives. Tungsten carbide or ceramic blades8 are best. They handle tough film materials and high speeds, offering superior wear resistance and thermal stability to prevent melting.

A film converter in Mexico contacted me with a challenging problem. They were slitting a very thin, high-toughness polymer film. Their tungsten carbide blades were generating too much heat at high speeds. This caused the film edges to melt slightly, creating a raised lip or burr. This made the rolls unusable for their end customer. We worked with them to test a set of solid ceramic blades. Ceramic has excellent thermal stability and very low friction. The blades cut through the film cleanly without generating excess heat. The melting issue was completely eliminated, and they could even increase their line speed.

High-Speed Cutting Challenges

When you cut plastic film at high speeds, heat is your biggest enemy. It can ruin the cut edge and damage the product. The blade material must be able to manage this heat effectively.

Material Performance Comparison

| Material | Strength | Weakness |

|---|---|---|

| Tungsten Carbide | Very tough and durable | Can generate heat at extreme speeds |

| Ceramic | Excellent thermal stability, stays sharp | More brittle than carbide |

The choice depends on balancing the need for speed with the toughness of the material being cut.

What Blades Are Required For The Metal Processing Industry?

Is your metal shearing process too slow? Using the wrong blade material on metal sheets can cause damage to both the blade and your machine. CBN blades9 can cut faster and last longer.

The metal processing industry uses shearing blades, slitting blades, and punch shears. Advanced materials like carbide, CBN (Cubic Boron Nitride), and ceramics are common. These blades must have exceptional hardness and thermal stability to cut metal sheets and wires at high speeds.

I once had a client in Poland who manufactured steel shelving. They were shearing thin-gauge steel sheets using standard tool steel blades. To prevent blade damage, they had to run their shearing machine at a relatively slow speed. They wanted to increase their throughput but were worried about blade life. We introduced them to blades with CBN cutting edges. CBN is second only to diamond in hardness. This allowed them to significantly increase their cutting speed without sacrificing edge quality or blade life. They were able to process more steel per shift, which directly boosted their profitability.

Cutting Demands For Metal

Cutting metal is about managing immense force and heat. The blade must be harder than the material it is cutting and able to withstand the high temperatures generated during the process.

Advanced Material Properties

| Material | Key Feature | Best Application |

|---|---|---|

| Carbide | Great all-around hardness and toughness | General purpose metal slitting and shearing |

| CBN | Extreme hardness at high temperatures | High-speed cutting of ferrous metals |

| Ceramic | Superior thermal and chemical stability | Specialized high-speed finishing operations |

Using these advanced materials is key to modern, efficient metal processing.

Which Blades Work Best For The Plastics And Rubber Industry?

Is sticky material building up on your blades? This common problem in plastics and rubber cutting slows production. Blades with special coatings can solve this issue.

In the plastics and rubber industry, you often see serrated blades10, circular blades, and slitting blades. Materials include high-speed steel, tungsten carbide, and coated alloys. The key is to have anti-adhesion and low-friction properties to prevent material buildup.

A client in Turkey who produces rubber gaskets faced a constant challenge with material buildup. They were using uncoated tungsten carbide circular blades to cut extruded rubber strips. The warm, tacky rubber would stick to the blade surface. This gummed up the works and required them to stop production for cleaning every hour. It was a major source of inefficiency. I suggested they try the same carbide blades but with a non-stick coating, similar to what you might find on cookware. The effect was incredible. The low-friction surface prevented the rubber from sticking. They could run for an entire shift without stopping for cleaning.

The Problem Of Adhesion

Many plastics and rubbers become sticky when cut, especially at production speeds. This buildup can ruin cut quality and cause machine jams. The right blade design11 and material can prevent this.

Solutions For Clean Cutting

| Blade Feature | How It Helps | Best For |

|---|---|---|

| Serrated Edge | Slices through soft materials cleanly | Soft rubbers and foam |

| Polished Finish | Reduces surface area for material to stick | General purpose plastics |

| Non-Stick Coating | Creates a slick surface that repels material | Tacky rubbers and adhesive plastics |

Combining the right edge geometry with the right surface finish is the key to success.

What Makes Food Processing Blades Different?

Are you worried about food safety in your cutting process? Using the wrong blade material can introduce risks. Food-grade stainless steel and carbide ensure safety and performance.

The food processing industry uses slicing blades12, circular blades, and trimming blades. Materials must be hygienic, like stainless steel (e.g., 420, 440) or special food-grade tungsten carbide. They need to be sharp, corrosion-resistant13, and easy to clean.

A large poultry processor in South Africa contacted us for help. They were using standard stainless steel blades to portion chicken breasts. The blades worked well initially, but they dulled quickly from cutting against small bones. This required frequent sharpening, which created downtime and raised concerns about maintaining a perfectly hygienic edge. We developed a custom blade for them using a food-grade tungsten carbide. The carbide was much harder and held its sharp edge for much longer. This reduced blade changes by 90% and provided a consistently clean cut. It improved their efficiency and CQC standards.

Hygiene And Performance

In food processing, the blade must do two things perfectly: cut cleanly and be completely safe for food contact. This means the material cannot rust, corrode, or react with food products.

Food-Grade Material Choices

| Material | Key Advantage | Common Use |

|---|---|---|

| 440 Stainless Steel | Excellent corrosion resistance and good edge retention | Slicing meat, cheese, and vegetables |

| Food-Grade Carbide | Extreme wear resistance for very long life | High-volume portioning and dicing |

These materials ensure that food products are cut efficiently and safely.

How Do You Select The Right Blade For The Wood Processing Industry?

Are your saw blades burning wood instead of cutting it? This is a sign of a dull blade or the wrong blade type. Choosing the right material and tooth design is essential.

The woodworking industry uses saw blades, slitting knives, and planing knives. Blade materials include cemented carbide, laminated steel14, or coated high-speed steel. They are designed for both rough and fine processing of logs, plywood, and high-density boards.

I worked with a furniture manufacturer in Indonesia that was having trouble with their laminated boards. The boards were made with dense tropical hardwoods and strong glues. Their standard steel saw blades were wearing out very quickly. The dull blades created friction, which caused burn marks along the cut edge. This required extra sanding, adding labor and time to their process. We supplied them with our carbide-tipped saw blades15. The carbide teeth stayed sharp much longer, even when cutting through the abrasive glue lines. The cuts were clean and free of burns. This eliminated the need for extra sanding and streamlined their production.

From Logs To Furniture

Wood processing involves a wide range of cutting tasks, from initial log breakdown to the fine finishing of furniture components. Each task requires a different type of blade for the best results.

Blade Materials For Wood

| Material | Best For | Why? |

|---|---|---|

| Laminated Steel | Planing knives and veneer cutters | Provides a tough core with a very hard cutting edge |

| Coated HSS | Cutting softwoods and some hardwoods | Offers good sharpness and durability at a lower cost |

| Cemented Carbide | Plywood, MDF, and hardwoods | Resists abrasion from glues and dense materials |

Matching the blade to the wood type and application is critical for quality and efficiency.

What Are The Blade Requirements For The Battery And New Energy Industry?

Is precision a challenge in your battery manufacturing? Cutting battery components requires extreme accuracy. Specialized ceramic blades can deliver the precision and cleanliness you need.

The battery and new energy industry uses slitting blades, punching blades, and film-cutting blades. Materials include carbide, ceramic, and specialized coatings16. These tools cut battery foils, separators, and composite materials, demanding high precision, wear resistance, and a contamination-free process.

A new energy startup in Canada was developing a new type of lithium-ion battery. They needed to slit extremely thin copper and aluminum foils to an exact width with no burrs. Any microscopic metal particle created during slitting could cause a short circuit in the finished battery. Their metal blades were creating too many particles. I recommended they test our solid zirconia ceramic blades. Ceramic is non-metallic, so it cannot create conductive contamination. It also can be sharpened to an incredibly fine edge. The ceramic blades produced a perfectly clean, burr-free cut. This was a critical step that helped them ensure the safety and reliability of their new battery design.

Precision Is Everything

In the new energy sector, especially in battery production, cutting is a high-stakes process. The tolerances are tiny, and the materials are delicate and reactive. Contamination can lead to catastrophic failure.

Advanced Materials For Advanced Tech

| Material | Key Feature | Industry Application |

|---|---|---|

| Coated Carbide | High precision and long life | Punching and shaping battery cell components |

| Ceramic | Ultra-sharp, non-conductive, no burrs | Slitting battery foils and separator films |

As technology evolves, blade materials17 must evolve with it to meet new manufacturing challenges.

Conclusion

Choosing the right industrial blade is key to efficiency. From packaging to new energy, the correct material and design will improve your quality, reduce waste, and boost your production.

Explore various cutting solutions tailored to meet industry-specific needs. ↩

Discover the advantages of tungsten carbide blades for durability and efficiency. ↩

Understand how high-toughness steel improves blade performance in various applications. ↩

Discover tips and techniques to maximize blade life and reduce downtime. ↩

Learn about the importance of trimming blades for achieving quality finishes. ↩

Learn about the properties of chrome steel that make it ideal for precision cutting. ↩

Discover how coated carbide blades enhance cutting efficiency in the printing industry. ↩

Explore how ceramic blades provide precision and thermal stability in film cutting. ↩

Learn about the extreme hardness of CBN blades and their benefits in metal cutting. ↩

Discover how serrated blades improve cutting performance for soft materials. ↩

Understand the critical factors that influence effective blade design. ↩

Discover the various applications of slicing blades in the food industry. ↩

Understand the significance of corrosion resistance for food safety. ↩

Explore how laminated steel enhances the performance of woodworking blades. ↩

Learn why carbide-tipped saw blades are preferred for cutting dense materials. ↩

Learn how specialized coatings enhance the performance of industrial blades. ↩

Find out which blade materials are optimal for various industrial applications. ↩