Choosing the wrong blade material can stop your production line. This leads to costly downtime and frustration. I'll help you understand the right choice for unbeatable performance and reliability.

For BHS shear blades, solid High-Speed Steel (HSS)1 is typically the better choice. Its superior toughness handles the high-impact cutting environment well. While solid Powdered High-Speed Steel (PM HSS)2 is harder, its brittleness often leads to premature failure and chipping in this specific application.

Choosing the right material seems complex, but it's simpler than you think. Let me break down the key differences based on my experience helping clients worldwide. Let's dive into why industry experts almost always lean one way.

Why Is Toughness More Important Than Hardness For BHS Shear Blades?

Is your harder blade chipping unexpectedly? This breakage can halt your entire line. The key is understanding that for high-impact jobs, toughness3, not just hardness4, is what truly matters.

Toughness allows a blade to absorb the intense, repetitive impacts of a BHS cross-cutter without fracturing. While a harder blade edge wears down slower, its brittleness makes it prone to chipping under stress. In this application, a tough blade ensures stability and prevents catastrophic failure.

I remember working with a large packaging manufacturer in Mexico. They were running their BHS line at very high speeds and were frustrated with frequent blade changes5. They had tested a blade made from a very hard material, hoping its wear resistance would extend its life. Instead, they experienced constant micro-chipping along the cutting edge. The problem wasn't wear; it was impact.

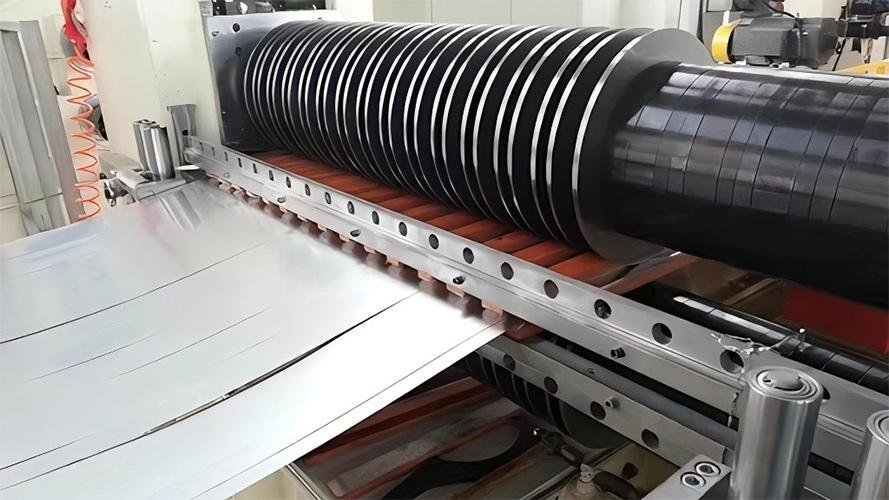

A BHS shear blade doesn't just slice; it chops through thick, corrugated board with immense force, hundreds of times a minute. This creates a cycle of intense impact and pressure. This is where material properties become critical.

Understanding The Trade-Off

Hardness and toughness are often a trade-off in steel.

| Property | Solid HSS | Solid PM HSS |

|---|---|---|

| Hardness | Good | Excellent |

| Toughness | Excellent | Fair |

| Impact Resistance | High | Low |

| Primary Failure Mode | Gradual Wear | Chipping/Fracture |

The solid HSS material can be thought of as a well-rounded athlete. It's strong and durable enough for the main event. The solid PM HSS is more like a world-class sprinter—incredibly powerful in one area but not built for the endurance and abuse of a marathon. For the Mexican client, we supplied our standard solid HSS blades. The chipping stopped immediately, and their production became smooth and predictable again. They achieved a more stable, reliable operation, which was far more valuable than the theoretical extended life of a brittle blade.

How Do Manufacturing Challenges Make Solid Powdered Steel So Expensive?

Surprised by the high cost of solid powdered steel blades? This price isn't just about the raw material. The real costs are hidden in a difficult and wasteful manufacturing process.

Solid PM HSS is extremely difficult to machine and heat-treat, especially for large blades. Its dense structure creates high resistance, and heat treatment6 can cause unpredictable warping. This leads to much higher scrap rates and labor costs, which are passed on to the final price.

A few years ago, a paper mill manager in Poland called me. He was searching for the "ultimate" blade and had requested a quote for a set of solid PM HSS shear blades. When he saw the price, he thought it was a mistake. It was nearly five times the cost of our premium solid HSS blades. I had to explain that the price was correct, and it was primarily due to the intense manufacturing challenges7.

Key Manufacturing Hurdles

- Machining: The material’s high hardness and dense particle structure fight back against every cutting and grinding tool. This slows down the process, wears out our equipment faster, and requires specialized machinery.

- Heat Treatment: This is the most critical and difficult step. A long shear blade is prone to warping as it's heated and cooled. With standard HSS, we have predictable ways to control this. With the dense structure of PM HSS, stresses build up unevenly, making deformation very hard to manage. A slightly warped blade is completely unusable.

- Scrap Rate: Because of these difficulties, the failure rate in production is significantly higher. For every successful solid PM HSS blade we might produce, we could have several failed attempts. This waste is factored into the cost of the final product.

After our discussion, the Polish client understood that the high price wasn't just for better material, but for a risky and inefficient manufacturing process. They opted for our reliable cobalt-HSS blades and were very happy with the balance of performance and price.

Is A Longer-Lasting Blade Always The Best Blade?

Everyone wants a blade that lasts longer. But what if that extended life comes with the risk of sudden, catastrophic failure? Sometimes, consistent and predictable performance is more valuable than just longevity.

Not always. In high-speed operations like a BHS line, stability is key. A blade that wears predictably (like Solid HSS) allows for planned maintenance. A blade that might last longer but could chip unexpectedly (like Solid PM HSS) introduces unacceptable risk and potential for major production stoppages.

I worked closely with a top-tier corrugated box plant in Germany. Their facility is a model of efficiency, running 24/7 with a focus on maximizing uptime. They weren't just looking for a long-lasting blade; they were looking for a predictable blade. The cost of an unscheduled line stoppage for them was enormous—far greater than the cost of a new set of blades.

They had experimented with different materials in the past. They found that extremely hard blades, while showing less gradual wear, were a constant source of anxiety. They never knew when a small inclusion in the paperboard or a slight jam could cause the brittle edge to fracture, bringing the entire line to a screeching halt.

Predictability Vs. Maximum Lifespan

We helped them analyze their performance data.

- Scenario A (Brittle Blade): Could last 1,200 hours, but had a 20% chance of failing unexpectedly at any point after 400 hours. This resulted in an average of two unscheduled downtimes per blade life cycle.

- Scenario B (Tough HSS Blade): Lasted a consistent 800 hours with gradual, predictable wear. This allowed them to schedule blade changes during planned maintenance shifts, with zero unscheduled downtime.

For the German plant, the choice was obvious. They chose predictability. We supplied them with our high-performance cobalt HSS blades. These offer better wear resistance than standard HSS but retain the toughness needed to prevent chipping. They could confidently run their lines at maximum speed, knowing the blades would perform reliably until the next scheduled stop. This highlights a crucial point: the "best" blade isn't just about how long it cuts, but how reliably it does so.

What Is The Best High-Performance Alternative To Solid HSS?

You need better performance than standard HSS, but solid powdered steel is too risky and expensive. So, where do you turn? There's a smarter solution that gives you the best of both worlds.

The best high-performance alternative is a composite blade, typically with an inlaid edge of PM HSS or Tungsten Carbide on a tougher steel body. This design provides extreme hardness and wear resistance on the cutting edge while the main body retains the toughness to absorb impact.

This is the solution we recommend for our most demanding customers. A great example is a massive box plant in Brazil that runs multiple BHS lines to serve South America. They wanted the absolute best performance possible—maximum sharpness, longest life, and total reliability. For them, solid PM HSS was off the table due to the risk of chipping.

We introduced them to our inlaid blade technology. It's a brilliant piece of engineering that solves the hardness-versus-toughness dilemma.

How Inlaid Technology Works

Imagine a kitchen knife. You want a razor-sharp edge, but you don't want the whole knife to be so hard that it snaps if you drop it. Our inlaid industrial blades work on the same principle.

- The Body: We start with a strong, tough steel that can handle the massive shock and stress from the cross-cutter. This forms the main structure of the blade.

- The Edge: We then use a specialized process to fuse a thin strip of much harder material—like PM HSS or even Tungsten Carbide8—right onto the cutting edge.

This composite design delivers the ultimate combination of properties. The Brazilian client switched to our inlaid PM HSS blades. They got the incredible wear resistance they wanted from the powdered steel edge, leading to a 50% increase in run time between changes. At the same time, the tougher blade body completely eliminated the risk of chipping. They achieved higher performance without compromising on the stability of their operation.

Conclusion

For BHS shear blades, solid HSS provides the best balance of toughness and value. For maximum performance, an inlaid PM HSS blade offers superior wear resistance without sacrificing critical impact strength.

Learn about the benefits of HSS in manufacturing, which can enhance your production efficiency and blade performance. ↩

Discover the drawbacks of PM HSS to make informed decisions about blade materials for your production needs. ↩

Understanding toughness can help you choose the right blades for high-impact applications, preventing costly downtimes. ↩

Explore how hardness impacts blade performance to ensure you select the best materials for your cutting needs. ↩

Understanding the factors that affect blade changes can help you optimize your production processes. ↩

Explore the role of heat treatment in blade durability to ensure you choose the right manufacturing processes. ↩

Gain insights into the manufacturing challenges of blades to better understand pricing and performance trade-offs. ↩

Learn about Tungsten Carbide's properties to understand its role in high-performance cutting tools. ↩