Struggling with blade performance1 and high costs? You might be overlooking a powerful solution. China's industrial blade technology offers world-class quality at a competitive price, solving your production headaches.

China's cemented carbide journey for industrial blades began in the 1950s and has progressed through four key stages. From basic coarse-grain materials to today's advanced nanocrystalline2 and coated blades, each step has significantly improved performance, reliability, and cost-effectiveness for global industries like yours.

This journey is not just about history; it is about the real-world value it creates for businesses today. As the Sales Manager at PASSION, I have seen how these material improvements solve complex cutting challenges3 for my clients around the world. The story started decades ago, but its impact is felt on factory floors every single day. Let’s look at how this evolution unfolded and what it means for your operations.

How Did Early Carbide Blades Shape China's Industries?

Are you using older blades that wear out far too quickly? This leads to rough cuts, frequent replacements, and costly downtime, slowing down your entire production line.

China's early cemented carbide blades, created in the 1950s, used medium-to-coarse grains. While not highly wear-resistant by today's standards, their excellent toughness was ideal for basic cutting in industries like paper, wood, and textiles, establishing the foundation for our domestic blade manufacturing.

Back in the 1950s, China began its journey into cemented carbide. We started by making our own versions of tungsten-cobalt (WC-Co) blades. These materials had medium-to-coarse grains, around 1 to 3 micrometers. This grain size offered great toughness, which was a huge advantage at the time. It meant the blades were less likely to break under stress. However, their wear resistance was only moderate. These blades became the workhorses for standard cutting tasks in the paper, wood, and textile industries. I remember speaking with a client in Egypt whose family had run a textile business for generations. He told me how switching from steel blades to these early carbide blades was a breakthrough. They were cutting thick cotton, and the new blades lasted much longer, providing cleaner cuts and reducing fabric waste. This was the first step in building China's own industrial blade system.

| Feature | High-Speed Steel | Early Cemented Carbide (1950s) |

|---|---|---|

| Hardness | Good | Better |

| Toughness | High | High |

| Wear Resistance | Low | Moderate |

| Best For | General Purpose | Basic Cuts in Paper, Wood, Textiles |

What Breakthroughs Made Chinese Blades Competitive In The 90s?

Do you need blades for high-speed jobs but find imported options too expensive? Settling for less can compromise both your speed and quality, directly hurting your output and profits.

During the 1980s and 90s, fine-grain cemented carbides (0.8–1.2 μm) became the new standard in China. This innovation dramatically improved blade wear resistance4 and stability. It made our blades perfect for high-speed paper cutting and film slitting, offering a strong cost-performance alternative to imports.

The 1980s and 1990s were a period of major advancement. New technologies like better powder metallurgy5 and vacuum sintering6 allowed us to produce fine-grain cemented carbides consistently. The grain size was much smaller, between 0.8 and 1.2 micrometers. This was a significant leap. It meant our blades became much more resistant to wear and chipping7. Their performance was also more stable during cutting. At PASSION, we developed new grades based on this technology. They were very successful in challenging applications like high-speed paper cutting and thin film slitting, where a sharp, durable edge is critical. I worked with a packaging company in Brazil that was struggling with this exact issue. They were slitting plastic film, but their blades dulled quickly, causing waste and downtime. Imported blades were outside their budget. We supplied them with our fine-grain blades. The result? They increased their machine speed by 20% and cut blade changes in half. It was proof that Chinese blades could deliver great performance at an affordable price.

| Feature | Early Carbide (1950s) | Fine-Grain Carbide (1990s) |

|---|---|---|

| Grain Size | 1–3 μm | 0.8–1.2 μm |

| Wear Resistance | Moderate | High |

| Chipping Resistance | Good | Very Good |

| Common Use | General Wood, Textiles | High-Speed Paper, Film Slitting |

How Has Modern Technology Made Chinese Blades World-Class?

Are you cutting tough, modern materials that destroy standard blades in no time? This frustration leads to poor cut quality, wasted material, and the risk of missing important deadlines.

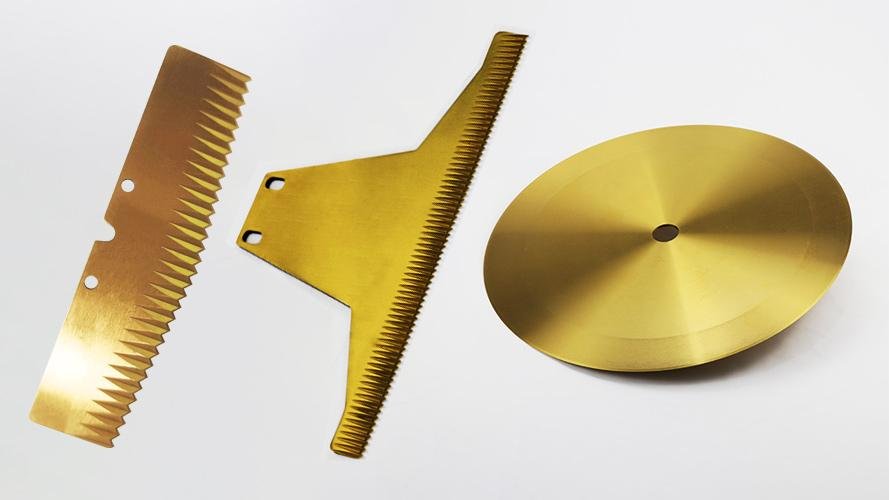

Since 2000, ultrafine and nanocrystalline carbides, combined with PVD coatings8, have defined China's blade industry. Technologies like Hot Isostatic Pressing9 (HIP) ensure maximum density and strength. This gives PASSION blades exceptional edge retention and a very long life, allowing them to compete with top premium brands.

From the early 2000s, everything changed again. We started using ultrafine (0.5–0.8 μm) and even nanocrystalline (0.2–0.3 μm) powders. We also adopted Hot Isostatic Pressing (HIP) technology, which uses high pressure and heat to eliminate any tiny voids in the material. This makes the blades incredibly dense and strong. The result is a blade with amazing edge retention and stability, even when cutting at very high speeds. On top of that, we began applying PVD coatings like TiN and AlCrN. These super-thin, hard coatings protect the blade from wear and heat. Recently, I helped a technical textiles manufacturer in Germany. They were cutting abrasive composite fibers for protective gear, and their expensive European blades were wearing out too fast. We provided them our nanocrystalline carbide blades with a special AlCrN coating. Not only did our blades match the performance, but they also lasted 30% longer at a better price. It's a perfect example of how far we've come.

| Grain Size | Key Benefit | Ideal Application |

|---|---|---|

| Ultrafine (0.5–0.8 μm) | Excellent Edge Retention | High-Speed Film, Composites |

| Nanocrystalline (0.2–0.3 μm) | Superior Wear Resistance | Abrasive Fibers, High-Strength Metals |

Furthermore, China possesses over 60% of the world's tungsten resources. This gives us a complete and stable supply chain, from raw material to finished product. It means companies like PASSION can offer blades that lead in quality, cost, and supply stability on the global stage.

Conclusion

From simple beginnings to today's high-tech solutions, China's carbide blade industry has grown immensely. At PASSION, we use this legacy to deliver precision, innovation, and unmatched value worldwide.

Explore this resource to discover proven strategies and technologies that can enhance blade performance and efficiency in your operations. ↩

Learn about nanocrystalline materials and how they revolutionize manufacturing processes. ↩

Identify common cutting challenges and solutions to improve manufacturing efficiency. ↩

Learn strategies to enhance blade wear resistance for better performance and longevity. ↩

Explore this link to understand how powder metallurgy enhances blade performance and cost-effectiveness in manufacturing. ↩

Explore this link to understand how vacuum sintering enhances carbide blade quality and performance, crucial for modern manufacturing. ↩

Explore this resource to discover advanced materials and technologies that enhance blade durability, reducing wear and chipping for better performance. ↩

Find out how PVD coatings enhance the durability and performance of cutting tools. ↩

Understand the significance of Hot Isostatic Pressing in producing high-quality materials. ↩