Struggling with poor cut quality or short blade life1? The problem might be your cutting method2. Let's fix that by understanding the basics of industrial cutting.

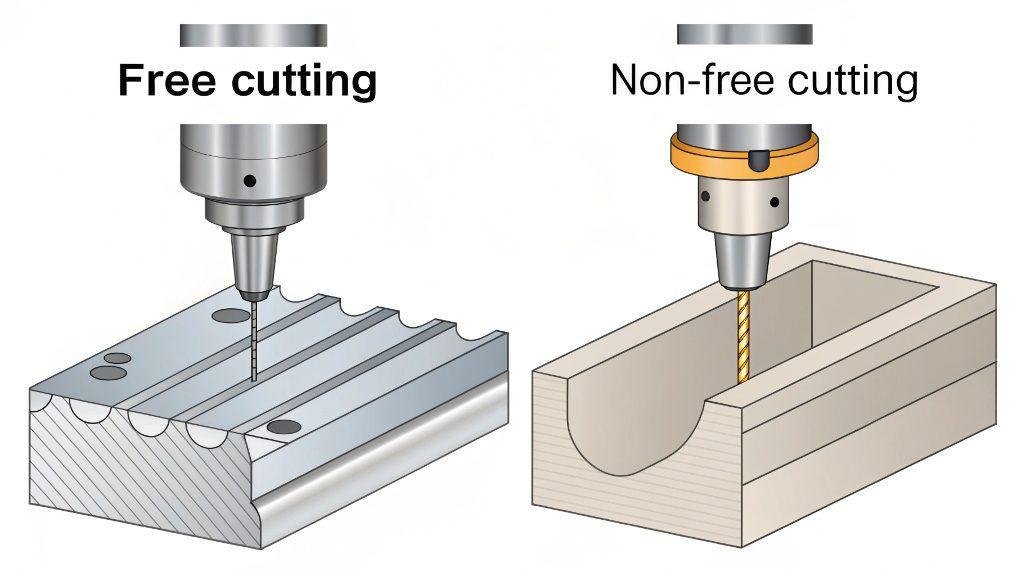

Free cutting uses a single, sharp edge for clean cuts on soft materials3 like paper or plastic. Non-free cutting uses a stronger, often curved edge for durable performance on hard materials like steel. The right choice depends entirely on your specific application and material.

Choosing the right blade is more than just finding the right size. The way it cuts is critical for efficiency and quality. I've seen many companies overlook this simple detail, costing them time and money. Let’s dive deeper into how these two fundamental cutting styles work, so you can make a better choice for your production line.

What Really Are The Advantages And Disadvantages Of Each Method?

Choosing the wrong blade design leads to costly mistakes. Let’s compare these two methods side-by-side so you can see the clear trade-offs for yourself.

Free cutting offers high precision and low heat but has a weaker edge. It's best for delicate tasks. Non-free cutting provides superior strength and longer life but generates more heat and uses more energy. It's built for tough jobs.

The choice between free cutting and non-free cutting always involves a trade-off between precision and durability4. Think of it like this: a surgeon's scalpel versus a wood axe. Both cut, but they are designed for completely different jobs. A free-cutting blade is like that scalpel. It's incredibly sharp and designed for clean, effortless cuts with minimal material damage. This is perfect for delicate films or high-quality paper goods where the final look is important. The downside is that its fine edge can't handle shocks or very hard materials5; it will chip easily. On the other hand, a non-free cutting blade is the axe. It’s built for impact and strength, allowing it to power through tough materials day after day without failing. This durability comes at the cost of higher friction and heat, which can sometimes create burrs or a rougher finish on the cut edge.

Here is a simple breakdown:

| Feature | Free Cutting | Non-Free Cutting |

|---|---|---|

| Edge Strength | Lower | Higher |

| Cutting Force | Low | High |

| Heat Generation | Minimal | Substantial |

| Best For | Soft, delicate materials | Hard, tough materials |

| Primary Goal | Precision, surface finish | Durability, blade life |

| Risk | Chipping on hard materials | Burrs, surface scorching |

Understanding this table is the first step to optimizing your cutting process and choosing a blade that works for you, not against you.

When Should You Choose A Free-Cutting Blade?

Are you seeing tears and rough edges on your finished products? This is a common sign you might be using the wrong type of blade for your delicate material.

Free-cutting blades are the best choice for materials where a clean cut is critical. This includes thin plastic films, paper products, textiles, and soft rubbers. The goal is to slice through the material with minimal force, preventing tearing, melting, or deformation.

A free-cutting blade is all about precision. You should choose it when the quality of the cut edge is your number one priority. Industries like flexible packaging, paper converting, and non-woven textiles rely almost exclusively on free-cutting designs. The sharp edge and large rake angle work together to slice material cleanly, rather than pushing or tearing it. This process generates very little heat. Why is that important? Heat is the enemy when you're cutting thin plastics, as it can cause melting and create a messy, unusable edge. A free-cutting blade glides through the material, which is exactly what you need for a high-quality finished product. It allows for faster machine speeds without sacrificing quality.

A Case From The Packaging Industry

I remember working with a client in Brazil who manufactures food packaging films. They were struggling with inconsistent product quality. Their existing blades were causing small melts and tears along the cut line, leading to a high rejection rate. Their machine was running, but they were losing a lot of money on wasted material and rework.

The Simple Solution

After examining their material and process, I recommended a custom free-cutting blade. We designed it with a very high rake angle and used a specific grade of steel that could hold an extremely sharp edge. The change was immediate. The new blade sliced through the film with almost no resistance, which eliminated the heat buildup. Their rejection rate dropped significantly within the first week, improving their overall efficiency and profitability. It was a perfect example of how the right blade geometry6 makes all the difference.

And When Is A Non-Free Cutting Blade The Right Choice?

Do your blades break or dull quickly when cutting tough materials? Constant downtime for blade changes can destroy your production schedule and increase your operational costs significantly.

A non-free cutting blade is essential for hard, abrasive, or thick materials. Use it for processing steel coils, thick recycled plastics, or composite materials7. Its robust edge is designed to withstand high impact and pressure, ensuring a longer operational lifespan under heavy loads.

Durability is the primary reason to choose a non-free cutting blade. These blades are the workhorses of heavy industry. When you're cutting materials that fight back, like metal sheeting or fiberglass composites, a delicate, sharp edge won't last. It will chip or break almost instantly. Non-free cutting blades solve this with a stronger edge geometry, often using a smaller or even a negative rake angle. This design increases the amount of material supporting the cutting edge, making it far more resistant to impact and wear. While this approach creates more force and heat, it's a necessary trade-off for blade longevity in demanding applications. The goal here isn't a perfect edge; the goal is to keep the machine running and complete the job.

A Challenge In The Composites Sector

I cooperated with a company in Germany that produces composite panels for industrial use. They were cutting sheets of fiberglass-reinforced plastic. The abrasive nature of the fiberglass was destroying their blades in just a few hours. They were spending a huge amount of time on machine downtime, just for blade changes. This bottleneck was slowing down their entire production line and driving up their labor costs.

The Durable Solution

We analyzed their situation and switched them to a robust non-free cutting blade made from a specialized tungsten carbide. The blade had a reinforced secondary cutting edge, which is a common feature in non-free cutting designs. This small change distributed the cutting stress over a wider, stronger area of the blade. The result was a blade that lasted for days instead of hours. While the initial blade cost was slightly higher, the massive reduction in downtime and replacement frequency saved them a significant amount of money in the long run.

Conclusion

Choosing between free-cutting and non-free cutting is about matching the blade to the material. Getting this right is the key to efficiency, quality, and a longer blade life.

Discover key factors that affect blade life and how to optimize it for better performance. ↩

Explore various cutting methods and their applications in the industrial blade sector. ↩

Discover the ideal blade types for achieving clean cuts on soft materials. ↩

Explore the features that contribute to the durability of industrial blades in tough environments. ↩

Find out which blades are designed for optimal performance on hard materials. ↩

Explore how different blade geometries affect cutting efficiency and quality. ↩

Discover effective cutting techniques for handling composite materials in manufacturing. ↩