Struggling with messy cuts and fast blade wear1? The wrong cutting geometry could be costing you money and causing production issues. A small change can make a big difference.

Right-angle cutting creates precise, 90-degree cuts, which is ideal for dimensional accuracy2. Bevel cutting, also called angled cutting, uses an angled blade for smoother, more efficient slicing. This reduces cutting force3 and extends blade life4. Each method suits different materials and production goals.

Choosing the right method is critical for your success. This choice affects everything from the quality of the cut to how often you need to replace your blades. Let's look closer at these two important cutting methods5 and see when you should use each one. This will help you improve your process.

When Is Right-Angle Cutting The Best Choice For Precision?

Do your products need perfect 90-degree edges? Inaccurate cuts can lead to material waste and product rejection. Right-angle cutting ensures a clean, perpendicular finish every single time.

Use right-angle cutting when geometric precision is your top priority. It is perfect for materials like corrugated cardboard, film, and metal sheets. These applications need exact dimensions and clean, perpendicular edges for the final product's quality and assembly.

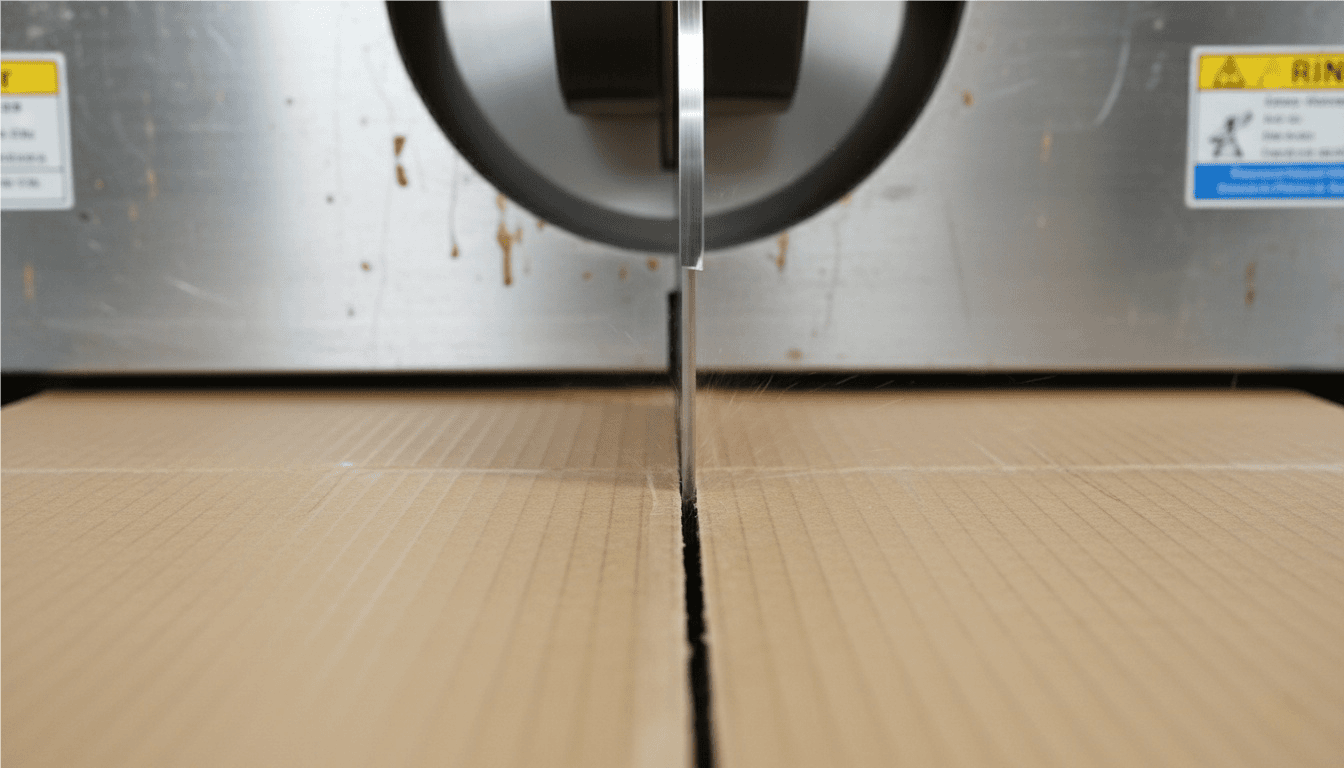

Right-angle cutting, sometimes called 90-degree cutting, is a very direct method. The blade enters the material at a perpendicular angle to the surface. This approach is all about creating straight cuts and exact angles. It is essential for many industries where parts must fit together perfectly. The main benefit is the high level of accuracy. You get smooth, straight edges that meet strict dimensional standards. However, this method has a downside. All the cutting force is focused on the very tip of the blade. This concentration of stress can cause the blade to wear out faster, especially when cutting very hard or very thick materials. The blade tip can chip or dull quickly, which leads to more frequent replacements and machine downtime.

A Case Of German Precision

I remember working with a packaging company in Germany. They manufactured high-end custom boxes and needed perfectly clean edges on their corrugated cardboard. Their old blades were causing fraying and crushing, which made their automated assembly line jam. They came to us at PASSION looking for a solution. I recommended our high-precision tungsten carbide right-angle slitting blades. After they installed them, the results were immediate. They achieved perfectly clean, perpendicular cuts. This small change improved their box assembly process and significantly reduced material waste.

| Right-Angle Cutting | Description |

|---|---|

| Pros | High geometric accuracy, clean 90-degree cuts, simple setup. |

| Cons | High stress on blade tip, faster wear on hard materials, not ideal for high speeds. |

How Does Bevel Cutting Improve Efficiency And Blade Life?

Are your blades wearing out much too quickly? High cutting resistance dulls blades and slows down your production line. Bevel cutting offers a smarter and more efficient solution.

Bevel cutting reduces the cutting force by slicing into the material at an angle. This action leads to a smoother cut, less heat buildup, and better chip removal. The result is improved machine efficiency, longer blade life, and fewer burrs on the final product.

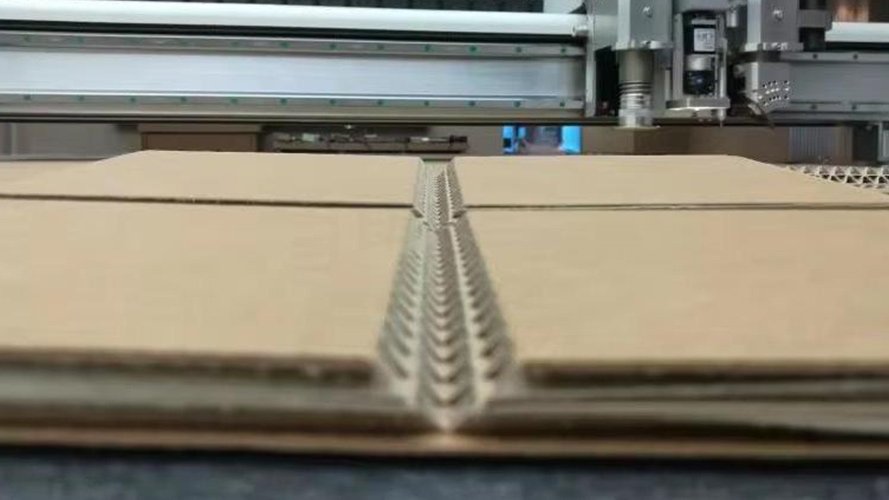

Bevel cutting, or angled cutting, changes how the blade interacts with the material. Instead of a direct, perpendicular impact, the blade enters at an angle. This slicing motion is much more efficient. It distributes the cutting force along the edge of the blade instead of concentrating it on the tip. This simple change has many benefits. The cutting action is smoother, which is ideal for continuous cutting or high-speed machines6. It also helps with heat dissipation and evacuating chips or waste from the cut zone. This process minimizes burrs and prevents chipping on the material's edge. The main challenge with bevel cutting is selecting the correct angle. If the angle is not right for the material, it can cause the cut line to skew or deform the material.

Solving A Tearing Problem In Brazil

A few years ago, a large textile manufacturer in Brazil contacted me. They were having a big problem with fabric tearing during their high-speed slitting process. The material was a delicate synthetic fiber, and the right-angle blades they used were pushing and pulling the threads apart. After discussing their process, I worked with our engineers to design a custom double-bevel blade for them. The angled V-shape allowed the blade to slice cleanly through the fibers instead of tearing them. This change completely eliminated the tearing issue and allowed them to increase their production speed by over 15%.

| Bevel Cutting | Description |

|---|---|

| Pros | Lower cutting resistance, longer blade life, better for high speeds, smoother finish. |

| Cons | Requires precise angle selection, can cause skewed cuts if set up incorrectly. |

How Do You Choose Between Right-Angle And Bevel Cutting?

Are you confused about which cutting method to use for your application? Making the wrong choice can easily damage your material, your blades, and your bottom line.

Your choice depends on your material and your main goal. For strict dimensional accuracy and straight edges, choose right-angle cutting. For high-speed slitting, delicate materials, or extending blade life, bevel cutting is usually the better option. You must analyze your material's properties.

Selecting the correct blade geometry is a critical decision. It is not always obvious which method is best. You need to consider four key factors: the material type, its thickness, the required cut quality, and your production speed. For hard, brittle materials, a bevel cut can prevent chipping. For soft materials, a right-angle cut may prevent deformation. Thicker materials often benefit from the reduced force of a bevel cut. If the final product needs a mirror-like finish, a specific bevel angle might be necessary. But if parts need to fit together perfectly at 90 degrees, right-angle cutting is the only way.

A Cool Solution For An Italian Food Processor

I worked with a food processing client in Italy who was slicing large, frozen blocks of vegetables. They started with right-angle blades, but the impact force on the hard, frozen material caused the blades to chip constantly. This was a major problem for them because of downtime and the risk of contamination. I suggested they switch to one of our tough, shallow-angle bevel blades. The angled edge allowed the blade to slice into the frozen block more gently. This change distributed the cutting force, which nearly eliminated the blade chipping issue. As a bonus, it also resulted in a smoother cut surface on the frozen product.

Decision-Making Guide

| Factor | Choose Right-Angle Cutting When... | Choose Bevel Cutting When... |

|---|---|---|

| Material Type | Stiff or rigid materials (cardboard, thin metal). | Soft, delicate, or hard/brittle materials (textiles, plastics, frozen food). |

| Cut Quality | Perfect 90-degree angles are essential. | A smooth, burr-free finish is the top priority. |

| Blade Life | Cutting soft materials where wear is low. | You need to maximize blade life with hard or abrasive materials. |

| Production Speed | Slower, more controlled processes. | High-speed, continuous slitting or cutting operations. |

Conclusion

Choosing between right-angle and bevel cutting depends entirely on your needs. Right-angle offers precision, while bevel cutting provides efficiency. Understanding both helps you optimize your entire cutting process.

Understand the factors contributing to blade wear and how to mitigate them for better performance. ↩

Discover why dimensional accuracy is crucial for product quality and how it affects production. ↩

Explore the concept of cutting force and its impact on blade wear and material integrity. ↩

Find tips and techniques to maximize blade life and reduce costs in your cutting operations. ↩

Explore various cutting methods and their applications to find the best fit for your needs. ↩

Discover the unique challenges and solutions for cutting with high-speed machinery. ↩