Are your current blades causing production headaches? If you're dealing with rust, material sticking to the blade, or frequent changes, you know how much it hurts your efficiency and product quality.

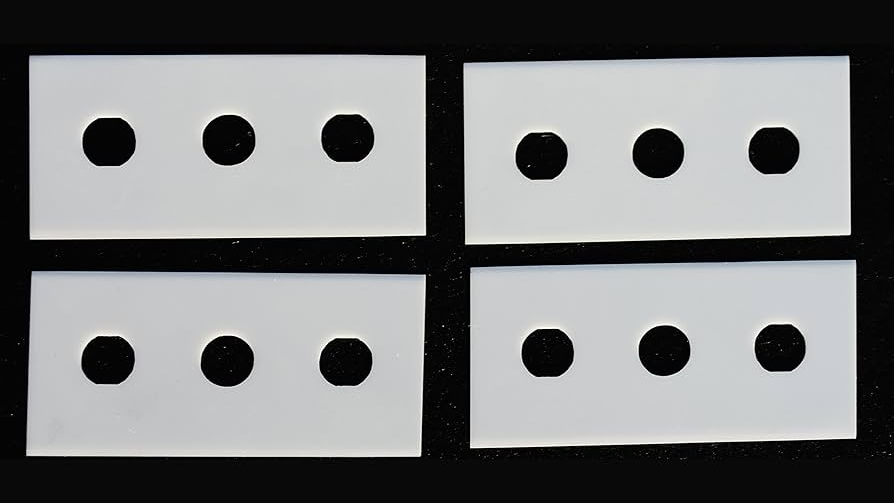

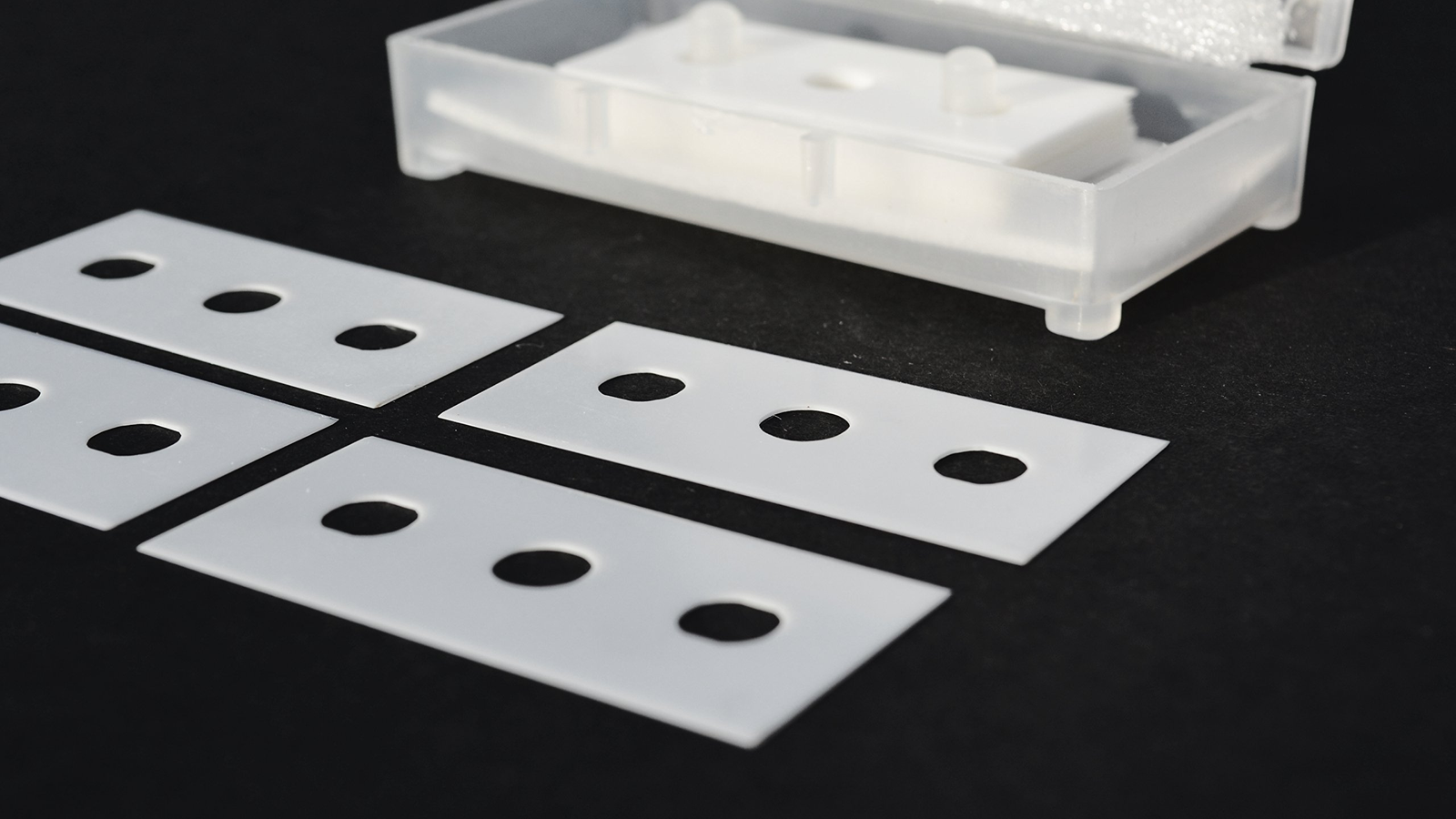

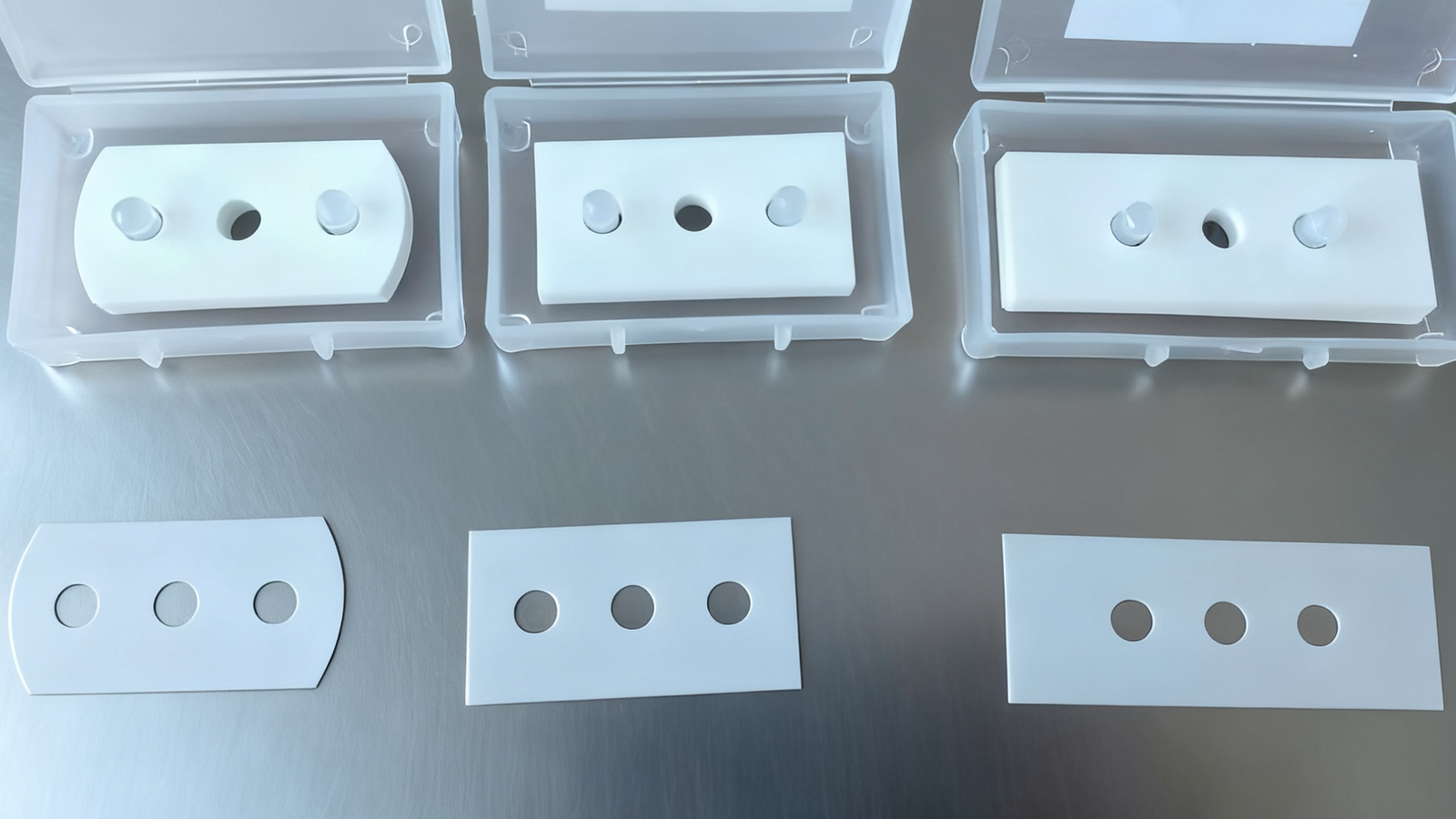

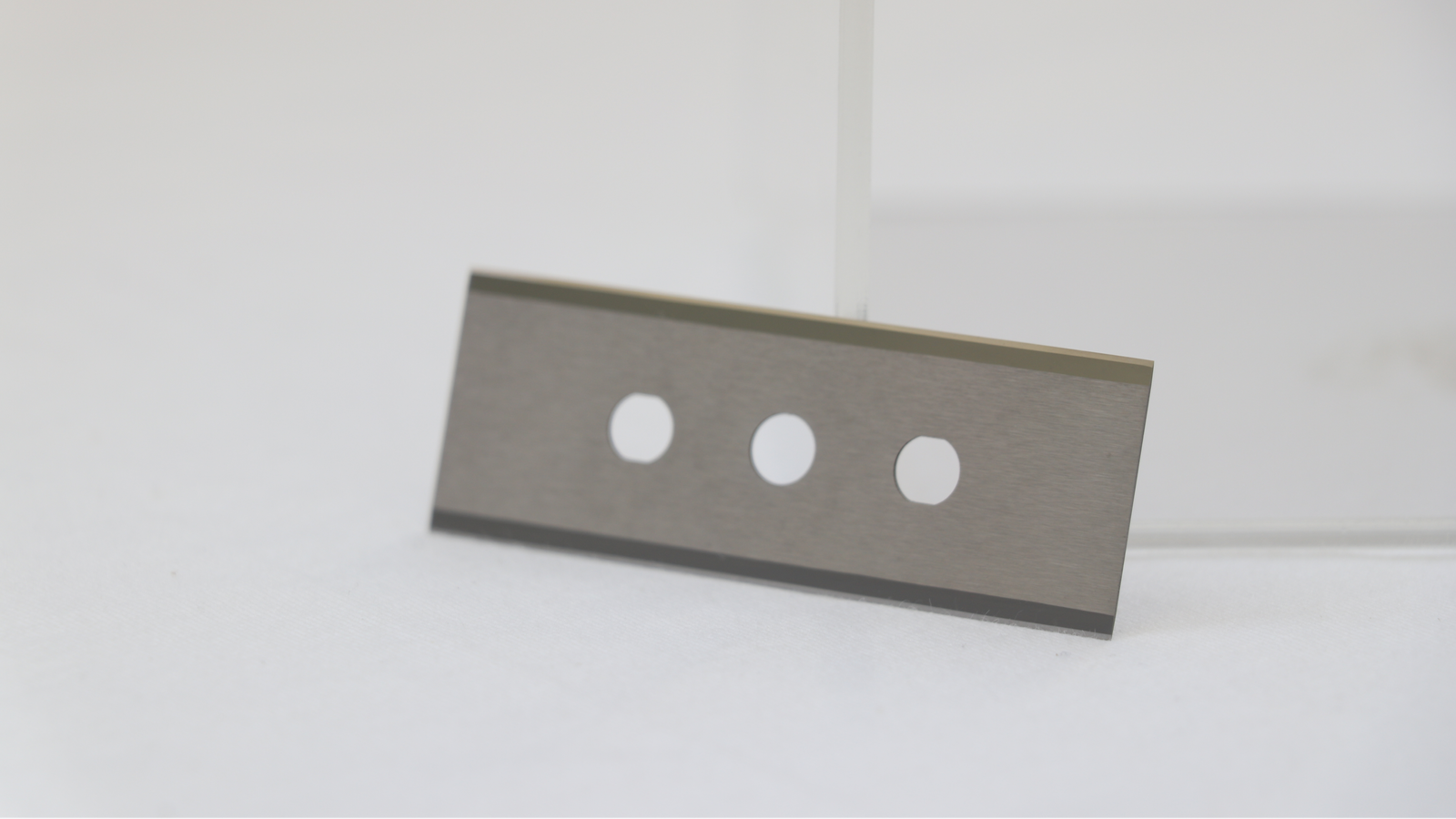

Ceramic three-hole blades1 offer incredible sharpness, wear resistance, and corrosion-free performance2, making them ideal for clean-cutting applications like film and fiber. However, their main disadvantage is brittleness, as they can chip or break under high impact, unlike more forgiving metal blades.

Choosing the right blade is a critical decision. A blade that works perfectly in one factory might cause serious problems in another. It's not just about what a blade can do, but also about what it can't. To find the best fit for your production line, you need to look closely at how different materials perform under your specific conditions. Let’s break down the details so you can make an informed choice.

How Do Ceramic Blades Compare To Metal Blades In Hardness And Wear Resistance?

Are you tired of stopping production to change dull blades? This downtime cuts directly into your output and profits. There is a solution that can keep your machines running much longer.

Ceramic blades are exceptionally hard. This means they maintain their sharp edge for a significantly longer time than steel blades, leading to fewer replacements and better long-term wear resistance in low-impact cutting environments.

When we talk about hardness, we're talking about a blade's ability to resist being worn down. Ceramic blades, typically made from zirconium oxide3 (ZrO₂), are among the hardest materials used for cutting tools. This extreme hardness is the reason they can hold a sharp edge for so long. For example, in film slitting applications, a ceramic blade can often last months, while a standard steel blade might need changing every few days or weeks.

I recently worked with Jason, an engineering supervisor at a medical film factory. His team was constantly replacing their metal blades. After switching to our ceramic three-hole blades, he found that the cutting quality remained stable for a much longer period, and the frequency of maintenance dropped dramatically. This is a direct result of the material's superior hardness.

Here's a simple comparison:

| Material | Hardness (HRA) | Wear Resistance |

|---|---|---|

| Ceramic (Zirconia) | 85 - 92 | Excellent |

| Tungsten Carbide | 88 - 94 | Very Good |

| Stainless Steel | 55 - 65 | Moderate |

| Carbon Steel | 60 - 70 | Good |

This table shows that while tungsten carbide is also very hard, ceramic offers a unique combination of hardness and other benefits that we will explore next.

Why Are Ceramic Blades The Top Choice For Cleanliness And Corrosion Resistance?

Do you worry about rust or material buildup on your blades contaminating your products? In sensitive industries like medical or food processing, this is a major risk that can lead to rejected batches.

Ceramic is chemically inert, so it cannot rust, corrode, or react with acidic substances. Its ultra-smooth, non-metallic surface also prevents materials from sticking, which guarantees an exceptionally clean cut every time. This makes it perfect for high-purity applications.

This was the exact problem Jason faced at his medical film factory. His old metal blades would develop small spots of rust from moisture in the air. Even worse, tiny particles of the film would stick to the blade surface, compromising the cleanliness of the final product. For medical applications, this is simply not acceptable.

When we recommended our ceramic three-hole blades, this problem disappeared. Since ceramic is an oxide, it’s already in its most oxidized state—it physically cannot rust. It's also non-porous and has a very low coefficient of friction. This means materials, like Jason’s medical film, slide right off without sticking. This property is also why ceramic blades are great for cutting sticky tapes or acidic foods. They provide a clean, pure cut that metal blades often can't match.

Here is how the materials stack up:

| Material | Corrosion Resistance | Chemical Inertness | Material Adhesion |

|---|---|---|---|

| Ceramic (Zirconia) | Excellent | Excellent | Very Low |

| Tungsten Carbide | Good | Good | Low |

| Stainless Steel | Good | Moderate | Moderate |

| Carbon Steel | Poor | Poor | High |

For any operation where product purity is the top priority, the chemical stability of ceramic blades makes them the safest and most reliable choice.

Is The Brittleness Of Ceramic Blades A Deal-Breaker For Your Application?

You've heard that ceramic blades are incredibly sharp, but maybe you're worried they will just chip and break. This fear of sudden, unexpected failure might be holding you back from trying them.

Yes, the primary drawback of ceramic is its brittleness. Ceramic blades have low toughness and cannot handle shocks, vibrations, or impacts well. They can easily chip or shatter if they hit a hard contaminant or if the machine is unstable, making them unsuitable for heavy-duty jobs.

It's important to understand the difference between hardness and toughness. A material can be very hard (resists wear) but not very tough (shatters on impact). Think of glass versus a rubber hammer. The glass is harder, but the rubber is tougher. Ceramic blades are like glass in this analogy. They excel in stable, controlled environments where they cut clean materials. However, if you are cutting cardboard that might have hidden staples, or if your slitting machine vibrates excessively, a ceramic blade is a high-risk choice. The shock from hitting a staple could instantly shatter the edge.

This is why, even after Jason was happy with the performance of our ceramic blades, we made sure to give him a clear warning. I told him, "These blades are perfect for your film, but remember they are brittle. Make sure your machine operators avoid any impact during setup and that the material you are cutting is free of hard impurities." This honesty is crucial.

Here’s a guide to help you decide:

| Material | Toughness (Impact Resistance) | Best For | Avoid |

|---|---|---|---|

| Ceramic (Zirconia) | Low | Thin film, fiber, paper, foil | Heavy impact, vibration, metal contaminants |

| Tungsten Carbide | Medium | Abrasive materials, corrugated board | Extreme shock loads |

| Stainless Steel | High | Humid environments, food processing | Highly abrasive materials |

| Carbon Steel | Very High | General purpose, high impact | Corrosive environments |

The success of a ceramic blade depends entirely on using it in the right scenario.

Conclusion

Ceramic blades offer unmatched sharpness and cleanliness for precise, low-impact tasks. Yet, their brittleness is a real limitation. The best blade choice always depends on balancing these factors for your specific needs.