Are dull blades causing poor cuts and slowing down your production? This inefficiency increases waste and puts unnecessary strain on your valuable equipment, a problem I see all too often.

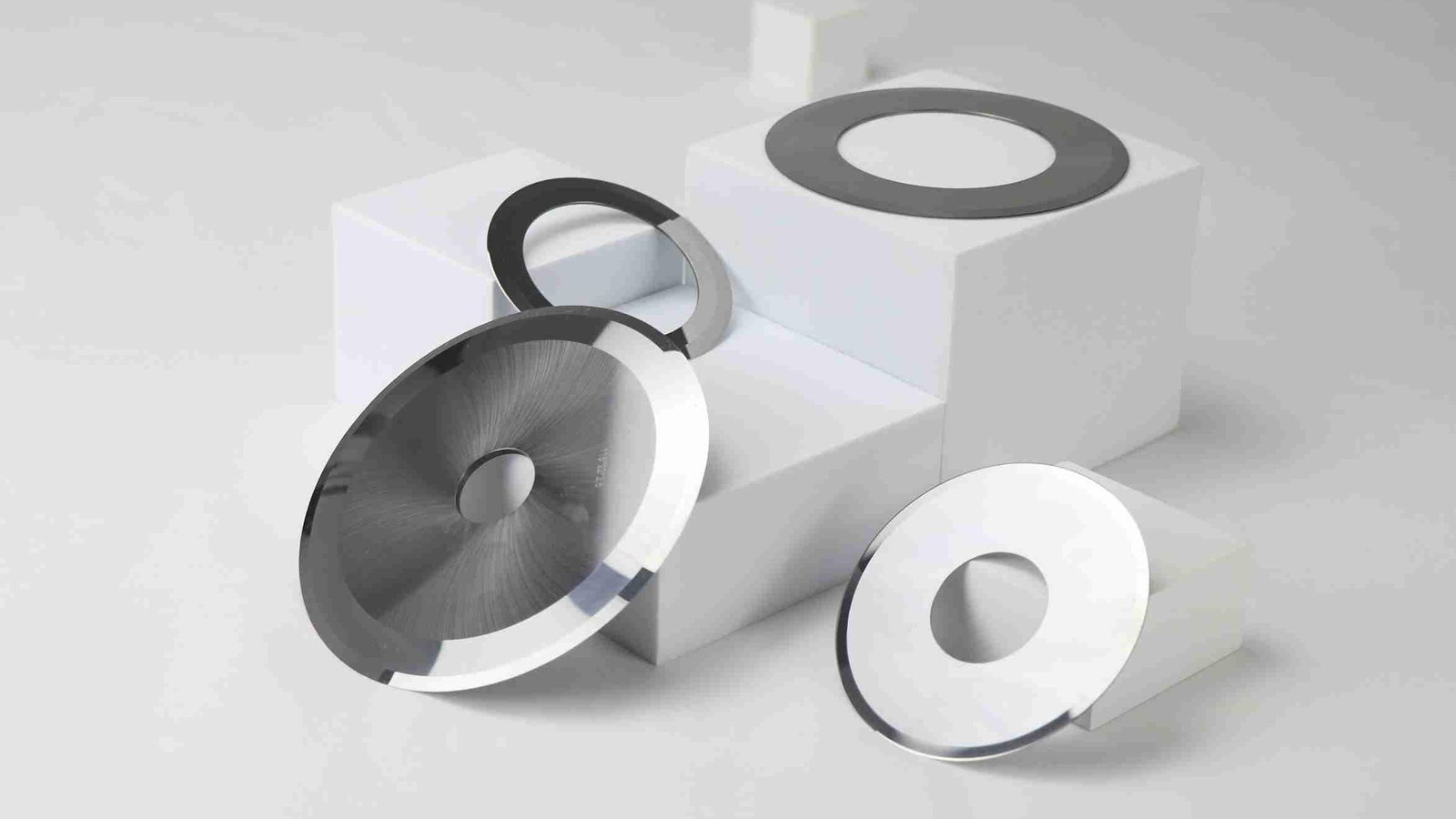

Regularly sharpening your tungsten carbide blades1 maintains a sharp cutting edge2 for high-quality results, reduces equipment load, and lowers energy use. It also boosts production efficiency, extends the blade's total lifespan, and significantly cuts down on long-term replacement costs, maximizing your investment.

The benefits are clear, but how do these advantages translate to your daily operations? Let's explore the specific ways sharpening can improve your process, one blade at a time.

How Does Blade Sharpness Directly Impact Your Cut Quality?

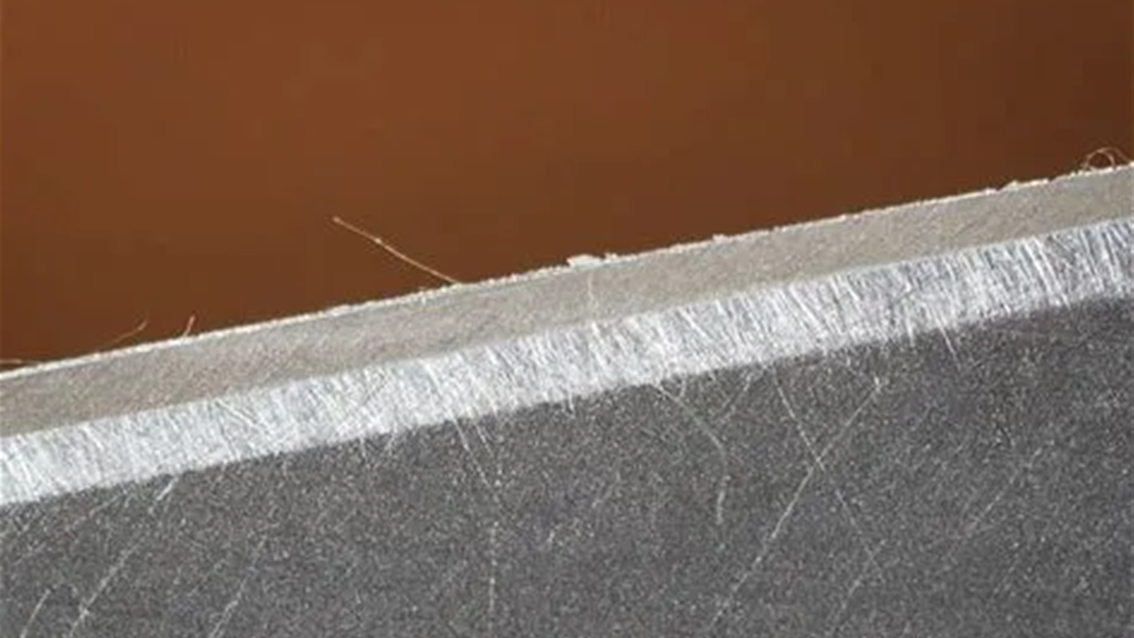

Are you tired of seeing frustrating burrs and rough edges on your finished products? These small flaws lead to material waste, potential customer complaints, and costly secondary processing3. Maintaining a perfectly sharp blade edge is the key to achieving a flawless cut every single time.

A sharp blade ensures clean, smooth cuts without any burrs or tearing. This directly improves the final product's appearance and structural integrity, reduces material waste, and often eliminates the need for any secondary finishing processes, saving you both time and money.

Tungsten carbide is an incredibly hard and durable material. However, even the toughest blades will develop microscopic wear after thousands of cuts. This tiny amount of dulling is what causes problems. I remember a client, David, a procurement manager at a packaging factory in the United States. He called me because his machine was leaving ragged edges on the plastic film he was cutting. The poor quality was hurting his output. We discovered his tungsten carbide blades were simply dull from extended use. After I told him to sharpen the knife, the problem vanished. The cuts were perfectly clean, and the final product looked great. His experience is a perfect example of how vital sharpness is.

The Anatomy of a Bad Cut

The difference a sharp blade makes is easy to see. It’s not just about aesthetics; it’s about performance.

| Feature | Sharp Blade | Dull Blade |

|---|---|---|

| Cut Edge | Smooth, Clean | Rough, Burred |

| Material Waste | Minimal | Increased |

| Finishing Steps | None Needed | Requires Rework |

| Product Integrity | High | Compromised |

Can Sharpening Blades Really Reduce Your Operational Costs?

Are rising energy bills and frequent machine repairs eating into your profits? A dull blade forces your equipment to work much harder for every single cut, causing excessive wear and consuming more power. Sharpening your blades is a simple, highly effective way to reduce machine strain4 and protect your bottom line.

Yes, absolutely. A sharpened blade cuts with less resistance, which lowers the load on your machine's motors and mechanical parts. This directly reduces energy consumption and minimizes wear and tear, leading to fewer breakdowns, longer equipment life, and significant long-term savings.

Think about cutting a vegetable with a dull knife versus a sharp one. With the dull knife, you have to push down with a lot of force. A sharp knife glides right through. Your industrial machinery experiences the same thing. A dull blade creates more friction and requires more force to make the cut. This extra force puts a huge strain on motors, bearings, and gears. Over time, this leads to premature part failure and expensive repairs. By keeping your blades sharp, you allow the machine to operate smoothly and effortlessly. More importantly, proper sharpening allows a single tungsten carbide blade to be reused many times. This is far more affordable than buying a new blade every time one gets dull.

Breaking Down the Cost Savings

The return on investment from regular sharpening is clear when you look at the numbers. It impacts multiple areas of your budget.

- Lower Energy Bills: A motor that isn't straining uses less electricity. This small daily saving adds up to a large amount over the year.

- Reduced Maintenance Costs: Less stress on machine components means fewer breakdowns and a smaller budget for replacement parts.

- Extended Blade Life: Re-sharpening costs a fraction of a new blade. You can extend a blade's service life multiple times, saving thousands.

- Longer Machine Lifespan: A machine that runs smoothly will last years longer, delaying major capital expenditures.

How Does A Sharp Blade Boost Production Efficiency And Stability?

Is unexpected downtime for blade changes constantly disrupting your production schedule? These frequent, unplanned stops kill your line's momentum, create bottlenecks, and make it nearly impossible to meet your output targets. A consistently sharp blade runs longer and faster, creating a stable and predictable workflow.

A sharp blade cuts faster and with greater precision, allowing you to run your machines at their optimal speed. It also dramatically reduces unplanned downtime5 for blade swaps. This creates a more stable, continuous production line, higher throughput, and predictable, reliable output.

Efficiency isn't just about speed; it's about consistency. A sharp blade allows a machine to run at its highest rated speed while maintaining perfect cut quality. When a blade starts to dull, operators often have to slow the machine down to avoid producing bad parts. This immediately hurts your total output. Even worse is when a blade fails unexpectedly, forcing the entire line to stop. This is where planned maintenance makes all the difference. When my client David got his blades sharpened, he told me something amazing. His overall production efficiency increased by 30%. That massive gain wasn't just from better cuts. It was because his machines were running smoothly for longer stretches, without the constant stop-starts he was dealing with before. That is the kind of stability that every production manager dreams of.

From Unplanned Stops To Stable Output

Shifting from a reactive to a proactive maintenance schedule for your blades completely changes your operational dynamic.

- With Dull Blades: You experience frequent, unplanned stops, inconsistent production speeds, and a constant risk of missing deadlines.

- With Sharpened Blades: You operate with planned, minimal downtime, maintain consistent high speeds, and can confidently rely on your production forecasts. This stability is essential for modern manufacturing.

Conclusion

Regularly sharpening your tungsten carbide blades improves cut quality, boosts efficiency, and cuts costs. It’s a vital maintenance step for maximizing performance and protecting your investment in machinery.

Explore the advantages of tungsten carbide blades for durability and performance in various cutting applications. ↩

Learn how maintaining a sharp cutting edge can enhance your production efficiency and reduce waste. ↩

Gain insights into secondary processing and its significance in achieving high-quality finished products. ↩

Understand the impact of machine strain on production costs and how to mitigate it for better profitability. ↩

Explore strategies to minimize unplanned downtime and maintain a smooth production flow. ↩