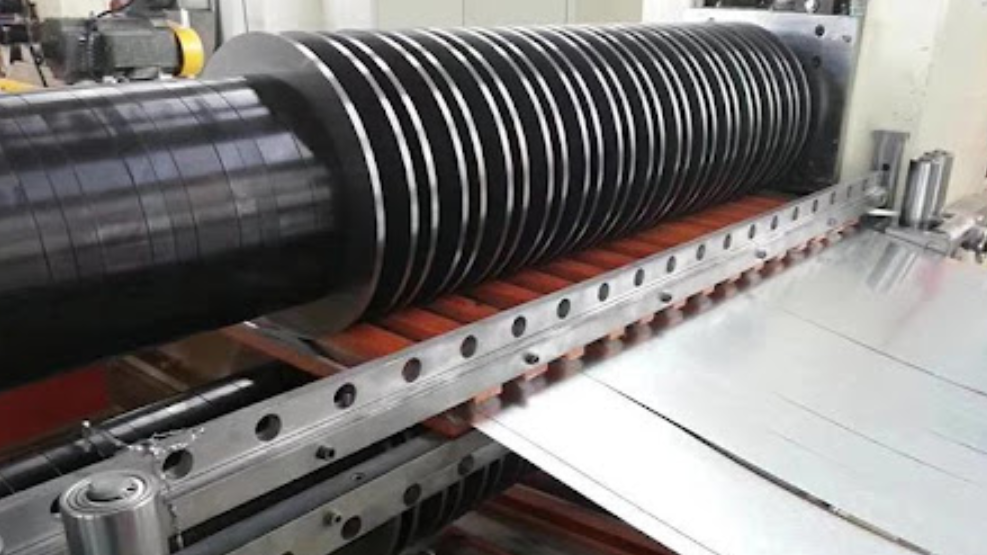

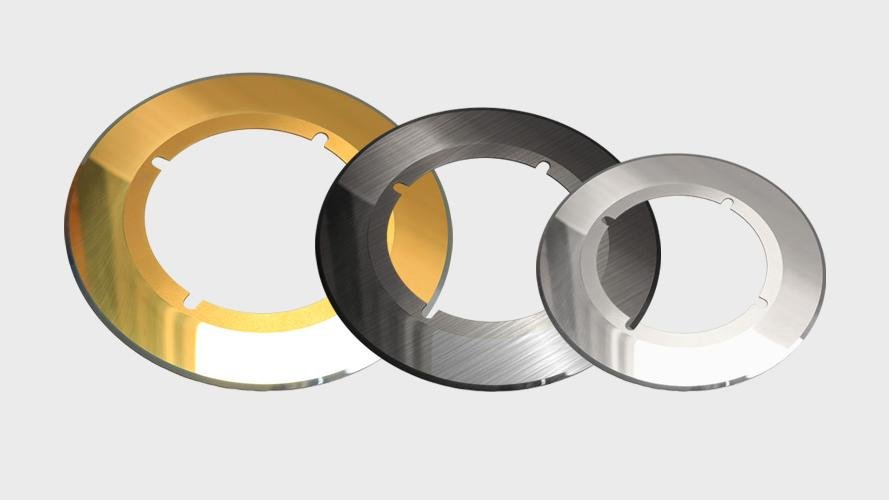

Facing rapid blade wear in demanding operations? This leads to expensive downtime and poor results. A TiN+Al₂O₃+TiCN1composite coating2 offers a powerful solution for superior blade performance.

This composite coating significantly boosts blade performance. It combines the toughness and adhesion of TiN3, the extreme heat resistance of Al₂O₃4, and the superior wear resistance of TiCN5. This combination results in longer blade life, better cut quality, and higher efficiency, especially in high-speed applications.

This multi-layer technology might seem complex, but its benefits are very clear. It’s not just a surface treatment; it's a strategic enhancement. Let's break down how each layer works to deliver such powerful performance. Understanding this structure will help you decide if this advanced coating is the right choice for your specific cutting needs and help you get the most out of your tools.

How Does The TiN Layer Enhance Blade Adhesion And Durability?

Worried your blade coating will chip or peel off? This kind of failure makes the blade useless and wastes your money. The TiN layer acts as a super-strong base, ensuring the entire coating stays put.

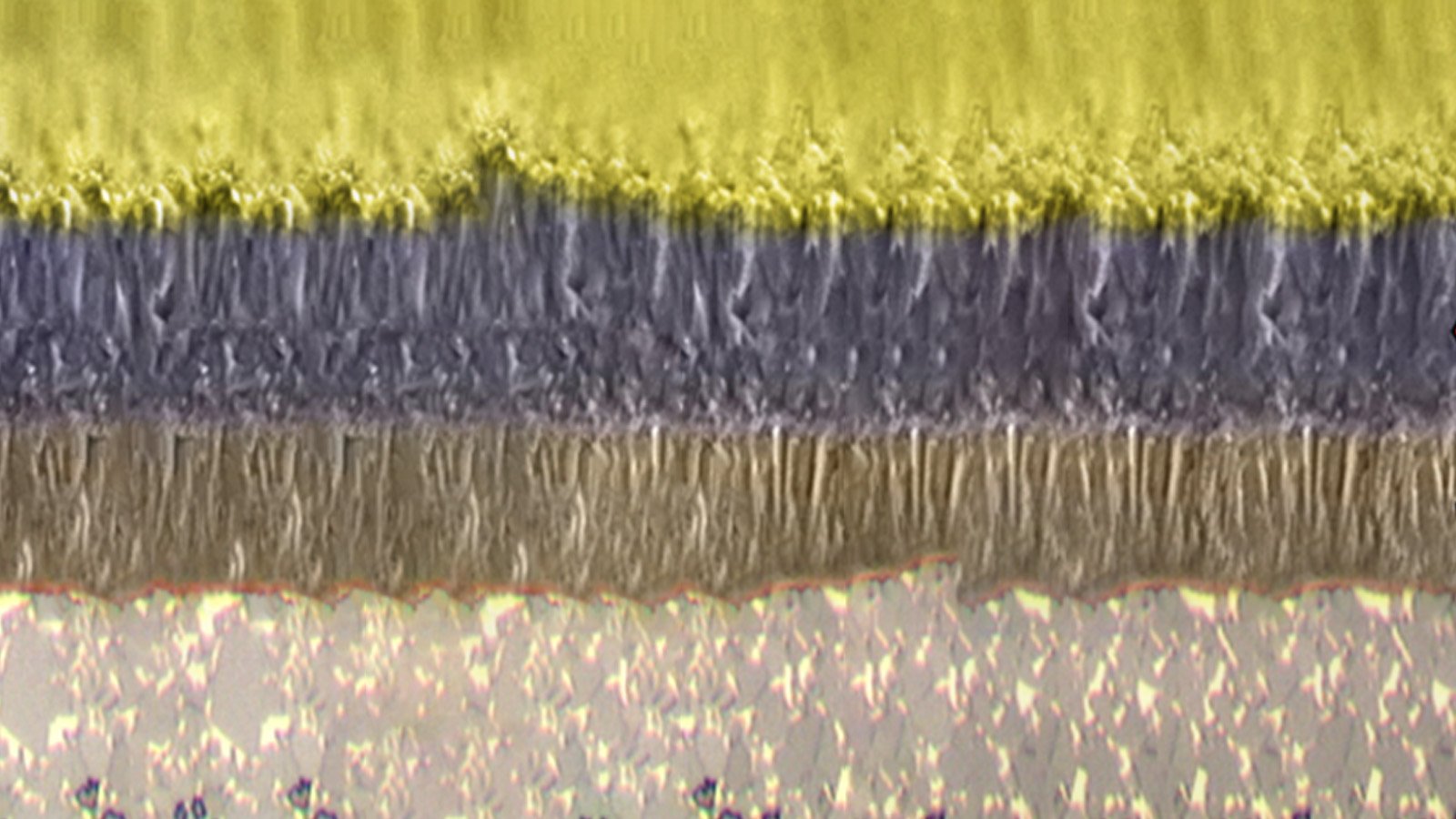

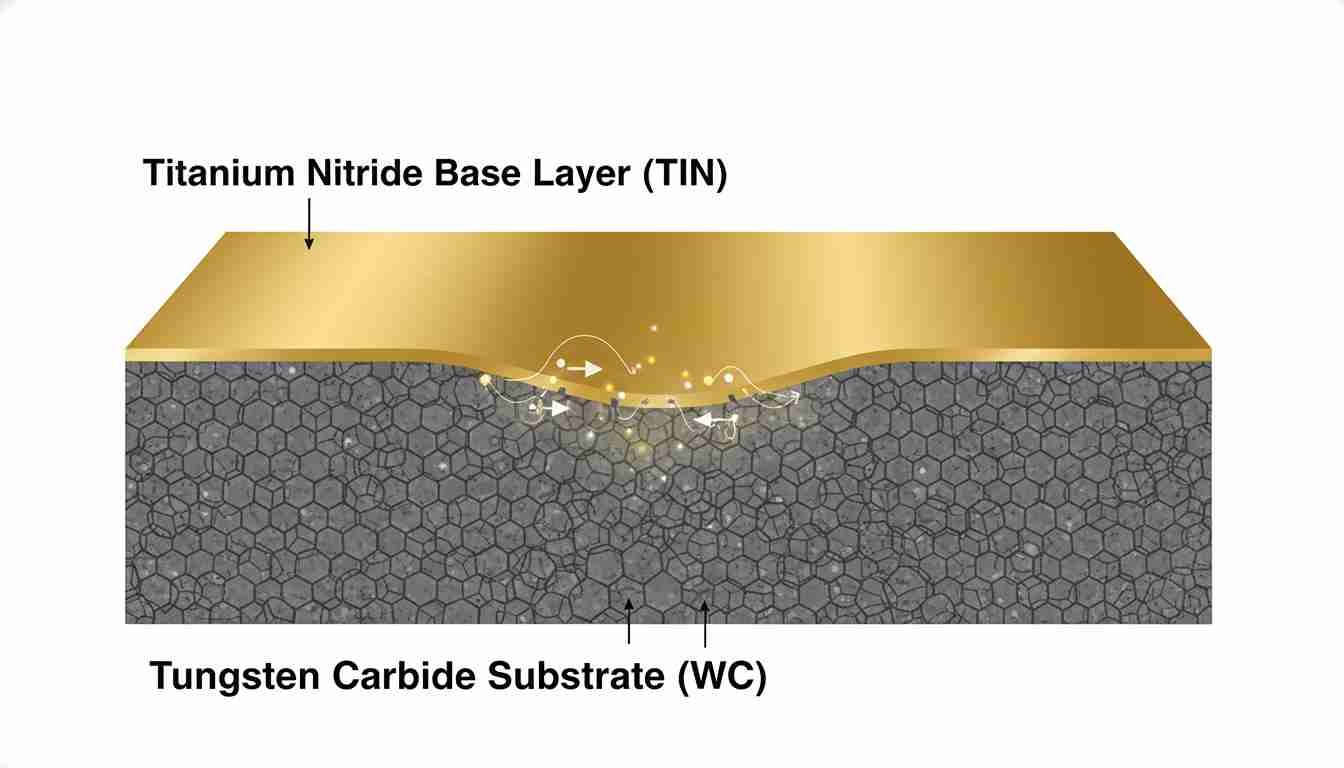

The TiN (Titanium Nitride) layer is the foundation. It bonds exceptionally well with the tungsten carbide substrate, which prevents peeling. Its good toughness also helps absorb cutting stress6. This creates a stable and durable base for the other layers, ensuring the whole coating system works effectively.

I often explain the TiN layer to my clients as the "primer" for the blade. Just like you prime a wall before painting, TiN prepares the tungsten carbide for the other high-performance layers. A client in the automotive parts industry from Germany, was struggling with coating delamination7 on his blades when cutting steel components. The stress was just too high. When we switched him to our blades with a TiN+Al₂O₃+TiCN coating, the problem disappeared. The TiN base layer provided the toughness and adhesion needed to withstand the cutting forces. Additionally, TiN offers other key benefits depending on where it is in the coating structure. For example, its gold color is a great visual indicator for wear, making it easy to see when a blade needs changing.

Key Functions Of The TiN Layer

| Position | Primary Function | Key Benefit |

|---|---|---|

| Base Layer | Excellent Adhesion & Toughness | Prevents the coating from chipping or peeling. |

| Top Layer | Low Friction & Wear Indicator | Reduces material buildup and easily shows wear. |

Why Is Al₂O₃ The Key To Heat Resistance In High-Speed Cutting?

Is intense heat from high-speed cutting destroying your blades? This heat softens the cutting edge, which causes rapid failure and poor cuts. The Al₂O₃ layer provides an essential thermal barrier8, protecting your blade.

Al₂O₃ (Aluminum Oxide) has exceptional thermal stability. It acts as a powerful insulator, preventing heat from getting to the blade's core. This is crucial for keeping the edge hard and performing well during high-speed, dry, or semi-dry machining, which extends the tool's life under extreme temperatures.

Think of the Al₂O₃ layer as the blade's personal heat shield. In modern manufacturing, everyone wants to cut faster to increase output, but higher speed means more heat. This is especially true in dry machining, where there's no coolant to carry the heat away. I remember working with a customer in the paper industry, Maria from Mexico, who was having issues with rapid wear on blades used for high-speed perforation. The heat was just too much. By introducing our blades with an Al₂O₃ core layer, we created that thermal barrier. The layer remained chemically stable at high temperatures and shielded the carbide substrate. This simple change allowed her to keep her high cutting speeds without the constant blade changes and production stops. It's a game-changer for high-temperature applications.

Al₂O₃'s Role In High-Temperature Cutting

| Machining Condition | Challenge | Al₂O₃ Solution |

|---|---|---|

| High-Speed Cutting | Extreme heat generation | Provides a thermal barrier to maintain edge hardness. |

| Dry/Semi-Dry Machining | Lack of coolant | Stays stable and protective without coolant. |

| Continuous Operation | Thermal fatigue | Resists breakdown from constant heating and cooling cycles. |

What Makes TiCN The Ultimate Defense Against Abrasive Wear?

Do abrasive materials wear down your blades almost instantly? This means constant replacements and poor cut quality for your products. The TiCN layer adds an extremely hard surface that effectively resists this abrasive wear.

TiCN (Titanium Carbonitride) is much harder than TiN. This high hardness makes it extremely resistant to abrasive wear, which is caused by hard particles in the material being cut. It acts as a protective shield for the cutting edge, keeping it sharp and extending its life.

The TiCN layer is the "armor plating" of the coating. Imagine cutting a material like cast iron. It often has tiny, hard particles or a rough outer skin from the casting process. These particles act like sandpaper on the cutting edge, causing what we call abrasive wear. I worked with a client, David, who runs a foundry in the USA. His blades were failing very quickly when machining cast iron parts. We recommended blades with the composite coating, and we specifically highlighted the TiCN layer. Its superior hardness gave him the protection he needed against those abrasive particles. The result was a big increase in tool life and a more consistent finish on his parts. It is the perfect layer to handle tough, dirty materials that would chew through lesser coatings.

Hardness Comparison Of Coating Materials

| Coating Material | Typical Hardness (HV) | Primary Advantage |

|---|---|---|

| TiN | ~2300 | Good all-rounder, excellent adhesion. |

| TiCN | ~3000 | Superior hardness, high abrasive wear resistance. |

| Al₂O₃ | ~2800 | Excellent thermal and chemical stability. |

Conclusion

In short, this composite coating combines toughness, heat resistance, and hardness. This unique synergy delivers longer blade life, better performance, and greater value for your demanding cutting operations.

Explore how this advanced coating can enhance blade performance and longevity in demanding applications. ↩

Explore the benefits of composite coatings and how they can enhance tool performance in various applications. ↩

Learn about the critical functions of TiN in coatings and how it contributes to tool durability. ↩

Understand the significance of Al₂O₃ in maintaining blade integrity under high-temperature conditions. ↩

Find out how TiCN protects cutting edges from abrasive wear and extends tool life. ↩

Discover the relationship between cutting stress and tool durability, and how to manage it. ↩

Understand the issues surrounding coating delamination and how to prevent it for better tool performance. ↩

Explore the importance of thermal barriers in maintaining tool performance during high-speed operations. ↩