Struggling with poor surface finish1es and rapid blade dulling2? Built-Up Edge (BUE) is a silent production killer. Understanding its causes is the first step to a solution.

Built-Up Edge (BUE) happens under high pressure and temperature3, creating an unwanted layer of material that alters the blade's geometry. This leads to poor performance and increased wear4.

It seems like a small issue, but its impact on production can be huge. To really fix the problem, you first need to understand exactly what it is and how to spot it. Let’s break it down so you can identify and solve it in your own operations.

What Is Bue In Machining?

Confused about what Built-Up Edge actually is? This unclear term describes a very real problem. I'll explain it simply so you can spot it immediately.

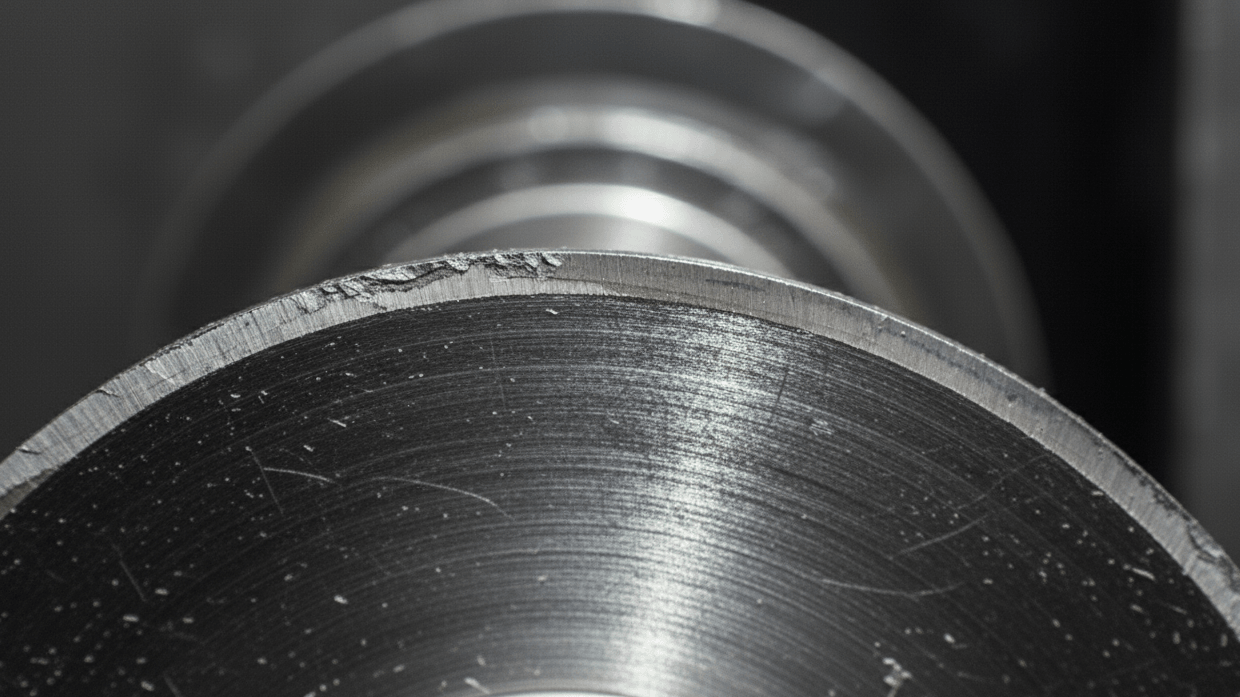

BUE is when workpiece material5 welds onto the industrial blade's cutting edge during machining. This happens due to intense friction and heat6, creating a new, unstable cutting surface. It's essentially unwanted material "welded" right where you need a clean, sharp edge.

Imagine you are cutting a soft, sticky material. The intense pressure and friction at the blade tip generate a lot of heat. This heat can be enough to weld a tiny particle of the material you are cutting directly onto the blade. As the cutting continues, more particles pile on top of the first one, forming a "built-up" edge. This new edge is not part of your precision-engineered blade. It is unstable and rough. I once worked with a client in Italy in the food processing industry who was cutting large blocks of cheese. They noticed a residue building up on their blades. At first, they thought it was just poor cleaning. I explained that this was a classic case of BUE. The material wasn't just stuck; it was bonded to the blade edge. This changed the blade's effective shape and made the cuts less precise.

Stages Of BUE Formation

| Stage | Description |

|---|---|

| Stage 1: Initial Adhesion | Microscopic particles of the workpiece material stick to the blade edge due to high pressure and friction. |

| Stage 2: Growth | More material layers build upon the initial adhered particles, growing in size and hardening under heat. |

| Stage 3: Fracture | The BUE becomes unstable and breaks off, sometimes taking a piece of the blade's edge with it. |

What Causes Built-Up Edge?

Do you know why BUE happens? It's not just bad luck. Specific conditions cause it. Let’s pinpoint the main triggers so you can avoid them.

The main causes of BUE are low cutting speeds, high friction between the blade and material, and using blades on "gummy" materials like aluminum or soft steel. Improper blade geometry7 and insufficient coolant8 also contribute significantly by increasing heat and adhesion.

Several factors can create the perfect environment for BUE. One of the biggest culprits is low cutting speed. When the blade moves slowly, there is more time for heat and pressure to build, which encourages material to weld to the edge. The material itself is another major factor. Soft, ductile, or "gummy" materials are much more likely to form a BUE. Their material was also naturally prone to sticking. This combination of the material's properties, the low cutting speed, and a standard blade geometry created a perfect storm for BUE. We had to look at all these factors together to find a solution.

Key BUE Triggers

| Cause | How It Contributes to BUE |

|---|---|

| Low Cutting Speed | Increases contact time, allowing heat to build up and promote material adhesion. |

| Ductile Materials | Materials like soft aluminum, copper, and certain plastics are naturally "sticky" under pressure. |

| Incorrect Blade Geometry | A low rake angle or a dull edge can increase friction and plowing action instead of clean cutting. |

| Inadequate Coolant | Lack of proper lubrication and cooling fails to reduce friction and carry away heat from the cutting zone. |

How Does Built-Up Edge Affect Cutting Blades And Production Efficiency?

Is BUE just a minor annoyance? Far from it. This problem directly harms your blades and slows production. Let me show you the real costs.

BUE severely impacts production. It alters the blade's shape, leading to increased cutting forces, poor surface finish, and inaccurate dimensions. This causes accelerated blade wear and can even lead to sudden blade fracture when the BUE breaks off.

The effects of BUE go far beyond just a messy-looking blade. Because the BUE changes the geometry of your cutting tool, it is no longer the sharp, precise blade you installed. This new, blunt edge requires much more force to push through the material. This extra force puts a huge strain on your blade, causing it to wear down much faster. It also affects the quality of your product. The surface finish will be rough and torn instead of smooth. I worked with a textile company in Vietnam that was cutting synthetic fabrics. They reported their blades were dulling incredibly fast and leaving frayed edges. When we looked at their blades, we found a clear BUE. The built-up material created a blunt edge, which increased the cutting force and caused rapid wear. Even worse, when bits of the BUE broke off, they would sometimes take a piece of the blade's edge with them, causing chipping. Their efficiency dropped because they had to change blades far too often and scrap poor-quality material.

Negative Impacts Of BUE

- Poor Surface Quality: Creates rough, torn, or uneven surfaces on the cut material.

- Increased Blade Wear: The blade's edge dulls, chips, or fractures much more quickly.

- Higher Power Consumption: The machine needs more energy to make the cut due to increased resistance.

- Dimensional Inaccuracy: The final parts do not meet the required size or shape specifications.

What Solutions Exist For Bue?

Tired of dealing with BUE? There is good news. You can prevent it. I'll share proven strategies to keep your cutting edges clean and sharp.

To prevent BUE, focus on four areas. Optimize cutting parameters9 by increasing speed. Select the right blade geometry with sharp edges. Use coated blades10 for lower friction. Ensure proper application of coolant to reduce heat and lubricate the cut.

You do not have to accept BUE as a normal part of your process. The solution is usually a combination of adjustments. A paper converting client in Germany was struggling with BUE when cutting coated paper stock. The sticky coating would build up on their slitter blades. Their first instinct was to slow the machine down, but that just made the problem worse. I recommended a multi-step solution. First, switching them to one of blades with a special low-friction coating. This made it much harder for the coating to stick. Second, we advised them to increase their cutting speed. This might seem counterintuitive, but a faster cut reduces contact time and heat buildup. Finally, we recommended a blade with a higher rake angle to create a cleaner shearing action. This combination completely eliminated the BUE, improved cut quality, and let them run their machines faster than before, a huge win for their production output.

BUE Prevention Strategies

| Strategy | Benefit |

|---|---|

| Increase Cutting Speed | Reduces the time for material to adhere to the blade edge. |

| Use Coated Blades | Coatings like TiN or DLC reduce surface friction and prevent material from welding to the blade. |

| Optimize Blade Geometry | A sharp edge and a high positive rake angle promote clean shearing and reduce cutting forces. |

| Apply Proper Coolant | Coolant flushes away chips, reduces temperature at the cutting zone, and provides lubrication. |

Conclusion

Built-Up Edge is a serious but solvable issue. By understanding its causes and applying the right blade and cutting parameters, you can ensure clean cuts and maximum efficiency.

Explore techniques to achieve a better surface finish and enhance product quality. ↩

Identifying causes of blade dulling can lead to better maintenance and tool longevity. ↩

Understanding these factors can help optimize machining conditions for better results. ↩

Discover strategies to reduce blade wear and extend tool life in machining. ↩

Explore how different materials impact machining processes and the formation of BUE. ↩

Learn about the relationship between friction, heat, and machining efficiency. ↩

Understanding blade geometry is key to optimizing cutting efficiency and quality. ↩

Proper coolant application is essential for reducing heat and improving cutting performance. ↩

Optimizing cutting parameters is crucial for enhancing efficiency and reducing BUE. ↩

Coated blades can significantly reduce friction and improve cutting performance. ↩