Are your metal blades failing you? Constant wear and rust create downtime and waste. Ceramic blades offer superior sharpness and cleanliness, solving these persistent issues.

Ceramic cutting blades are known for extreme hardness1, wear resistance2, and chemical stability3. They excel in high-precision, low-load applications like film slitting, fiber cutting, and food processing, where their sharpness and non-reactive properties are essential for quality and efficiency.

So, you see that ceramic blades have some amazing qualities. But what does that mean for your specific industry? The real value is in understanding where their unique strengths shine and where their weaknesses might be a problem. Over the years, I've helped many clients navigate this choice. Let’s look at some real-world examples to understand their practical benefits and limitations.

Why Are Ceramic Blades Ideal For Cutting Thin Films And Foils?

Tired of replacing blades when cutting films? Frequent stops for changes kill your efficiency and product quality suffers. Ceramic blades maintain their edge for longer, ensuring consistent, clean cuts.

Ceramic blades are ideal for films and foils because their extreme hardness prevents the microscopic wear that abrasive materials cause. This sustained sharpness ensures clean, burr4-free cuts, reduces dust, and extends production runs, dramatically improving overall efficiency and product quality.

Ceramic blades, often made from zirconia, are significantly harder than even the toughest steel. When you're slitting thin, abrasive materials like BOPP or PET films, a steel blade edge quickly erodes. This leads to ragged edges and dust contamination. A ceramic blade resists this wear, holding its sharp edge for a much longer time. This means fewer blade changes and more consistent product quality. I remember working with a packaging company in Germany. They were changing their steel blades three times a day. After switching to our ceramic blades, they only needed to change them once every two weeks. This simple change drastically reduced their downtime and improved their cutting precision.

Material Hardness Comparison

| Material | Hardness (Mohs Scale) | Key Benefit |

|---|---|---|

| Ceramic (Zirconia) | ~8.5 | Extreme wear resistance |

| High-Speed Steel | ~6.5 | Good toughness |

| Carbon Steel | ~4.5 | Low cost, general use |

How Does Chemical Stability Make Ceramic Blades Perfect For Food And Medical Industries?

Concerned about rust or contamination from metal blades? This can ruin sensitive products like food and medical supplies. Ceramic blades are chemically stable, ensuring a pure, safe cut.

Ceramic's chemical stability3 means it won't rust, corrode, or react with acids or salts. This makes it perfect for food processing and medical applications, where preventing contamination is critical. You get a clean cut every time, without transferring any metallic taste or residue.

Unlike metal, ceramic material is like glass. It doesn't react with its environment. Steel blades, even stainless steel, can corrode when exposed to salts, acids, or cleaning agents. This creates risks of contamination. Ceramic blades are non-porous and chemically inert. They simply don't rust. This is a huge advantage in industries with strict hygiene standards. A client of mine in Brazil processes fruits. The high acidity of the fruit was causing their steel blades to corrode quickly, affecting the taste and requiring constant sanitization. We supplied them with our zirconia blades. The corrosion problem disappeared completely. Their cleaning process became simpler, and product quality improved significantly.

Blade Properties For Sensitive Applications

| Property | Ceramic Blades | Stainless Steel Blades |

|---|---|---|

| Rust/Corrosion | Immune | Resistant, but can corrode |

| Chemical Reactivity | Inert | Low, but can react with acids |

| Hygiene | Easy to clean, non-porous | Can develop micro-pitting |

When Is High-Temperature Resistance A Key Advantage For Ceramic Blades?

Are your blades failing during high-speed cutting? The intense heat softens the metal, causing the edge to dull quickly. Ceramic blades stay hard and sharp even above 800°C.

Ceramic's high-temperature resistance is crucial in applications creating significant friction and heat, like cutting fiberglass or composites. While metal blades soften and lose their edge, ceramic blades maintain their structural integrity and cutting performance, ensuring reliability in thermally demanding environments.

Metal blades have a "tempering" temperature. If you heat them beyond that point, they lose their hardness permanently. This can happen easily in high-speed cutting operations due to friction. Ceramic blades are different. They are created in a furnace at temperatures well over 1000°C. So, a cutting temperature of 800°C doesn't affect their properties at all. I worked with an automotive supplier in Mexico that manufactured parts from fiber composites. The cutting process generated so much heat that their HSS blades would fail within hours. By switching to ceramic blades, they could run their machines faster and for longer periods without the blades losing their cutting edge. This improved their throughput substantially.

Performance At High Temperatures

| Material | Max Operating Temp (Approx.) | Performance Result |

|---|---|---|

| Ceramic (Zirconia) | >800°C | Retains hardness and sharpness |

| High-Speed Steel | ~600°C | Softens, loses edge |

| Cemented Carbide | ~700°C | Good, but can oxidize |

What Are The Main Limitations Of Ceramic Blades You Should Know?

Ready to switch all your blades to ceramic? Be careful. Using them for high-impact jobs can lead to shattering and failure. Knowing their limits is crucial for success.

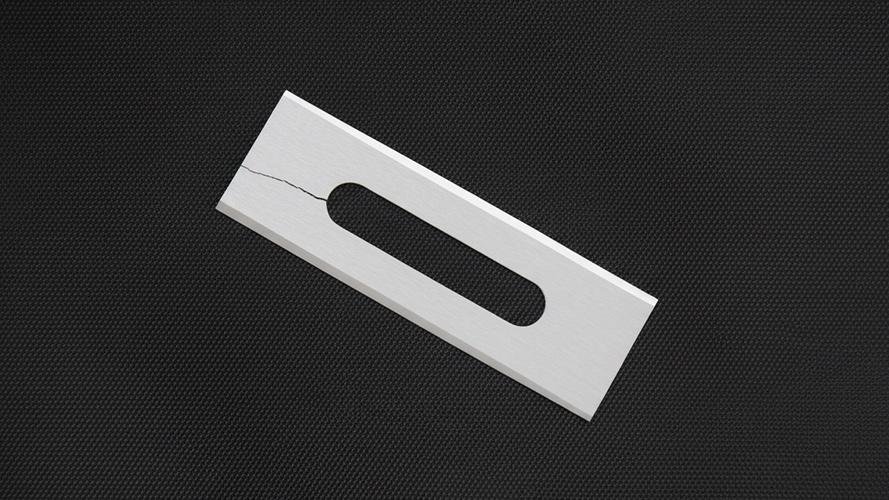

The primary limitation of ceramic blades is their high brittleness and low impact resistance. They are not suitable for cutting thick metals or materials with hard inclusions. Sudden shocks or uneven force can easily cause the blade to chip or fracture, leading to immediate failure.

While ceramic is extremely hard, it is not tough. Think of it like glass versus steel. You can't scratch glass with steel, but you can shatter glass with a steel hammer. This is brittleness. Ceramic blades need a stable, vibration-free cutting environment and are not for jobs that involve shocks or impacts. I once consulted for a textile recycling facility in India. They wanted to use ceramic blades for their longevity. However, their raw material often contained hidden metal staples and zippers. The first time a ceramic blade hit a staple, it shattered. We concluded that tougher cemented carbide blades were a better fit for their unpredictable application, even if they needed to be changed more often.

Toughness Vs. Hardness

| Material | Toughness (Impact Resistance) | Hardness (Wear Resistance) | Best Use Case |

|---|---|---|---|

| Ceramic | Low | Very High | Precision, low-impact cutting |

| Cemented Carbide | Medium-High | High | General purpose, moderate impact |

| High-Speed Steel | High | Medium | High-impact, tough materials |

Conclusion

In summary, ceramic blades offer incredible advantages in specific situations. Understanding their hardness, stability, and brittleness is key to choosing the right tool for your manufacturing needs.

Learn how extreme hardness enhances cutting performance and longevity in blades. ↩

Discover the significance of wear resistance in maintaining blade sharpness and reducing downtime. ↩

Understand how chemical stability prevents contamination and enhances safety in food and medical industries. ↩

Understanding burr formation is crucial for improving cutting precision and product quality, especially when using ceramic blades. ↩