Poor cuts and frequent downtime are hurting your bottom line. The wrong blade edge is likely the culprit. Let's find the geometry that perfects your production process.

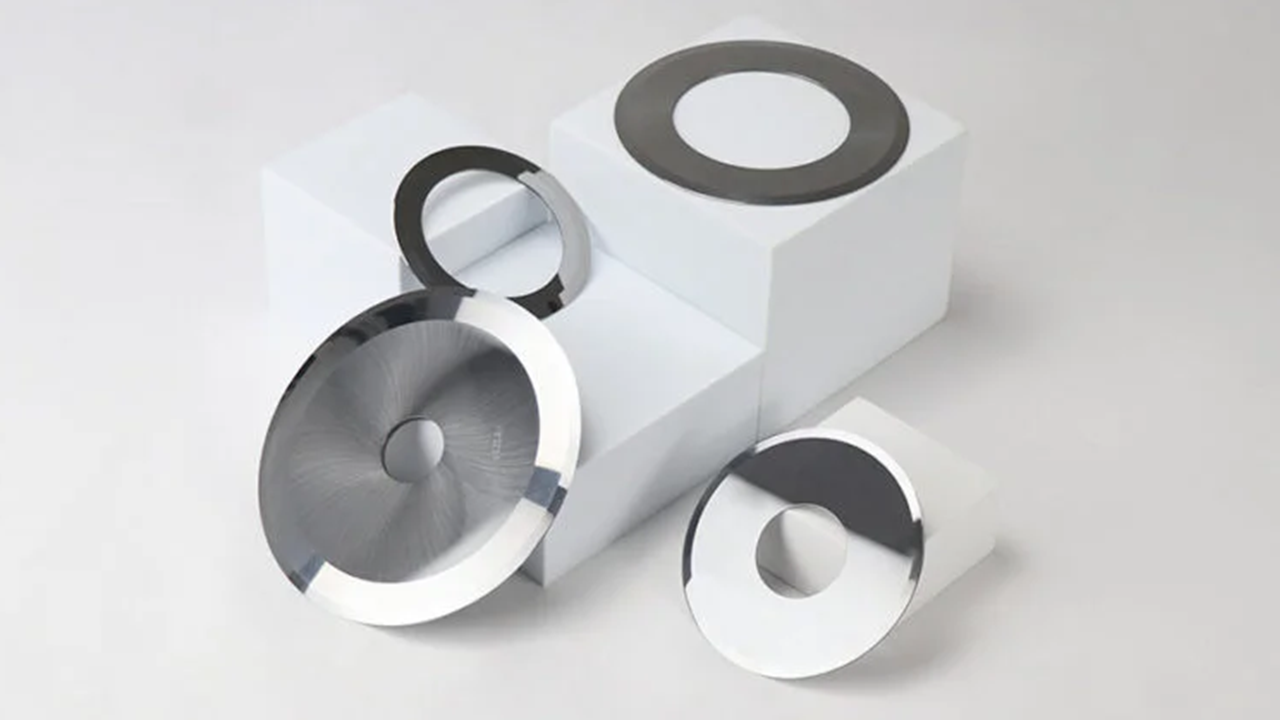

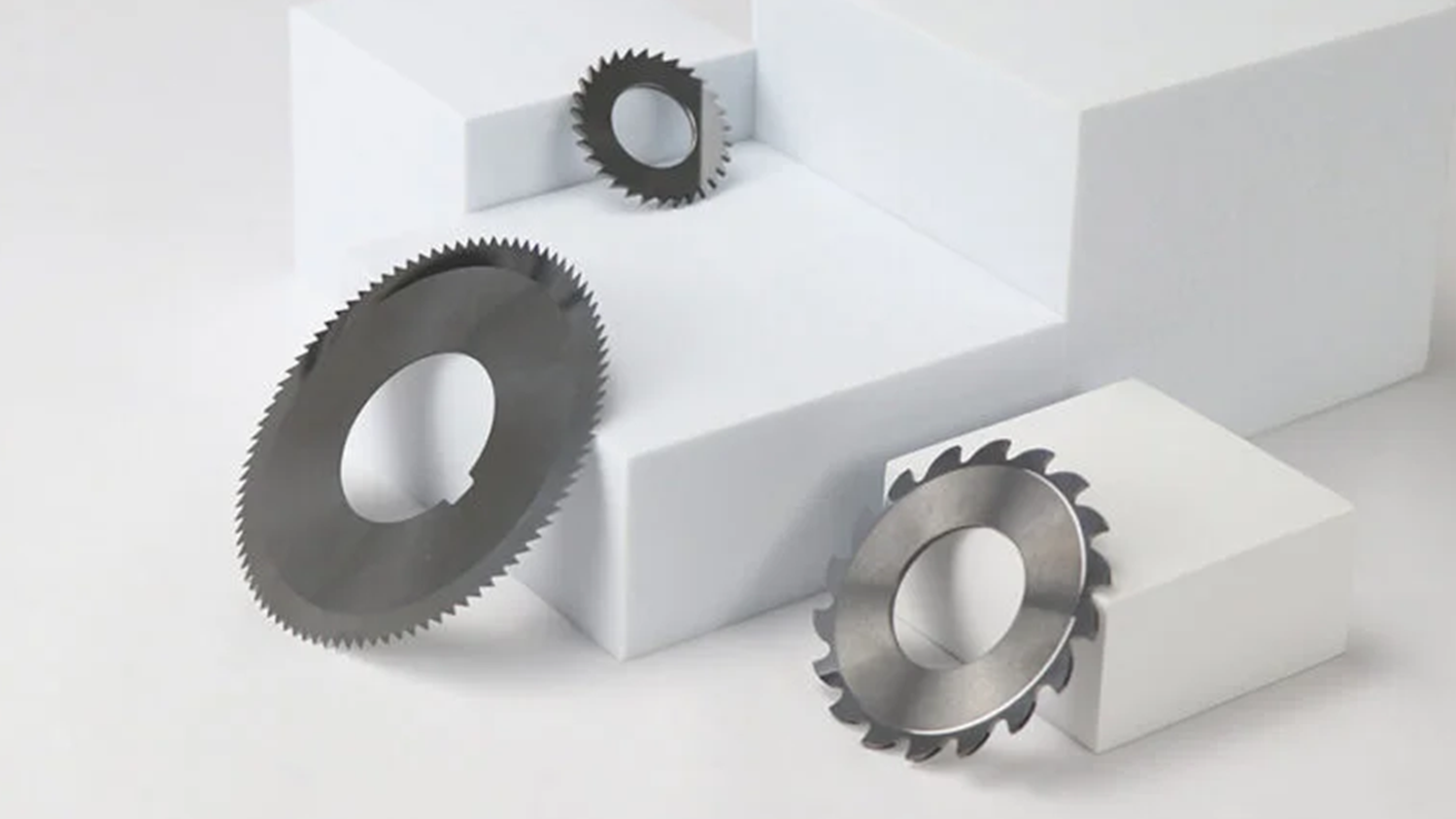

The most common industrial blade edges are straight, arc, and serrated. A straight edge1 is for paper and film. An arc edge2 works on soft materials like fabric. A serrated edge3 grips and cuts tough or slippery materials like rubber and fiberglass.

Understanding these basic shapes is the first step. But the real magic happens when you look closer at the blade's geometry. Factors like the bevel and the edge angle4 are what truly define a blade's performance and lifespan. Let's explore these critical details together.

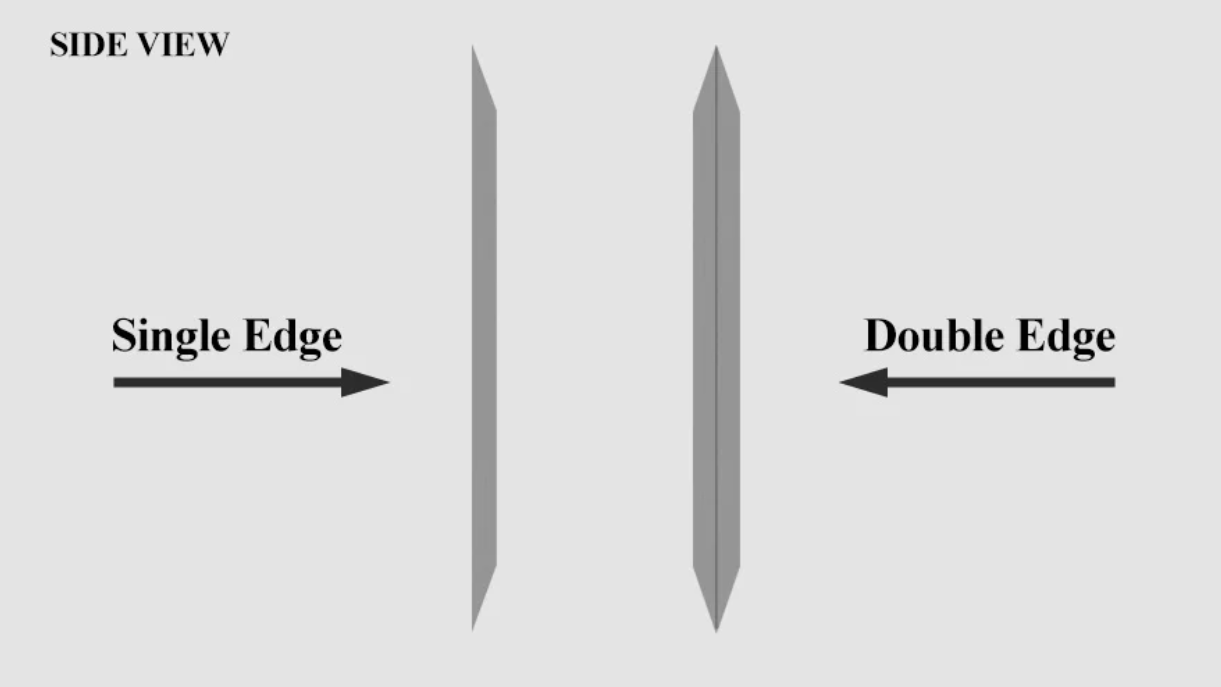

What Are Single And Double Bevels?

Are you confused by terms like "single bevel5" and "double bevel6"? Choosing the wrong one can lead to skewed cuts, material waste, and frustration. Let me simplify it for you.

A single bevel is ground on only one side, creating a razor-sharp edge for precision cuts. A double bevel is ground on both sides, making a strong, versatile edge for general-purpose work. It is a choice between ultimate sharpness and robust durability.

I always explain this to my clients as the difference between a scalpel and a kitchen knife. Both cut, but they are designed for very different tasks and levels of finesse. The geometry of the bevel directly impacts how the blade interacts with the material, influencing everything from the straightness of the cut to how long the edge stays sharp. Understanding this distinction is fundamental to optimizing any cutting operation, whether you're slitting delicate film or chopping thick rubber. It's a small detail with a massive impact on your final product quality and operational efficiency. Let's break it down further.

The Mechanics Of A Single Bevel Blade

Think of a single bevel, also known as a chisel grind, like a woodworker's chisel. The edge is formed by grinding a single plane on one side of the blade, while the other side remains flat. This creates an incredibly sharp and acute angle that excels at fine slicing. When it cuts, it tends to push the material away from the flat side, resulting in a very clean, straight cut line, especially in slitting applications. This is why it's the preferred choice for tasks needing extreme precision. I remember working with a client, David in the UK, who manufactures sterile medical packaging. He was experiencing microscopic tearing when slitting thin polymer films. We switched his machine to a single bevel blade from PASSION. The flat side of the blade provided support to the film, while the beveled side performed the cut, eliminating the tearing and ensuring the package integrity he needed. Single bevels are the specialists of the blade world, perfect for converting tape, labels, and thin films where a flawless edge is not just desired, but required.

The Strengths Of A Double Bevel Blade

The double bevel, or V-edge, is the industry's workhorse. It is created by grinding both sides of the blade to meet at a central edge. This symmetrical design makes the edge inherently stronger and more durable than a single bevel. It is more resistant to chipping and rolling when it encounters tougher materials or minor inconsistencies. The V-shape parts the material evenly on both sides, which makes it ideal for chopping, dicing, and guillotine cutting where brute force and longevity are more important than microscopic precision. For instance, a packaging company in Spain was struggling with blades chipping when cutting thick, recycled corrugated board. The abrasive fillers in the recycled material were destroying their single bevel blades prematurely. I recommended a robust double bevel blade with a slightly wider angle. This change immediately reduced chipping, doubled their blade life, and significantly decreased machine downtime. The double bevel is the go-to solution for its balance of sharpness, strength, and ease of use in a wide range of applications.

Here is a table summarizing the key differences:

| Feature | Single Bevel (Chisel Edge) | Double Bevel (V-Edge) |

|---|---|---|

| Edge Geometry | Asymmetrical, ground on one side | Symmetrical, ground on both sides |

| Primary Strength | Extreme Sharpness & Precision | Durability & Versatility |

| Cutting Action | Pushes material to one side | Parts material on both sides |

| Best Applications | Slitting film, tape, labels, paper | Chopping, guillotine cutting, general use |

| Wear Pattern | Wears on one side, can be complex to resharpen | Wears evenly, easier to resharpen |

| Material Suitability | Thin, soft, homogenous materials | Thick, tough, or abrasive materials |

What Is The Relationship Between Edge Angle And Cutting Performance?

Is your blade dulling too quickly or chipping unexpectedly? The problem might be the edge angle. This one specification can dramatically change how your blade performs and how long it lasts.

A smaller, more acute angle creates a sharper edge that cuts with less force but is more fragile. A larger, more obtuse angle creates a stronger edge that is more durable but requires more force to cut. It is a critical balance between sharpness and strength.

Finding the ideal edge angle is one of the most common challenges I help my customers solve. It’s not about finding the "sharpest" blade; it's about finding the "right" blade. The angle dictates how the cutting force is distributed. A narrow angle concentrates all the force on a very small area, allowing it to pierce and slice easily. A wide angle spreads that force out, making the edge more resilient to impact and abrasion. The perfect angle depends entirely on the material you're cutting, the speed of your machine, and your main goal, whether that's a pristine finish or maximum uptime.

The Physics Of A Sharp, Acute Angle (e.g., 15-25 degrees)

A blade with a sharp, acute angle is the epitome of cutting efficiency. Think of a surgeon's scalpel. Its narrow profile displaces very little material as it passes through, requiring minimal pressure to create a cut. This results in an exceptionally clean finish with little to no material deformation or burring. This is ideal for delicate materials like thin plastics, flexible films, and high-quality paper. However, this high performance comes at a cost. The fine edge has less metal supporting it, making it more vulnerable to wear and tear. It can easily chip if it hits a hard impurity, or roll over when cutting highly abrasive materials. Heat buildup can also be an issue during high-speed operations, as the small surface area can heat up and lose its temper, causing the edge to dull rapidly. I often recommend acute angles for controlled environments where material quality is consistent and the highest cut quality is the primary objective. It delivers unparalleled performance but requires careful handling and more frequent replacement.

The Durability Of A Wide, Obtuse Angle (e.g., 30-45 degrees)

A wide, obtuse angle is built for toughness. Imagine an axe splitting wood. The wide "V" shape has a significant amount of metal directly behind the cutting edge, providing robust support. This makes the edge far more resilient to impact, shock, and abrasion. It can power through tough, dense, or contaminated materials like recycled plastics, fiberglass, and thick rubber without failing. I worked with a client, Maria from Mexico, who was processing recycled plastics into pellets. Her blades, which had a standard 25-degree angle, were chipping within hours because of hard contaminants in the recycled material. We engineered a custom blade for her with a 40-degree angle. While it required slightly more motor power, the new blades lasted for an entire week. The wider angle distributed the cutting force and shrugged off impacts that would have destroyed the sharper edge. The trade-off is a lower quality cut; it tends to crush or fracture material more than slicing it, and it requires significantly more downward pressure from the machine. This is the angle you choose when durability and machine uptime are your most important goals.

| Characteristic | Acute Angle (15-25°) | Obtuse Angle (30-45°) |

|---|---|---|

| Initial Sharpness | Extremely High | Good |

| Edge Durability | Low | Very High |

| Required Cutting Force | Low | High |

| Cut Finish Quality | Excellent, Clean | Fair, can cause crushing |

| Heat Buildup | Can be high at speed | Lower |

| Ideal Materials | Thin films, paper, foils, non-abrasive plastics | Recycled materials, rubber, composites, thick board |

| Primary Goal | Precision and Finish | Longevity and Uptime |

How To Choose The Right Edge For Your Application?

Feeling overwhelmed by all the options for bevels, angles, and edge types? Choosing incorrectly can lead to production nightmares and wasted money. Let me give you a straightforward process to select the perfect blade.

To choose the right edge, you must analyze three things: your material's properties, your machine's cutting action, and your primary performance goal. A systematic evaluation of these factors will always guide you to the most effective and economical blade choice for your operation.

This is the exact process I walk through with every new client. It's easy to get focused on just one aspect, like sharpness, and forget the bigger picture. I often say that a blade is part of a system. The blade, the material, and the machine all have to work together in harmony. By breaking the problem down into these three core areas, we can move from guessing to making an informed, data-driven decision. This approach not only solves immediate cutting problems but also uncovers opportunities for longer blade life, faster production speeds, and a better final product.

Step 1: A Deep Dive Into Your Material

The first and most critical step is to understand the material you are cutting. Go beyond simple labels like "plastic" or "paper." Think about its specific properties. Is it abrasive? Paper products often contain fillers like clay or calcium carbonate, which are highly abrasive and will dull a blade quickly. Is it stretchy? Elastomeric materials like rubber will stretch before they cut, often requiring a serrated edge or a very specific sharp angle to initiate the cut cleanly. Is it sticky? Adhesives on tapes and labels can build up on the blade edge, a problem that can be solved with the right blade coating and a polished edge finish. Is it tough and dense, or light and fragile? Each of these characteristics dictates a different approach to blade geometry. I helped a food processing plant that was having trouble with their blades gumming up while slicing cured meats. The solution wasn't a sharper blade, but one with a non-stick coating and a polished, double-bevel edge that resisted residue buildup.

Step 2: Matching The Blade To The Machine's Action

Next, consider how your machine performs the cut. The mechanical action is just as important as the material. A slitting machine that uses a razor blade to make long, continuous cuts in a web of film requires an extremely sharp, low-friction, single-bevel blade. The goal is a clean slice with minimal web disturbance. In contrast, a guillotine cutter that chops through a thick stack of paper needs a heavy-duty, double-bevel blade with a durable, wide angle that can withstand immense impact force without chipping. A perforating machine needs a blade with teeth designed to pierce and withdraw cleanly. Machine speed is another huge factor. High-speed lines generate more heat at the cutting edge. This can cause a standard steel blade's edge to soften and fail prematurely. In these cases, I often recommend blades made from tungsten carbide or a coated steel that can retain its hardness at higher temperatures, ensuring a consistent cut from the beginning to the end of the production run.

Step 3: Defining Your Key Performance Indicators (KPIs)

Finally, you need to be honest about your primary goal. In an ideal world, we would all have a blade that is incredibly sharp, lasts forever, is inexpensive, and works on every material. In reality, we must make trade-offs. What is your top priority?

- Cut Quality: For products like premium packaging or medical devices, a perfect, clean edge is non-negotiable. Here, we would prioritize a very acute angle and advanced materials, even if it means more frequent blade changes.

- Blade Lifespan: For high-volume production of industrial goods, minimizing downtime is key. The goal is to keep the machine running. In this case, we would choose a tougher, more durable blade with a wider angle, even if the cut finish is slightly less perfect.

- Production Speed: If your goal is maximum throughput, you need a blade that can withstand the heat and stress of high-speed operation. This often points towards carbide blades or those with specialized PVD coatings like TiN or AlTiN.

By identifying your most important KPI, we can select an edge geometry that is optimized to deliver that result.

Conclusion

Choosing the right industrial blade edge, bevel, and angle is essential for optimal performance. Match the blade to your material, machine, and goals to guarantee efficiency, quality, and longevity in every cut.

Learn about the specific applications of straight edge blades and how they can improve your cutting processes. ↩

Discover the advantages of arc edge blades for soft materials and how they enhance cutting performance. ↩

Find out how serrated edge blades grip and cut tough materials effectively, improving your production outcomes. ↩

Discover the critical relationship between edge angle and cutting performance to make informed blade choices. ↩

Learn about the precision and sharpness of single bevel blades and how they can enhance your cutting tasks. ↩

Explore the durability and versatility of double bevel blades and how they can improve your cutting efficiency. ↩