Struggling with messy cuts, wasted material, and low efficiency? Choosing the wrong cutting method can damage your products and hurt your bottom line. The right technique is essential for a perfect finish.

The main industrial cutting methods1 include high-force options like shear, rotary, and punch cutting2; precision methods like razor slitting and creasing; and advanced solutions like oscillating, thermal, and abrasive grinding.

Understanding the differences between these methods is the key to unlocking peak performance on your production line. It’s about more than just a sharp edge; it's about a complete cutting strategy. Let's break down these methods so you can find the perfect one for your needs.

Which Are The Most Common High-Force Cutting Methods?

Are you struggling to cleanly cut through robust materials like metal sheets or thick paperboard? Using an underpowered method can lead to slow production and poor-quality edges. You need a solution built for strength.

The most common high-force cutting methods are shear, rotary, and punch cutting. These industrial workhorses are designed to apply significant force to efficiently process strong, rigid, or thick materials in high-volume settings.

These three methods are the foundation of many manufacturing industries. I work with clients every day who depend on them for everything from metal fabrication to packaging production. Each one operates on a different principle, and selecting the right one depends entirely on your material, desired cut shape, and line speed. Let’s look at how they work.

Shear Cutting

Shear cutting is the most straightforward high-force method. It works just like a pair of industrial-strength scissors. Two blades, an upper and a lower, are forced past each other to slice the material. This method is incredibly effective for making clean, straight cuts on flat materials like sheet metal, thick plastic, rubber, and stacked paper. The key to a perfect shear cut is maintaining the correct clearance between the blades. If the gap is too wide, the material might get bent or torn. If it’s too tight, you'll see premature blade wear. I often advise my clients that investing in high-quality, hardened steel shear blades reduces maintenance and ensures consistent cut quality.

Rotary Cutting

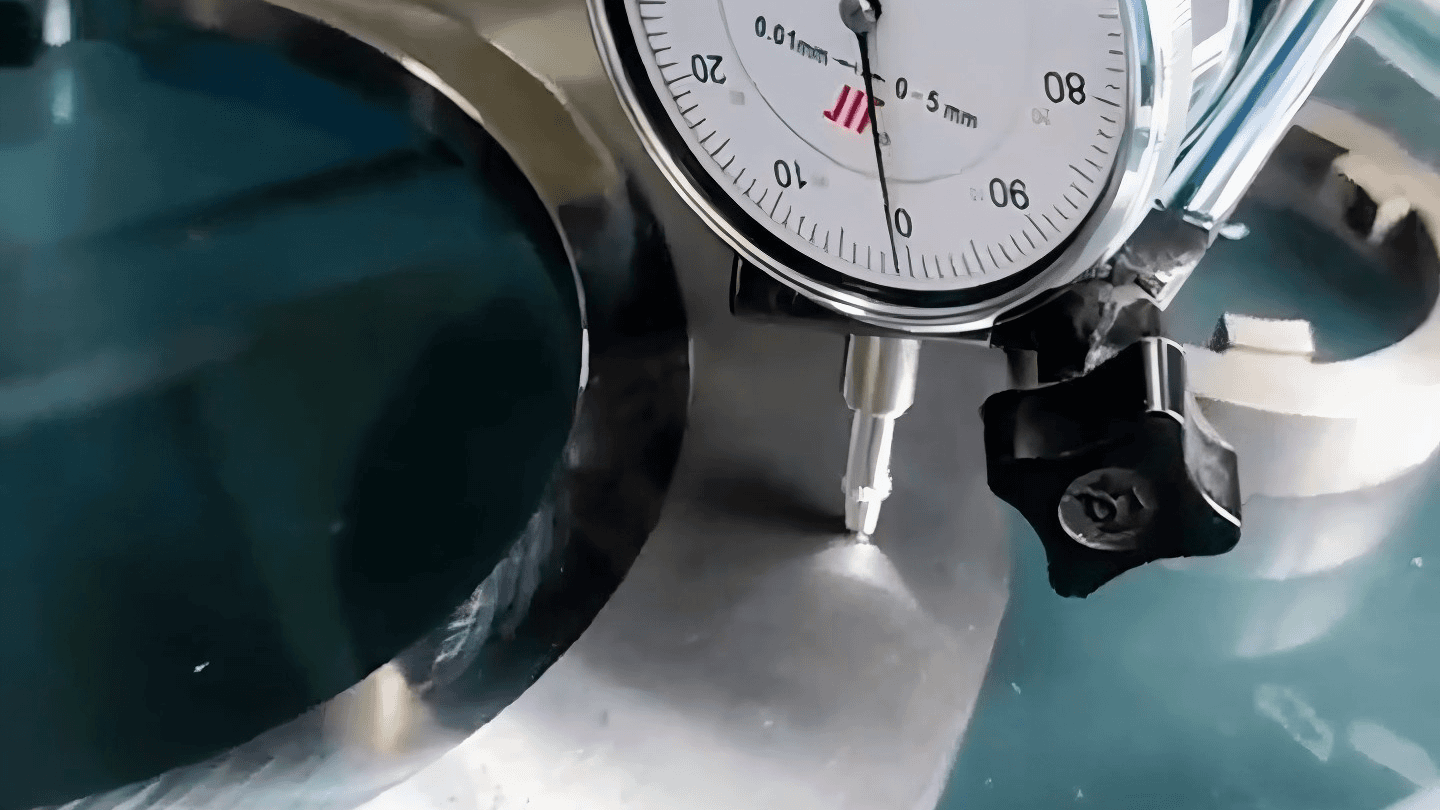

Rotary cutting uses spinning circular blades to make continuous cuts at high speeds. This is the go-to method for industries that process materials in large rolls, such as paper, foil, and textiles. The system typically involves two interlocking rotary blades (an upper and lower) that create a continuous shearing action as the material passes through them. This process, often called rotary shear slitting, is incredibly fast and efficient, making it perfect for high-speed converting lines where a master roll is slit into many narrower rolls. The precision of these systems is exceptional, delivering clean, burr-free edges when properly aligned.

Punch Cutting

Punch cutting is all about creating specific shapes or holes with speed and repeatability. In this process, a shaped blade (the punch) is pressed through the material with high force into a custom-shaped die. Think of an industrial-scale cookie cutter. This method is vital in the packaging industry for creating features like handles in boxes, in label making for cutting out custom shapes, and in gasket manufacturing. Because punch cutting involves repeated high impact, the tooling must be extremely durable. We often recommend tool steels or tungsten carbide for our clients' punching applications to ensure the blades can withstand millions of cycles without chipping or deforming.

| Cutting Method | Principle of Operation | Common Materials | Key Advantage |

|---|---|---|---|

| Shear Cutting | Two blades move past each other like scissors. | Metal sheets, thick paper, rubber. | Delivers high force for clean, straight cuts. |

| Rotary Cutting | Two spinning circular blades create a continuous cut. | Paper rolls, foil, film, textiles. | Very high speed for continuous processes. |

| Punch Cutting | A shaped tool is forced through the material into a die. | Cardboard, leather, labels, gaskets. | Creates custom shapes and holes quickly. |

How Do You Achieve Precision Cuts On Delicate Or Thin Materials?

Are you tired of tearing, stretching, or deforming delicate materials like thin films and foils? Standard cutting methods are often too aggressive, leading to costly waste. You need a technique that offers a gentler touch.

For delicate materials, razor cutting3, slitting, and creasing provide the necessary precision. These methods use minimal force and advanced control to slice or score materials cleanly without causing damage or distortion.

When a client comes to me with issues cutting ultra-thin or sensitive materials, I know their high-force tools are the problem. You can't use a sledgehammer to perform surgery. This is where finesse and precision become more important than brute force. Let’s explore the methods designed specifically for these challenging applications.

Razor Cutting

Razor cutting is the ultimate solution for high-precision slitting of very thin materials like plastic films, adhesive tapes, and aluminum foils. Unlike shear cutting4, this method uses a single, incredibly sharp blade to slice through the material with almost no pressure. The material is held under tension as it passes over the blade, which cleanly parts it. There is no bottom blade or anvil, so there is zero risk of crushing or distorting the material. This results in a perfectly clean, smooth edge with no burrs. However, success with razor cutting depends on precise control over material tension and blade angle. We provide blades in advanced materials like ceramic and tungsten carbide to ensure the edge stays sharp for an extremely long time, even when cutting abrasive films.

Slitting Cutting

Slitting is the overall process of cutting a wide roll of material into several narrower rolls. This process can be accomplished using different cutting methods, primarily rotary shear cutting (as discussed earlier) or razor cutting. The choice depends on the material. For thicker, more robust materials like paperboard or metal foil, rotary shear slitting is ideal. For thin, delicate films where edge quality is critical, razor slitting is the preferred method. In my role, I help customers analyze their material and end-product requirements to determine the optimal slitting technology—be it shear, razor, or another variation—to maximize their line's efficiency and quality.

Creasing Cutting

Creasing, or score cutting, is a unique precision method where the goal is not to cut all the way through the material. Instead, a dull-edged blade or wheel is used to create a precise line of compression or a partial cut. This creates a defined fold line, making it essential for the packaging industry in manufacturing folded cartons and cardboard boxes. It's also used to create "easy-tear" features on packaging or to "kiss cut" labels, where the top layer is cut but the backing paper is left intact. Achieving a consistent crease requires precise control over pressure and depth. Too much pressure can weaken or tear the material, while too little results in a poor fold.

| Method | Principle of Operation | Best For | Key Advantage |

|---|---|---|---|

| Razor Cutting | A single, sharp blade slices a tensioned web. | Thin films, foils, adhesive tapes. | Flawless edge quality, no material deformation. |

| Slitting Cutting | The process of cutting a wide roll into narrow strips. | All roll-fed materials. | Enables high-volume production of custom-width rolls. |

| Creasing Cutting | A dull blade creates a fold line or partial cut. | Cardboard, paperboard, labels. | Creates precise fold lines or "kiss cuts." |

What Advanced Cutting Solutions Exist For Difficult-To-Cut Materials?

Do your standard blades fail when faced with soft foams, tough composites, or extremely hard ceramics? Some materials simply defy traditional cutting methods, leading to tool damage and poor results. You need a specialized solution.

Advanced methods like oscillating, thermal, and abrasive grinding cutting5 are designed for these challenges. They use unique principles like vibration, heat, or abrasion to process materials that are otherwise considered "un-cuttable."

Over the years, I've encountered many materials that laugh in the face of a standard steel blade. This is where true innovation in cutting technology shines. These advanced methods solve very specific problems that stump conventional equipment, allowing for the creation of new and complex products.

Oscillating Cutting

Oscillating cutting is a game-changer for soft, porous, or flexible materials. Instead of spinning or shearing, the blade is a tangentially controlled knife that vibrates up and down at an extremely high frequency—often thousands of times per minute. This rapid sawing motion allows it to cleanly cut through materials like foam, rubber, gasket materials, leather, and corrugated plastic without crushing or distorting them. It's almost always paired with a CNC flatbed table, enabling it to cut incredibly intricate shapes and patterns with high precision. Because it generates very little heat, it's perfect for materials that might otherwise melt or burn.

Thermal (Hot) Cutting

Thermal cutting, or hot knife cutting, is the ideal method for synthetic textiles, ropes, and webbing made from materials like nylon or polyester. This technique uses a blade that is electrically heated to a high temperature. As the hot blade makes contact with the material, it melts its way through rather than cutting it mechanically. The major advantage of this method is that the heat instantly seals the cut edge, preventing the synthetic fibers from fraying or unraveling. This creates a clean, durable, and sealed edge in a single step, making it indispensable in the textile and apparel industries.

Grinding (Abrasive) Cutting

When you need to cut extremely hard or brittle materials like hardened steel, ceramics, glass, or tungsten carbide, a standard blade won't even scratch the surface. This is where abrasive cutting comes in. This method uses a rapidly spinning wheel made of or coated with super-hard abrasive particles (like diamond or cubic boron nitride). Instead of shearing the material, the wheel grinds its way through, removing microscopic particles with each rotation. While it can be a slower process, it is one of the only ways to achieve a precise, clean cut on these ultra-hard materials without causing fractures or thermal damage.

| Method | Principle of Operation | Best For | Key Advantage |

|---|---|---|---|

| Oscillating Cutting | A blade vibrates up and down at high speed. | Foam, rubber, leather, soft plastics. | Cuts complex shapes in soft materials without distortion. |

| Thermal Cutting | A heated blade melts through the material. | Synthetic fabrics, webbing, ropes. | Cuts and seals the edge simultaneously to prevent fraying. |

| Grinding Cutting | A spinning abrasive wheel grinds material away. | Hardened steel, ceramics, glass. | The only effective way to cut ultra-hard materials precisely. |

What Factors Should Be Considered When Selecting An Appropriate Cutting Method?

Have you ever invested in new blades only to find they wear out quickly or give you a poor-quality cut? Making a choice based on price alone rarely works. A methodical approach is needed to find the truly optimal solution.

Key factors for selecting a cutting method include the material's properties (hardness, thickness), the required cut quality and precision, the necessary production speed, and the overall cost-effectiveness, including blade life and maintenance.

When a new client reaches out, they often ask, "What's the best blade for cutting plastic?" My answer always starts with more questions. To guide them to the right solution, I walk them through a simple yet critical evaluation process. It's a framework I've refined over years of experience, ensuring we consider the entire picture, not just one piece of it. We break it down into four main areas.

Material Characteristics

This is the starting point and the most critical factor. You have to know your material inside and out. Is it hard and brittle like glass, or soft and flexible like rubber? Is it a thin film or a thick metal plate? Is it sensitive to heat? The answers dictate the viable cutting options. An abrasive cutting method6 is necessary for hardened steel, while an oscillating blade7 is perfect for soft foam. A hot knife8 is great for synthetic fabric but would be a disaster on paper. Understanding your material’s properties immediately narrows down the choices.

Precision And Cut Quality Requirements

What does the final product's edge need to look like? For some applications, like rough-cutting lumber, a slightly ragged edge is perfectly fine. For others, such as slitting medical-grade film or electronic components, the edge must be perfectly smooth, clean, and free of any dust or burrs. High-precision methods like razor slitting9 deliver that flawless finish but may operate at slower speeds. A high-speed shear cutter is efficient but might leave a slight burr. You must balance the demands for quality with the need for throughput.

Production Speed And Efficiency

How does cutting fit into your overall manufacturing workflow? A continuous, 24/7 process converting giant rolls of paper requires a high-speed rotary cutting system built for endurance. In contrast, an operation that creates individual stamped parts from sheets of metal needs an intermittent punch-cutting process. The goal is to match the cutting method to the rhythm of your production line to prevent bottlenecks. I've helped customers double their output just by switching from a stop-and-go cutting station to a continuous rotary system.

Cost And Maintenance

Finally, we must talk about the budget. But it's not just about the upfront cost of the blades. You have to consider the Total Cost of Ownership10 (TCO). This includes the initial investment, the expected lifespan of the blade, the frequency of sharpening or replacement, and the cost of machine downtime during blade changes. A cheaper carbon steel blade may seem like a good deal, but if a more expensive tungsten carbide blade lasts ten times longer, it's the more cost-effective choice in the long run.

| Factor | Key Questions to Ask | Example Impact |

|---|---|---|

| Material Properties | What is the material's hardness, thickness, and texture? | A thick, hard metal needs shear cutting; a soft foam needs oscillating cutting. |

| Cut Quality | How smooth must the edge be? Are burrs or dust acceptable? | High-precision films require razor slitting for a perfect edge. |

| Production Speed | Is this a continuous or intermittent process? What is the target output? | High-volume roll converting requires fast rotary cutting systems. |

| Cost | What is the blade's price versus its lifespan and maintenance needs? | A high-cost carbide blade may offer a lower total cost due to longevity. |

How To Choose Between Horizontal Or Vertical Cutting?

Is your factory layout causing headaches with material handling? The orientation of your cutting machine can create bottlenecks you never expected. Choosing the wrong setup wastes valuable floor space and time.

The choice between horizontal and vertical cutting11 depends on material flow, floor space, and the specific application. Vertical cutting is ideal for stacked sheets and gravity-assisted processes, while horizontal cutting12 integrates better with continuous conveyor systems.

This question is less about the blade itself and more about the machine and the entire production line. I've seen clients struggle with inefficient workflows simply because their machine's orientation fought against their material flow. The decision between horizontal and vertical is a practical one that impacts everything from operator safety to how easily you can move products to the next station.

Vertical Cutting Logic

Vertical cutting systems are what most people picture when they think of a guillotine shear13. The blade moves up and down to make the cut. This orientation is extremely effective for a few key reasons. First, it uses gravity to its advantage. For cutting thick stacks of paper or sheet metal, the vertical clamping and cutting action ensures the material stays securely in place. Second, these machines often have a smaller footprint, which is a major benefit in crowded production floors. They are typically stand-alone units where an operator feeds material, makes a cut, and then removes the finished pieces. This makes them ideal for intermittent, batch-based production where precision cuts on stationary material are required.

Horizontal Cutting Logic

Horizontal cutting systems are designed for integration and continuous flow. In these machines, the blade assembly moves side-to-side across the material, or the material moves past a fixed horizontal blade. This setup is perfectly suited for long production lines where materials are transported on conveyor belts or rollers. Imagine cutting large sheets of insulation foam or textiles that are fed continuously from a large roll. A horizontal cutter can be integrated directly into that conveyor line to cut pieces to length without ever needing to stop the flow. This orientation also makes it easier to manage long or awkwardly shaped materials, as they are fully supported by the conveyor or table surface throughout the cut.

| Orientation | Best For | Material Flow | Key Benefit |

|---|---|---|---|

| Vertical | Stacked sheets, thick plates, batch work. | Intermittent; material is loaded and removed. | Utilizes gravity, smaller footprint, high cutting force. |

| Horizontal | Continuous web materials, long parts, integrated lines. | Continuous; material flows on a conveyor or table. | Easy integration, excellent support for long materials. |

What Is The Selection Logic Between Continuous And Intermittent Cutting?

Is your production line plagued by constant starting and stopping? Aligning your cutting style with your overall workflow is crucial. The wrong rhythm can create massive bottlenecks and slash your efficiency.

Continuous cutting, like rotary slitting, is for high-volume, non-stop processes that convert large rolls of material. Intermittent cutting, like punch or guillotine shearing, is used when individual pieces are cut from a stationary or indexed material.

The decision between continuous and intermittent cutting14 is fundamental to your production strategy. It’s dictated entirely by how your raw material is supplied and what your final product looks like. I always tell my customers to map their entire production line. Seeing where material flows without stopping and where it needs to be positioned for a specific action makes the choice instantly clear.

When To Choose Continuous Cutting

Continuous cutting methods are the heart of web-based or roll-fed manufacturing. Think of giant rolls of paper, plastic film, or metal foil being fed into a machine at high speed. The material is in constant motion, and the cutting happens on the fly. Rotary cutting is the best example of this. Spinning blades can slit, perforate, or cut the moving web without ever needing to slow it down. This is incredibly efficient for high-volume production where the goal is to process as much material as possible in the shortest amount of time. If your raw material comes in a roll and you are converting it into smaller rolls or long strips, a continuous cutting15 process is the only logical choice. It maximizes throughput and minimizes the mechanical stress of constantly starting and stopping heavy equipment.

When To Choose Intermittent Cutting

Intermittent cutting is necessary when the material must be stopped, cut, and then advanced to the next station. This is common in any "cut-to-length16" or "form-in-place17" application. A classic example is a guillotine shear. A large sheet of metal is fed into the machine, it stops in the precise position, the blade comes down to make the cut, and then the finished piece is removed. Punching is another quintessential intermittent process. A sheet of material is indexed under the press, it stops, the tool comes down to punch out the shape, and the material advances to the next position. While the stop-and-go motion might seem less efficient, it offers perfect control over cut placement and is essential for creating discrete, individual products.

| Aspect | Continuous Cutting | Intermittent Cutting |

|---|---|---|

| Material Flow | Material is constantly moving (web/roll-fed). | Material stops for each cut (sheet/part-fed). |

| Primary Method | Rotary Cutting, Slitting. | Shear Cutting, Punch Cutting, Oscillating Cutting. |

| Main Advantage | Maximum throughput and production speed. | High precision in cut placement, creates individual parts. |

| Common Use | Converting large rolls of film into smaller rolls. | Stamping metal parts, cutting sheets to size, forming boxes. |

| Selection Logic | Choose when the process is roll-to-roll and speed is the priority. | Choose when creating discrete parts or when cutting is one step in a sequence. |

Conclusion

Choosing the right cutting method improves your quality, speed, and profit. Analyze your material, speed, and precision needs to find the perfect industrial blade solution for your operation.

Explore the various industrial cutting methods to find the best fit for your production needs. ↩

Find out how punch cutting creates custom shapes efficiently, crucial for packaging and manufacturing. ↩

Understand how razor cutting achieves flawless edges on delicate materials without deformation. ↩

Learn about shear cutting's effectiveness for clean, straight cuts and its applications in various materials. ↩

Understand the necessity of grinding cutting for ultra-hard materials and its precision. ↩

Abrasive cutting methods are essential for hard materials; discover their applications and benefits. ↩

Oscillating blades are perfect for soft materials; learn how they enhance cutting efficiency. ↩

Hot knives are ideal for synthetic fabrics; explore their unique benefits in cutting applications. ↩

Razor slitting provides high precision; find out when it's the best choice for your cutting needs. ↩

Understanding TCO helps in making cost-effective decisions for blade selection and maintenance. ↩

Vertical cutting systems utilize gravity effectively; learn how they can optimize your production. ↩

Horizontal cutting systems are great for continuous flow; explore their benefits in manufacturing. ↩

Guillotine shears are vital for batch cutting; learn how they enhance precision in your operations. ↩

Intermittent cutting allows for precise control; learn when to use this method for best results. ↩

Continuous cutting maximizes efficiency; find out if it's the right choice for your production line. ↩

Cut-to-length processes are essential for precision; discover how they fit into your production strategy. ↩

Form-in-place cutting is crucial for specific applications; explore its unique benefits. ↩