Choosing the wrong carbide grade causes frequent blade changes and production downtime. Understanding the differences helps you select the perfect blade, saving you time, money, and frustration.

The main differences in tungsten carbide grades (like YG, YT, YW) come from the binder (usually cobalt), the size of the tungsten carbide particles, and any added alloys. These factors directly change the blade's hardness, toughness1, and resistance to wear, heat, and chipping.

The world of tungsten carbide can seem complex, with all its letters and numbers. It's my job to help you understand these details so you can make the best choice. Once you understand the system, it becomes much clearer. Let's break it down together, step by step, so you can make informed decisions for your cutting applications.

What Are The Rules For Naming Tungsten Carbide Grades?

Do grade names like YG8 and YT15 look like a secret code? This can lead to ordering mistakes. But understanding the system is simple and makes you a confident buyer.

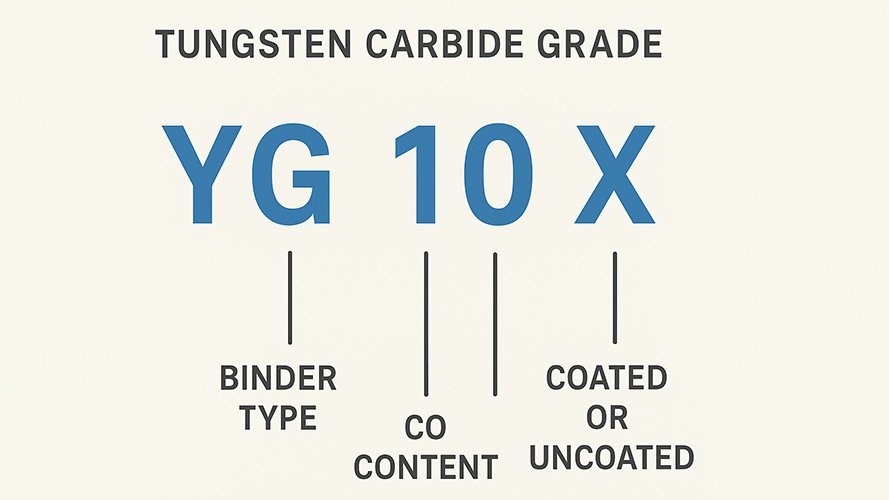

In the Chinese standard (GB/T), "Y" stands for cemented carbide. The second letter indicates the main components: "G" for Tungsten-Cobalt (WC-Co) and "T" for Tungsten-Titanium-Cobalt (WC-TiC-Co). The number usually indicates the cobalt or titanium carbide content.

When I talk with engineers and buyers, we need a common language. The grade naming system is that language. While many international standards exist, the Chinese GB/T standard is very direct and what we often use to specify materials. Let me break it down for you.

What The Letters Mean

The first letter is always Y, which stands for cemented carbide in Chinese. The second letter tells you about the composition.

- G comes from Cobalt. YG grades are a simple mix of Tungsten Carbide (WC) and a Cobalt (Co) binder.

- T comes from Titanium. YT grades contain Tungsten Carbide (WC), Titanium Carbide (TiC), and a Cobalt (Co) binder.

- W stands for "universal" and is a more complex blend, often containing Tantalum Carbide (TaC) for added versatility.

What The Numbers Mean

The numbers give a hint about the properties.

- In YG grades, the number is the percentage of Cobalt. For example, YG8 has 8% Cobalt. More cobalt means more toughness but less hardness.

- In YT grades, the number is the percentage of Titanium Carbide. For example, YT15 has 15% TiC. More TiC means more hardness and heat resistance.

| Grade Prefix | Main Components | Primary Characteristics |

|---|---|---|

| YG | Tungsten Carbide - Cobalt (WC-Co) | Good toughness and wear resistance. |

| YT | Tungsten Carbide - Titanium Carbide - Cobalt (WC-TiC-Co) | High hardness and heat resistance. |

| YW | WC-TiC-TaC-Co | "Universal" grade with balanced properties. |

Now that you understand the basic families, you might wonder where to start. While the specialized YT and YW grades are important for specific high-heat or universal applications, the truth is that the YG series is the workhorse of the industry. In my experience helping customers worldwide, most cutting challenges2 in paper, plastics, textiles, and non-ferrous metals can be solved by selecting the right YG grade. Understanding the relationship between its cobalt content3 and grain size4 is the most fundamental skill you can learn. It provides the foundation for everything else. So, let’s dive deeper into just the YG series to see how these properties translate into real-world performance.

What Are The Common YG Grades And Their Properties?

Knowing YG8 means 8% cobalt is one thing, but how does it actually perform? Without this knowledge, you are just guessing. Let's look at what these common YG grades actually do.

YG grades are tough workhorses. A higher cobalt percentage (like YG15) means much higher toughness for resisting impact. A lower percentage (like YG6) delivers higher hardness for wear resistance5. Grain size, often shown by an 'X', further refines performance.

The performance of any YG series blade is a trade-off between hardness and toughness. You can't maximize both. The key is finding the right balance for your specific cutting job.

The Role Of Cobalt (Co) Content

Cobalt is the "glue" that provides toughness, which is the blade's ability to resist chipping and breaking.

- High Cobalt (e.g., YG15, YG20): These blades are extremely tough and can absorb a lot of shock and vibration. They are ideal for high-impact jobs but are softer and will wear down faster from simple abrasion.

- Low Cobalt (e.g., YG6): These blades are very hard and hold a sharp edge for a long time against abrasive wear. However, they are more brittle and can chip easily if subjected to shocks or heavy vibration.

- Medium Cobalt (e.g., YG8, YG10): These offer a versatile balance between wear resistance and impact resistance, making them popular for many general-purpose applications.

The Role Of Grain Size

The letter 'X' in a grade like YG6X often means it has a finer grain structure compared to a standard YG6.

- Fine/Ultra-fine Grain (grades with 'X'): For the same cobalt content, a finer grain structure increases hardness and wear resistance significantly. This is perfect for cutting highly abrasive materials where a clean cut is essential.

- Medium/Coarse Grain (standard grades): These grades have better toughness and are more resistant to fracturing under heavy loads or impact.

| Grade | Cobalt % | Grain Size | Key Property | Best For |

|---|---|---|---|---|

| YG6 | 6% | Medium | High Hardness | Clean cuts, less abrasive materials. |

| YG6X | 6% | Fine | Extreme Hardness | Highly abrasive materials, precision cutting. |

| YG8 | 8% | Medium | Balanced | General purpose, good mix of toughness/wear. |

| YG15 | 15% | Medium | High Toughness | High impact, interrupted cuts, soft metals. |

How Do You Choose The Right YG Grade For Your Application?

You need a blade, but are you unsure if a high-cobalt or fine-grain YG grade is better? The wrong choice can destroy blades or ruin your product. Let's match grades to real-world scenarios.

Choose high-cobalt grades (YG12, YG15) for high-impact cutting. Choose low-cobalt grades (YG6) for precision and wear resistance. Use fine-grain 'X' grades (YG8X, YG10X) for cutting extremely abrasive materials where you need both hardness and some toughness.

Matching the YG grade to the application is where we create real value at PASSION.

Scenario 1: High Impact Cutting

A client in Poland working in metal recycling was shearing thin steel scrap. They were using a very hard, low-cobalt YG6 blade because they wanted it to stay sharp. However, the shock of the blade hitting the uneven stacks of metal was causing the blades to chip and fracture constantly. This was dangerous and expensive. I recommended a switch to a high-toughness YG15 grade. The 15% cobalt content absorbed the impact energy, preventing the blade from chipping. Although it wore down a bit faster, their total blade life6 increased by over 70% because they eliminated premature failures.

Scenario 2: Cutting Abrasive Materials

I cooperated with a textile manufacturer in Turkey who was cutting synthetic fabric reinforced with fiberglass. This is one of the most abrasive applications I have ever seen. Standard steel blades were useless, and even a standard YG8 carbide blade wore out in a single shift. The fiberglass was just grinding away the edge. The solution was a special fine-grain grade, YG6X. The extremely small tungsten carbide particles created a very hard and wear-resistant edge that could stand up to the abrasive fiberglass, while the 6% cobalt provided just enough toughness to prevent chipping. They went from changing blades daily to changing them weekly.

Scenario 3: The Balanced General Purpose

Most applications fall somewhere in the middle. I had a client in Brazil in the packaging industry who was slitting recycled cardboard. The cardboard contained abrasive fillers and staples, causing both wear and chipping on their blades. A high-cobalt grade would resist the staples but wear out too fast. A low-cobalt grade would resist the wear but chip on the staples. The perfect solution was a standard YG8 blade. It provided a great "all-around" performance—enough toughness to handle the occasional staple and enough hardness to provide good life against the abrasive cardboard.

| Application Need | Recommended YG Grade Type | Example Grade | Reason |

|---|---|---|---|

| Maximum Toughness | High Cobalt (12%+) | YG15, YG20 | Resists shock, vibration, and impact in interrupted cuts. |

| Maximum Wear Resistance | Fine-Grain, Low Cobalt | YG6X | Ultra-hard for extremely abrasive materials like composites. |

| Balanced Performance | Medium Cobalt (8%-10%) | YG8, YG10X | A reliable, versatile choice for many materials like paper. |

Conclusion

Understanding the YG tungsten carbide series—balancing cobalt for toughness and grain size for hardness—empowers you to choose the perfect blade. This boosts efficiency and cuts costs for your operation.

Explore the significance of toughness in ensuring the durability of cutting tools. ↩

Learn about typical cutting challenges and how to select the right carbide to address them. ↩

Discover how cobalt content influences the toughness and hardness of tungsten carbide blades. ↩

Understanding grain size can help you select the right blade for specific cutting tasks. ↩

Learn why wear resistance is crucial for selecting the right carbide for your application. ↩

Discover the key factors that influence the longevity of tungsten carbide blades. ↩