Struggling with inconsistent cuts in your fiber production? The wrong blade could be damaging materials and wasting money. I have seen this problem many times.

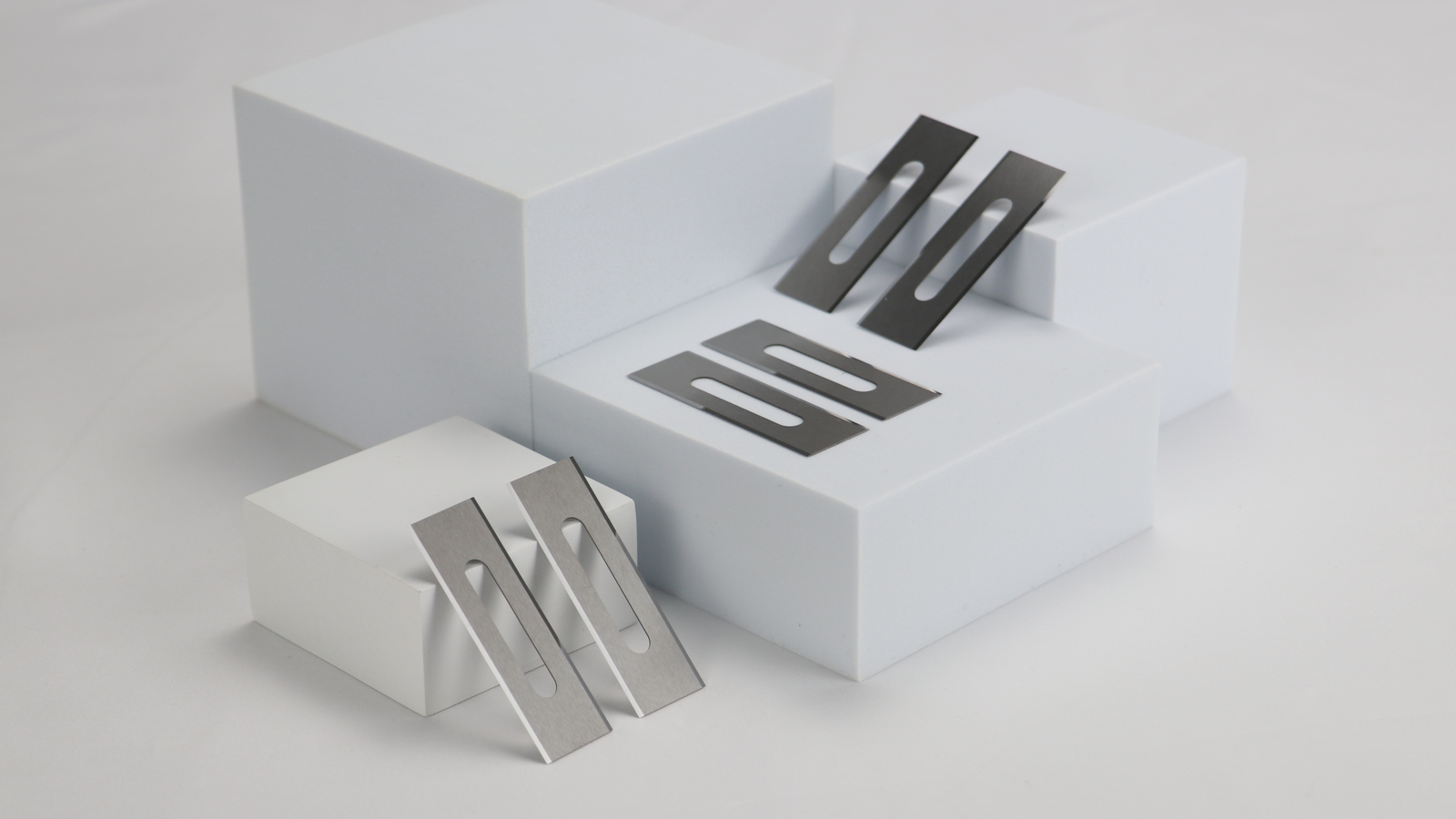

The main difference lies in their mounting design1. Three-hole blades offer fixed, stable positioning for high-speed precision. Slotted razor blades allow for fine adjustments, offering greater flexibility for various machine setups.

Understanding this core difference is the first step. But to truly optimize your cutting process, we need to look closer at how these designs affect installation, performance, and your final product. It reminds me of a client I worked with, Martin from the UK. He was a production supervisor at a chemical fiber plant and noticed his cutting results were all over the place. He was using both blade types and couldn't figure out why one performed so differently from the other. His story is a perfect example of why this choice matters so much. Let's break it down so you can make the best decision for your own production line.

How Does The Design Difference Impact Blade Installation And Stability?

Is blade setup causing production delays? Improper mounting leads to poor cuts and machine wear. A simple design choice makes a huge difference in performance.

Three-hole blades use fixed points for precise, repeatable installation, ensuring maximum stability. Slotted blades provide an adjustable range. This is flexible but can be less rigid if not secured perfectly.

When we talk about industrial cutting, the way a blade is held in the machine is just as important as how sharp it is. Even a tiny amount of vibration or movement can lead to a messy cut, especially at high speeds. The mounting design directly controls this stability. Three-hole and slotted blades2 approach this in two fundamentally different ways, and choosing the right one depends entirely on what you need to achieve. I always tell my clients to think of it as choosing between a rock-solid foundation and an adjustable one. Both have their place, but using one where you need the other can cause a lot of problems. Let's look at the specifics of each mounting style.

The Precision Of Three-Hole Mounting

The three-hole design is all about stability and precision. The three holes create a fixed, triangular mounting pattern. This setup locks the blade firmly in place, distributing the cutting force evenly across its surface. This rigidity is critical because it minimizes vibration during high-speed operations. The result is a cleaner, more consistent cut, pass after pass. For operators, this means easier and faster blade changes. The positioning is always the same, which removes guesswork and reduces setup time. This reliability is why we see three-hole blades3 used so often in high-volume, automated production lines where every second and every millimeter counts.

The Flexibility Of Slotted Mounting

The slotted blade, sometimes called a "waist-hole" blade, is designed for adaptability. The long, oval slot in the center allows the operator to make small adjustments to the blade's position before tightening it down. This flexibility is incredibly useful in certain situations. For example, it can help compensate for slight misalignments in older machinery. It also allows you to easily adjust the slitting width without needing completely different blade holders. This makes slotted blades a great choice for workshops that handle a variety of jobs or for production lines that require frequent changes. The trade-off, however, is that this adjustability can sometimes compromise the absolute rigidity you get from a three-hole blade if not secured with extreme care.

| Feature | Three-Hole Blade | Razor Slotted Blade |

|---|---|---|

| Mounting | Fixed, rigid | Adjustable, flexible |

| Stability | Excellent, minimal vibration | Good, requires careful tightening |

| Installation | Fast and repeatable | Requires fine adjustment |

| Best For | High-speed, consistent runs | Variable setups, machine adjustments |

Which Blade Is The Right Choice For Your Specific Cutting Task?

Are you choosing blades based on guesswork? The wrong choice can ruin an entire production run and damage your equipment. Let's match the blade to the job.

For high-speed, continuous cutting of uniform materials like staple fibers, the stability of three-hole blades is superior. For tasks requiring frequent width adjustments, the flexibility of slotted blades is invaluable.

After understanding the mechanical differences, the next step is to connect them to your daily work. The perfect blade for one company might be the wrong choice for another. It all comes down to the specifics of your application: the material you are cutting, the speed of your machines, and the consistency of your production runs. I guide my customers through this thought process all the time. Thinking about these factors will help you move from a blade that "works" to a blade that truly enhances your process, increases your output, and improves your product quality. Let's explore the ideal scenarios for each blade type so you can see where your needs fit in.

Ideal Scenarios For Three-Hole Blades

A three-hole blade truly shines in environments that demand speed and consistency. Think of large-scale manufacturing of chemical fibers, where machinery runs continuously for hours on end. In these settings, you need a blade that delivers the exact same perfect cut every single time. The unmatched stability of the three-hole design prevents chatter and deflection, which is crucial when cutting delicate filaments or thin films at high speeds. This leads to less material waste and a higher quality final product. If your business depends on high-volume output and minimal downtime, and your machines are well-calibrated, the three-hole blade is almost always the best choice. It provides the reliability you need to run an efficient and predictable operation.

When To Use A Razor Slotted Blade

A razor slotted blade is the problem-solver's tool. Its value comes from its adaptability. Consider a factory that produces specialty fibers in smaller batches with varying widths. A slotted blade allows operators to quickly adjust the cutting setup between jobs without a major tooling changeover. This is a huge advantage for efficiency in a low-volume, high-mix environment. Moreover, if you're working with older equipment that may have some wear and minor alignment issues, the adjustability of a slotted blade can be a lifesaver. It allows you to compensate for these imperfections and still achieve a straight cut. So, if your operation prioritizes flexibility and the ability to adapt to different requirements over sheer, uninterrupted speed, the slotted blade is your most valuable asset.

How Do You Select The Right Material And Make The Final Choice?

Does your blade dull too quickly? Premature wear increases costs and downtime. The blade's material is just as important as its shape, a lesson I learned with Martin.

Both blade types come in materials like tungsten carbide, high-speed steel, or ceramics. The choice depends on your cutting material. Carbide offers the best wear resistance for abrasive fibers, ensuring longevity.

Once you’ve decided between a three-hole and a slotted design, the final piece of the puzzle is the material. Choosing the right material ensures your blade not only cuts well but also lasts long, giving you the best return on your investment. This is where I often see companies make a mistake; they choose the right shape but the wrong material, and then wonder why performance suffers. This is exactly the conversation I had with my client, Martin. He was frustrated with his process, and by working through it together, we found the perfect combination of design and material for his factory. His experience clearly shows how a holistic approach to blade selection can transform a production line.

A Real-World Example: Martin's Challenge

Martin is a production supervisor for a large chemical fiber manufacturer in the UK. When he first contacted me, he was facing a persistent problem with cut quality. His production line was modern and ran at very high speeds, but the cut edges on his fibers were often inconsistent. This led to a higher-than-acceptable rejection rate. He explained that his team was using both three-hole and slotted blades, often interchangeably, without a clear strategy. They just used whatever was available. He knew there was a difference but couldn't pinpoint why his results were so unpredictable. This lack of standardization was costing his company time and money, and it was a constant source of stress for his team.

Our Solution-Oriented Approach

I listened carefully to Martin’s situation. Given his high-speed, high-volume operation, my first thought was that stability was his primary issue. The inconsistencies he described sounded like the classic signs of blade vibration or micro-movements during the cutting process. We discussed his machinery and the specific fibers he was cutting. It became clear that the flexibility of the slotted blades was not needed in his highly standardized process. In fact, it was likely the source of the problem. I recommended that he switch his entire line to high-precision tungsten carbide three-hole blades. The three-hole design would provide the rock-solid stability his high-speed machines required. Just as important, the tungsten carbide material would offer superior wear resistance against the abrasive nature of the chemical fibers, ensuring a sharp edge for much longer. He agreed to a trial run. The results were immediate. His cutting process became stable, efficiency improved, and his product rejection rate dropped significantly. Martin was thrilled, and it proved once again that the right blade is a combination of the right design and the right material.

Conclusion

Choosing between slotted and three-hole blades depends on your need for flexibility versus stability. Understanding this helps you optimize your cuts and improve production efficiency dramatically.