Are your expensive carbide blades failing too soon? This downtime and replacement cost hurts your bottom line. Understanding common mistakes can dramatically increase their lifespan and performance.

The most common mistakes include incorrect blade selection1, wrong cutting parameters2, poor machine stability, inadequate maintenance, and a lack of operator training. Addressing these issues is key to maximizing blade life3, improving cut quality, and reducing operational costs for any industrial cutting application.

Carbide blades are fantastic tools. They are known for their high hardness, great wear resistance, and ability to withstand heat. This is why we see them used in so many industries, from paper and plastic to metal and food processing. However, I often see companies making simple, preventable mistakes that cost them time and money. These errors stop them from getting the full value out of their investment. Let's break down these common problems so you can avoid them in your own operations.

Is Incorrect Blade Selection And Geometric Parameters The Root Cause?

Choosing the wrong blade for the job? It can cause chipping, poor cuts, and rapid wear. This simple mistake at the start can lead to major production problems.

Yes, it often is. Selecting a blade with the wrong material grade4, rake angle, or coating for your specific application is a primary cause of premature failure. Matching the blade's geometry and composition to the material being cut is the first step toward efficient and reliable performance.

One of the most fundamental errors I see is a mismatch between the blade and the material. It seems simple, but the details matter. Every material you cut has unique properties, and the blade must be designed to handle them. A few years ago, I worked with a textile company in Brazil. They were cutting large rolls of synthetic fabric and their blades were chipping constantly, which caused frayed edges on their product. They were frustrated because they had bought high-quality, very hard carbide blades. The problem was that the blade was too hard and brittle for the flexible fabric. The edge geometry was also wrong. We worked with them to switch to a tougher grade of carbide with a sharper, more acute cutting angle. The change was immediate. Blade life tripled, and their cut quality was perfect.

Understanding Key Blade Parameters

The geometry of the blade's edge is just as important as the carbide material itself. Using the wrong parameters increases cutting forces, generates excess heat, and leads to poor results. It’s important to get this right from the start.

| Parameter | Incorrect Choice (Example) | Correct Choice (Example) |

|---|---|---|

| Material Grade | Using a very hard but brittle blade on a flexible material. | Using a tougher, less brittle carbide blade for materials that cause vibration. |

| Rake Angle | A negative rake on soft plastic, which pushes instead of slices. | A positive rake angle for soft materials to ensure a clean shear cut. |

| Coating | An uncoated blade for cutting abrasive materials like fiberglass. | A TiN or DLC coating to reduce friction and increase wear resistance. |

Getting these basic parameters right is the foundation for success.

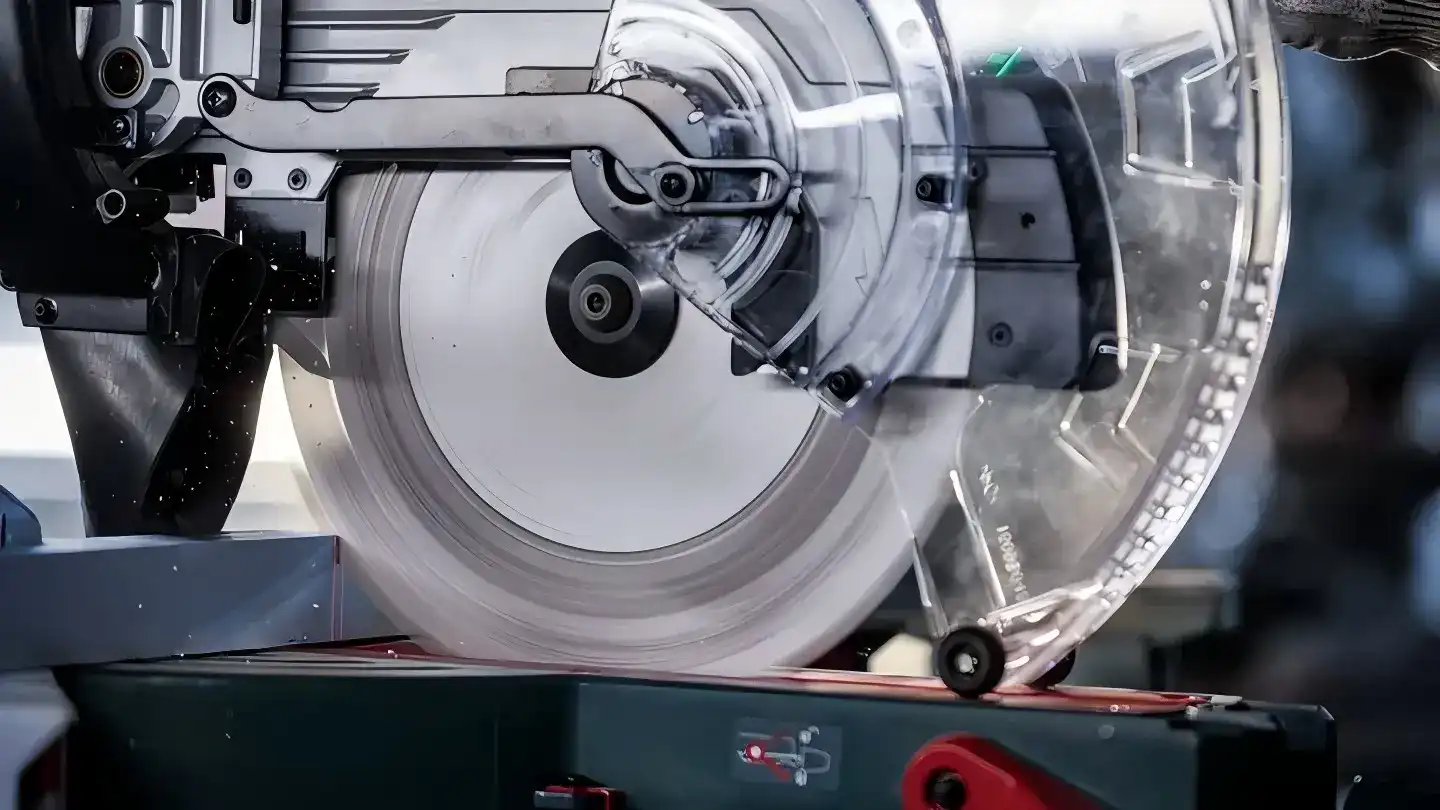

Are Cutting Parameter Settings And Thermal Management Being Overlooked?

Running your machines too fast or without proper cooling? Excess heat can destroy even the toughest carbide blade, leading to unexpected stops and damaged products.

Absolutely. Many operators overlook the impact of cutting speed5, feed rate6, and coolant. Improper settings generate excessive heat, which softens the blade's cutting edge, degrades its coating, and causes micro-cracks. Optimizing these parameters and ensuring proper cooling is crucial for extending blade life.

Carbide blades handle heat well, but they have their limits. Pushing them too hard without managing the temperature is a recipe for failure. I remember a case with a client in Germany who specializes in converting plastic films. They contacted me because their slitter blades were dulling very quickly, and they were getting melted residue on the cut edges. Their goal was to maximize output, so their operators had increased the machine speed. The problem was that the increased speed generated far more heat than their cooling system could handle. The blade edge got so hot that it started to soften and melt the thin plastic film instead of cutting it. We did a review together. I recommended they reduce the speed by 15% and adjust the coolant nozzles to aim directly at the cutting point. The result was a dramatic improvement in both cut quality and blade lifespan. They actually increased their overall output because they had less downtime for blade changes and cleaning.

Finding The Balance

Every application has a "sweet spot" for its cutting parameters. It is a balance between speed, feed rate, and depth of cut. Finding it requires testing and careful observation.

| Parameter | Too High/Fast | Too Low/Slow | Just Right |

|---|---|---|---|

| Cutting Speed | Generates excessive heat, causes blade edge damage. | Can cause built-up edge, poor surface finish. | Clean cut, managed heat, optimal blade life. |

| Feed Rate | High stress on the edge, risk of chipping. | Wastes time, can cause rubbing instead of cutting. | Efficient material removal without overloading the blade. |

| Coolant Flow | Wasted coolant, potential for thermal shock. | Not enough heat removal, leading to edge failure. | Consistently cools the blade and workpiece at the cut zone. |

Never assume faster is better. Listen to your machine and look at the blade and the material for signs of stress.

How Critical Are Tool Clamping, Machine Rigidity, And Vibration Control?

Experiencing blade chipping even with the right settings? The problem might not be the blade, but your machine. Vibration is a silent killer for brittle carbide blades.

They are extremely critical. Carbide has high hardness but low toughness, making it very sensitive to vibration. Loose clamping, poor machine rigidity, or misalignment can cause micro-chipping, leading to poor surface finishes and rapid blade failure. A stable cutting environment is non-negotiable.

You can have the perfect blade and the perfect parameters, but if the machine isn't stable, you will have problems. Carbide's hardness is its strength, but its relative brittleness is its weakness. It cannot handle shock or vibration well.

Identifying And Solving Vibration Issues

Vibration is the enemy of precision cutting. It can come from many sources, and identifying them is the first step to fixing the problem.

| Source of Vibration | Potential Solution(s) |

|---|---|

| Loose Blade/Holder | Clean contact surfaces, tighten all bolts to the correct torque, inspect holders for wear. |

| Worn Machine Parts | Check for worn bearings, slides, or gears. Implement a regular machine maintenance schedule. |

| Unstable Workpiece | Ensure the material being cut is clamped securely and cannot move during the process. |

| External Factors | Isolate the machine from building vibrations or other heavy equipment operating nearby. |

A stable, rigid setup is essential to protect your carbide blades and ensure a high-quality cut.

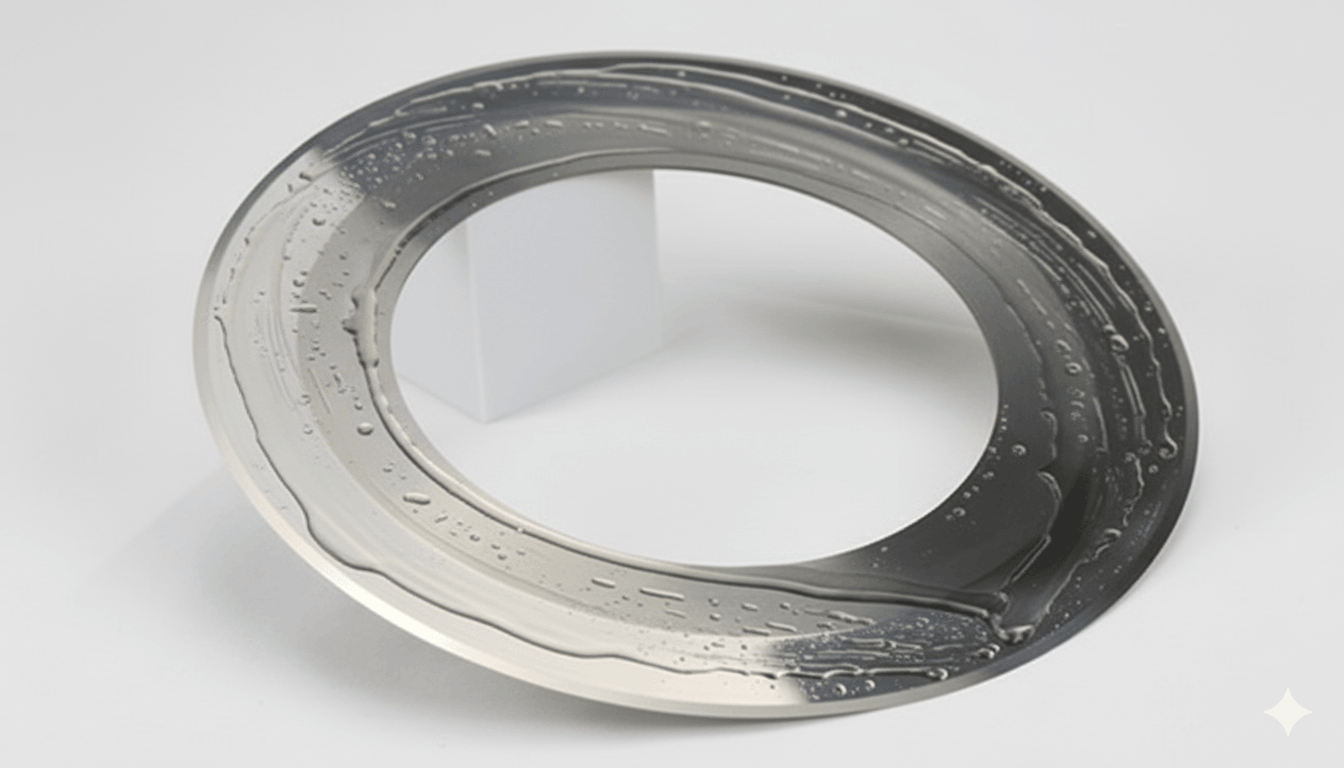

What Happens With Inadequate Blade Maintenance And Replacement Protocols?

Trying to use a blade for too long? Neglecting regular checks and proper regrinding can turn a valuable blade into scrap metal, compromising your entire production line.

Poor maintenance leads to predictable failure. Over-regrinding, ignoring edge wear, and failing to maintain coolant quality all shorten blade life. A clear protocol for inspection, maintenance, and knowing when to replace a blade prevents catastrophic failures and ensures consistent cut quality and safety.

Even the best carbide blades need to be cared for. They are wear parts, not permanent fixtures. Pushing a blade past its service life is a very common and costly mistake. I worked with a food processing client in Italy who used carbide dicing blades to cut frozen vegetables. To save money, they were regrinding their blades in-house. The issue was that they were regrinding them too many times. Each time you regrind a blade, you remove material. After too many cycles, the blade's critical edge geometry and strength were compromised. Their cuts became less clean, and they started crushing the product instead of dicing it, which led to a lot of waste. We helped them establish a clear protocol: inspect blades daily for wear, regrind them a maximum of three times, and then replace them. This simple system gave them consistent quality and, in the end, saved them money by reducing product waste.

A Simple Maintenance Checklist

A good maintenance plan doesn't have to be complicated. Having a simple checklist can make a huge difference in extending blade life and maintaining performance.

| Check Point | Frequency | Action Required |

|---|---|---|

| Cutting Edge | Daily / Per Shift | Visually inspect for chips, cracks, or signs of wear. |

| Blade Cleanliness | Daily / Per Shift | Remove any material buildup from the blade and holder. |

| Coolant System | Weekly | Check coolant concentration, cleanliness, and filter status. Ensure nozzles are clear. |

| Blade Replacement | Per Protocol | Replace the blade after a set number of hours or regrinds, or when wear reaches a certain point. |

Regular care is not a cost; it is an investment in reliability and quality.

Is The Lack Of Training And Process Feedback Mechanisms Holding You Back?

Are your operators making the same mistakes over and over? Without proper training and feedback, costly errors become part of your normal, inefficient process.

Yes, this is a major hidden cost. Untrained operators may not understand carbide's properties, leading to incorrect use. Without a feedback system to report and analyze blade failures, the root causes are never fixed, and the same expensive problems continue to happen again.

Often, the root cause of a blade failure is not the blade or the machine, but a gap in knowledge. The people who run the machines every day are your first line of defense against blade problems. If they are not trained properly, mistakes will happen. A client in Mexico that cuts corrugated cardboard had high blade consumption. Their operators knew that carbide could handle high speeds, so they kept pushing the machines faster to increase production. But the machine frames were not rigid enough to handle the increased operational vibration. As a result, the blades were wearing out prematurely. The operators thought they were helping, but they were actually causing the problem. The solution was two-fold. First, we provided training on the properties of carbide and the limits of their specific machines. Second, we helped them create a simple feedback log next to each machine. Now, when a blade is changed, the operator notes the reason. This simple data helps their supervisors spot trends and fix problems before they become costly.

Creating A Simple Feedback Loop

Giving your team the knowledge they need and a system to report issues is powerful. It creates a cycle of continuous improvement.

| Feedback Step | Description | Purpose |

|---|---|---|

| 1. Train | Teach operators about blade handling, installation, and signs of wear. | Empowers the operator to make better decisions. |

| 2. Operate | Run the machine according to established best practices. | Ensures consistent and efficient production. |

| 3. Observe & Report | Operator notices a problem and logs it on a simple form. | Captures valuable data from the production floor. |

| 4. Analyze & Act | A supervisor reviews the logs, identifies root causes, and makes changes. | Solves problems permanently instead of just fixing symptoms. |

Investing in your people is just as important as investing in good blades.

Conclusion

By avoiding these common mistakes in selection, operation, and maintenance, you can fully unlock the performance of your carbide blades, boosting efficiency and saving significant costs in the long run.

Understanding the impact of incorrect blade selection can help you avoid costly mistakes and improve cutting efficiency. ↩

Learn how optimizing cutting parameters can enhance blade life and cut quality, leading to better production outcomes. ↩

Understanding the factors that affect blade life can lead to significant cost savings and efficiency improvements. ↩

Learn how selecting the right material grade can prevent premature blade failure and improve cutting results. ↩

Understanding the relationship between cutting speed and blade performance can help optimize production efficiency. ↩

Learn how adjusting feed rate can enhance cutting efficiency and reduce blade wear. ↩