Your industrial blades keep failing, causing costly downtime. The problem isn't just the blade, but a mismatch of its physical properties. Understanding them is key to boosting efficiency.

Industrial blade properties include hardness1, strength2, toughness3, and wear resistance4. These traits determine a blade's cutting performance and durability. The right balance ensures efficiency and a long lifespan, moving beyond the old idea that 'harder is always better' for every application.

These properties are not just terms on a specification sheet. They are the core of how a blade truly performs in your machines. A deeper understanding of these characteristics is the most important step in solving cutting problems. So, let's break down what each one really means for your operations and how they work together to create the perfect cut.

Why Is Balancing Hardness, Strength, And Toughness So Crucial?

You chose a super-hard blade, but it chipped immediately. You switched to a tougher one, and it dulled just as fast. The key isn't choosing one property, but balancing them.

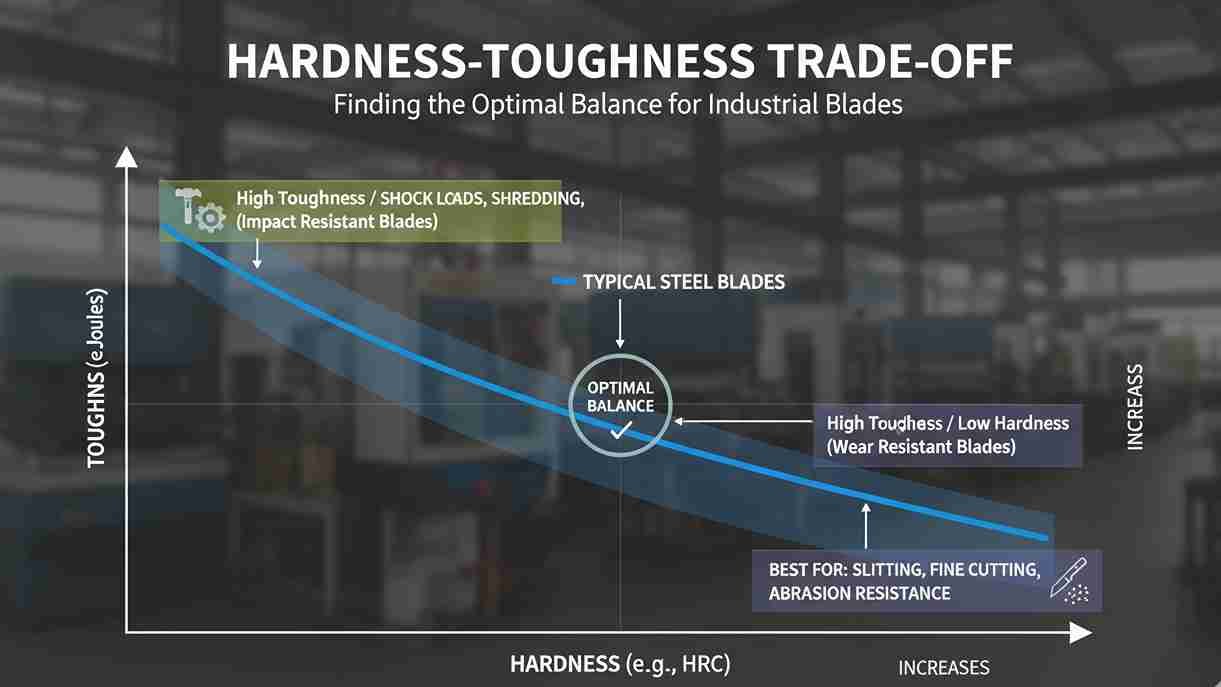

Balancing hardness, strength, and toughness is crucial because they are often in opposition. A hard blade stays sharp but can be brittle. A tough blade resists chipping but may wear faster. The ideal blade has the right mix of all three to match the specific cutting application.

Many people I talk to believe that the hardest blade is always the best blade. It's a common idea, but it's outdated. In modern industry, with faster machines and more complex materials, hardness alone is not enough. The secret to a high-performing blade lies in the harmony between its core properties. Think of it like a sports team. You don't want a team of only goal-scorers. You also need strong defenders and resilient midfielders. For blades, hardness, strength, and toughness are that core team.

Hardness: The Edge Keeper

Hardness is the blade's ability to resist being scratched or worn down. It's what allows the edge to stay sharp cut after cut. We measure it on a scale, often HRC (Rockwell Hardness C). For many industrial blades, this is between HRC60 and HRC80. High hardness is great for cutting clean materials efficiently. But if you push hardness too high, the blade becomes like glass. It's very hard, but a small shock can make it chip or shatter.

Strength: The Backbone

Strength is the blade's ability to handle force without bending or breaking permanently. This is critical when you are cutting thick materials or making heavy-duty cuts that put a lot of load on the blade. A strong blade maintains its shape under pressure. Materials like alloy steels, especially after proper heat treatment, give us this high strength.

Toughness: The Shock Absorber

Toughness is the opposite of brittleness. It's the blade's power to absorb sudden impacts or vibrations without cracking. If your cutting process involves shocks, like shearing metal with impurities or chopping recycled materials, toughness is your most important property. A tough blade can take a hit and keep going. This usually means sacrificing some hardness, as the two properties are a trade-off.

Here’s a simple way to look at it:

| Property | What It Does | Best For... |

|---|---|---|

| Hardness | Keeps the edge sharp. | Clean, high-precision cutting (film, paper). |

| Strength | Resists bending under load. | Heavy-duty cutting of thick materials. |

| Toughness | Resists chipping from impact. | Interrupted cuts or contaminated materials. |

The goal at PASSION is always to find the perfect recipe that balances these three properties for your specific job.

How Do Wear And Impact Resistance Affect Blade Lifespan?

Your blade's lifespan seems unpredictable. Some last for weeks, others for days, even on the same job. This inconsistency messes with your production schedule and budget, making it hard to plan.

Wear resistance determines how long a blade stays sharp during continuous use, directly affecting its working life. Impact resistance prevents the blade from fracturing under sudden shocks. Both are essential for long-term durability, especially in high-speed or demanding environments like metal recycling or heavy-duty shearing.

A blade's lifetime is its most direct measure of value. To achieve that longevity, we have to focus on two key defensive properties: wear resistance and impact resistance5. They are the guardians of your blade's edge and structure.

Wear Resistance: The Marathon Runner

Wear resistance is all about endurance. It's the blade's ability to fight off the gradual dulling that comes from friction. Every cut creates friction, which slowly grinds away the blade's sharp edge. For materials that are abrasive, like paper with fillers, fiberglass, or recycled plastics, wear resistance is a top priority. A blade with poor wear resistance will get dull fast, leading to poor cut quality and frequent changes. To fight this, we use materials with hard particles in their structure, like high-carbon, high-chromium steels or tungsten carbide. We also apply advanced coatings like Titanium Nitride (TiN). These ultra-hard coatings act as a shield, letting the blade slide through material with less friction and wear.

Impact Resistance: The Safety Net

If wear resistance is a marathon, impact resistance is a boxer's ability to take a punch. It's the blade's capacity to survive sudden, high-force events without catastrophic failure, like cracking or breaking. This is non-negotiable in applications like shredding scrap metal, where you can't predict if a harder piece of debris will enter the machine. It's also vital in high-speed shearing operations where the blade experiences a sharp shock with every cut. To achieve high impact resistance, we often use a steel with higher toughness as the base. We can also use special heat treatments to make the surface hard for wear while keeping the core of the blade tough to absorb impacts. A blade can be extremely wear-resistant, but if it shatters the first time it hits a staple in a cardboard box, it’s useless.

What Are The Hidden Properties That Guarantee Precision?

You have a sharp, durable blade, but the cut quality is still poor. You see rough edges, burn marks, or material sticking to the blade. These almost invisible issues are hurting your final product's quality.

Hidden properties like thermal conductivity6, surface finish7, and microstructure8 are vital for precision. Good thermal conductivity prevents overheating. A smooth surface finish reduces friction and ensures clean cuts. A uniform microstructure guarantees consistent performance across the entire blade.

When customers come to me with problems related to cut quality, we often look beyond the big three (hardness, strength, toughness). The solution is frequently found in the details—the properties that are not as obvious but have a huge impact on the final result. These are the properties that separate a good blade from a great one. They ensure every cut is clean, precise, and consistent.

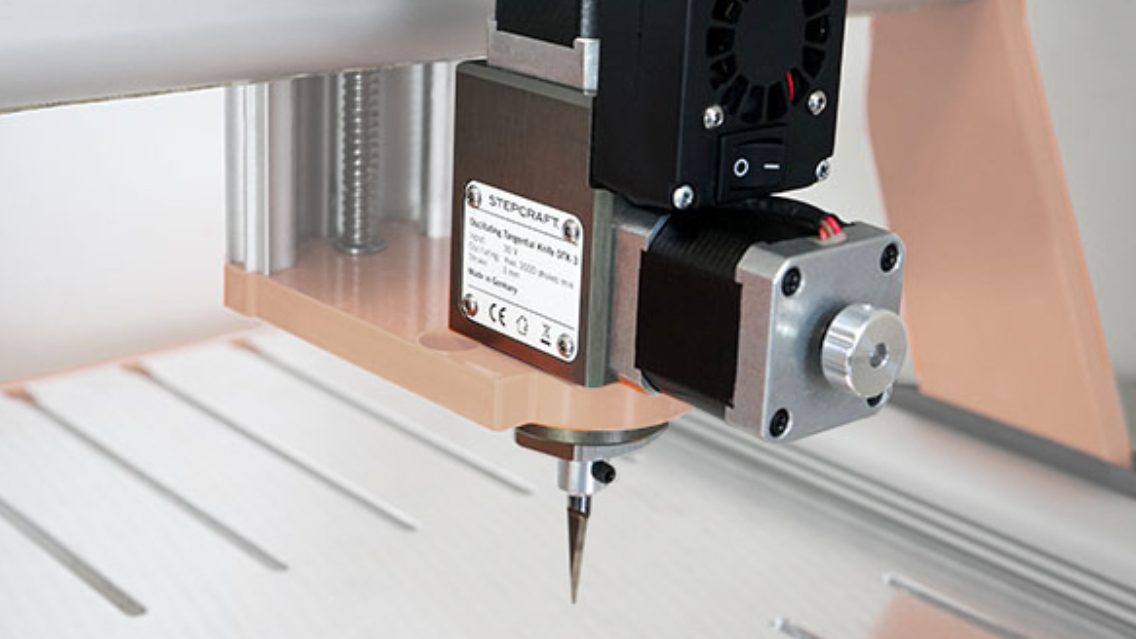

Thermal Conductivity: Staying Cool Under Pressure

Friction creates heat. In high-speed cutting, this heat can build up on the blade's edge very quickly. If the blade can't get rid of this heat, its edge can become so hot that it actually softens. This process, called annealing, ruins the hardness and makes the blade dull instantly. Good thermal conductivity allows the blade to pull heat away from the cutting edge and dissipate it through the body of the blade. This keeps the edge cool, hard, and sharp. Materials like tungsten carbide have excellent thermal conductivity, which is why they are so popular for high-speed applications.

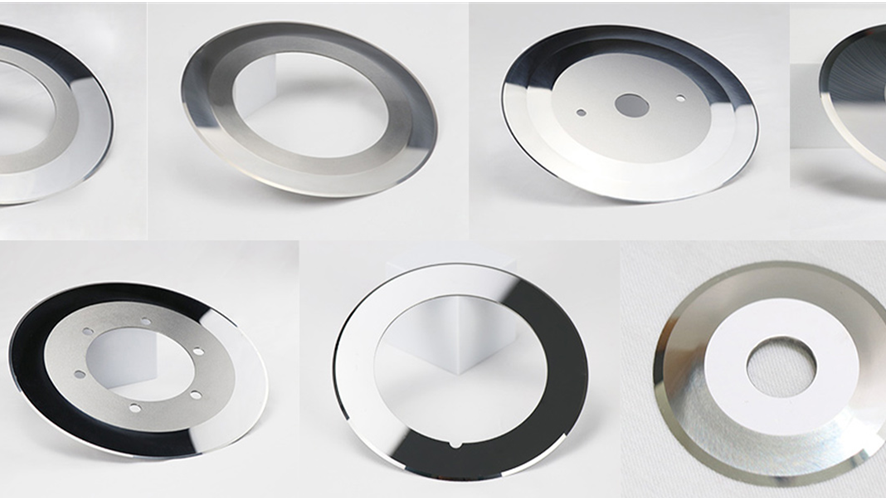

Surface Finish: The Secret to a Clean Cut

Surface finish refers to how smooth the blade's surface is, especially its cutting edge. A rough blade, even if sharp, creates more friction. This increased friction can cause material to melt, stick to the blade, or lead to a jagged, messy cut. For industries like film, foil, or tobacco cutting, a perfect cut edge is everything. We achieve a high-quality surface finish through grinding and polishing processes. A mirror-polished blade has extremely low friction. It glides through material, resulting in a cleaner cut, less heat generation, and less material sticking to the blade.

Density & Microstructure: The Foundation of Performance

This is the deepest level of blade science. The microstructure is the internal arrangement of a material's crystals. An even, dense, and fine-grained microstructure means the properties like hardness and toughness are consistent across the entire blade. There are no weak spots. Modern manufacturing methods like powder metallurgy are excellent for this. In this process, fine metal powders are pressed into shape and heated, creating a blade that is incredibly dense and uniform. This results in a blade that wears predictably and has superior strength, which is why it's a core technology for our high-performance blades at PASSION.

How To Select The Right Combination Of Physical Properties For Different Application Scenarios?

Choosing the right blade feels like guesswork. You look at spec sheets, but you're not sure which properties matter most for your specific job. Making the wrong choice leads to wasted material and money.

First, identify your primary cutting challenge: is it abrasion, impact, or the need for precision? Then, match the blade's dominant properties to that challenge. For example, choose high toughness for impact-heavy jobs, and prioritize hardness and surface finish for high-precision film cutting.

Putting all this theory into practice is what my job is all about. It's about translating a customer's problem into a blade specification. Let me share a story.

A while ago, I started working with Javier, a production manager at a large packaging company in Canada. They were cutting thick, recycled cardboard to make boxes. Their problem was twofold. First, their blades were dulling very quickly because recycled cardboard is surprisingly abrasive. Second, their blades would often chip or break completely. This was because the recycled material sometimes contained hidden metal staples, which delivered a hard shock to the blade edge. They were stuck in a frustrating cycle of changing blades constantly.

When I spoke with Javier, I knew this wasn't a simple "hardness" problem. They needed a balanced solution. They needed high wear resistance for the abrasive cardboard, but they also needed excellent impact resistance to survive the staples.

Based on this, I recommended a blade made using a powder metallurgy steel. This material offered two key advantages. It had a very high concentration of hard carbide particles, which provided fantastic wear resistance to combat the abrasive cardboard. At the same time, its incredibly uniform microstructure gave it a higher toughness than a traditional steel of similar hardness. This meant it could absorb the shock from hitting a staple without chipping.

The results were immediate. Javier reported that the new blades were lasting three times longer than their old ones. This drastically reduced their machine downtime and blade replacement costs. More importantly, their cut quality became consistent, which improved the look and strength of their final boxes.

This case perfectly shows the selection process. We matched the properties to the application:

| Application Scenario | Main Challenge(s) | Key Properties Needed |

|---|---|---|

| Thin Film & Foil Cutting | Precision, clean edge, no stretching | High Hardness, Excellent Surface Finish |

| Paper Converting | Abrasion from fillers, high speed | High Wear Resistance, Hardness |

| Metal Shearing | High force, heavy impact | High Strength, High Toughness, Impact Resistance |

| Recycling & Demolition | Unpredictable impacts, abrasion | High Toughness, Impact Resistance, Good Wear Resistance |

| Food Processing | Hygiene, corrosion, clean cuts | Corrosion Resistance, Surface Finish, Hardness |

By starting with your unique challenge, we can zero in on the physical properties that matter most and engineer a blade that doesn't just work, but excels.

Conclusion

Choosing the right blade is not about finding the hardest one. It is about matching a balanced set of physical properties to your specific cutting needs to achieve optimal performance.

Explore how hardness influences cutting efficiency and blade longevity. ↩

Learn about the role of strength in maintaining blade shape under pressure. ↩

Discover how toughness helps blades absorb impacts and resist chipping. ↩

Find out how wear resistance can extend the life of your industrial blades. ↩

Understand the importance of impact resistance for blades in unpredictable cutting environments. ↩

Learn how thermal conductivity prevents overheating and maintains blade sharpness. ↩

Explore how a smooth surface finish can enhance cutting quality and reduce friction. ↩

Discover how microstructure affects the consistency and durability of blades. ↩