Struggling with inconsistent cuts in your production line? Poor quality shear slitting leads to wasted material and costly downtime. Rolling shear blades1 offer the precision and reliability you really need.

Rolling shear blades are high-precision industrial tools used for slitting continuous materials. They excel in metal processing, packaging, plastics, lithium battery production, and paper industries. Their design ensures clean, consistent cuts at high speeds, significantly improving production efficiency and final product quality.

Those are the high-level applications, but the real value is in the details of each industry. Let's look closer at how these blades perform in different sectors, starting with metal processing. The specific challenges in each industry really show why choosing the right blade is so important.

How Do Rolling Shear Blades Excel In The Metal Processing Industry?

Are burrs and rough edges ruining your metal coil slitting? This compromises product quality and can damage downstream equipment. Rolling shear blades provide a clean, burr-free cut2 every time.

In metal processing, rolling shear blades are key for slitting steel, aluminum, and stainless steel coils. Their superior hardness and precision ensure a clean cut with a smooth surface finish. This is essential for industries like automotive, home appliances, and construction where quality standards are very high.

I remember working with a client in Germany, let's call him Klaus, who manufactures parts for the automotive industry. His old blades were leaving tiny burrs on the edges of the steel coils. This was a huge problem because these imperfections were scratching the dies in his stamping presses, leading to frequent and costly replacements. He was frustrated with the constant downtime and material waste. We switched them to our high-speed steel rolling shear blades. The difference was immediate. The cuts were clean and precise, completely eliminating the burr issue. Klaus told me his press die lifespan doubled, and his overall efficiency went up by nearly 20%. This case really showed me how a small component like a blade can have a massive impact on the entire production line.

Understanding The Blade's Impact

The effectiveness of a rolling shear blade in metal processing depends on several factors. It's not just about the blade itself but how it matches the material and the machine's parameters.

| Factor | Description | Impact on Quality |

|---|---|---|

| Material Hardness | The blade material must be significantly harder than the metal being cut. | Prevents premature wear and ensures a clean shear. |

| Edge Geometry | The angle and sharpness of the blade's edge. | Determines the level of burr and edge deformation. |

| Blade Clearance | The precise gap set between the upper and lower blades. | Critical for controlling cut quality and minimizing stress on the material. |

| Cutting Speed | The operational speed of the slitting line. | High-quality blades maintain performance even at high speeds. |

Why Are Rolling Shear Blades Essential For The Packaging And Plastics Industry?

Is your plastic film slitting process causing material stretching3 or curling? These defects compromise the final product's integrity and appearance. Rolling shear blades cut cleanly without causing heat or distortion.

For packaging and plastics, rolling shear blades provide the precision needed to slit delicate films like PE, PP, and PET. Their low-friction cutting action4 avoids pulling or deforming the material. This ensures uniform roll widths and high-quality finished products that meet strict industry standards.

In the flexible packaging sector, consistency is everything. I once helped a customer in Mexico who produces food-grade plastic wrap. Their main issue was edge curl5. When their old blades began to dull even slightly, the heat generated would cause the thin film edges to curl up. This made the rolls unusable for their automated packaging machines. We introduced them to our rolling shear blades. The ultra-low friction surface generated almost no heat during the slitting process. Their edge curl problem vanished completely, and because the blades stayed sharp longer, they reduced their blade changeover downtime by 70%. It proved that for sensitive materials, the blade's surface finish is just as important as its sharpness.

Key Benefits For Thin Materials

Slitting thin films and plastics presents unique challenges that rolling shear blades are perfectly designed to solve. The goal is to separate the material without introducing stress or heat.

-

No Thermal Damage

The rolling shear action is a mechanical cut that generates minimal friction. Unlike other methods, it doesn't heat up the material. This is very important for plastics like PE that have a low melting point. A cool cut prevents melted or hardened edges.

-

Prevents Material Stretching

The blades make a clean, instantaneous cut. This prevents the pulling or stretching common with duller or less precise cutting tools. The film maintains its original tension and structural integrity, which is vital for later processing steps like printing or laminating.

-

Reduces Dust and Debris

A sharp, well-aligned rolling shear blade creates a clean fracture6, not a tear. This minimizes the creation of plastic dust and small particles. A cleaner processing environment is safer and results in a higher-quality end product, especially for food and medical packaging applications.

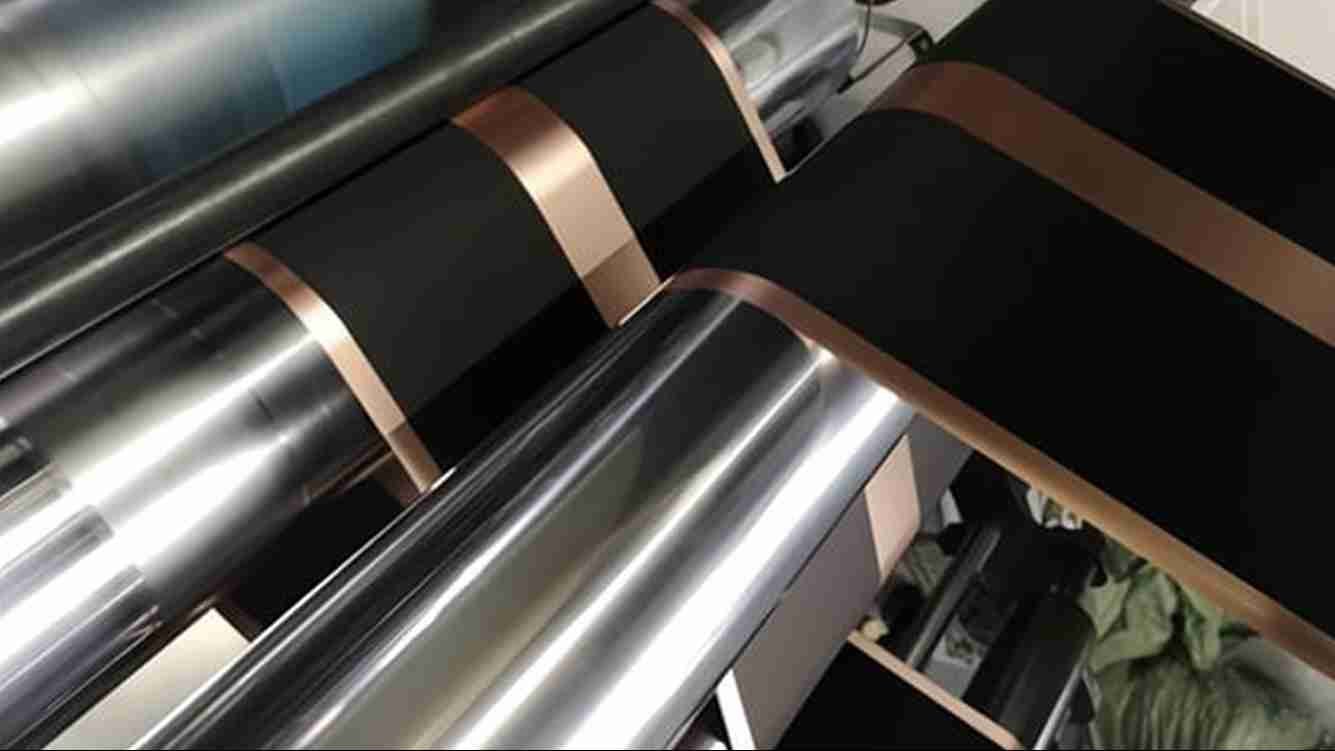

What Role Do Rolling Shear Blades Play In The Lithium Battery Industry?

Are inconsistent electrode edges causing safety concerns in your battery production? Burrs and dust can lead to short circuits and compromise battery performance. Rolling shear blades deliver clean, dust-free cuts.

In the lithium battery industry, rolling shear blades are used for precise slitting of anode and cathode electrode sheets. A perfectly clean, burr-free edge is essential. This prevents contamination and internal short circuits, directly improving the battery's safety, consistency, and overall lifespan.

The precision needed in battery manufacturing is on another level. I worked with an emerging battery tech company in South Korea. They were having trouble with microscopic dust particles created during the electrode slitting process. This dust, containing active material, could contaminate the cell and lead to failure. Their existing setup was simply not clean enough. We designed a custom set of rolling shear blades for them. It resulted in a near-perfect cut with virtually zero dust generation. Their battery scrap dropped significantly, helping them secure a major contract. It was a clear example of how the right blade technology can enable innovation in other industries.

Critical Requirements For Electrode Slitting

The quality of the slit edge on a battery electrode directly influences the final product's safety and performance. Rolling shear blades are preferred because they meet these strict demands.

| Requirement | Why It Matters | How Rolling Shear Blades Help |

|---|---|---|

| No Burrs | Metal burrs can pierce the separator film, causing a dangerous internal short circuit. | Properly set rolling shear blades produce a clean, flat edge with no protruding metal fragments. |

| No Dust | Loose particles of active material can contaminate the electrolyte and interfere with performance. | The sharp, shearing action minimizes particle creation compared to other cutting methods. |

| Edge Straightness | A wavy or uneven edge leads to inconsistent stacking and affects battery capacity and life. | High-rigidity blades and precise machine alignment ensure a perfectly straight cut along the entire coil. |

| Consistency | Every meter of the electrode must be slit to the same exact width for automated assembly. | Rolling shear technology is stable and reliable, providing exceptional dimensional consistency at high speeds. |

How Do Rolling Shear Blades Boost Efficiency In The Paper Processing Industry?

Is your paper slitting process slow and creating a lot of dust? Inefficient cutting leads to production bottlenecks and lower quality rolls. Rolling shear blades offer high-speed, clean cutting for paper.

In the paper industry, rolling shear blades are vital for converting large parent rolls into smaller, finished rolls of specific widths. Their ability to operate at high speeds while maintaining a clean, dust-free cut is key to maximizing throughput and ensuring the quality of the final product.

A paper mill I consulted with in Southeast Asia was facing a major bottleneck at their slitting stage. They produced huge master rolls of paper, but their slitting machines were old and couldn't run fast without causing blade vibration and producing a fuzzy, dusty edge. The dust was a big problem, as it contaminated the final product. We recommended an upgrade to a set of our D2 tool steel rolling shear blades, known for their excellent balance of toughness and wear resistance. With the new blades installed and properly aligned, they were able to increase their line speed by 40%. The cuts were sharp and clean, significantly reducing the dust problem. This single change allowed their finishing department to finally keep up with the paper machine's output.

Improving Speed And Quality in Paper Slitting

The main goals in paper processing are speed and quality. Rolling shear blades contribute directly to both of these objectives.

-

Higher Production Speeds

Modern paper converting lines run at incredible speeds. Rolling shear blades are designed to handle this. Their circular design provides a continuous cutting edge, allowing for smooth, uninterrupted slitting even on the fastest machines. This directly translates to higher output and better operational efficiency.

-

Reduced Dust Generation

Paper dust is a major concern in mills. It can be a fire hazard, cause respiratory issues for workers, and contaminate the final product. A sharp shear cut slices the paper fibers cleanly, while a dull blade tears them. This tearing action is what creates the most dust. Consistently sharp rolling shear blades are essential for a cleaner, safer work environment.

-

Superior Edge Quality

The quality of the slit edge affects how the final paper roll will perform. A clean-cut edge prevents issues like edge cracks or web breaks in subsequent printing or converting processes. It also gives the final product, whether it's printing paper or cardboard, a more professional appearance. This quality is achieved through the precise shearing action of the blades.

Conclusion

Rolling shear blades are essential in many industries. They deliver the precision, speed, and quality needed for materials from steel to paper, ensuring efficient production and superior final products.

Explore the mechanics and benefits of rolling shear blades for improved production efficiency. ↩

Learn why burr-free cuts are crucial for maintaining product quality. ↩

Explore solutions to prevent material stretching in slitting processes. ↩

Discover how low-friction cutting improves material handling and quality. ↩

Learn about edge curl issues and solutions for maintaining film quality. ↩

Discover the significance of clean fractures for product integrity. ↩