Blades dulling too fast? This downtime costs you money and slows production. Understanding key blade characteristics is the first step to solving this problem and boosting your output.

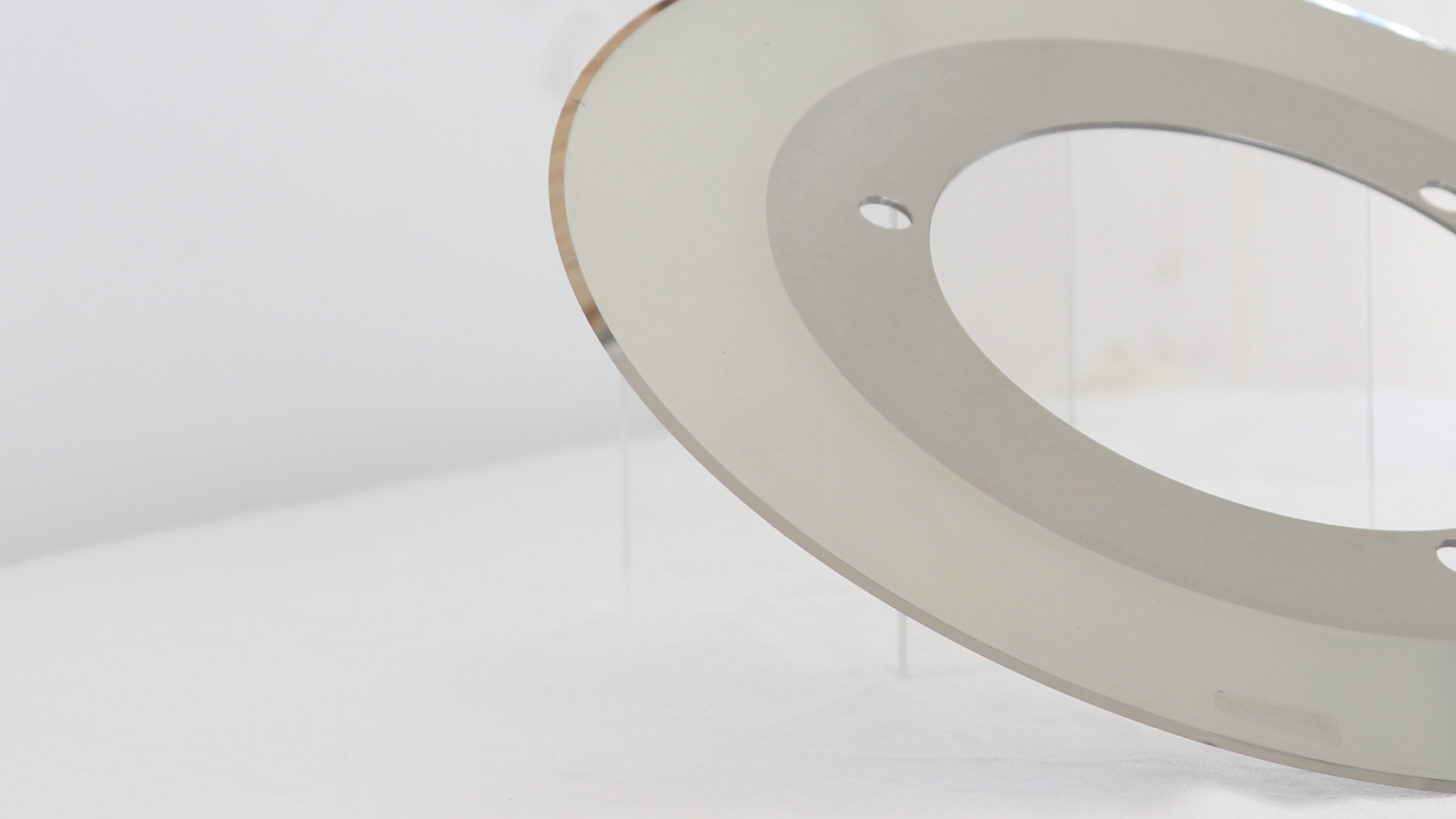

The primary characteristics influencing an industrial blade's cutting performance are its physical properties, like hardness1 and wear resistance2, and its chemical properties, such as corrosion resistance3. Finding the right balance among these three factors is key to achieving optimal performance for any specific application.

These three factors—hardness, wear resistance, and corrosion resistance—might seem simple on the surface. But each one plays a complex role, and how they interact is what truly defines a blade's performance. Let's break down each characteristic so you can make a more informed choice for your operation. This will help you find the perfect cutting solution.

How Does Hardness Affect A Blade's Sharpness And Durability?

Your blade chips easily under pressure. This causes unexpected stops and wasted material. The issue is likely an imbalance between hardness and toughness in your blade's material.

Hardness allows a blade to resist deformation and maintain a sharp cutting edge under pressure. However, extremely hard materials can be brittle. The ideal blade balances high hardness for sharpness with sufficient toughness to prevent chipping and breaking during operation.

When we talk about hardness, we are talking about a material's ability to resist being bent or deformed. In industrial blades, this is crucial. A hard blade holds its sharp edge for a much longer time, even when cutting tough materials. This means you get clean, precise cuts for more production cycles. But hardness is only half the story. The other half is toughness, which is the ability to absorb impact without fracturing. I remember working with Fabian, a procurement manager from a paper mill in Germany. His slitter blades were chipping constantly, which caused a lot of downtime. The problem was that his previous supplier focused only on extreme hardness. The blades were hard, but they were also very brittle. They couldn't handle the small vibrations and impacts of the high-speed machine. We helped him by providing a custom alloy blade that balanced high hardness with improved toughness. The new blades resisted chipping and their lifespan doubled.

Hardness vs. Toughness: A Necessary Balance

It’s easy to think that harder is always better, but that’s a common mistake. Imagine the difference between glass and a car tire. Glass is very hard but shatters easily. A tire is much softer but can take a huge amount of impact. An industrial blade needs to find the sweet spot between these two extremes. We measure hardness on a scale like the Rockwell Hardness C scale4 (HRC).

| Material Property | Description | High Level Benefit | High Level Drawback |

|---|---|---|---|

| Hardness | Resists deformation and maintains a sharp edge. | Longer edge retention, precision cuts. | Can become brittle, prone to chipping. |

| Toughness | Absorbs impact and energy without fracturing. | Resists chipping and catastrophic failure. | Softer edge, may dull faster. |

Finding this balance is what we specialize in at PASSION. For Fabian, we didn't just give him the hardest blade; we gave him the right blade for his specific machine and paper type.

Why Is Wear Resistance Crucial For Blade Longevity?

Are you constantly replacing worn-out blades? This frequent maintenance is expensive and cuts into your production time. The problem is likely low wear resistance in your current blade material.

Wear resistance is a material's ability to withstand abrasion and friction during cutting. High wear resistance directly translates to a longer blade lifespan, reduced maintenance, and more consistent cutting quality over time, making it a critical factor for high-volume operations.

Wear resistance is closely related to hardness, but it’s not exactly the same thing. Think of it as the blade's endurance. Every cut creates friction. Over thousands or millions of cuts, this friction slowly grinds away the blade's edge. A material with high wear resistance can fight this process much more effectively. This is especially important in industries where the material being cut is abrasive. For example, paper and corrugated board contain fillers like clay or calcium carbonate. These tiny, hard particles act like sandpaper on the cutting edge. In the plastics industry, some materials reinforced with glass fibers are extremely abrasive. In these situations, a standard blade will dull very quickly, no matter how sharp it was at the start. You need a material, like tungsten carbide or certain high-alloy tool steels, specifically designed to handle this friction.

Understanding The Types Of Wear

Wear isn't just one thing. It comes in different forms, and knowing which one affects you is key. Two common types in our industry are:

- Abrasive Wear: This is caused by hard particles in the material being cut, like the fillers in paper I mentioned. It physically scrapes material off the blade edge.

- Adhesive Wear: This happens when small fragments from the blade and the workpiece weld together due to pressure and heat, then get torn away. You might see this when cutting certain gummy plastics or soft metals.

By understanding the type of wear your application causes, we can select a blade material with the right microstructure and alloy composition to combat it. This advanced analysis is a core part of how we deliver Precision in Every Cut, Innovation in Every Blade. Choosing the right material from the start means fewer blade changes, less downtime, and a more efficient production line.

When Does Corrosion Resistance Become The Most Important Factor?

Do you see rust or pitting on your blades? This degradation ruins cut quality and can contaminate your products. You need a blade designed to withstand your specific operating environment.

Corrosion resistance is vital when blades operate in humid, wet, or chemically active environments. In industries like food processing or cutting certain plastics, it prevents rust and chemical reactions that degrade the blade, ensuring product safety and extending its life.

Sometimes, the biggest threat to your blade isn't the material it cuts, but the air and moisture around it. Corrosion is a chemical attack on the blade's material. The most common form is rust, which happens to steel when it's exposed to oxygen and water. For many industrial applications, a little surface rust isn't a huge problem. But in certain industries, it's a complete deal-breaker. In food processing, for example, a rusty blade is a major contamination risk. Any blade that touches food must be made from a material like stainless steel, which has a high chromium content to resist rust and acidic juices from fruits and vegetables. In these cases, corrosion resistance is the number one priority, even if it means sacrificing a small amount of hardness or wear resistance. A blade that stays clean and safe is much more valuable than one that stays sharp but contaminates the product.

Environments That Demand Corrosion Resistance

The need for corrosion resistance goes beyond just food and water. Many industrial processes involve chemicals, adhesives, or high humidity that can attack standard tool steels.

- Packaging: Cutting tapes or films with aggressive adhesives can lead to chemical reactions on the blade's surface.

- Textiles: The dyes and treatments used in fabric production can be corrosive.

- Plastics: The manufacturing of certain polymers can release corrosive gases.

In my experience, customers sometimes focus so much on cutting performance that they forget about the environment. I worked with a client in the frozen food industry who was using a high-carbon steel blade. It was very hard and held its edge well for a few hours, but the constant moisture and temperature changes from wash-down cycles caused it to rust quickly. We switched them to a specialized 440C stainless steel blade. It might have needed sharpening slightly more often, but it never rusted, which eliminated product contamination risk and ultimately saved them money.

How Do You Find The Right Balance Between These Key Characteristics?

Confused by all the material options? Choosing the wrong one means poor performance and wasted money. The secret isn't finding the "best" material, but the right one for your job.

The right balance is found by first analyzing your specific application. You must consider the material being cut, the machine's speed, and the operating environment. This analysis determines which characteristic—hardness, wear, or corrosion resistance—should be prioritized for the best results.

There is no single "best" industrial blade material. A tungsten carbide blade that is perfect for slitting abrasive paper would be a terrible choice for a high-impact chopping application because it would shatter. A stainless steel blade that is essential for food processing might wear out too quickly when cutting fiberglass. The key is to understand the trade-offs. You can’t maximize all three properties at once. If you increase hardness, you often reduce toughness. If you want the highest wear resistance, you might have to give up some corrosion resistance. This is where a deep understanding of your application is critical. This is where partnership with an expert blade manufacturer comes in. When a customer comes to us, we don't just ask "What blade do you want?" We ask, "What are you cutting? What are your machine's speeds? What is the environment like? What is your biggest problem right now—chipping, dulling, or rust?"

A Practical Guide To Prioritizing

The answers to those questions help us find the perfect balance. This is exactly what we did for Fabian and his paper mill. His problem was chipping (low toughness) and dulling (low wear resistance). He didn't need corrosion resistance for his dry paper application. So we focused on a material that prioritized hardness and wear resistance, with just enough toughness for his machine.

| Application Example | Priority 1 | Priority 2 | Lower Priority | Common Material Choice |

|---|---|---|---|---|

| Dry Paper Slitting | Wear Resistance | Hardness | Corrosion Resistance | Tungsten Carbide, D2 Steel |

| Frozen Meat Slicing | Corrosion Resistance | Hardness | Wear Resistance | 440C Stainless Steel |

| Plastic Slitting | Toughness (Impact) | Wear Resistance | Corrosion Resistance | Shock-Resistant Tool Steel |

Choosing the right blade is a strategic decision that directly impacts your efficiency and profitability. At PASSION, our goal is to be more than a supplier; we are your partner in finding the most effective cutting solution for your unique needs.

Conclusion

The best blade performance comes from the right balance of hardness, wear, and corrosion resistance for your specific job. We can help you find your perfect cut.

Understanding hardness helps you choose blades that maintain sharpness and resist deformation, crucial for efficient cutting. ↩

High wear resistance ensures longer blade lifespan and consistent cutting quality, reducing maintenance costs. ↩

Corrosion resistance is vital for blades in humid or chemically active environments, ensuring product safety and longevity. ↩

The Rockwell Hardness C scale measures material hardness, helping you select the right blade for your cutting needs. ↩