Choosing the wrong blade material causes frequent downtime and poor cuts. This hurts your production and profits. The right material choice ensures efficiency, longevity, and superior performance.

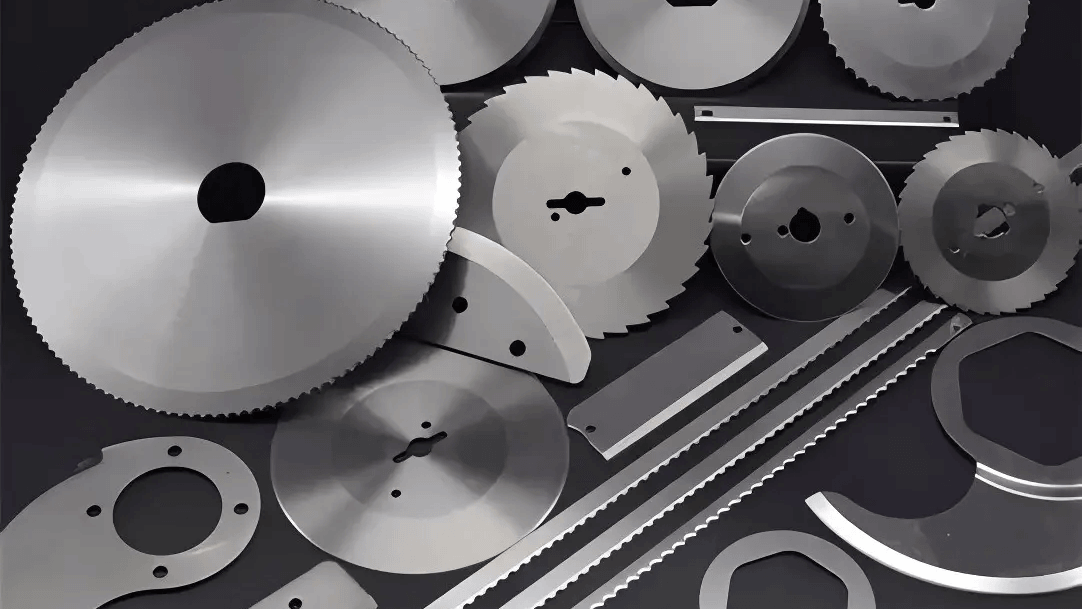

The top ten blade materials include High-Carbon Steel, Stainless Steel, Tungsten Carbides1, High-Carbon High-Chromium Tool Steels, High Speed Steels, 52100 High-Carbon Chromium Alloy Steel, M-2 molybdenum high-speed steel, D-2 air-hardening high-carbon, high-chromium tool steel, CPM 10V high-vanadium tool steel and Ceramics. Each offers a unique balance of hardness, toughness, and wear resistance, making them ideal for specific industrial cutting applications, from paper and plastics to metals and textiles.

Selecting the right material is crucial for blade performance2. It impacts everything from the cut quality to how long the blade lasts. I have worked with many clients, helping them find the perfect match for their needs. Let's look at each material in more detail. This will help you understand which one is best for your specific application.

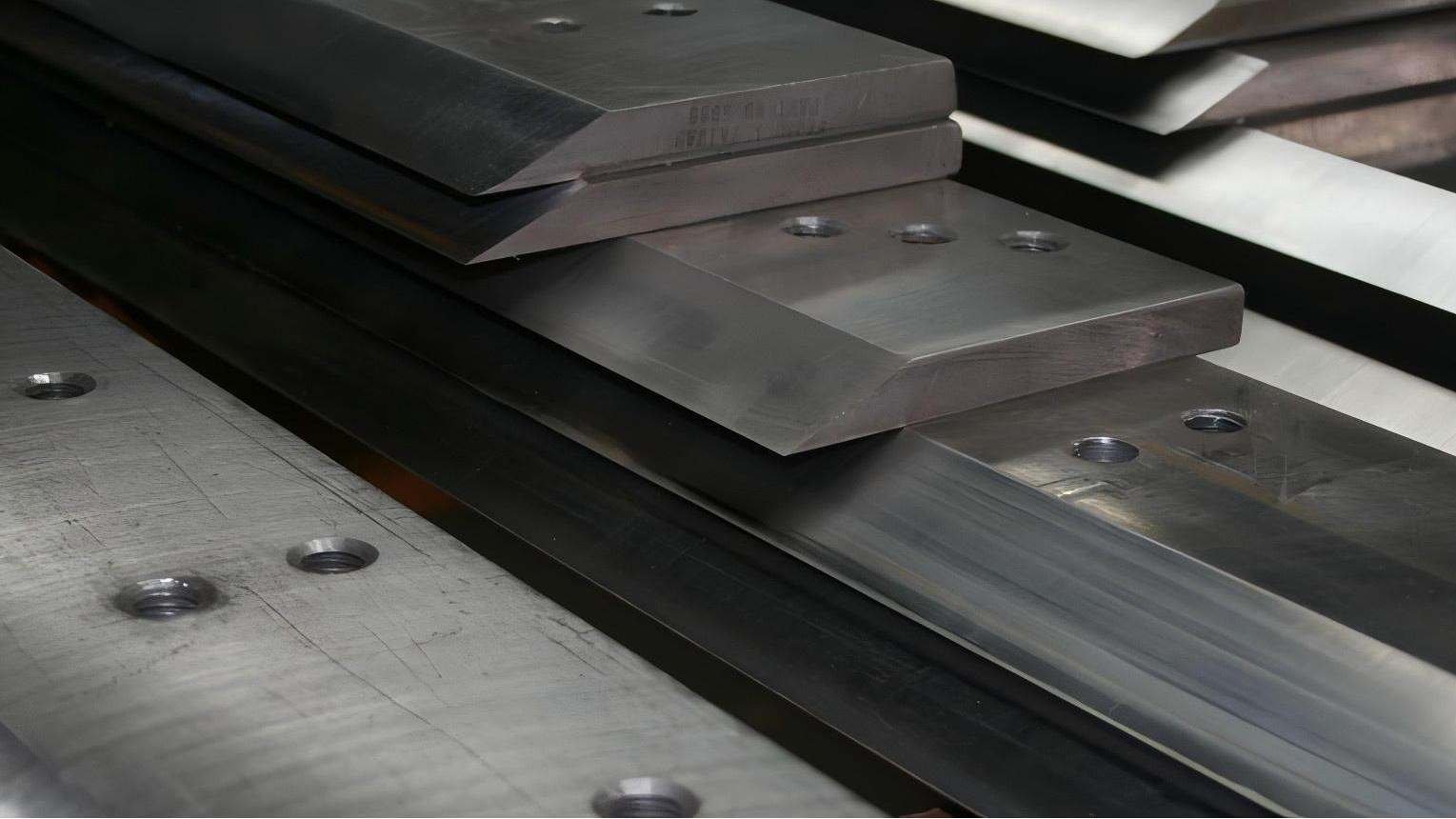

Why Is High-Carbon Steel A Cost-Effective Choice For Industrial Blades?

Are production costs squeezing your budget? Frequent blade replacement3s can be expensive. High-carbon steel offers a reliable, low-cost solution without sacrificing performance in many common applications.

High-carbon steel is cost-effective due to its simple composition and manufacturing process. It provides excellent hardness and good wear resistance4 for its price. This makes it a popular choice for general-purpose cutting in industries like paper, plastics, and food, where high corrosion resistance5 isn't needed.

I remember working with a client in Brazil, a large-scale paper converting company. They were struggling with high blade costs for their sheeting machines. Their existing blades were expensive and did not offer a much longer life to justify the price. They needed a material that was hard enough for clean cuts but did not break their budget. I recommended our high-carbon steel blades. The transition was seamless. They found the blades provided sharp, clean cuts and the lower cost per blade significantly reduced their operational expenses. They were able to maintain their production quality while improving their bottom line. It was a perfect example of how the right material can be both effective and economical.

Key Characteristics Of High-Carbon Steel

| Feature | Description | Best For |

|---|---|---|

| Hardness | High hardness after heat treatment. | General shearing. |

| Cost | Very economical and widely available. | Budget-conscious operations. |

| Processability | Easy to machine and sharpen. | Low-speed applications. |

| Limitation | Poor corrosion resistance; rusts easily. | Dry environments. |

When Should You Choose Stainless Steel For Your Industrial Blades?

Worried about rust and contamination in your cutting process? Standard blades corrode in damp environments. Stainless steel blades offer superior rust resistance, ensuring clean, hygienic cuts every time.

Choose stainless steel for blades used in damp, humid, or sterile environments. Its chromium content provides excellent corrosion resistance, making it ideal for the food processing, medical, and packaging industries. While not as hard as high-carbon steel, its durability and cleanliness are key advantages.

A client of ours in Thailand runs a large fruit processing facility. They faced constant issues with blade rusting due to the high moisture and acidity of the fruit. This not only contaminated the product but also forced them to replace blades almost daily. I suggested they switch to our food-grade stainless steel blades. The results were immediate. Blade lifespan increased dramatically, and the rust issue was completely eliminated. It ensured their products met strict hygiene standards and cut down their maintenance time and costs. This case showed me how critical material choice is when safety and hygiene are the top priorities.

Key Characteristics Of Stainless Steel

| Feature | Description | Best For |

|---|---|---|

| Corrosion Resistance | Excellent resistance to rust and chemicals. | Food, medical, humid settings. |

| Toughness | Good toughness and resistance to chipping. | Applications with some impact. |

| Hygiene | Easy to clean and sterilize. | Sterile environments. |

| Limitation | Lower hardness than high-carbon steels. | Less demanding wear applications. |

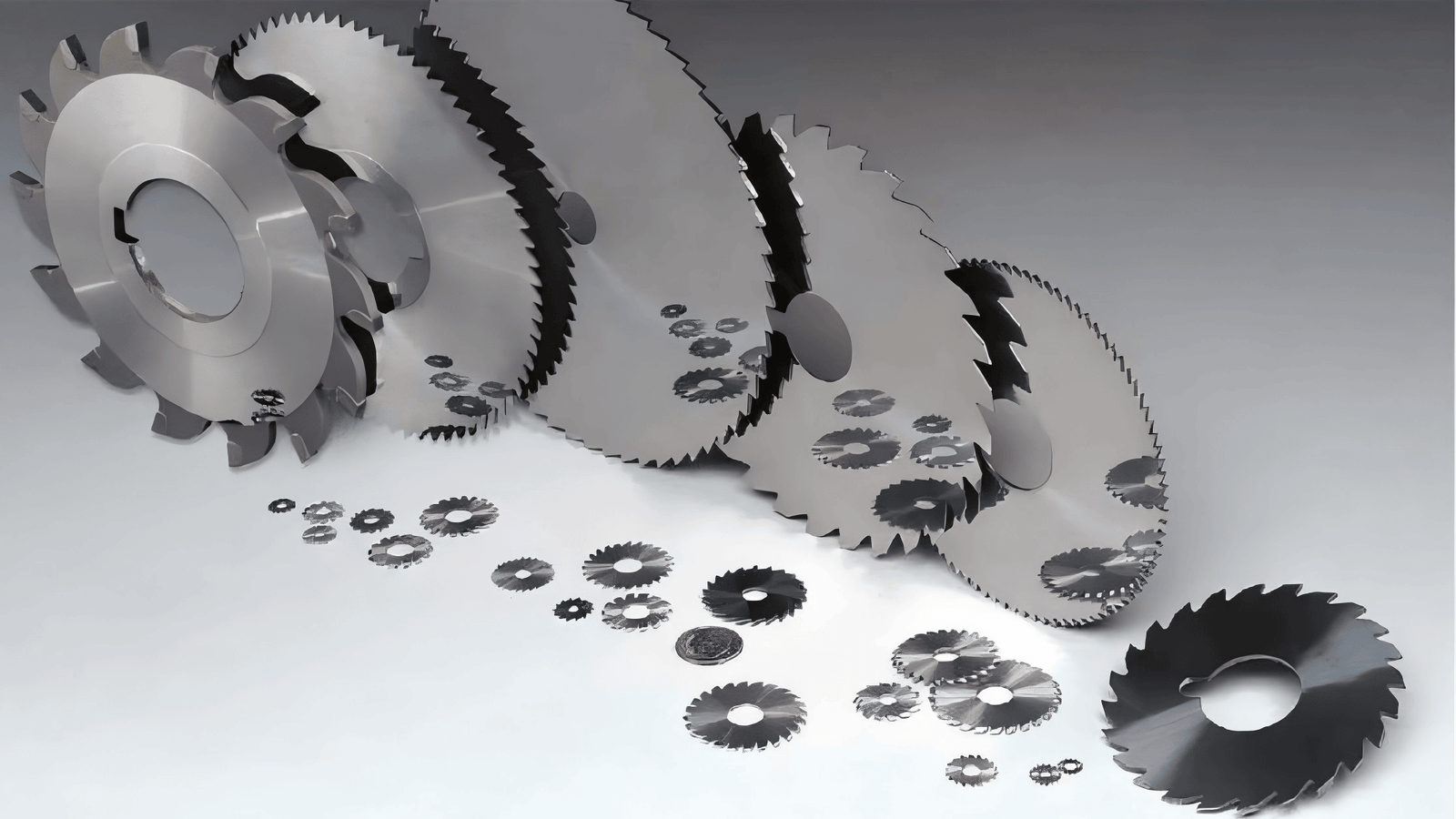

What Makes Tungsten Carbide Ideal For High-Wear Applications?

Are your blades dulling too quickly on abrasive materials6? This leads to poor cuts and constant machine downtime. Tungsten carbide offers exceptional hardness for maximum wear resistance.

Tungsten carbide is ideal for high-wear applications because it is one of the hardest materials available. Its exceptional resistance to abrasion means it stays sharp far longer than steel blades. This makes it perfect for cutting tough materials like corrugated cardboard, fiberglass, and composite materials.

I once worked with a packaging company in Germany that specialized in heavy-duty corrugated cartons. They were frustrated because their steel blades would wear out in just a few shifts, causing dusty, frayed edges on the cartons. The abrasive nature of the cardboard was too much for their blades. We supplied them with our solid tungsten carbide slitter blades. The difference was night and day. Their blade change intervals went from twice a day to once every few weeks. The cut quality was consistently clean and precise. This greatly improved their productivity and reduced waste. It is a clear example of how investing in a superior material like tungsten carbide pays off in demanding situations.

Key Characteristics Of Tungsten Carbide

| Feature | Description | Best For |

|---|---|---|

| Hardness | Extremely high hardness (near diamond). | Cutting abrasive materials. |

| Wear Resistance | The best wear resistance of any material. | Long production runs. |

| Sharpness | Holds a sharp edge for a very long time. | High-precision slitting. |

| Limitation | Brittle and can chip under high impact. | Stable, vibration-free cutting. |

Why Is High-Carbon High-Chromium Tool Steel A Versatile Choice?

Do you need a blade that is both hard and tough? Some materials are too brittle, others wear too fast. High-carbon high-chromium tool steel provides a great balance.

This type of steel is versatile because it balances high wear resistance with good toughness. The high chromium content forms hard carbides that resist abrasion, while the base steel provides strength. It is excellent for cold work applications like shearing thin metal and die cutting.

A plastics recycling company in Mexico contacted me. They were shredding various types of plastic waste, and the blades on their granulators were failing frequently. Some blades would wear down quickly on harder plastics, while others would chip from contaminants. They needed a more robust and versatile solution. I recommended our blades made from high-carbon, high-chromium tool steel. Its balanced properties were perfect for their unpredictable feedstock. The new blades resisted wear from abrasive plastics and had enough toughness to withstand minor impacts without chipping. Their machine uptime improved significantly, and their blade replacement cycle was extended by 300%.

Key Characteristics Of High-Carbon High-Chromium Tool Steel

| Feature | Description | Best For |

|---|---|---|

| Wear Resistance | High resistance to abrasive wear. | Long-lasting cutting edges. |

| Hardness | Achieves high hardness after heat treatment. | Shearing and punching tools. |

| Dimensional Stability | Holds its shape well after heat treatment. | Precision cutting tools. |

| Limitation | Moderate toughness, not for heavy shock. | Cold work applications. |

How Does High-Speed Steel Perform In High-Temperature Cutting?

Does your cutting process generate a lot of heat? This can soften standard blades, causing them to fail. High-speed steel is designed to stay hard even when hot.

High-speed steel (HSS) performs exceptionally well in high-temperature cutting due to its "red hardness." This property allows it to retain its hardness and sharp cutting edge even when heated to high temperatures. This makes it ideal for metal cutting, drilling, and high-speed woodworking applications.

I consulted for a client in India that manufactures metal tubes. Their circular saw blades, used for cutting the tubes to length, were overheating and losing their sharpness quickly. The friction from the high-speed cutting was generating too much heat for their standard tool steel blades. This slowed down their entire production line. We provided them with our HSS blades. The red hardness of the material made all the difference. The blades could withstand the heat without softening, allowing them to cut faster and for longer periods between changes. Their productivity saw a major boost, and the finish on the cut tubes was much cleaner. It was a classic case of matching the material to the thermal demands of the job.

Key Characteristics Of High-Speed Steel (HSS)

| Feature | Description | Best For |

|---|---|---|

| Red Hardness | Retains hardness at high temperatures. | High-speed metal cutting. |

| Wear Resistance | Very good wear resistance due to alloys. | Milling and drilling. |

| Toughness | Tougher than carbide, resists chipping. | Interrupted cuts. |

| Limitation | More expensive than carbon steels. | High-performance applications. |

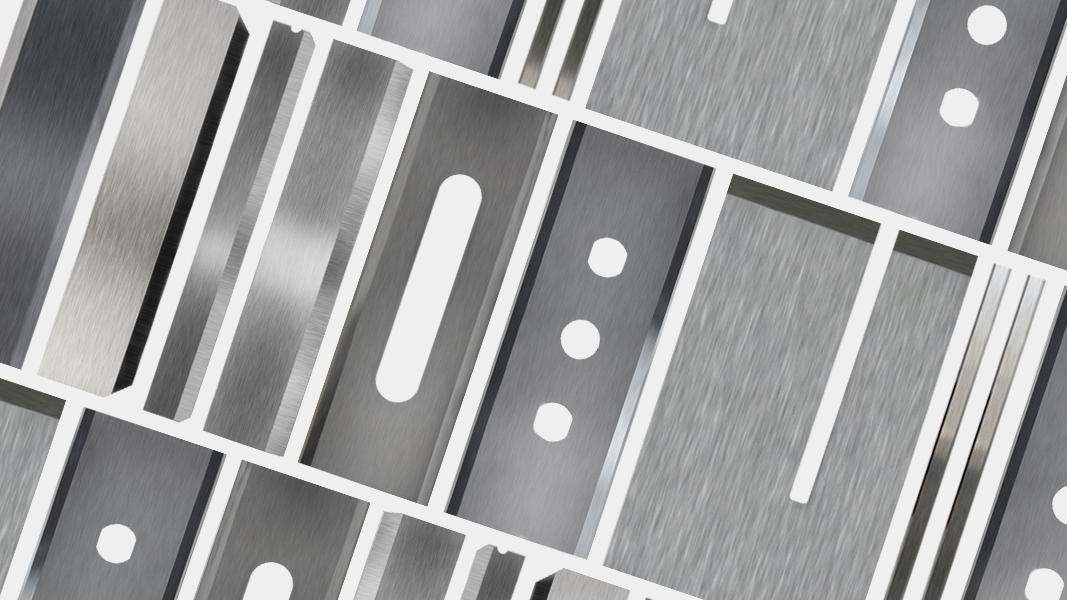

What Makes 52100 Steel A Top Choice For Precision Blades?

Are you struggling to achieve the perfect, clean cut? Minor imperfections in the blade material can ruin your product. 52100 steel offers exceptional structural purity for precision.

52100 steel is a top choice for precision blades because it is a very clean, high-purity alloy steel. Originally designed for ball bearings, it has excellent wear resistance and can be honed to an extremely fine, sharp edge7. This makes it perfect for razor-sharp blades.

A textile manufacturer in Turkey faced a challenge with their fabric slitting operation. They were cutting delicate synthetic fibers, and their blades were leaving behind tiny frays and pulls. The issue was traced back to microscopic imperfections on the blade edge. They needed an incredibly smooth and sharp blade. After understanding their problem, I knew our 52100 steel blades would be the solution. This material can be polished to an almost perfect edge. Once they installed the new blades, the problem vanished. The cuts were flawlessly clean, which improved their fabric quality and reduced waste. This experience highlighted how important material purity is for ultra-fine cutting tasks.

Key Characteristics Of 52100 Steel

| Feature | Description | Best For |

|---|---|---|

| Edge Retention | Holds an extremely fine and sharp edge. | Razor-sharp cutting. |

| Wear Resistance | Excellent resistance to wear and abrasion. | Textile and film slitting. |

| Hardness | Can be heat-treated to a high hardness level. | Precision blades. |

| Limitation | Low corrosion resistance, requires care. | Dry cutting environments. |

Why Is M2 Considered The "Go-To" High-Speed Steel?

Choosing between different high-speed steels can be confusing. You need a reliable, all-around performer. M2 steel offers a great combination of toughness, wear resistance, and cost-effectiveness.

M2 is considered the "go-to" high-speed steel because of its excellent and well-balanced properties. It provides high hardness, good toughness, and great wear resistance at a lower cost than many other HSS grades. This versatility makes it the industry standard for a wide range of cutting tools8.

I remember a client in Canada who ran a metal fabrication shop. They needed blades for various tasks, including sawing, milling, and punching different types of steel. They were buying different specialized blades for each job, which was complicated and costly. I recommended they consolidate and use blades made from M2 high-speed steel. Its balanced profile meant it could handle almost everything they threw at it. The M2 blades were tough enough for interrupted cuts in milling and hard enough for sawing structural steel. This simplified their inventory and purchasing, and the overall performance was consistently reliable across all applications. It showed me the true value of a versatile workhorse material like M2.

Key Characteristics Of M2 High-Speed Steel

| Feature | Description | Best For |

|---|---|---|

| Versatility | Excellent balance of toughness and hardness. | General metalworking. |

| Red Hardness | Good resistance to softening at high heat. | Drills, taps, and saw blades. |

| Cost-Effectiveness | The most popular and economical HSS. | All-purpose high-speed cutting. |

| Limitation | Not the absolute best in any single category. | When extreme performance is not needed. |

Where Does D2 Tool Steel Excel In Industrial Cutting?

Do your blades wear out too fast, forcing constant replacements? You need a material that lasts. D2 tool steel is known for its incredible wear resistance for long life.

D2 tool steel excels in applications requiring high wear resistance and long blade life. Its high carbon and chromium content create a large volume of hard carbides. This makes it perfect for slitting paper, film, and foil, and for tools used in stamping and forming operations.

A flexible packaging converter in Poland was having issues with their film slitting blades. They were processing abrasive plastic films with additives, and their blades were losing sharpness in a matter of hours. This resulted in poor roll quality and a lot of scrap. They needed a blade that could hold its edge for an entire shift. We introduced them to our D2 tool steel blades. The high wear resistance was the key. The new blades easily lasted through multiple shifts without needing to be changed or sharpened. Their productivity increased, and their scrap rate dropped significantly

Key Characteristics Of D2 Tool Steel

| Feature | Description | Best For |

|---|---|---|

| Extreme Wear Resistance | One of the best wear-resistant tool steels. | Abrasive material slitting. |

| Edge Retention | Holds a working edge for a very long time. | Long-life industrial blades. |

| Hardening | Air-hardening provides good stability. | Complex tool shapes. |

| Limitation | Moderate toughness, can be brittle. | Applications without heavy shock. |

When Is It Worth Investing In Cpm 10V Tool Steel?

Are even the best tool steels not lasting long enough? Extreme wear can stop your production cold. CPM 10V offers unparalleled wear resistance for the toughest jobs.

It is worth investing in CPM 10V when you face extreme abrasive wear and standard tool steels fail prematurely. Made with powder metallurgy, it has a high volume of vanadium carbides, giving it toughness and the highest wear resistance of any tool steel on the market.

A company in the United States that produces composite materials had a major problem. They needed to cut fiber-reinforced plastics, which are incredibly abrasive. Their D2 steel blades were wearing out in less than an hour, making the process almost impossible. The downtime was costing them a fortune. They were skeptical, but I convinced them to try our CPM 10V blades. The investment was higher, but the performance was staggering. The new blades lasted for days instead of hours. The clean cuts also reduced secondary finishing operations. This case proved that for the most extreme cutting challenges, a premium material like CPM 10V is not a cost, but an investment that pays for itself.

Key Characteristics Of Cpm 10V Steel

| Feature | Description | Best For |

|---|---|---|

| Ultimate Wear Resistance | Unmatched abrasion resistance. | Cutting fiber composites, plastics. |

| Toughness | Good toughness for a high-wear steel. | Stamping and punching tools. |

| Powder Metallurgy | Fine, uniform carbide structure. | High-performance, consistent tools. |

| Limitation | Very expensive and harder to sharpen. | Only for extreme wear applications. |

Why Are Ceramic Blades Used In Specialized Cutting Applications?

Do you need a blade that is non-metallic and extremely hard? Metal blades can cause contamination or wear too quickly. Ceramic blades offer a unique, high-performance solution.

Ceramic blades are used in specialized applications due to their extreme hardness, superior corrosion resistance, and non-magnetic properties. They hold an edge much longer than steel and do not rust, making them ideal for precision cutting in electronics, medical, and fiber optic industries.

I once helped a client in South Korea who manufactured magnetic tape for data storage. They were using steel blades to slit the tape, but microscopic metal particles from the blade wear were contaminating the tape surface. This caused data errors and was a critical quality issue. We recommended our zirconia ceramic blades. Because ceramics are non-metallic, the contamination issue was completely solved. Furthermore, the ceramic blade's incredible hardness meant it stayed sharp for an exceptionally long time. This improved the slitting precision and reduced downtime. It was a perfect application that showcased why ceramic blades are sometimes the only possible solution for specialized, high-tech manufacturing.

Key Characteristics Of Ceramics

| Feature | Description | Best For |

|---|---|---|

| Extreme Hardness | Second only to diamond in hardness. | Ultra-long edge life. |

| Corrosion Proof | Chemically inert; will not rust or corrode. | Medical, food, chemical uses. |

| Non-Conductive | Electrically non-conductive and non-magnetic. | Electronics manufacturing. |

| Limitation | Very brittle, shatters under high impact. | Stable, low-impact cutting only. |

Conclusion

Selecting the right material is key to blade performance. Understanding each material's strengths ensures you get the best cutting solution, balancing cost, longevity, and quality for your specific needs.

Discover why Tungsten Carbide is the go-to material for cutting tough and abrasive materials. ↩

Explore the critical role of material choice in enhancing blade performance and efficiency. ↩

Learn about the factors that influence the frequency of blade replacements in industrial settings. ↩

Understand the significance of wear resistance in prolonging the life of cutting tools. ↩

Discover the importance of corrosion resistance in maintaining blade performance over time. ↩

Discover the difficulties faced when cutting abrasive materials and how to overcome them. ↩

Understand the critical role of a sharp edge in achieving clean and efficient cuts. ↩

Discover the various types of cutting tools and the materials that enhance their performance. ↩