Choosing the wrong blade for food processing can lead to contamination and inefficiency. This risks consumer safety and damages your brand's reputation. Understanding the right material is key to performance.

The best blade materials for food processing include food-grade stainless steel1 (like 420 and 440), high-carbon steels2, and food-safe tungsten carbide3. The ideal choice depends entirely on your specific application, balancing durability, corrosion resistance4, and compliance with strict food safety standards like the FDA.

Selecting the right blade material is about more than just getting a sharp edge; it's a critical decision that impacts your product quality, operational efficiency, and brand reputation. The material you choose has to perform perfectly day in and day out under demanding conditions. Before we look at specific materials, it's important to first understand the core job these blades need to do. Let's start by breaking down the fundamental characteristics that every good food processing blade must have to succeed.

What Are The Fundamental Working Characteristics Of Food Processing Blades?

Your blades dull quickly and wear unevenly. This ruins product quality and slows your production lines. The key is knowing the essential characteristics of a high-performance food blade to solve this.

Food processing blades must have four fundamental characteristics. These are exceptional sharpness for clean cuts, hygienic safety to prevent contamination, high corrosion resistance against moisture, and consistent stability for reliable, high-frequency performance.

A food processing blade is not just a piece of sharpened metal; it's a precision tool that directly impacts the final product. Each characteristic plays a vital role. Sharpness ensures you get clean, precise cuts without crushing or tearing the food, which is crucial for presentation and texture. Hygienic safety means the blade material itself won't contaminate the food. It must be non-porous and easy to clean. Corrosion resistance is non-negotiable in an environment filled with water, salts, and acids. Finally, stability ensures the blade performs consistently over long shifts without failing.

I remember working with a client in France who runs a large industrial bakery. They were having trouble with their dough-cutting blades. The blades would get sticky, tear the dough, and dull very quickly. This created inconsistent product sizes and a lot of waste. We identified that they needed a blade that not only had superior sharpness but also a specific non-stick property. We provided them with a custom blade made from a polished high-carbon steel. The new blade maintained its sharp edge for much longer and the polished surface prevented the dough from sticking. This simple change improved their product quality and reduced downtime significantly. It’s a perfect example of how focusing on these core characteristics can solve real-world production problems.

Key Blade Characteristics

| Characteristic | Importance in Food Processing | Common Issues if Lacking |

|---|---|---|

| Sharpness | Ensures clean, precise cuts; preserves food texture and appearance. | Tearing, crushing, inaccurate portions, product waste. |

| Hygienic Safety | Prevents bacterial growth and cross-contamination; ensures food safety. | Risk of contamination, difficulty in sanitation, failed safety audits. |

| Corrosion Resistance | Withstands moisture, acids, and cleaning agents without rusting or degrading. | Rust particles in food, blade degradation, shortened lifespan. |

| Stability | Delivers consistent performance under high-speed, continuous use. | Blade chipping, inconsistent cuts, unexpected equipment downtime. |

What Requirements Must Food Processing Blades Meet?

Are you worried that your blades don't meet food safety standards? Non-compliant blades can lead to hefty fines, product recalls, and severe damage to your brand. Understanding the requirements is essential.

Food processing blades must use food-grade, corrosion-resistant, and easy-to-clean materials. Their surfaces must be non-toxic and have no flaking coatings, complying with standards like FDA and EFSA. They also need to be durable, stable in harsh environments, and require simple maintenance.

Beyond the basic working characteristics, food processing blades must meet a strict set of requirements to be considered safe and effective for use. The single most important requirement is that the material must be "food-grade." This is a legal and ethical obligation. It means the material has been tested and certified as safe for direct contact with food, ensuring that no harmful substances can transfer from the blade to the product. This includes compliance with regional and international standards like the FDA in the United States or EFSA in Europe.

A few years ago, I helped a poultry processing plant in Brazil. They were facing major challenges with blade hygiene. Their existing blades were corroding quickly due to the acidic nature of the processing environment and the harsh cleaning chemicals they used. This created tiny pits on the blade surface where bacteria could hide, posing a serious contamination risk. Their team was spending too much time scrubbing blades and still worried about passing inspections. I worked with them to select a blade made from a specific grade of corrosion-resistant stainless steel with a highly polished finish. This new material not only met all local food safety regulations but was also much easier to clean, which saved them valuable time and gave them peace of mind about product safety. This case shows that meeting these requirements isn't just about compliance—it's about operational excellence.

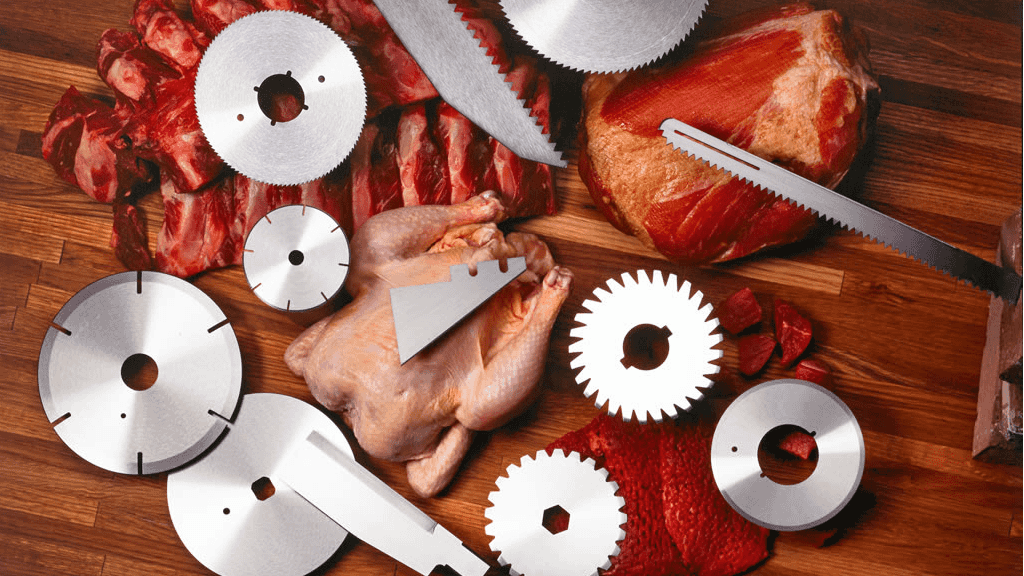

What Are The Common Manufacturing Materials For Food Processing Blades?

Are you confused by the huge variety of blade materials available? Choosing the wrong one can lead to poor performance, frequent replacements, and wasted money. Let’s break down the most common materials.

Common materials include stainless steel (grades 420 and 440) for general use, high-carbon steel for durability, food-safe tungsten carbide for frozen items, and ceramics for specific non-metallic applications. Each offers a different balance of sharpness, longevity, and hygiene.

Choosing the right material is a balance of performance, longevity, and cost. There isn't one "best" material; there is only the best material for your specific job. Stainless steel is the most common choice because of its excellent corrosion resistance and affordability. However, it may not hold an edge as long as other materials. High-carbon steels and powdered high-alloy steels are harder, so they stay sharp for much longer, but they often require more care to prevent rust. For the most demanding applications, like cutting frozen food blocks, tungsten carbide is the top performer. It is extremely hard and wear-resistant. Ceramic blades are also an option as they are chemically inert and will never rust, but they are brittle and can chip easily if they hit something hard.

I once consulted for a large vegetable processing plant in the Netherlands. They were slicing hard root vegetables like carrots and beets for hours on end. Their standard stainless steel blades were becoming dull in just a few hours, forcing them to stop the line for blade changes multiple times a day. After analyzing their process, I recommended they test a blade made from a powdered high-alloy steel. This material is significantly harder and more wear-resistant than standard stainless steel. The results were immediate. The new blades held their sharp edge through an entire eight-hour shift. This drastically reduced their downtime and improved the consistency of their slices. It was a clear demonstration of how matching the material to the application can deliver a huge return on investment.

Material Comparison

| Material | Key Advantage | Best Use Case | Potential Drawback |

|---|---|---|---|

| Stainless Steel (420, 440) | Excellent corrosion resistance | General food processing, wet environments | Dulls faster than harder steels |

| High-Carbon Steel | Superior edge retention | Slicing where sharpness is critical | Can rust if not properly maintained |

| Tungsten Carbide | Extreme wear resistance | Cutting frozen foods, bone-in meat | Higher cost, can be brittle |

| Ceramic | Chemically inert, no corrosion | Slicing non-metallic, soft foods | Very brittle, can chip or shatter |

How Should Blade Materials Be Selected Based On Application Scenarios?

Are your blades failing in your specific processing environment? A mismatch between your blade material and its application is a common cause of premature wear, frequent downtime, and inconsistent product quality.

For moist or corrosive environments like cutting fish, use high-grade stainless steel. For frozen or hard foods like bone-in meat, choose wear-resistant tungsten carbide. For dry goods or produce, consider powder metallurgy steels5 for superior edge retention and hygiene.

The secret to maximizing blade life and performance is to think about the specific scenario where the blade will be used. You need to consider the type of food, its temperature, and the overall processing environment. A blade that excels at slicing bread might fail completely when used to portion frozen fish. Each application presents a unique set of challenges. For wet and corrosive environments, like seafood or acidic fruit processing, corrosion resistance is the top priority. For hard or frozen items, you need a material with exceptional wear resistance and toughness to prevent chipping. For abrasive products like vegetables with dirt, wear resistance is again a key factor to maintain sharpness.

I have a great example from a client in Canada. They operate a large facility that processes frozen fish blocks. They were using high-carbon steel blades, and they were extremely frustrated. The blades were chipping and breaking constantly due to the combination of extreme cold and the hardness of the fish blocks. They had to stop their lines multiple times a day for blade changes, which was costing them a fortune in lost production. I worked with their engineering team to trial a set of blades made from a specific grade of nickel-bonded tungsten carbide6. While the initial cost of the carbide blades was higher, the performance difference was night and day. The new blades lasted over ten times longer than the old steel ones. The reduction in downtime and replacement costs saved them thousands of dollars in the first few months alone. It was a perfect case of investing in the right material for a very specific, very tough job.

What Regulations Must Food Processing Blades Comply With?

Are you unsure which global food safety regulations apply to your blades? Ignoring these rules can block your access to key markets and lead to serious legal issues. Knowing the regulations is critical.

All food processing blades must comply with food contact material regulations. Key global standards include the U.S. FDA 21 CFR, EU Regulation (EC) No 1935/2004, and China's GB 4806.1. These ensure blade materials are non-toxic, non-adsorptive, and corrosion-resistant.

Compliance is not optional in the food industry. When you select a blade, you must ensure its material is certified for food contact under the regulations of the country where you operate and where you sell your products. These regulations are designed to protect consumers by ensuring that no harmful chemicals can migrate from equipment into food. The core requirements across most major standards are similar: materials must be non-toxic, they should not impart any taste or odor to the food, and they must be corrosion-resistant under normal use and cleaning conditions. Working with a blade supplier who understands these regulations and can provide the necessary documentation is essential. This protects your business and gives you confidence in the safety of your products.

I recently assisted a snack food producer from Australia who had a wonderful opportunity to expand into the European market. However, they were stopped by the EU's strict food contact material regulations. They needed to prove that every part of their production line, including the blades in their slicers, was compliant with EC 1935/2004. They were completely lost in the paperwork. I was able to help them by supplying blades made from a fully certified stainless steel grade that we stock specifically for our European clients. We provided them with all the necessary Declarations of Compliance and material traceability documents. This documentation allowed them to clear the regulatory hurdles quickly and confidently launch their products in the EU. This experience highlights how important it is for us at PASSION to be experts not just in blades, but also in the global standards our customers must meet.

Conclusion

Choosing the right blade material is a critical commitment to safety, quality, and efficiency. It directly impacts your final product and operational success. Contact us at PASSION for expert guidance.

Explore the significance of food-grade stainless steel in ensuring food safety and quality. ↩

Learn how high-carbon steels enhance blade performance and longevity in food processing. ↩

Discover the advantages of tungsten carbide for cutting frozen and hard foods. ↩

Understand the importance of corrosion resistance in maintaining blade integrity and food safety. ↩

Find out how powder metallurgy steels improve blade durability and performance. ↩

Discover how this advanced material enhances blade performance in tough applications. ↩