Your slitting blades keep chipping and breaking. This leads to costly machine downtime and wasted corrugated board. You need to find the root cause to stop this from happening again.

Poor performance is often caused by several issues working together. These include poor grinding quality, thick or wet board, a dirty blade holder, bad installation, the wrong blade material, or a dull cutting edge. Finding and fixing these problems will improve blade life.

The Poor performance problem is usually not just one thing. It is often a mix of small things that add up to a big failure. Let's look at the main reasons why your blades might be failing. We can work together to find the real source of the trouble and get your production line running perfectly.

Why Does Poor Grinding Wheel Quality Cause Blade Chipping?

You sharpened your slitting blade, but it chipped almost right away. This is very frustrating. It makes you think the sharpening process is not working or is a waste of time.

Poor grinding wheel quality creates a weak and uneven cutting edge. This edge can't handle the stress of cutting. It will develop micro-cracks1 and quickly lead to chipping or a complete fracture. A good grind is essential for a strong blade.

I remember talking with a customer named Jacky. He was having a terrible time with blade chipping. He told me small nicks would appear on the blade edge. During operation, these nicks would get bigger until the blade broke. He was sure the blades themselves were bad.

I asked him about his grinding machine. After he checked his equipment, he found the problem. The grinding wheel was wobbling because it was installed wrong. This wobble created a weak, poorly finished edge that chipped easily. Once he fixed the grinding wheel installation, his problem went away. This shows how important the grinding process is.

| Phenomenon | Probable Cause | Solution |

|---|---|---|

| Blade Chipping | The grinding wheel has runout (wobble) or is damaged. | Replace the grinding wheel or reinstall it correctly. |

| Blade Fracture | The grinding wheel bearings are binding or worn out. | Inspect the bearings and replace them if they are not smooth. |

| Uneven Wear | The grinding wheel material is wrong for the blade steel. | Choose a grinding wheel that matches your blade material specification. |

How Can Thick Or Wet Corrugated Board Damage Your Blades?

You are cutting a new batch of corrugated board, and suddenly your slitting blades are failing. Your production stops. The blade was fine yesterday, but today it is dull and damaged.

Excessively thick, hard, or wet corrugated board puts much more stress on the blade edge. This increased workload accelerates wear, causes overheating, and can lead to dullness and breakage.

The material you cut is just as important as the blade itself. Not all corrugated board is the same. I've seen customers struggle when they switch suppliers or start using board with more recycled content. The blades that worked perfectly before now fail quickly.

This is because thick face and liner papers require more cutting force. Wet board is also a big problem. The moisture makes the paper fibers soft and harder to slice cleanly. Instead of a clean cut, the blade tears the paper. This creates more friction and heat, which ruins the blade's sharp edge. You must always consider the board's condition.

| Phenomenon | Probable Cause | Solution |

|---|---|---|

| Rapid Blade Dulling | The face and liner papers of the board are too thick or hard. | Use a tougher blade material. Slow down the cutting speed. |

| Ragged, Fuzzy Cuts | The corrugated board is too wet or has high moisture content. | Properly store the board to control moisture. Use a sharper blade angle. |

| Sudden Chipping | The board contains hard foreign materials like sand or metal. | Inspect incoming board quality. Install a metal detector on your line. |

Could A Dirty Blade Holder Be Ruining Your Cuts?

You installed a brand-new slitting blade, but it is already wobbling. The cuts are not straight. It feels like the blade is loose even though you tightened everything.

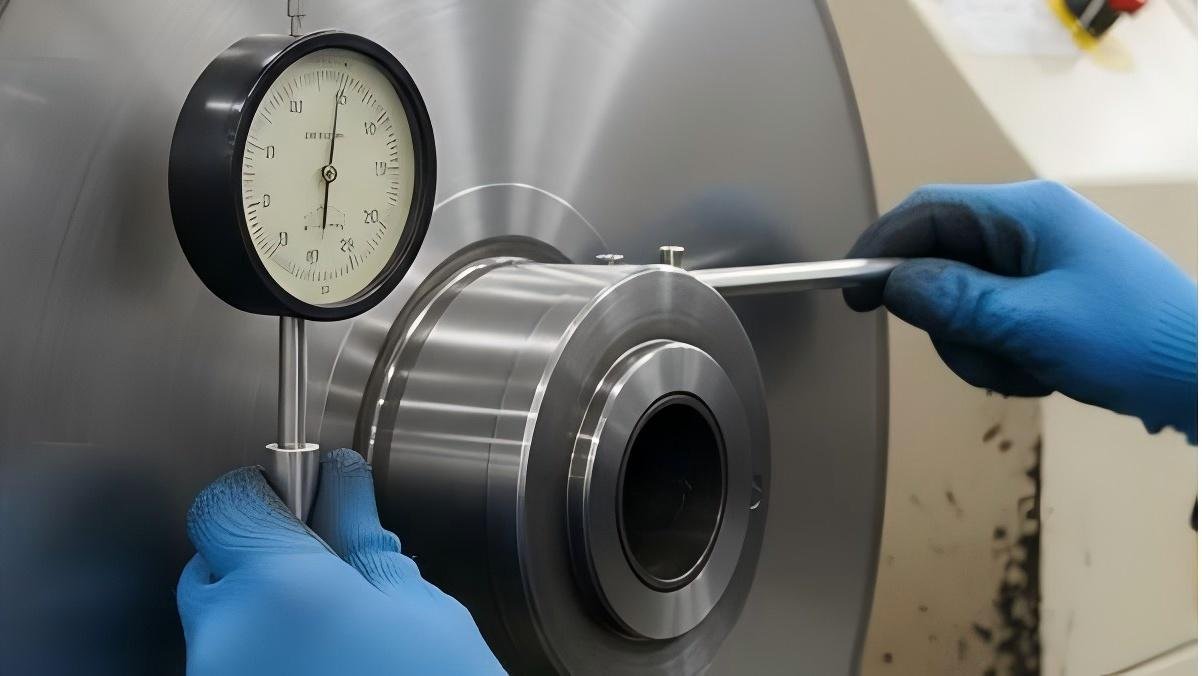

Yes, a dirty blade holder is a common and serious problem. Any dust, paper debris, or rust on the mounting surface will prevent the blade from seating flat. This causes misalignment and runout, which will quickly damage the blade edge and bearings.

This is one of the first things I ask customers to check. It is a simple thing that people often forget. During production, paper dust and small debris can get packed onto the blade holder or the hub surface. When you install a new blade on top of this debris, the blade cannot sit perfectly flat.

Even a very small piece of debris can cause a big problem. It will make the blade tilt slightly. As the slitting blade spins at high speed, this small tilt creates a wobble, which is called runout. This runout puts uneven force on the cutting edge, leading to vibration, poor cut quality, and eventually, a chipped or broken blade. Always clean the mounting surfaces before installing a new blade.

| Phenomenon | Probable Cause | Solution |

|---|---|---|

| Blade Wobble (Runout) | Paper dust or other debris is trapped on the blade holder. | Remove the blade. Clean all mounting surfaces thoroughly with a brush and air. |

| Uneven Cuts | Rust or damage is present on the hub or holder surface. | Polish the surfaces to remove rust. Replace any damaged parts. |

| Vibration | The blade is not sitting flat against the mounting hub. | Always check for a clean, flat fit before tightening the blade. |

Is Improper Blade Installation Causing Your Performance Issues?

A new slitting blade should solve your cutting problems, but it doesn't. Your downtime remains high, and the cut quality is still poor. You start to wonder if the new blades are any good.

Absolutely. Improper installation is one of the top causes of blade failure. Even a perfect slitting blade will perform poorly if it is not installed correctly. Misalignment and runout will severely damage the cutting edge and cause major issues with cut quality.

A slitting blade is a precision tool. It must be installed with precision. I always tell my customers to think of it like changing a tire on a car. You have to tighten the bolts evenly and make sure the wheel is perfectly flat against the hub. If not, the car will vibrate and be unsafe.

The same is true for a slitting blade. The blade must be perfectly parallel to the bottom knife. It must spin without any wobble. If the blade is misaligned, one side of the edge does all the work. This side wears out very fast. If the blade has runout (wobble), it impacts the board instead of slicing it. This impact creates micro-cracks that lead to chipping and failure.

| Phenomenon | Probable Cause | Solution |

|---|---|---|

| One Side Wears Faster | The top blade is not aligned with the bottom knife. | Loosen the blade holder and carefully adjust the alignment. Then retighten. |

| Vibration and Noise | The blade has excessive runout. | Reinstall the blade. Make sure all mounting surfaces are clean and flat. |

| Blade Becomes Loose | The locking bolts were not tightened correctly. | Tighten bolts in a star pattern to the recommended torque specification. |

Is Your Tungsten Carbide Slitting Blade Right For The Job?

You invested in premium tungsten carbide slitting blades, but they are still chipping. You spent more money for better performance, but you are not seeing the results. This is very expensive and frustrating.

tungsten carbide2 is extremely hard, but it can also be brittle. If the material grade is not tough enough for your specific cutting application, it will chip easily under impact or side-pressure. The right balance of hardness and toughness is critical.

People hear that tungsten carbide is the best, so they want it for every job. But there are many different grades of tungsten carbide. Some grades are designed for maximum wear resistance, which means they are very hard but also more brittle. Other grades have more cobalt binder, which makes them tougher and better at resisting impact.

If your blade material does not have enough toughness for your corrugated board, it can chip. This is especially true when cutting very thick board or if there is any machine vibration. Choosing the exact tungsten carbide grade that provides the best balance of hardness for long life and toughness to prevent chipping.

| Phenomenon | Probable Cause | Solution |

|---|---|---|

| Micro-Chipping on Edge | The blade material is too hard and brittle for the application. | Switch to a tougher grade of tungsten carbide with a higher cobalt content. |

| Premature and Rapid Wear | The blade material is not hard enough to resist the abrasive board. | Switch to a harder grade of tungsten carbide with better wear resistance. |

| Catastrophic Fracture | The material cannot handle the impact from machine vibration or thick board. | Choose a tougher material grade. Also, inspect your machine for vibration issues. |

What Happens When A Cutting Edge Becomes Dull?

Your machine seems to be working harder, and the edges of your corrugated board look fuzzy and torn. You have to run the machine slower to get a decent cut. This kills your productivity.

A dull cutting edge does not slice the paper fibers. It tears and crushes them. This results in "ragged edges" and "collapsed edges." A dull blade also generates more heat and stress, which can cause micro-cracks and lead to blade failure.

The purpose of a blade is to stay sharp. Many people try to make blades last longer without re-sharpening to save time. This is a big mistake. A sharp blade cuts with minimal effort, slicing cleanly through materials.

A dull blade is the opposite. It uses brute force to push its way through the corrugated board. This creates a lot of friction and heat. The heat can soften the steel at the very edge of the blade, making it get dull even faster. This tearing action also leaves a very poor quality finish on the board. You get ugly, torn edges that customers will reject. Continuous use of a dull blade is the fastest way to destroy it completely.

| Phenomenon | Probable Cause | Solution |

|---|---|---|

| Ragged or Fuzzy Cuts | The blade edge is blunt and tearing the paper. | Regrind the blade immediately. Establish a regular sharpening schedule. |

| Collapsed Board Edges | The blade is crushing the board, not cutting it. | Sharpen the blade. Check that the blade's cutting angle is correct. |

| Blade Overheating | High friction from a dull edge. | Do not wait until the blade is dull. Regrind it when it starts to lose its edge. |

Conclusion

To fix blade performance, you must look at your entire system. Blade material, sharpening, installation, and board quality are all connected. A complete review will solve your cutting issues.