Struggling with messy cuts on soft materials? Traditional methods are slow and inaccurate. A CNC oscillating knife1 offers a precise, versatile solution for clean, perfect results.

A CNC oscillating knife performs three main functions: precision cutting for complex shapes, creasing and kiss-cutting2 for packaging, and detailed engraving3 for marking. This versatility makes it essential for processing soft and composite materials.

When I first started helping clients expand their cutting capabilities, many were stuck with old methods. They used die cutters, lasers, or even manual tools. These tools worked, but they had big limitations. Die cutters are expensive for small batches. Lasers can burn materials and release harmful fumes. I saw businesses everywhere facing the same challenge. They needed a single tool that could handle different materials and different jobs with precision.

This is where CNC oscillating knives come in. They are fast, accurate, and incredibly versatile. I believe understanding their core functions is the first step for any business looking to improve its cutting process. Let's explore exactly what these machines can do and how they can help you.

What Materials Can Be Precisely Cut With A CNC Oscillating Knife?

Are you wasting material because of inaccurate cuts? Old methods can be messy and imprecise. This leads to costly errors and rework, hurting your bottom line and production timeline.

CNC oscillating knives excel at precision cutting a wide range of soft and semi-rigid materials. They are ideal for textiles, leather, foam, rubber, gaskets, composites like carbon fiber, and corrugated cardboard.

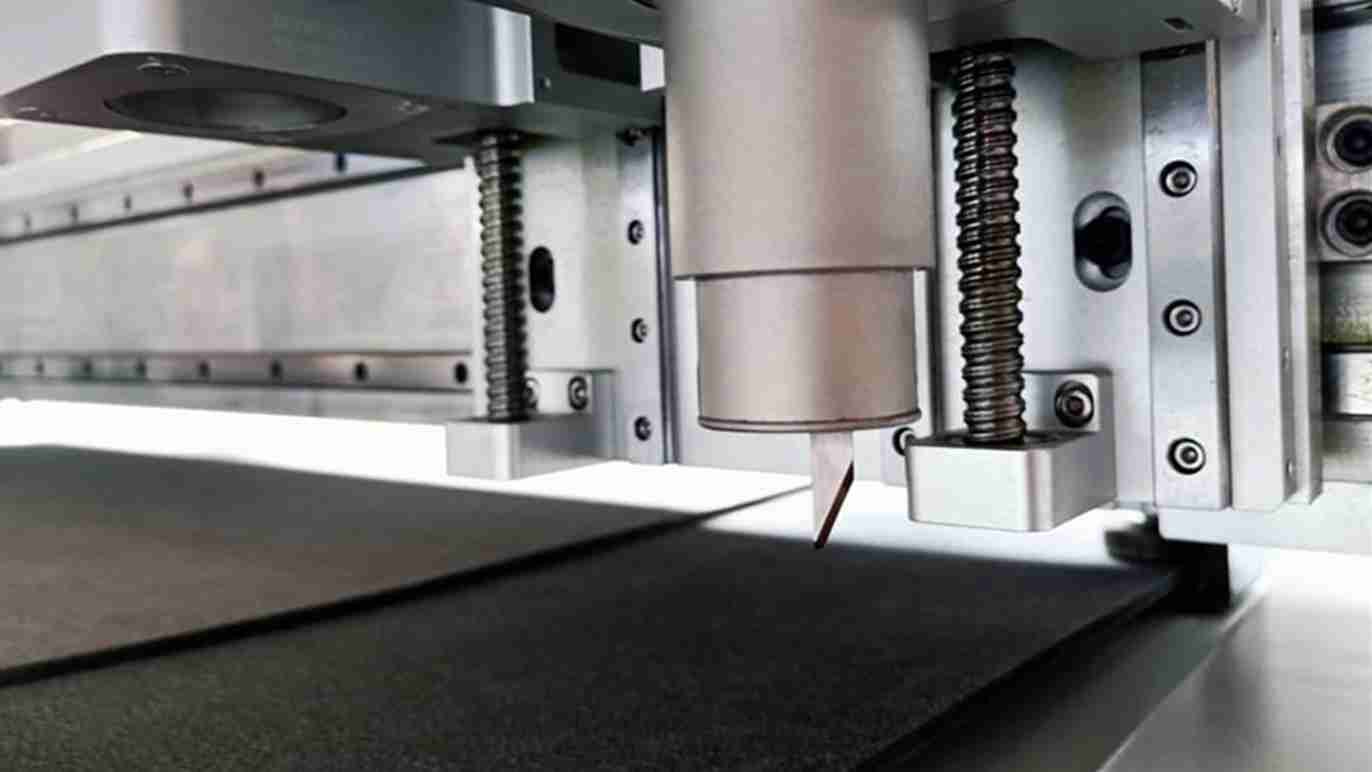

The real magic of a CNC oscillating knife is its high-frequency vibration4. The blade moves up and down thousands of times per minute. This "sawing" motion allows it to slice through materials cleanly without pulling or dragging them. Lasers, on the other hand, use heat. This can melt, burn, or discolor the edges, which is a major problem for materials like textiles or leather. Traditional die-cutting is fast for high volumes, but it’s not flexible for custom jobs or prototypes.

Material Applications

| Industry | Common Materials Cut | Key Benefit |

|---|---|---|

| Packaging | Corrugated board, foam core | Fast prototyping, no tooling costs |

| Textiles & Apparel | Fabric, felt, leather | Intricate patterns, no edge burning |

| Automotive | Leather, vinyl, carpet, gaskets | High accuracy for interior components |

| Aerospace | Carbon fiber, composites | Clean cuts on advanced materials |

This precision helps businesses reduce waste and improve product quality.

How Does Creasing and Kiss-Cutting Work On A CNC Oscillating Knife?

Do you need to create perfect folds or easy-peel labels? Scoring materials by hand is slow and inconsistent. Getting the depth just right for a clean fold is a huge challenge.

By precisely controlling the blade's downward pressure and depth, a CNC oscillating knife performs creasing and kiss-cutting. It can create fold lines without cutting through or slice only the top layer of sticker material.

This function is a game-changer, especially for the packaging industry. Instead of a sharp cutting blade, the machine can use a creasing wheel or a specially designed blade. The CNC system tells the tool exactly how deep to press into the material. For creasing, it creates a crisp fold line in cardboard or paperboard. For kiss-cutting, it cuts through the top vinyl or paper layer of a sticker sheet but leaves the backing paper intact. This allows for easy peeling.

I remember working with a client in Italy. He runs a company that makes beautiful, custom luxury boxes. He was struggling with prototyping. Creating new die-cutting tools for each small batch was too expensive and slow.

The Client's Challenge

He needed a way to produce high-quality samples quickly. His designs had complex folds and cutouts. His old process was simply not keeping up with customer demands for fast turnarounds.

Our Solution

We recommended the CNC oscillating knife. This gave him the power to do everything on one machine. He could cut the box shape, create perfect fold lines, and even kiss-cut decorative vinyl logos. He went from taking weeks to create a prototype to just a few hours. This flexibility transformed his business and helped him win more clients.

How Do You Use A CNC Oscillating Knife For Engraving?

Do you need to add logos or part numbers to your products? Traditional engraving methods can be expensive or may not work on soft materials. You need a reliable, cost-effective solution.

The CNC oscillating knife can perform engraving tasks. With high-precision control, the blade can carve lines, etch patterns, or make shallow cuts to add logos, serial numbers, or decorative details.

While it's not a replacement for a high-power laser or a rotary engraver on metal, it is perfect for many soft and semi-rigid materials. The process works by controlling the knife tip to follow a path defined in a CAD file. The system finely adjusts the depth of the cut. This is great for marking parts without compromising their structural integrity. For example, you can add assembly guides on foam inserts or brand a leather product with a subtle logo.

This capability adds another layer of value to the machine. You can cut a part and mark it in the same operation. This saves time and ensures the markings are perfectly aligned.

Engraving Vs. Other Functions

| Function | Tool Used | Material Interaction | Primary Use |

|---|---|---|---|

| Cutting | Sharp Oscillating Blade | Slices completely through | Separating parts, creating shapes |

| Creasing | Creasing Wheel/Dull Blade | Compresses material | Creating fold lines |

| Engraving | V-Cut Blade/Sharp Tip | Removes small amount of material | Marking, decorating, branding |

This multi-functionality is why so many of my clients see a fast return on their investment. They are not just buying a cutter; they are buying a complete production solution.

Conclusion

A CNC oscillating knife offers precision cutting, creasing, and engraving. This makes it a powerful, all-in-one solution that boosts efficiency, reduces waste, and opens up new creative possibilities.

Explore this link to understand the technology behind CNC oscillating knives and their benefits for precision cutting. ↩

This resource will clarify the techniques of creasing and kiss-cutting, essential for packaging. ↩

Find out how CNC machines achieve intricate engravings, adding value to your products. ↩

Understand the role of high-frequency vibration in achieving clean cuts with CNC technology. ↩