Slitter knives are a big deal in a lot of industries. They’re the cutting tools that let manufacturers take big materials and cut them into narrower strips with precision. Whether you’re in packaging, textiles, or metalworking, you need slitter knives to make sure you’re being efficient and making a good product. But, if you don’t know what you’re looking for, picking the right slitter knife can be a little overwhelming. What types are there? What materials? How do you take care of them? In this guide, we’ll walk you through everything you need to know about slitter knives. We’ll tell you what they are and how they work. We’ll give you some tips on picking the right one for your application. And, we’ll talk about how to take care of them so you get the most out of your blade.

What Is A Slitter Knife?

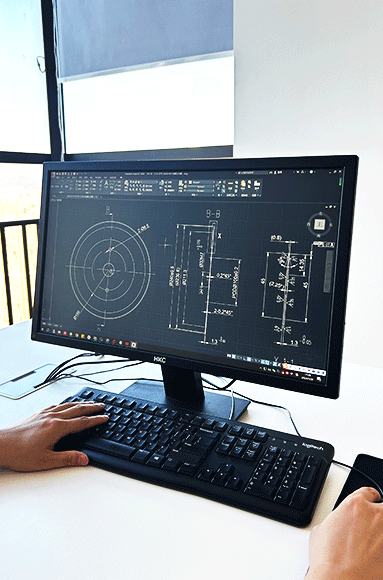

A slitter knife is a circular cutting tool used in a slitting machine. Slitting machines are designed to cut materials like paper, plastic, metal, and textiles into narrow strips. The continuous edge of the slitter knife makes it perfect for precision cutting, and it’s used in a lot of different industries where you need to convert material. Whether you’re cutting thin films for packaging or metal coils in the steel industry, a slitter knife gives you the sharpness and durability you need to make consistent, high-quality cuts.

What Are Slitter Blades Used For?

Slitter knives do a lot of different things in a lot of different industries, but their main job is to take wide stuff and make it narrow. They’re used in processes like:

Metal Slitting: In industries like automotive and construction, they cut big coils of metal into smaller widths for different applications.

Film and Packaging Slitting: In packaging, they cut plastic films and shrink-wraps. The continuous edge of the slitter knife makes sure the cuts are clean, which is important for keeping your product looking good.

Paper Slitting: In the paper industry, they trim rolls of paper into the width you want so you can use it for printing or packaging.

Textile Slitting: They cut fabrics so you can get them ready for whatever you’re going to do with them.

What Materials Are Slitter Knives Made Of?

The material of a slitter knife is a big factor in how well it performs and how long it lasts. The most common materials used to make slitter knives are:

Stainless Steel: This is the most common material used for slitter knives. People like stainless steel because it doesn’t rust and it lasts a long time. There are different kinds of stainless steel, but the ones most people use for slitter knives are 420 and 440. These stainless steel blades stay sharp longer and don’t wear out as fast.

Carbide: Carbide is really hard, so people use it a lot for slitter knives. You can get carbide-tipped or solid carbide slitter knives. These blades last a lot longer, so they’re good for cutting tougher stuff like metal or thicker plastic.

Ceramic: Ceramic slitter knives are really hard and last a long time. Not as many people use them, but they’re out there. Ceramic blades can be more brittle and chip easier if you’re not careful with them.

Each material has its own good things and bad things about it, but which one you use usually depends on what you’re cutting, how long you want the blade to last, and where you’re using it.

How To Choose The Right Slitter Knife For Your Needs?

Choosing the right slitter knife is important if you want to get the best results for your job. Here are some things to think about:

Material Type: What you’re cutting will help you decide which slitter knife to use. For example, if you’re cutting thin films or paper, you’ll need a different blade material and sharpness than if you’re cutting metal coils or fabrics.

Blade Size and Thickness: The size of the blade should match the width and thickness of the material you’re slitting. If you’re cutting bigger stuff, you’ll need a thicker and wider blade to handle the extra cutting pressure.

Blade Edge: Slitter knives can have different kinds of edges. Some have a beveled edge, some are single-sided, and some are double-sided. The kind of edge you have can affect how precise and clean your cut is.

Hardness: How hard the blade is (measured on the Rockwell scale) can make a difference in how it performs and how long it lasts. Blades that are harder last longer but can chip easier. Blades that are softer don’t last as long, but they’re not as brittle.

Common Types Of Slitter Knives

Different types of slitter knives are used for different cutting jobs. Here are some of the most common types used in industrial settings:

Shear Slitting: This is when you have two blades (one on top and one on the bottom) that work like scissors. Shear slitting is good for cutting thicker stuff like metals or heavier plastics.

Razor Slitting: This is when you have one razor blade that cuts thinner, softer stuff like plastic films, paper, or textiles. Razor slitting is good for jobs where you need to be really precise but you’re not cutting anything thick or tough.

Crush Slitting: This is when you crush the material between a blade and a hard roll. This is usually used for cuts that don’t have to be as clean but you need to go really fast.

Each type of slitting has its good things depending on what you’re cutting, how good you want the cut to be, and what your machine can do.

How To Maintain And Care For Slitter Knives

Taking care of your slitter knives is important if you want them to stay sharp and work right. If you don’t take care of them, they’ll get dull, your cuts won’t be as good, and you’ll have to stop and put in new blades more often. Here are some things you should do to take care of your slitter knives:

Sharpen Them: Slitter knives can get dull over time, so you have to sharpen them to keep them working right. Depending on what you’re cutting and how much you use them, you might have to sharpen your slitter knives every few weeks or months.

Clean Them: After you use them, you should clean your slitter knives to get all the stuff off them. This will help keep them from rusting or getting messed up, especially if they’re stainless steel.

Store Them Right: You should keep your slitter knives in a dry place where they won’t get messed up by the weather or anything else.

Check Them for Damage: Before you use them, you should look at your slitter knives to see if they’re messed up. If they’re chipped or cracked, you should put in new ones before they break and mess up your machine.

Benefits Of Using High-Quality Slitter Knives

If you spend a little more money on good slitter knives, you’ll get a few benefits:

Better Cuts: Good knives give you nice, clean cuts every time. That means you’ll waste less material, and your machine will run better.

Last Longer: Good knives are made from better stuff, like carbide or high-grade stainless steel. That means they last longer, so you don’t have to change them as often, and your machine doesn’t have to stop as much.

Run Faster: Good knives stay sharp longer, so you don’t have to change them as often. That means you can keep running your machine without stopping to change the blades.

Challenges When Using Low-Quality Slitter Knives

While low-quality slitter knives may seem like a good way to save money in the short term, they can cause a lot of problems. Here are a few:

They get dull faster: Low-quality knives get dull faster, which means you have to replace or sharpen them more often. That’s a waste of time and money.

They don’t cut consistently: Low-quality blades are more likely to give you jagged or uneven cuts. That means you’re going to waste more material and have a lower-quality product.

They cost you more in the long run: Even though they might be cheaper when you buy them, low-quality knives wear out faster, which means you have to replace them more often. That’s going to cost you more money in the long run.

Slitter knives are a big deal if you’re in an industry where you have to cut stuff. Knowing the different types of slitter knives, how to pick the right one, and how to take care of it can make a big difference in how well you can cut your stuff and how good your product is when you’re done. If you pick a good slitter knife and take care of it, you can cut your stuff faster, better, and cheaper for a long time.