Are your cutting results inconsistent and causing product waste? You check the blade, but the problem isn't there. The real issue might be a small, overlooked component: the bearing1.

Bearings are critical to the cutting process. They ensure precision, stability, and extend blade life by reducing friction and withstanding heavy loads. A high-quality bearing guarantees your cutting system operates smoothly, which directly impacts the quality of your final product and your operational efficiency.

It is easy to focus only on the blade itself when troubleshooting cutting issues. However, the components that support the blade are just as important for achieving that perfect cut. The bearing is a perfect example of an unsung hero in the cutting assembly. Let's take a closer look at how these small parts play such a massive role in your production line. Understanding their function will help you improve your processes and save costs.

How Do Bearings Impact Cutting Accuracy And Blade Stability?

Do you struggle with annoying burrs and uneven cuts on your materials? These small mistakes can lead to a lot of wasted material and expensive production delays. The solution often lies in understanding how the precision of a bearing directly affects cutting stability.

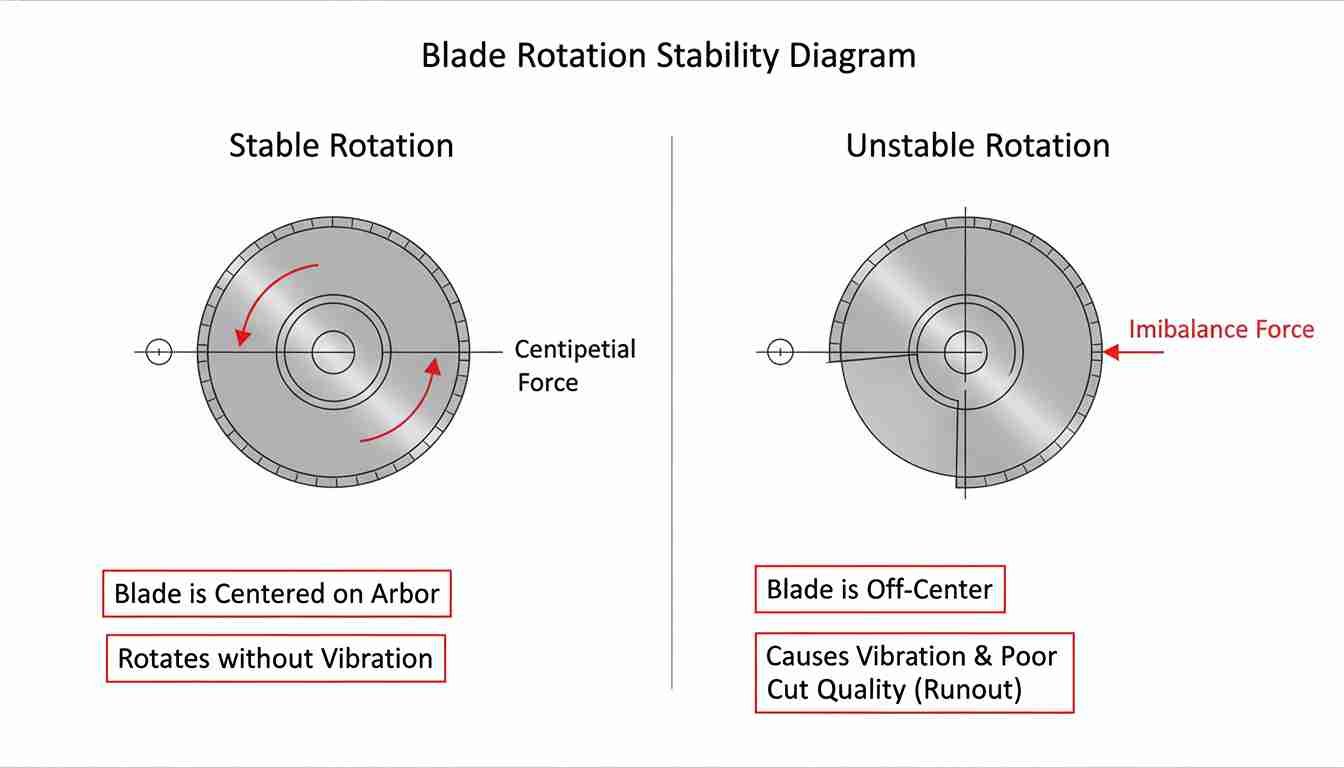

High-precision bearings are essential for cutting accuracy. They maintain the rotational shaft's concentricity and minimize any wobble, known as runout. This ensures the blade moves smoothly and consistently, resulting in clean, precise cuts every time, especially with very thin or delicate materials.

When we talk about cutting accuracy, we are really talking about control. A bearing's main job is to provide that control for any rotating part, like the shaft holding a circular knife. In high-speed slitting operations2, even the smallest vibration can be amplified at the blade's edge. This leads to inaccurate cuts. I saw this firsthand with a client in the electronics industry who was slitting ultra-thin battery foils. They were experiencing inconsistent slit widths and rough edges, which caused a high rejection rate.

They believed our blades were the problem, but after an inspection, we found the blades were perfectly fine. The issue was the low-grade bearings in their slitting machine. These bearings had poor runout control, causing the shaft to vibrate at high speeds. Once they upgraded to high-precision bearings, the problem disappeared completely. Their cuts became clean and consistent. This shows how a small component makes a huge difference.

Key Factors In Bearing Precision

| Factor | What It Is | Impact on Cutting |

|---|---|---|

| Concentricity | How well the center of the bearing aligns with the center of the shaft. | High concentricity ensures the blade spins perfectly true, preventing uneven cuts. |

| Runout | The amount of "wobble" or off-center movement in a rotating part. | Low runout is critical for minimizing vibration and achieving a smooth finish. |

| Stiffness | The bearing's ability to resist deformation under load. | High stiffness maintains the blade's position during tough cuts, ensuring accuracy. |

Can A Bad Bearing Really Reduce Your Blade's Lifespan?

Are your blades getting dull much faster than you expect? Constantly replacing blades increases your operational costs and leads to more machine downtime. The cause might not be the blade's quality, but a failing bearing working against it.

Yes, a bad bearing can significantly shorten your blade's life. Worn or poorly lubricated bearings create extra friction, resistance, and heat in the system. This additional stress and heat make the blade's cutting edge wear down much faster, leading to quicker dulling, chipping, and sometimes total failure.

Think of it like trying to run in sand instead of on a smooth track. A worn bearing creates a similar drag on the cutting system. The motor has to work harder to spin the blade, which generates excess heat. This heat can soften the blade's hardened steel edge, making it lose its sharpness quickly. Furthermore, the vibration from a bad bearing creates tiny impacts on the cutting edge with every rotation. Over millions of rotations, these small impacts can lead to micro-chipping and weaken the blade.

I remember a case with John, a production manager at a large paper converting plant in the UK. He called me because his slitter knives were only lasting half as long as we projected. I visited his facility and immediately noticed a high-pitched noise coming from one of the slitting heads. We stopped the machine and inspected it. The bearings on that shaft were completely worn out and had not been lubricated properly. After his maintenance team replaced the bearings and started a regular lubrication schedule, the blade life on that machine doubled. It was a simple fix that saved him thousands of dollars.

What Should You Consider When Selecting Bearings For Your Blades?

Choosing the right bearing can feel like a complicated technical decision. If you make the wrong choice, you could compromise your entire cutting process and end up with poor results. But if you focus on a few key factors, you can make the selection process much simpler and more effective.

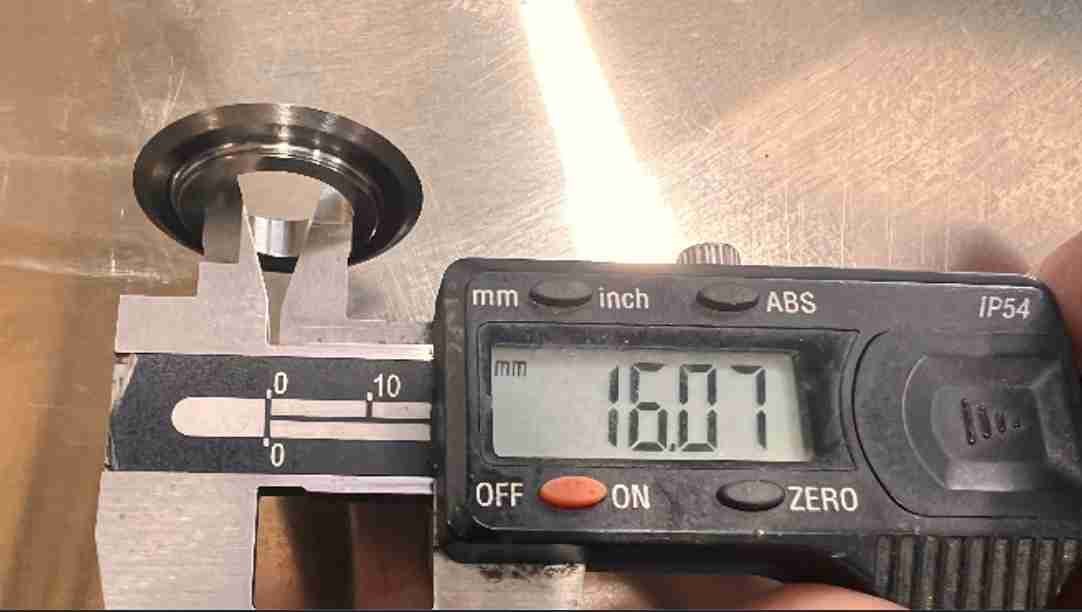

When selecting a bearing, you should focus on its load capacity, speed rating3, precision grade4, and material. It is also very important to ensure the bearing's inner diameter tolerance is a perfect match for your blade's bore. This prevents any slippage or vibration during operation.

Selecting the correct bearing is about matching the component to the specific demands of your application. A bearing used for heavy-gauge steel slitting will have very different requirements than one used for high-speed film converting. When a client asks for a custom cutting solution5, our questions go beyond just the blade. We ask about the machine, the operating speeds, and the loads involved. This helps us ensure the entire system works together perfectly. A great blade can only perform its best when it is supported by the right components.

Choosing the right bearing is a foundational step for any high-performance cutting operation. You need to consider not just the immediate specifications but also the long-term reliability you need from your machinery.

Key Selection Criteria For Bearings

| Criteria | Description | Why It Is Important For Cutting |

|---|---|---|

| Load Capacity | The maximum force (radial and axial) the bearing can safely handle. | Heavy cutting generates strong forces. The bearing must resist these forces to prevent shaft deformation and maintain a stable blade gap. |

| Speed Rating | The maximum rotational speed (RPM) the bearing can operate at without overheating. | In high-speed slitting, exceeding the speed rating can cause bearing failure, leading to machine damage and unsafe conditions. |

| Precision Grade | A standardized rating (like ABEC or ISO) that defines the manufacturing tolerances. | A higher precision grade means less runout and vibration. This is essential for achieving the cleanest, most accurate cuts. |

| Fit and Tolerance | How tightly the bearing fits on the shaft and inside the blade's bore. | A precise fit eliminates any movement between components. This is crucial for preventing vibration and ensuring consistent cut quality. |

Conclusion

Bearings are vital for cutting precision, blade life, and overall efficiency. Choosing the right ones and maintaining them properly is a fundamental step for achieving top-quality production results.

Explore this resource to understand how different bearings can enhance cutting precision and efficiency in your operations. ↩

Understanding the challenges in high-speed slitting can help you improve your cutting processes. ↩

Learn about speed ratings and their importance in preventing bearing failure during high-speed operations. ↩

Discover how precision grade affects cutting accuracy and overall performance. ↩

Explore the key considerations for developing effective custom cutting solutions. ↩