Struggling with tungsten carbide blades that dull fast or chip easily? The hidden culprit could be a chemical process weakening your tools, costing you time and money.

Decarburization strips carbon from a tungsten carbide blade1's surface during manufacturing. This process reduces hardness2, wear resistance3, and overall strength, leading to premature blade failure, edge chipping, and shorter service life.

This issue might seem technical, but understanding it is key to improving your cutting operations. Let's break down what decarburization really is and how it impacts your bottom line. We will explore this complex topic in detail to help you make more informed decisions.

What Is Decarburization?

You know high temperatures are needed for blade production. But what if that same heat is creating a weak surface layer on your tungsten carbide blades?

Decarburization is the loss of carbon from the surface of tungsten carbide material. It happens during high-temperature processes like sintering4 when carbon reacts with oxygen, water vapor, or carbon dioxide.

Decarburization is a chemical reaction that happens at a microscopic level. During the manufacturing of tungsten carbide, we use very high heat, often over 700°C. If the atmosphere in the furnace contains oxygen or water vapor, it can pull carbon atoms right out of the blade's surface. This changes the material's chemical makeup. The strong tungsten carbide (WC) breaks down, leaving behind weaker metallic tungsten (W) or other compounds. This creates a soft "skin" on the blade that compromises the entire blade's integrity. A blade is only as strong as its surface, and decarburization directly attacks that strength.

| Property | Normal Tungsten Carbide Surface | Decarburized Tungsten Carbide Surface |

|---|---|---|

| Composition | Tungsten Carbide (WC) | Metallic Tungsten (W) |

| Hardness | Very High | Significantly Lower |

| Wear Resistance | Excellent | Poor |

| Structure | Dense and Strong | Porous and Brittle |

How Does Decarburization Affect Tungsten Carbide Cutting Blades?

Ever had a new blade underperform, chipping or wearing out almost immediately? This frustrating experience is often a direct result of unseen material defects like decarburization.

It significantly reduces a blade's performance. The loss of carbon lowers surface hardness and wear resistance. This leads to rapid dulling, edge chipping, and decreased blade lifespan, which ultimately affects your cut quality and increases costs.

The effects of a decarburized layer are immediate and costly. Because the surface is softer, the cutting edge cannot hold its sharpness. It dulls quickly, requiring more frequent changes and downtime. This softness also leads to brittleness, making the edge prone to chipping and micro-fracturing, especially when cutting tough materials. I remember working with a plastic film manufacturer in Brazil. They were experiencing inconsistent cuts and frequent blade changes. Their slitter blades were chipping unpredictably. After some investigation, I suspected their blades had a decarburized surface. The poor edge retention was a classic sign. Once they switched to a supplier with better quality control, their production stability and blade lifespan improved dramatically. A weak surface layer undermines the entire purpose of using a premium material like tungsten carbide.

Critical Performance Impacts

- Reduced Hardness: The blade's edge dulls much faster than expected.

- Lower Wear Resistance: The blade wears out prematurely, shortening its useful life.

- Increased Brittleness: The cutting edge becomes prone to chipping and breaking.

- Poor Surface Finish: The weakened edge can lead to rougher, less precise cuts on your material.

How Can Decarburization Be Removed?

Have you discovered a batch of blades with weakened surfaces? Don't discard them just yet. There are ways to salvage them and restore performance in some cases.

Decarburization is a surface issue, so the weakened layer can often be removed. This is typically done through precision grinding. By carefully grinding away the top layer, you expose the unaffected, strong tungsten carbide underneath.

While prevention is always the best solution, sometimes you need to deal with blades that already have this defect. The only effective way to remedy a decarburized blade is to mechanically remove the soft outer layer. This requires a very precise grinding process. You must remove enough material to get past the weakened zone but not so much that you compromise the blade's dimensions or integrity. I once advised a client in Poland who runs a large corrugated cardboard facility. They noticed an increase in cutting dust and frayed edges, which are signs of dull blades. I explained that their current batch of blades likely had a decarburized surface. For a short-term fix, I suggested a light regrinding process to expose the harder material underneath. It saved their production run, but it also highlighted the importance of starting with a high-quality, properly manufactured blade in the first place.

The Grinding Process

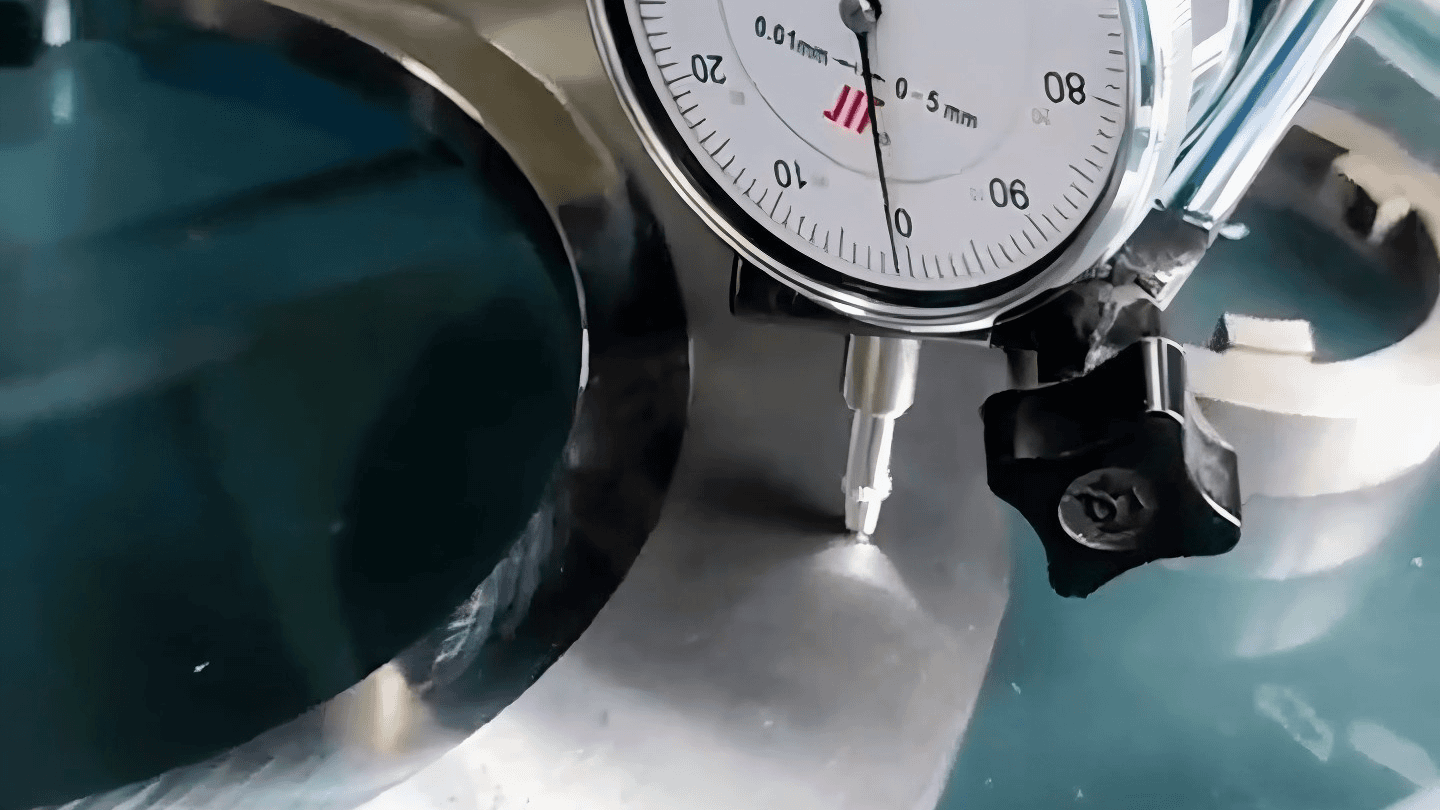

The key to successful removal is precision. The depth of the decarburized layer must be measured first. Then, a controlled grinding operation removes that specific amount of material. This is not a simple sharpening; it is a restorative process that requires specialized equipment.

Limitations of Removal

This process is not always practical. It removes material, which changes the blade's dimensions. It is also an additional step that adds cost and time. The best strategy is always to prevent decarburization from happening at all by sourcing from a reliable manufacturer.

How Is Decarburization Measured?

Suspect a blade is underperforming due to a bad surface? You can't just see decarburization. You need specific methods to confirm its presence and severity.

Decarburization is measured by examining a cross-section of the blade's surface. Methods include Rockwell hardness testing5 to detect a drop in surface hardness or microscopic analysis6 (metallography) to identify changes in the material's microstructure.

Identifying decarburization requires more than a visual inspection. The most common methods involve testing the physical properties of the blade's surface. Hardness testing is a quick way to check. We compare the hardness on the surface to the hardness of the core material. A significant drop in the surface reading is a clear red flag. For a more detailed analysis, we use metallography. This involves cutting a sample of the blade, polishing it, and examining it under a high-powered microscope. Under magnification, we can see the change in the grain structure and identify the exact depth of the weakened layer. These tests are not just for us; they provide our customers with the assurance that they are receiving blades with the highest surface integrity.

| Measurement Method | How It Works | Best For |

|---|---|---|

| Hardness Testing | Measures resistance to indentation on the surface. | Quick quality checks, comparing surface to core. |

| Microscopic Analysis | Visually inspects the material's grain structure. | In-depth analysis, determining the exact depth of the layer. |

How Can Decarburization Be Prevented?

Constantly dealing with blade failures is expensive and inefficient. What if you could stop the problem at its source, before the blade is even made?

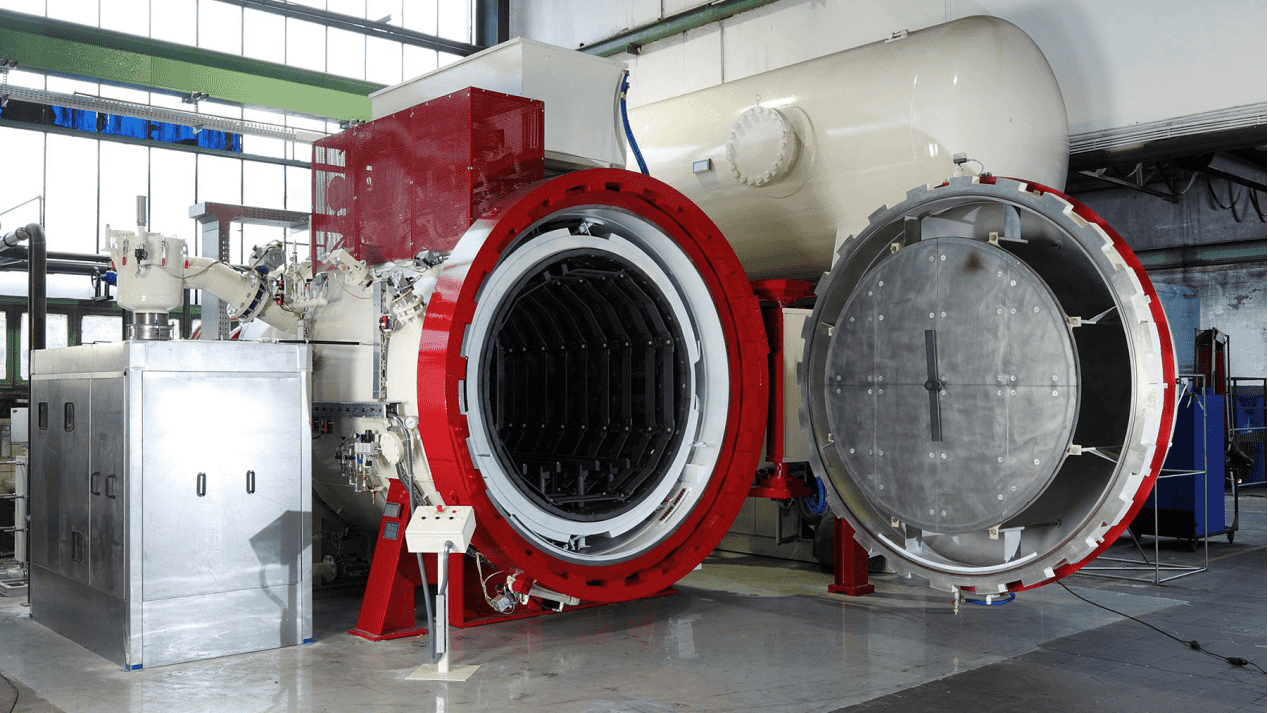

Prevention is key and happens during manufacturing. It involves controlling the furnace atmosphere during high-temperature sintering by using a vacuum or an inert gas7 like argon. This prevents oxygen from reacting with the carbon.

The only true solution to decarburization is to prevent it during the manufacturing process8. This is where a manufacturer's expertise and equipment make all the difference.

Controlled Atmosphere Sintering

We use advanced vacuum furnaces that remove almost all the oxygen from the chamber. In other cases, we fill the furnace with an inert gas, like argon or nitrogen. These gases do not react with carbon, creating a protective bubble around the blades as they are being sintered. This strict environmental control ensures that the carbon stays where it belongs: in the tungsten carbide.

I recently worked with a textile manufacturer in Turkey. Their previous supplier provided blades with very inconsistent lifespans. I explained our manufacturing process, focusing on how our vacuum sintering prevents surface defects like decarburization. They decided to try our blades. Six months later, they reported a major improvement in blade longevity and fewer production stops, which directly improved their bottom line. It all came down to a better, more controlled manufacturing process.

Conclusion

Understanding and preventing decarburization is crucial for achieving high-performance, reliable tungsten carbide blades. It ensures you get the cutting edge quality and lifespan you pay for.

Learn about the advantages of tungsten carbide blades for improved cutting performance. ↩

Discover methods for measuring hardness to ensure your blades perform optimally. ↩

Find out how wear resistance impacts tool longevity and performance. ↩

Learn about the sintering process and its importance in blade production. ↩

Understand the Rockwell hardness testing method for evaluating blade quality. ↩

Discover how microscopic analysis helps in assessing material integrity. ↩

Learn how inert gases help maintain the integrity of cutting tools during sintering. ↩

Explore best practices to ensure high-quality cutting tools are produced. ↩