Dull blades slow production and ruin products. This costs you money in waste and frequent replacements. Proper sharpening is your key to saving costs and boosting quality.

The key is knowing why (cost savings1), how (grinding methods2), when (performance decline), and when not to (severe damage). Mastering these extends blade life, improves quality, and reduces operational costs significantly. This is your core knowledge base for effective blade management.

I have seen many companies struggle with this topic. They either replace blades too often or sharpen them the wrong way. This guide will walk you through the essential knowledge I share with my clients to help them succeed. Let's start with the most important question: why should you even bother with sharpening?

Why Should You Sharpen Industrial Blades?

Are you constantly buying new blades? This expense eats directly into your profits. A smart sharpening strategy can cut this cost and make your business more competitive.

You should sharpen blades to extend their life and reduce purchasing costs. Resharpening often costs only 10%–30% of a new blade. This also improves product quality, lowers machine wear, and minimizes expensive production downtime. It is a direct investment in your bottom line.

The decision to sharpen blades instead of replacing them is one of the most impactful financial choices you can make for your production line. The benefits go far beyond just saving on the cost of a new blade.

The Economic Impact

The most obvious benefit is cost control. A new, high-quality industrial blade can be a significant investment. Resharpening that same blade typically costs just 10% to 30% of the replacement price. Most industrial blades are designed to be resharpened 3 to 5 times, or even more, before they need to be retired. This simple practice can lead to savings of 50-70% on your annual blade budget. I once worked with a client, a packaging company in Germany, who was replacing their slitter blades every month. After we helped them set up a simple in-house sharpening station and a schedule, they cut their annual blade spending by over 40%.

Quality And Efficiency Gains

A sharp blade is essential for a quality product. Dull blades tear, crush, or fray materials instead of cutting cleanly. This leads to product rejects and material waste. A sharp blade also requires less force to make a cut. This means your machines can run faster and more efficiently, increasing your overall output. You use less energy, and the wear and tear on your equipment is significantly reduced. This prevents expensive repairs and extends the life of your machinery.

What Are The Main Methods For Sharpening Industrial Knives?

The world of sharpening can be confusing. Choosing the wrong method might damage your expensive blades or waste valuable time. Let’s clarify the two main approaches to sharpening.

The two main methods are machine-level grinding and tool-level sharpening. Machine-level grinding uses large equipment like surface grinders for high precision and volume. Tool-level sharpening uses smaller tools like grinding wheels or honing stones for quick, on-site repairs. The best choice depends on your blade.

Choosing the correct sharpening method is critical. The right choice depends on your blade's type, material, required precision, and your production scale. I always advise my clients to think of these methods in two distinct categories.

Machine-Level Grinding: For Precision And Volume

This method is for high-stakes operations where precision is everything. It involves large, stationary machines that can restore a blade to its exact original specifications.

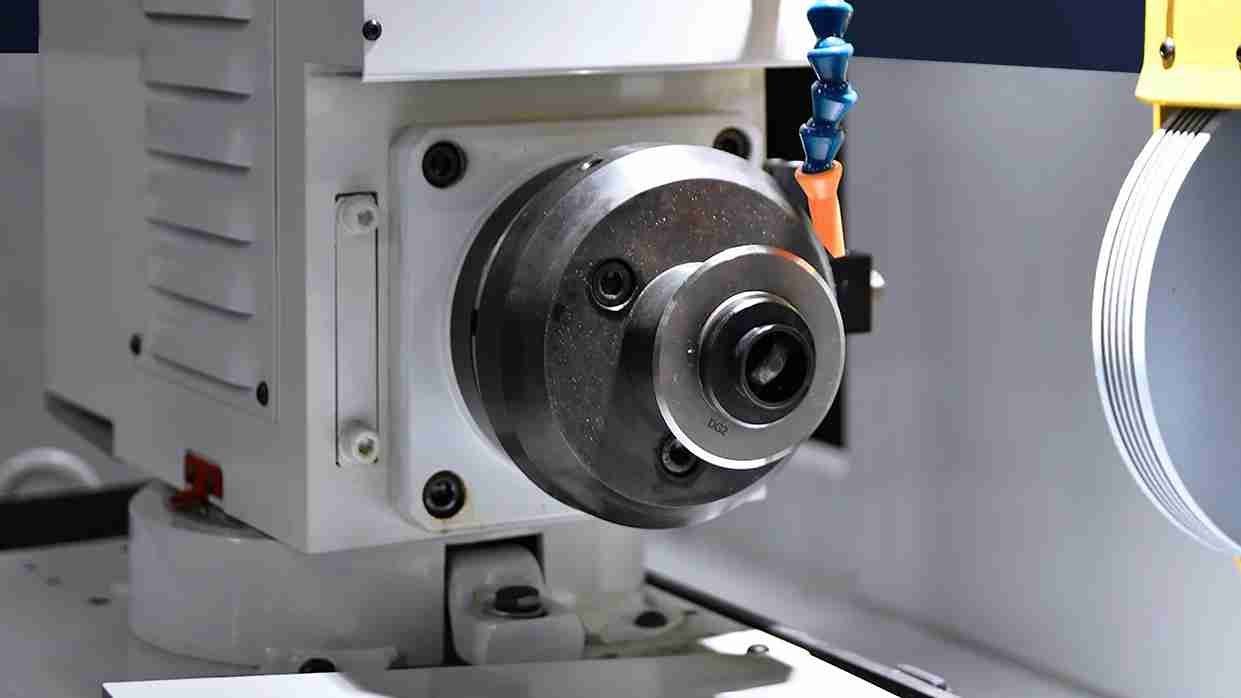

- Surface Grinders: Excellent for straight blades. They create a perfectly flat, sharp edge.

- Cylindrical Grinders: Used for circular blades, ensuring the entire circumference is uniformly sharp.

- CNC Grinders: These are the top-tier solution. Computer-controlled machines can handle complex blade geometries with incredible accuracy and repeatability.

This approach is best for high-hardness blades, high-volume production, and applications where a perfect cut is non-negotiable.

Tool-Level Sharpening: For Speed And Convenience

This method involves smaller, often portable tools for quick touch-ups or repairs on the factory floor.

- Bench Grinders: A common tool for quick edge restoration.

- Whetstones and Oil Stones: Traditional but effective for fine-tuning an edge.

- Handheld Electric/Pneumatic Grinders: Great for on-the-spot repairs of small nicks on larger blades that are hard to remove from a machine.

This approach is best for small-scale operations or for quick maintenance between professional machine-level grindings.

| Sharpening Method | Best For | Pros | Cons |

|---|---|---|---|

| Machine-Level | High precision, high volume, complex blades | Extremely accurate, repeatable, best finish | High initial cost, requires skilled operator |

| Tool-Level | Quick repairs, simple blades, low volume | Low cost, convenient, fast for touch-ups | Lower precision, risk of human error |

How Long Does It Take To Sharpen An Industrial Blade?

Planning for sharpening downtime can be difficult. Unpredictable timings disrupt your production schedule and cost you money. Let's break down what affects the time it takes.

A lightly dull blade might take only 5-10 minutes for a quick touch-up. A heavily worn blade could require 30 minutes or more, sometimes in multiple stages. The time depends on the blade's material, wear level, complexity, and the equipment used for sharpening.

The time required for sharpening is not a fixed number. It varies greatly based on several factors. Understanding these factors will help you better plan your maintenance schedules and minimize unexpected downtime.

Key Factors Influencing Sharpening Time

I always tell my clients to consider these four points when estimating how long a sharpening job will take:

- Material Hardness: Harder materials like tungsten carbide take much longer to grind than softer stainless steel. They require different grinding wheels and slower speeds.

- Blade Complexity: A simple straight knife is quick to sharpen. A circular or toothed blade with complex angles requires more setup time and careful work, which increases the overall time.

- Degree of Wear: This is the biggest variable. A blade that is just slightly dull needs only a quick pass to restore its edge. A blade with small chips or significant rounding requires much more material to be removed, which takes considerably more time and may need multiple steps.

- Equipment and Operator Skill: A high-end CNC grinder can sharpen a blade much faster and more accurately than manual methods. Similarly, an experienced operator will be more efficient and produce better results than someone who is new to the process.

The Critical Role Of Cooling

One thing that is often overlooked is the need for proper cooling3. Grinding creates a lot of heat. Without a coolant, usually a water-based or oil-based fluid, the blade's edge can overheat. This can cause it to lose its hardness, a process known as annealing. A burnt or annealed edge will become dull almost immediately upon use, no matter how sharp it looks. Proper cooling is not optional; it is essential for a good sharpening job.

When Is The Right Time To Resharpen Your Blades?

Are you waiting for poor cuts to tell you that a blade is dull? Waiting too long causes more damage and lowers the quality of your product. Let's look at the early signs.

Resharpen your blade when you first notice signs of dullness. These include increased cutting resistance, a decline in product surface quality, unusual machine noise, or visible rounding of the cutting edge. Acting on these early signs prevents bigger problems and extends blade life.

The goal should be to move from a reactive to a proactive sharpening strategy. Instead of waiting for a blade to fail, you should learn to recognize the early warning signs that it’s time for maintenance. This approach saves time, money, and protects both your products and your machinery.

Key Indicators For Sharpening

You don't need a microscope to tell when a blade is getting dull. You and your machine operators can look for these simple signals:

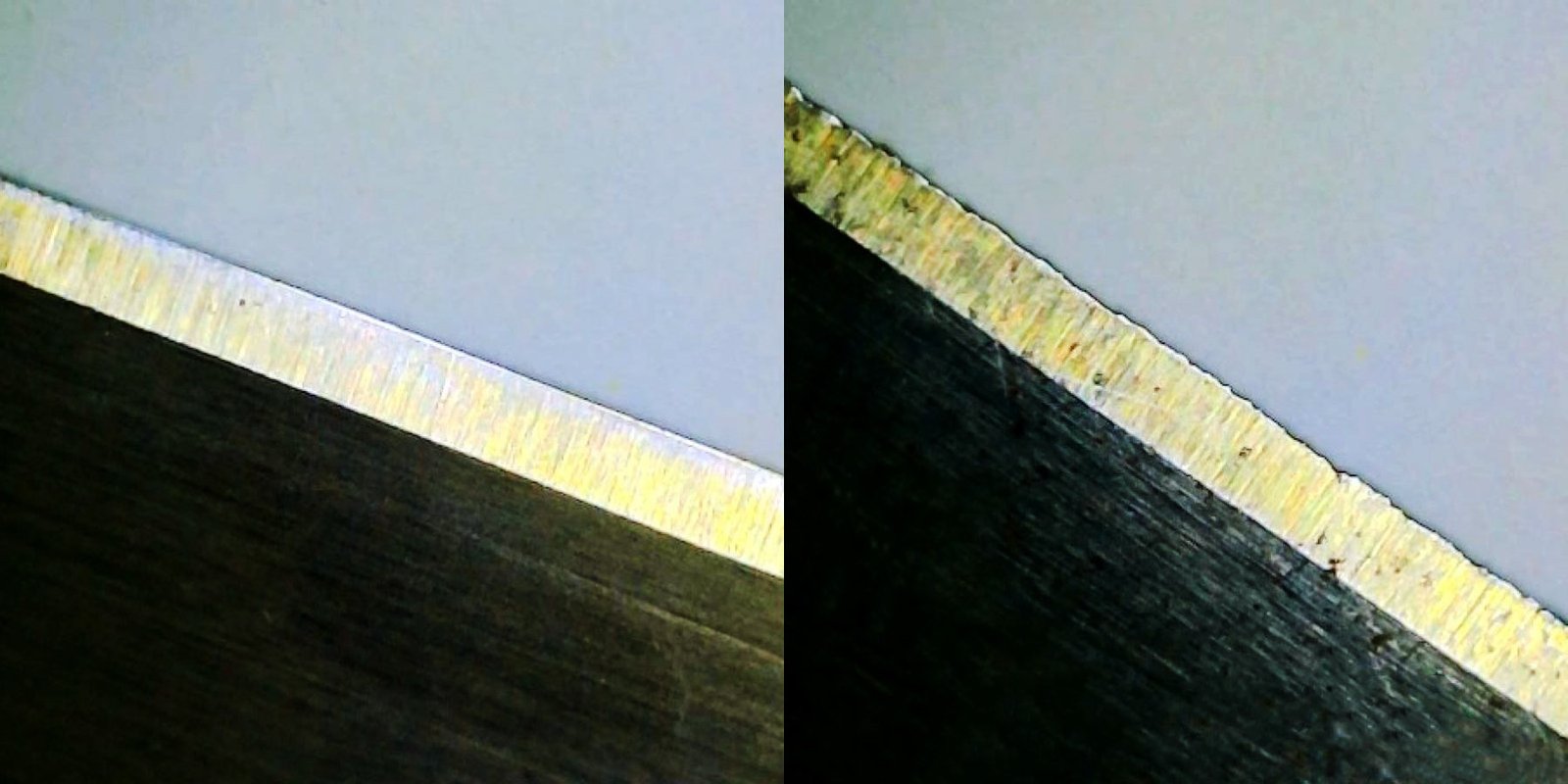

- Product Quality Declines: This is often the first sign. Look for rough edges, fraying (in textiles), burrs (in metal), or crushing (in paper and packaging). If your finished product doesn't look as clean as it used to, check the blade.

- Increased Cutting Resistance: The machine may sound like it's working harder. You might notice the motor drawing more power, or the cutting speed slowing down. This is because the dull blade is pushing its way through the material instead of slicing cleanly.

- Unusual Noise or Vibration: A dull blade can cause vibrations that you can both hear and feel. This is a clear sign that the blade is no longer cutting efficiently and is putting stress on the machine.

- Visual Inspection: Sometimes, the simplest check is the best. Look at the cutting edge. If it reflects light, it means the edge has become rounded and is no longer a fine point. A truly sharp edge is too thin to reflect light and will look like a dark line.

By training your team to spot these signs, you can create a sharpening schedule based on actual performance, ensuring you always get the best results.

When Is It Not Worth Sharpening A Blade?

Do you try to sharpen every single blade? Sharpening a badly damaged blade wastes time and money, and can even be dangerous. Knowing when to stop is a crucial skill.

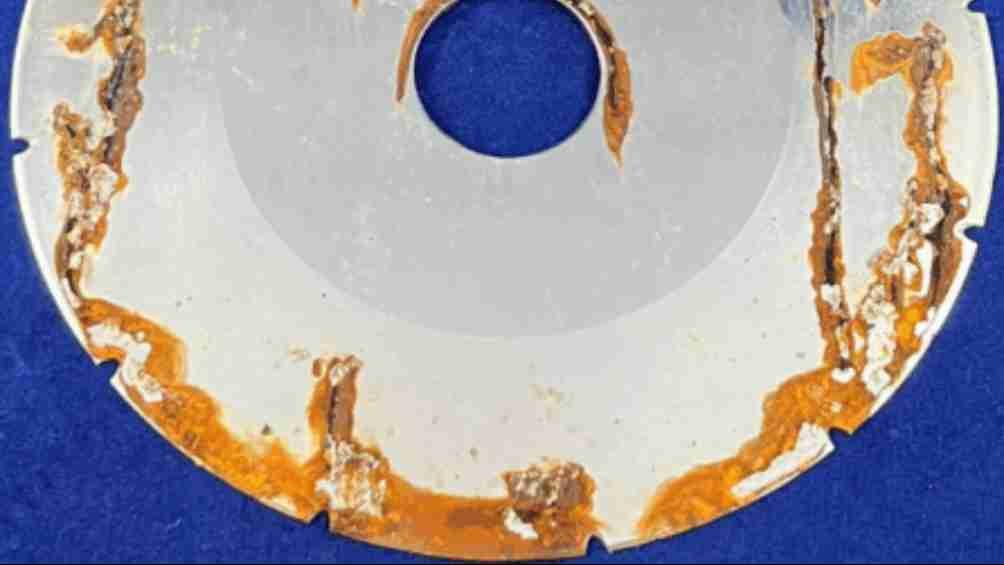

It is not worth sharpening a blade when the repair cost exceeds 60% of a new one's price. Also, discard blades with large chips, cracks, or signs of heat damage4 (discoloration). For cheap, disposable blades, the cost of managing sharpening is not worth it.

Knowing when to retire a blade is just as important as knowing when to sharpen it. Trying to save a blade that is past its useful life is not economical and can create safety risks on your production floor. I always advise my clients to establish clear "end-of-life" criteria for their blades.

The Point Of No Return

Here are the three main signs that a blade should be replaced, not re-sharpened:

- Major Physical Damage: Look for large chips (macro-chipping) in the cutting edge, deep cracks in the body of the blade, or any signs that the blade is bent or warped. Sharpening cannot fix these structural problems. Using a structurally compromised blade is extremely dangerous, as it could shatter during operation.

- Heat Damage (Annealing): If you see a blue, brown, or purple discoloration on or near the cutting edge, it's a sign that the blade has been overheated. This heat changes the molecular structure of the steel, causing it to lose its temper and hardness. Even if you grind a new sharp edge onto it, the metal will be too soft to hold that edge for long. It will become dull very quickly.

- The Economic Calculation: As a rule of thumb, if the cost to repair and sharpen a blade is more than 60% of the cost of a brand new blade, it is no longer worth it. You are better off investing in a new blade that will give you a full, predictable lifespan. This also applies to inexpensive, disposable blades where the labor and management cost of a sharpening program outweighs the cost of the blade itself.

In Which Industries Is Blade Sharpening Most Cost-Effective?

Some businesses think sharpening is not for them. They use disposable blades or think their blades are too complex. This mistake could be costing them thousands.

Sharpening is highly cost-effective in industries with high-volume cutting and expensive blades. This includes paper and pulp, packaging, plastics recycling, metalworking, and textiles. These sectors see huge savings on blade replacement costs and improved production quality through regular maintenance.

While nearly any industry using industrial blades can benefit from a sharpening program, the return on investment is much faster and more significant in certain sectors. The key factors are the cost of the blades themselves, how quickly they wear down, and the precision required for the cut. A good sharpening strategy moves from being a "nice-to-have" to an absolute necessity for staying competitive. For example, a small food processing plant using simple knives might manage with quick in-house tool sharpening, but for large-scale industrial operations, the savings are on a completely different level.

High-Impact Industries

Here are the industries where I consistently see the biggest financial and operational gains from implementing a professional sharpening system:

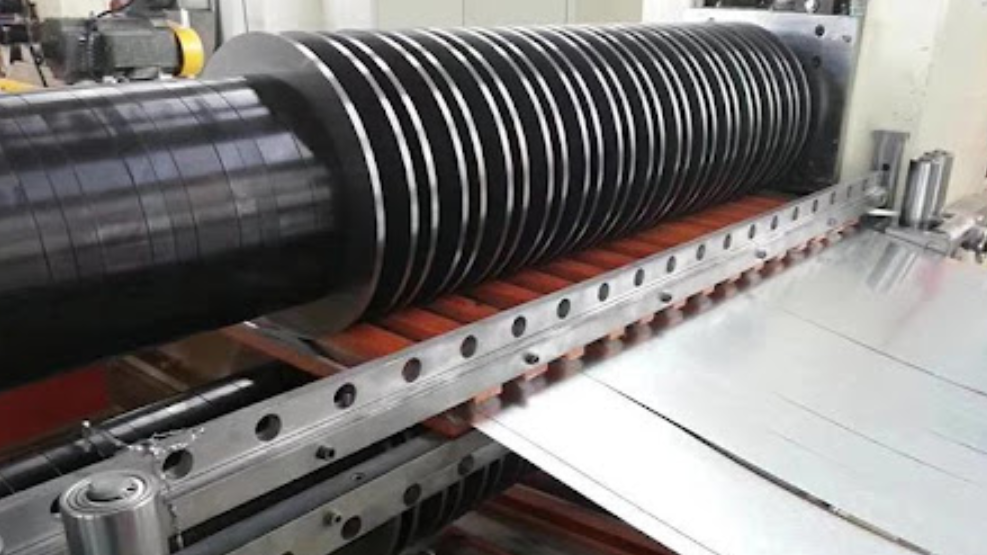

- Paper and Packaging: This industry uses large, long blades like guillotine knives and circular slitters. These blades are expensive and need to be extremely sharp to prevent paper dust, crushing, and uneven cuts. Because paper is abrasive, blades dull relatively quickly. A consistent sharpening cycle is vital for both cost management and product quality.

- Plastics and Recycling: Grinder and granulator blades used in plastics recycling take a huge amount of punishment. They are thick, durable, and expensive. Replacing them frequently is not financially viable. A proper sharpening program is the only way to manage costs in this tough environment.

- Metalworking: Shear blades for cutting sheet metal must withstand incredible forces. Maintaining a precise, sharp edge is crucial for clean cuts without burrs. Given the high cost and hardness of these blades, resharpening is standard practice.

- Textiles: Cutting fabric, especially modern synthetics, requires an exceptionally clean cut to prevent fraying. Blades used here, from circular knives to straight knives, benefit hugely from regular honing and sharpening to maintain that perfect edge.

Conclusion

Mastering industrial knife sharpening is not just about technique. It’s a key business strategy that cuts costs, boosts quality, and improves your overall production efficiency.

Understanding cost savings can help you optimize your blade management strategy and improve your bottom line. ↩

Exploring various grinding methods can enhance your sharpening techniques and blade longevity. ↩

Understanding the role of cooling can prevent damage to blades and ensure effective sharpening. ↩

Understanding heat damage can prevent costly mistakes and ensure safe blade usage. ↩