Your carbide blades1 are failing too soon. This unexpected downtime is costing you money. Learn what extreme conditions are to blame and how to fight back.

The most common extreme conditions are high temperatures, high cutting speeds, and machining abrasive or high-hardness materials2. These factors cause issues like micro-cracks, edge dulling, corrosion, and chipping, drastically reducing your blade’s service life.

Customers come to me frustrated with poor blade performance. They want to know why their tools are failing and what they can do about it. The truth is, the working environment is just as important as the blade itself. Let's break down these tough conditions one by one. This way, you can get the most out of every cut.

How Do High Temperatures Destroy Carbide Blades?

Heat is ruining your blades. Constant thermal stress leads to cracking and failure. I can explain why this happens and how to identify the root cause.

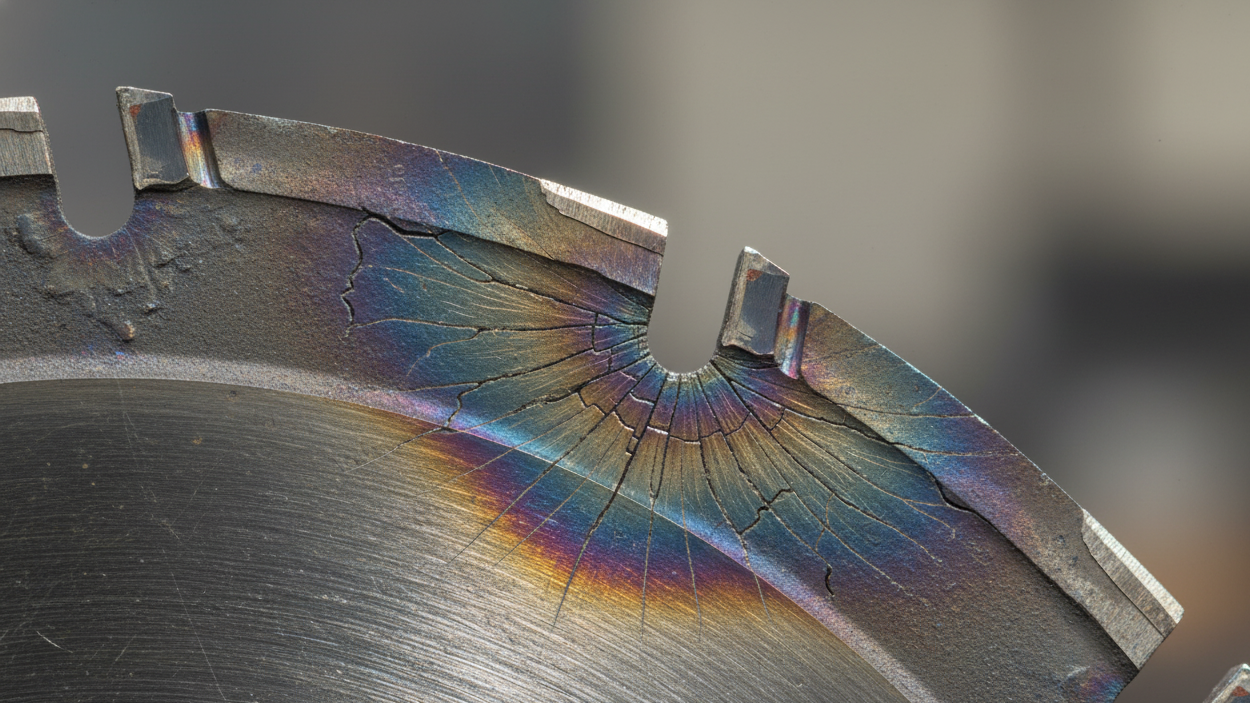

Extreme heat, especially above 800°C, softens the cobalt binder holding the carbide particles together. This weakening effect, combined with thermal stress, causes tiny cracks to form along the cutting edge, leading to premature failure and poor performance.

High temperature is one of the biggest enemies of a carbide blade. I recently cooperated with a client in the automotive industry who faced this exact problem. They were using our tungsten carbide trimming blades on a hot stamping line. The operating temperatures reached up to 850°C. Their blades were failing much faster than expected, and a close look revealed micro-cracks along the cutting edge. The problem wasn't a bad batch of blades. It was the extreme heat attacking the blade's core structure.

The Breakdown Of Heat Damage

Carbide blades are a composite material. They are made of hard tungsten carbide grains held together by a softer metal binder, usually cobalt. This structure is very strong, but high heat changes everything.

- Binder Softening: At temperatures above 800°C, the cobalt binder starts to soften and lose its strength. It can no longer hold the carbide grains securely in place.

- Thermal Fatigue: The constant cycle of heating and cooling creates stress between the carbide grains and the binder. This stress eventually leads to tiny fractures.

- Coating Oxidation: Many blades have a protective coating, like TiAlN. High heat causes this coating to oxidize and break down, leaving the blade unprotected.

In my client's case, we found that equipment maintenance was also a factor. Their grinding machine had issues, which added extra stress. After they fixed the grinding wheel and bearings, the blade life improved. It shows that you must look at the whole system, not just the blade.

Why Do High-Speed Production Lines Dull Blades So Quickly?

You increased production speed, and now your blades are failing faster. The efficiency gains are lost to blade replacement costs. Let's solve this problem together.

Line speeds over 250 meters per minute create massive friction and heat. This can raise the edge temperature to 300°C, causing micro-melting on the blade's surface. The result is a dulled edge that sticks to the material.

I often talk to production managers who are pushing for more output. They increase the speed of their cutting lines, but then blade life plummets. It’s a classic trade-off. While the temperature from high speed (around 300°C) is much lower than in hot stamping, the effect is just as damaging, but in a different way. The enemy here is extreme friction. This friction generates a very localized thermal load right at the tip of the cutting edge. This intense heat causes the very surface of the blade to micro-melt. The melted material then re-solidifies, but the edge is no longer sharp. It becomes dull and rounded. This also leads to another problem: blade sticking. The material being cut starts to adhere to the dulled, sticky edge, which makes the cut quality worse and accelerates wear even more.

Speed's Impact On The Cutting Edge

Understanding the relationship between line speed and edge temperature is critical for optimizing your process. Small changes in speed can have a big impact on tool life.

| Line Speed (m/min) | Estimated Edge Temp (°C) | Primary Wear Mechanism |

|---|---|---|

| 100 - 150 | 100 - 150°C | Normal Abrasive Wear |

| 150 - 250 | 150 - 250°C | Accelerated Abrasive Wear |

| > 250 | ~ 300°C | Micro-melting, Adhesion (Sticking) |

The key is to find the sweet spot. You want the highest speed possible without triggering that micro-melting point. Sometimes, a blade with a more advanced coating or a slightly different geometry is all you need to handle that extra speed successfully.

How Do Abrasive Materials Quietly Corrode Your Blades?

Your blades wear out cutting abrasive materials, but the reason is not just friction. A hidden chemical attack is destroying your tool. Let's expose this silent killer.

Abrasive materials can trigger chemical reactions3 that dissolve the blade’s cobalt binder phase. This creates localized pitting corrosion under the surface. This corrosion weakens the coating, causing it to peel off and exposing the blade to rapid wear.

When people think of "abrasive wear4," they usually imagine a sandpaper effect that slowly grinds down the blade. But for materials like fiberglass, composites, or even some types of paper with high filler content, something more complex is happening. These materials can be chemically abrasive. They attack the structure of the blade itself. I've seen blades used for cutting composites that looked fine on the surface, but a microscope showed that the coating was peeling away in large flakes. This is a sign of underlying corrosion. The abrasive material doesn't just rub against the coating; it finds microscopic pores and attacks the cobalt binder underneath. This chemical reaction is like rust, but on a much smaller scale. It creates tiny pits in the binder material.

The Stages Of Chemical Wear

This process happens in a sequence that results in rapid failure once the damage becomes visible.

- Chemical Dissolution: The abrasive material reacts with the cobalt binder. This slowly dissolves the binder, weakening the bond between the carbide grains.

- Pitting Corrosion: As the binder is eaten away, small pits and voids form just below the surface. The blade's foundation becomes unstable, but the damage is still hidden by the coating.

- Coating Delamination: With its foundation weakened, the hard coating can no longer adhere properly. It begins to chip and peel away, exposing the now-vulnerable carbide structure to direct abrasive wear.

Once the coating is gone, the blade fails very quickly. The solution is often to use a blade with a more corrosion-resistant binder or a specialized multi-layer coating5 that better seals the blade's structure from chemical attack.

What Happens When Your Blade Cuts Extremely Hard Materials?

Cutting very hard materials generates intense heat and pressure at the cutting edge. This concentration of force can easily overwhelm the blade’s toughness, causing it to chip. These chips lead to inaccurate cuts and damaged products.

In my work, I help many clients in the metalworking industry. They often machine high-hardness materials like hardened steels or superalloys. Their biggest complaint is often "chipped edges." Unlike gradual wear, chipping is a catastrophic failure. A small piece of the cutting edge breaks off suddenly. This immediately ruins the surface finish of the part being cut. It also throws the dimensions off, which can lead to scrapping an expensive component. This happens because cutting hard materials puts an incredible amount of stress on a very small area. The pressure and friction create intense heat right at the tip. If the blade's material grade isn't tough enough to absorb that pressure, it will fracture. The blade's micro-structure matters a lot here. A blade made for general-purpose cutting will fail quickly in this application.

Balancing Hardness And Toughness

Choosing the right blade grade is a balancing act. You need a material that is hard enough to hold an edge, but also tough enough to resist chipping.

| Blade Characteristic | Benefit | Downside |

|---|---|---|

| Higher Hardness | Resists abrasive wear, holds a sharp edge longer. | Can be more brittle and prone to chipping. |

| Higher Toughness | Resists impact and shock, less likely to chip. | May wear down faster in abrasive conditions. |

For machining high-hardness materials, we at PASSION typically recommend carbide grades with a finer grain structure and sometimes a modified binder. These adjustments increase the blade's toughness without sacrificing too much wear resistance. Proper machine setup, like ensuring maximum rigidity and minimizing vibration, is also essential to prevent the shock loads that lead to chipping.

Conclusion

Understanding these extreme conditions is the first step. At PASSION, we provide blades engineered for these challenges, giving you the precision and long tool life you need.

Explore the intricacies of carbide blades to understand their construction and performance. ↩

Learn about the difficulties of machining high-hardness materials. ↩

Discover how chemical reactions can lead to rapid wear of cutting tools. ↩

Understand abrasive wear and its implications for tool longevity. ↩

Learn about the advantages of multi-layer coatings in enhancing tool life. ↩